FAQ – Water Bottling Plant for Sale

1. What types of bottled water can your plant produce?

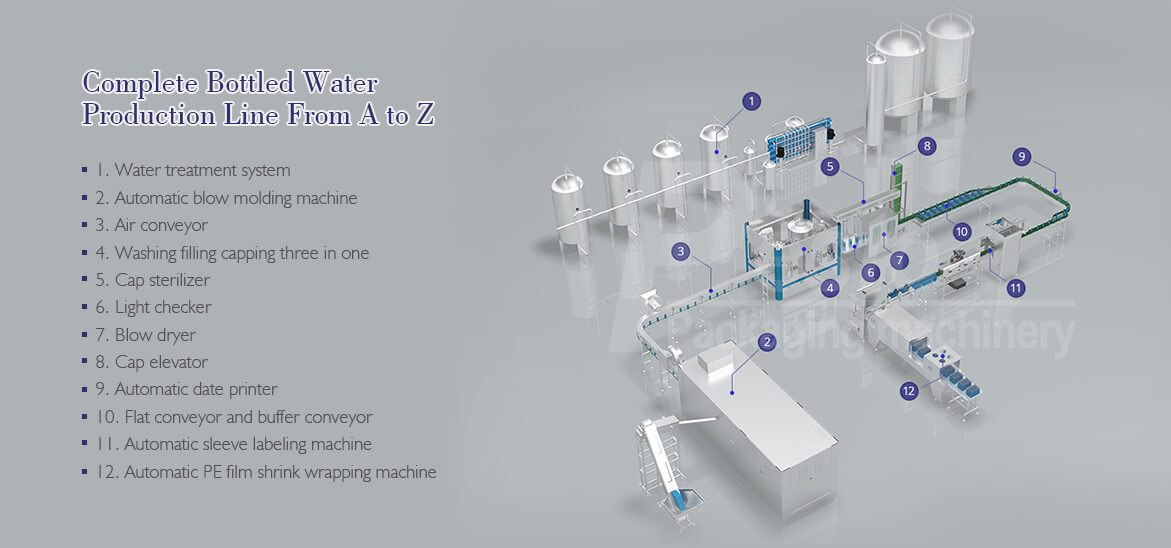

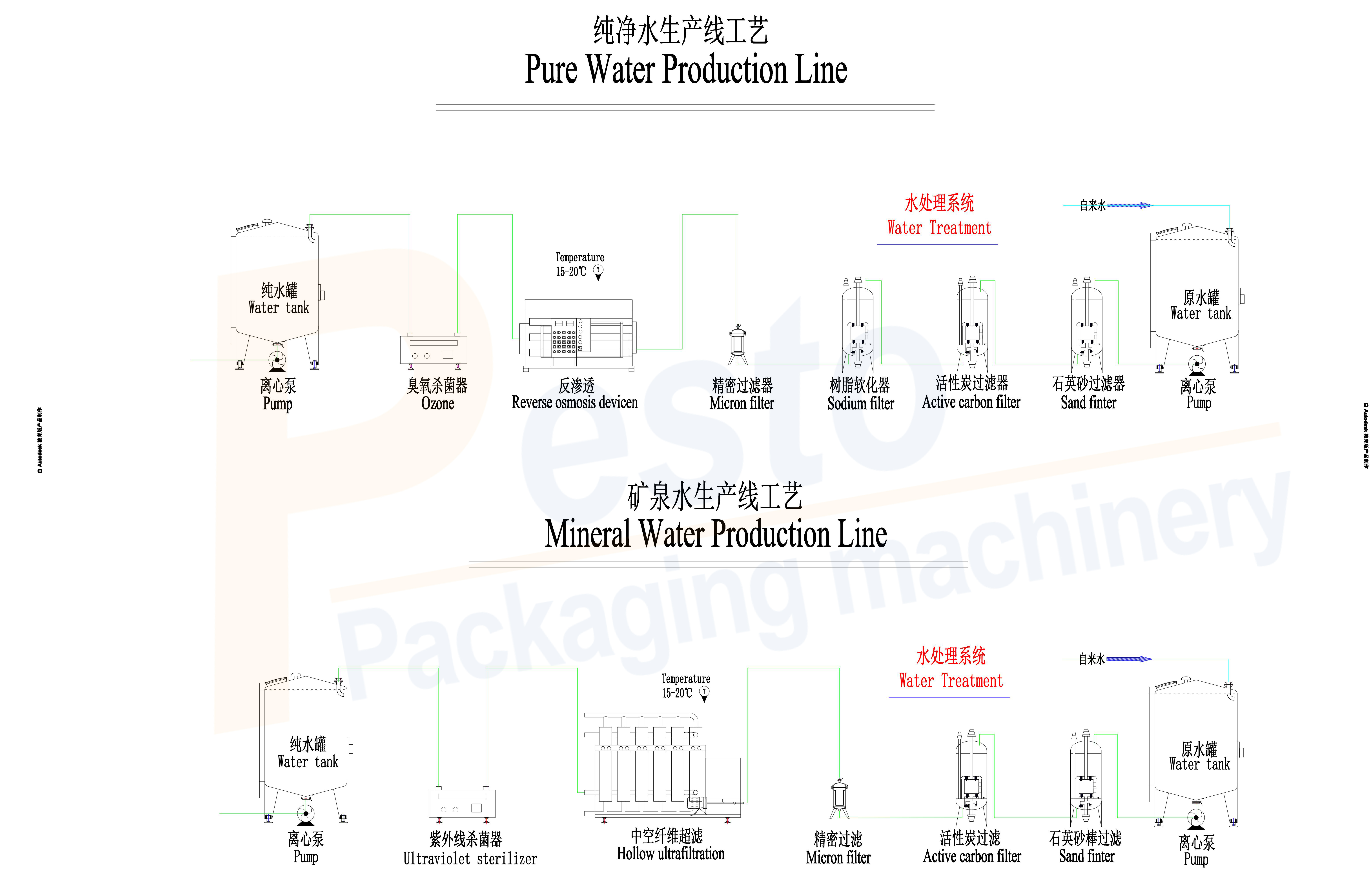

Our production lines support purified water, RO water, mineral water, spring water, soda water, and lightly carbonated beverages. We customize the water treatment system based on your local water source.

