- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 75

IS THE WATER INDUSTRY PROFITABLE IN SOUTH AFRICA

MARKET RESEARCH AND BUSINESS PLANNING

REGULATIONS AND GOVERNMENT APPROVALS

WATER SOURCE AND SITE SELECTION

EQUIPMENT PRECUREMENT AND PRODUCTION PROCESS DESIGN

FINANCIAL PLANNING AND CAPITAL PREPARATION

HOW TO FIND A RELIABLE WATER BOTTLING MACHINE SUPPLIER

COST FOR BUYING A COMPLETE WATER BOTTLING PLANT MACHINE

Embarking on the journey to build a water bottling plant in South Africa is not only a strategic business endeavor but also an opportunity to contribute to the growing demand for clean and safe drinking water in the region. This guide aims to provide comprehensive insights into the various aspects involved in establishing a successful water bottling facility. From market profitability and regulatory considerations to the intricacies of machine selection and operational planning, this article serves as a roadmap for entrepreneurs seeking to venture into the thriving bottled water industry in South Africa.

South Africa, as a continuously developing country, presents significant growth potential in the water industry market. The scarcity of water resources and the continuous pursuit of healthy and safe water sources by the population have led to the gradual rise of the bottled water market in South Africa. In this environment, establishing a bottled water factory has become a noteworthy business opportunity.

Rising Demand: The demand for clean and safe drinking water is continuously increasing among the South African population, driving the rapid expansion of the bottled water market.

Increased Health Awareness: With the rising awareness of health, consumers are placing more emphasis on the quality of drinking water, providing a broad market for high-quality bottled water.

Intense Competition: As the market grows, competition becomes more fierce. Entrepreneurs need to stand out through differentiation and innovation.

Environmental and Sustainability Considerations: Consumer concern for environmental protection and sustainability is on the rise, making bottled water factories that adhere to these standards more likely to be favored by consumers.

Detailed Market Research: Conducting detailed market research before making investment decisions is crucial. Understanding the potential customer base, competitors, and market growth trends helps investors formulate strategic plans.

Risk Analysis: In-depth understanding of potential market risks, including policy changes and water resource limitations, helps investors make comprehensive risk assessments.

Establishing a bottled water factory in South Africa has evident profit potential, especially when catering to market demands and focusing on sustainability. Investors should pay attention to long-term market trends and conduct thorough investigations into market prospects to provide a solid foundation for your investment decisions.

Before venturing into the water bottling business, a meticulous market research process is essential. This involves delving into the intricacies of the bottled water market in South Africa, gaining insights into demand patterns, competitive landscapes, and identifying potential customer demographics. By analyzing market trends and understanding consumer preferences, entrepreneurs can tailor your offerings to meet the specific needs of the target audience.

The business plan serves as a roadmap, outlining the vision and strategies for the water bottling plant. It encompasses various critical components:

Clearly define the unique selling propositions (USPs) that set the water bottling plant apart from competitors. This involves identifying what makes the product distinct and appealing to the target market.

Develop effective sales strategies that align with the identified market needs and preferences. Consider distribution channels, pricing models, and promotional activities to maximize reach and impact.

Prepare meticulous financial forecasts that project the anticipated revenue, expenses, and profitability over a defined period. This helps in gauging the financial feasibility and sustainability of the business.

Detail the operational processes, from sourcing raw materials to the distribution of the final product. Establish efficient production workflows and logistical strategies to ensure smooth operations.

Identify potential risks and challenges that the business might encounter. Develop contingency plans to mitigate these risks and ensure resilience in the face of uncertainties.

Address regulatory considerations and ensure that the business adheres to all relevant laws and standards governing the water bottling industry. This includes obtaining necessary permits and certifications.

Purpose: An EIA evaluates the potential environmental impact of the bottled water plant.

Process: Entrepreneurs must submit a comprehensive EIA report detailing the project's environmental implications, mitigation strategies, and proposed measures to minimize negative effects. This report is typically reviewed by environmental authorities.

Approval: Obtaining approval for the EIA is critical before proceeding with other aspects of the project.

Purpose: A Water Use License is required to regulate and monitor the water usage by the bottled water plant.

Process: Entrepreneurs must apply for a Water Use License, providing details on the water source, quantity, and usage plans. The license ensures responsible water consumption and protects water resources.

Approval: Approval is granted by the Department of Water and Sanitation after a thorough assessment of the application.

Purpose: Operational licenses and permits are necessary for the legal operation of the bottled water plant.

Process: Entrepreneurs need to apply for various licenses, including manufacturing, health, and safety permits. These documents confirm compliance with industry standards and regulations.Approval: Relevant government departments and municipal authorities issue these licenses based on inspections and adherence to specified criteria.

Purpose: Registering the business ensures legal recognition and compliance with tax regulations.

Process: Entrepreneurs must register the bottled water plant as a legal entity, such as a private company. This includes obtaining a tax identification number and complying with corporate governance requirements.

Approval: Business registration is approved by the Companies and Intellectual Property Commission (CIPC) and ensures compliance with tax laws.

Purpose: Certifications ensure the safety and quality of the bottled water for consumer protection.

Process: Obtaining certifications, such as Hazard Analysis and Critical Control Points (HACCP) and ISO 22000, involves implementing food safety management systems.

Approval: Certifying bodies assess compliance and grant approvals, confirming adherence to international standards.

Purpose: Municipal approvals are necessary for land use, zoning, and adherence to local bylaws.

Process: Entrepreneurs must engage with local municipalities to ensure the bottling plant's location aligns with land-use plans and zoning regulations.

Approval: Local authorities issue approvals after reviewing plans and ensuring compliance with municipal regulations.

Purpose: Ensures a safe working environment for employees and compliance with occupational health and safety standards.

Process: Implementation of safety protocols and procedures, along with regular safety audits, is essential.

Approval: Ongoing compliance is monitored by the Department of Employment and Labour, ensuring adherence to safety regulations.

Navigating the intricacies of obtaining these government approvals is critical for the successful establishment and operation of a bottled water plant in South Africa. Entrepreneurs are advised to work closely with relevant government agencies, environmental authorities, and certification bodies to ensure a seamless and legally compliant process.

Quality Testing: Conduct rigorous water quality tests on potential water sources to ensure they meet regulatory standards and provide a safe, clean, and consistent water supply.

Sustainability: Assess the sustainability of the water source by considering factors such as seasonal variations, water table levels, and long-term availability. A sustainable source is crucial for uninterrupted production.

Legal Considerations: Verify water rights and permissions to extract water from the chosen source. Compliance with local water use regulations and licensing requirements is essential.

Proximity to Market: Choose a site that is strategically located in proximity to target markets. This reduces transportation costs and ensures timely product delivery to consumers.

Accessibility: Ensure that the selected site is easily accessible for both raw material transportation and distribution of finished products. This contributes to operational efficiency.

Infrastructure: Assess the availability of necessary infrastructure, such as roads, utilities, and telecommunications, to support the water bottling plant's operations.

Eco-Friendly Practices: Consider environmental sustainability by conducting an environmental impact assessment (EIA). This evaluation identifies potential environmental impacts and outlines measures to mitigate and minimize them.

Biodiversity Conservation: Ensure that the chosen site minimizes negative effects on local biodiversity. Adopt practices that align with environmental conservation and sustainable water use.

Land Use Zoning: Confirm that the chosen site complies with local land use zoning regulations. Obtain the necessary permits and approvals from municipal authorities for establishing a water bottling facility.

Water Rights: Ensure compliance with water rights regulations and secure the required permits from the Department of Water and Sanitation. This includes obtaining a Water Use License.

Stakeholder Consultation: Engage with local communities and stakeholders to address concerns, build positive relationships, and ensure community support for the water bottling plant.

Corporate Social Responsibility (CSR): Develop CSR initiatives that benefit the local community, emphasizing sustainable practices and community development.

Natural Hazards: Evaluate the susceptibility of the chosen site to natural hazards such as floods, earthquakes, or droughts. Implement risk mitigation strategies to safeguard the plant against potential threats.

Security: Assess the security of the site to prevent unauthorized access, theft, or vandalism, ensuring the protection of both infrastructure and water resources.

Scalability: Choose a site that allows for future expansion based on market demand. Consider factors such as available space, zoning regulations, and potential infrastructure upgrades.

Flexibility: Plan for flexibility in the layout and design of the water bottling plant to accommodate technological advancements and changes in production processes.

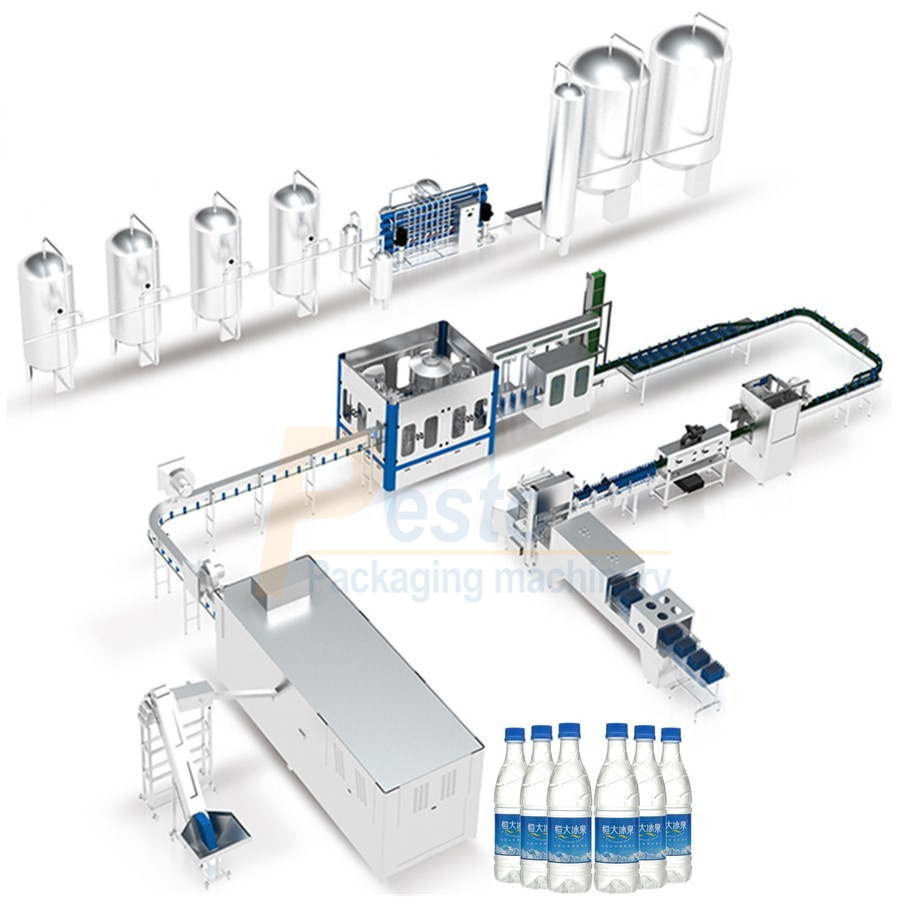

Setting up a bottled water plant in South Africa involves careful consideration of the necessary equipment procurement and the design of an efficient production process. This entails selecting the right water bottling plant for sale and designing workflows that ensure the quality, safety, and cost-effectiveness of the bottled water production.

Water Filtration Systems: Invest in advanced water filtration systems to remove impurities, contaminants, and ensure the water meets quality standards.

Reverse Osmosis Units: Implement reverse osmosis units for thorough purification, eliminating dissolved minerals and enhancing water purity.

UV Sterilization Systems: Utilize UV sterilization systems to disinfect water, ensuring it is free from harmful microorganisms.

Filling Machines: Invest in automated water filling machine to precisely measure and fill bottles with purified water.

Capping Machines: Implement capping machines for sealing bottles securely, maintaining the freshness and hygiene of the product.

Labeling and Packaging Equipment: Procure machinery for labeling and packaging that ensures accurate labeling and efficient packaging of the bottled water.

Quality Control Stations: Integrate quality control stations at various points in the production line to monitor water quality and packaging integrity.

Automated Inspection Systems: Implement automated inspection systems for detecting any defects or inconsistencies in the bottles and packaging.

Compressed Air Systems: Install compressed air systems for various pneumatic operations within the production process.

Power Supply Infrastructure: Ensure a reliable power supply infrastructure to prevent disruptions in production.

Water Storage Tanks: Incorporate water storage tanks to maintain a consistent water supply during production.

Workflow Optimization: Design an optimized production workflow that minimizes bottlenecks and ensures smooth transitions between production stages.

Automation Integration: Integrate automation where possible to enhance efficiency, reduce manual labor, and minimize the risk of errors.

Batch Processing: Implement batch processing to facilitate quality control at each stage and enhance traceability.

Waste Management System: Develop an efficient waste management system to handle by-products and ensure environmental sustainability.

Cleaning-in-Place (CIP) Systems: Implement CIP systems to automate the cleaning of equipment, ensuring hygiene and preventing contamination.

Personal Protective Equipment (PPE): Provide necessary PPE for workers involved in the production process to maintain a hygienic environment.

Sanitary Design: Choose equipment with a sanitary design that facilitates easy cleaning and reduces the risk of bacterial growth.

Training on Equipment Operation: Conduct thorough training programs to ensure employees are proficient in operating and maintaining the equipment.

Hygiene Practices: Emphasize hygiene practices among employees to maintain the highest standards of cleanliness throughout the production process.

Energy-Efficient Equipment: Choose energy-efficient water bottling machine for sale to reduce environmental impact and operational costs.

Waste Reduction Strategies: Implement strategies to minimize waste generation and adopt eco-friendly packaging materials.

Recycling Initiatives: Consider incorporating recycling initiatives within the production process to contribute to environmental sustainability.

Establish a comprehensive quality control system to ensure that the bottled water produced meets high standards of quality. Conduct regular quality inspections and tests to guarantee consistent product quality.

Initiate brand building activities, design attractive packaging, and create eye-catching branding. Develop a comprehensive marketing plan, encompassing digital marketing, traditional advertising, and social media promotions, to enhance brand awareness.

Recruit and train qualified personnel, including production staff, sales representatives, and managerial personnel. Ensure that the team possesses the necessary professional knowledge and skills to guarantee the smooth operation of the business.

Develop a detailed financial plan considering startup capital, operating costs, and anticipated returns. Ensure there is sufficient capital to support the establishment of the plant and initial operations.

Begin by conducting thorough research on potential suppliers. Utilize online resources, industry publications, and business directories to compile a list of candidates. Pay attention to customer reviews, testimonials, and industry forums to gauge the reputation of the suppliers.

Investigate the reputation of potential suppliers within the water bottling industry. A supplier with a solid reputation is more likely to offer reliable and high-quality equipment. Seek recommendations from industry peers and forums, and consider suppliers who have successfully served businesses similar to yours.

Ensure that the supplier adheres to industry standards and holds relevant certifications. Certifications like ISO and CE are indicators of a commitment to quality and compliance. Verify that their equipment meets the regulatory standards of the regions where you plan to operate.

Request detailed information about the supplier's manufacturing facilities. A transparent supplier should be willing to share insights into their production processes, technology, and quality control measures. If possible, consider visiting their facilities to assess manufacturing capabilities firsthand.

Evaluate the level of technical support and training provided by the supplier. A reliable supplier will offer comprehensive training on machine operation, maintenance, and troubleshooting. Inquire about their responsiveness to technical queries and their commitment to assisting clients post-purchase.

Carefully review the warranty terms offered by potential suppliers. A reputable supplier typically provides a solid warranty and robust after-sales service. Understand the terms and conditions of the warranty, and inquire about their after-sales support to ensure ongoing assistance if issues arise.

PESTOPACK stands as a distinguished entity in the water bottling machinery industry, renowned for our unwavering commitment to quality, innovative solutions, and exceptional customer service. Having successfully catered to a diverse clientele on a global scale, our state-of-the-art manufacturing facilities, strict adherence to industry standards, and comprehensive after-sales support underscore our standing as a reliable choice for businesses in search of top-tier water bottling machine for sale.

Establishing a water bottling plant in South Africa involves a critical consideration of the costs associated with acquiring a complete water bottling plant machine. This investment is influenced by factors such as production capacity, automation levels, and operational efficiency.

Consider the scale of your bottling operation and choose an appropriate production capacity for the water bottling plant machine. Options typically range from 2000 bottles per hour (BPH) to 36000 BPH, catering to diverse business sizes and production needs.

For smaller-scale operations or those entering the market cost-effectively, the semi-automatic water bottling plant machine is an attractive choice.

Investment Estimate:

The semi-automatic production line generally starts at a minimum cost of approximately $50,000, providing a budget-friendly solution without compromising efficiency.

Opting for a fully automatic water bottling plant machine offers increased efficiency and productivity.

Investment Estimate:

Costs for a fully automatic production line vary based on production capacity and technological features. Detailed quotations tailored to specific requirements can be obtained by contacting our team for proposals.

Beyond the initial investment, it's crucial to estimate ongoing operational costs to ensure the sustained and efficient operation of the water bottling machine. Consider factors such as electricity, labor, and routine maintenance.

Investing in a complete water bottling plant machine is a significant undertaking that requires careful consideration of production needs, budget constraints, and long-term operational efficiency. Whether opting for a semi-automatic or fully automatic solution, assessing these costs comprehensively and seeking professional guidance are essential steps in making a well-informed investment for your bottling venture in South Africa.