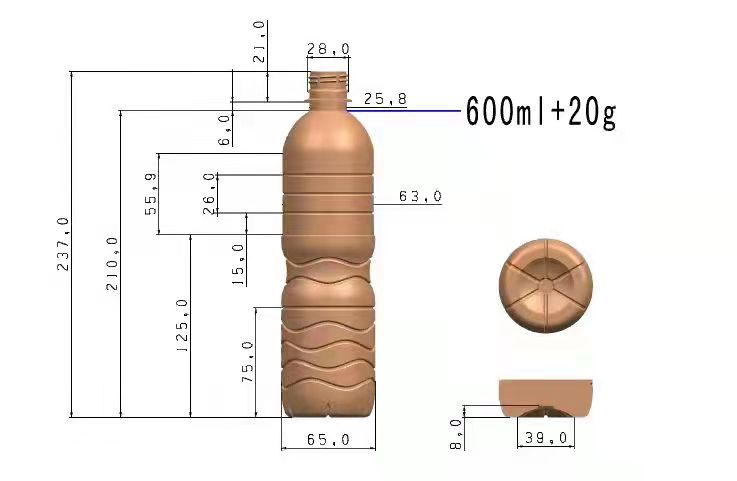

2. What bottle sizes are supported?

Standard PET bottle sizes from 200 ml to 2 liters can be used. We also offer custom bottle mold design to match local market preferences.

3. What production capacities are available?

We offer water bottling plants from 3,000 BPH to 24,000 BPH. For larger-scale factories, higher capacities can be developed upon request.

4. Do you provide installation services worldwide?

Yes. PESTOPACK offers overseas installation, commissioning, operator training, and lifetime technical support in Africa, the Middle East, Asia, Europe, and South America.

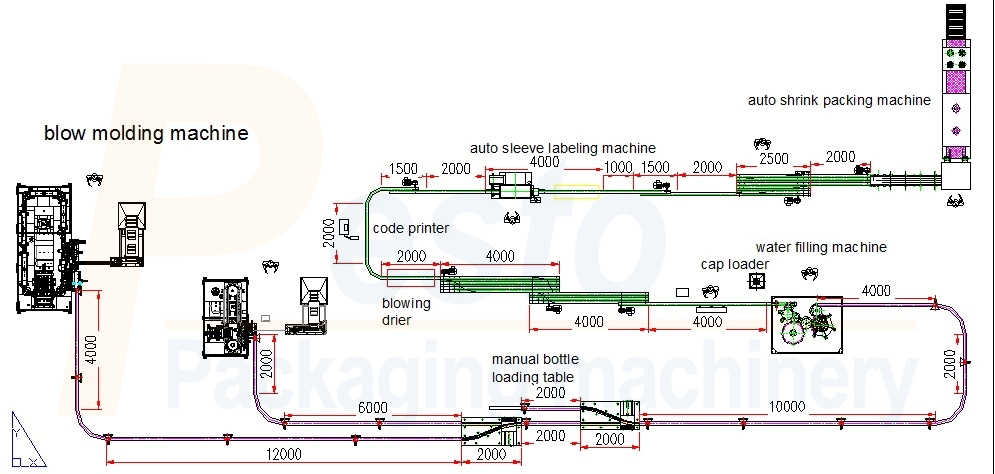

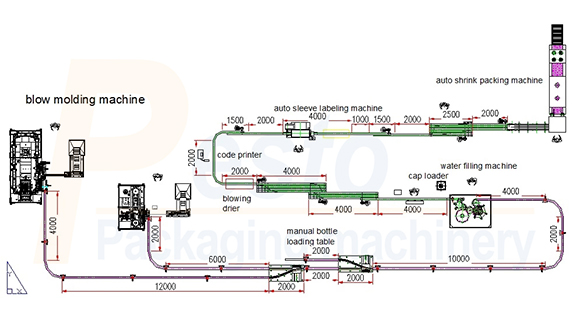

5. How much workshop space is required?

3000–6000 BPH: approx. 300–500 m²

8000–12000 BPH: approx. 500–800 m²

18000–24000 BPH: approx. 800–1200 m²

Exact layout depends on the bottle blowing, filling, and packaging configuration.

6. Can I start with a small bottling line and upgrade later?

Yes. Many investors begin with a small-capacity line and expand to larger filling machines and faster production systems as demand grows.

7. What support do you provide after installation?

We offer 1-year warranty, lifetime technical support, spare parts supply, online troubleshooting, and complete project guidance from design to operation.

8. Can the same plant produce both still and carbonated water?

Yes. With an additional carbonation mixer and CO₂ system, the production line can switch between still water, sparkling water, and soft drinks.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu