Isicelo somshini we-automatic beer othomathikhi

Lo mshini webhiya we-othomathikhi we-automatic usetshenziselwa ukukhiqizwa okuncane okuphakathi nendawo ephakathi nendawo futhi ungafakwa kule mikhiqizo:

Ubhiya wendabuko

Umshini wokugcwalisa we-semi-othomathikhi ulungele izinhlobo ezijwayelekile zebhiya ezinjenge-lager, ama-stouts, ama-Ales, nokuningi. Ingagcwalisa ubhiya emabhodleleni futhi enze imisebenzi yokubopha uphawu.

Craft ubhiya

Okwenziwe izikebhe ubhiya Brewers, umshini we-semier auto bootling uyithuluzi elisebenzayo. Inikeza ukuguquguquka nokusebenza kahle kokukhiqizwa kukabhiya ophakathi nendawo, okwenza ukupakishwa nokuthengisa.

Ubhiya owenziwe ngokwezifiso

Umshini wokugcwalisa webhiya othomathikhi angasetshenziselwa ukwenza ngokwezifiso imikhiqizo yobhiya. Amabha, izindawo zokudlela, noma imishini yokushayisana okuncane angayisebenzisa ukugcwalisa izindlela ezikhethekile noma ubhiya onongiwe, unikeza izinqumo ezenziwe ngezifiso kumakhasimende.

Ukukhiqizwa okuncane kwe-batch kanye nokuhlolwa kokuhlola

Umshini wokugcwalisa we-semi-othomathikhi we-automatic ulungele ukukhiqizwa kukabhiya omncane kanye nokwenziwa kokuhlola. Kuyasiza i-Brewers Lawula inqubo yokugcwalisa, iqinisekisa ikhwalithi yomkhiqizo nokuvumelana.

Ngakho-ke ngokuthola okuncane kwabasezingeni eliphakathi nendawo noma okulinganiselwe kokukhiqiza, umshini wokugcwalisa ibhodlela webhodlela le-semier auer uyisinqumo sezomnotho nesisebenzayo.

Isebenza kanjani umshini we-othomathikhi webhiya

Umshini we-Pestopack's's Semi Outomatic Bottling Machine, usebenza ngalezi zinyathelo ezilandelayo:

1. Ukulungiselela ibhodlela likabhiya

Amabhodlela angenalutho ahlanzwa, ahlanzwa, futhi alungiselelwe ukugcwaliswa. Lokhu kufaka phakathi ukukhala ngomshini wokuhlanza nokudonsa.

2. Ukudla kwebhodlela likabhiya

Amabhodlela ahlanjululwe abekwa ebhodleleni lebhodlela lebhodlela le-semi auer.

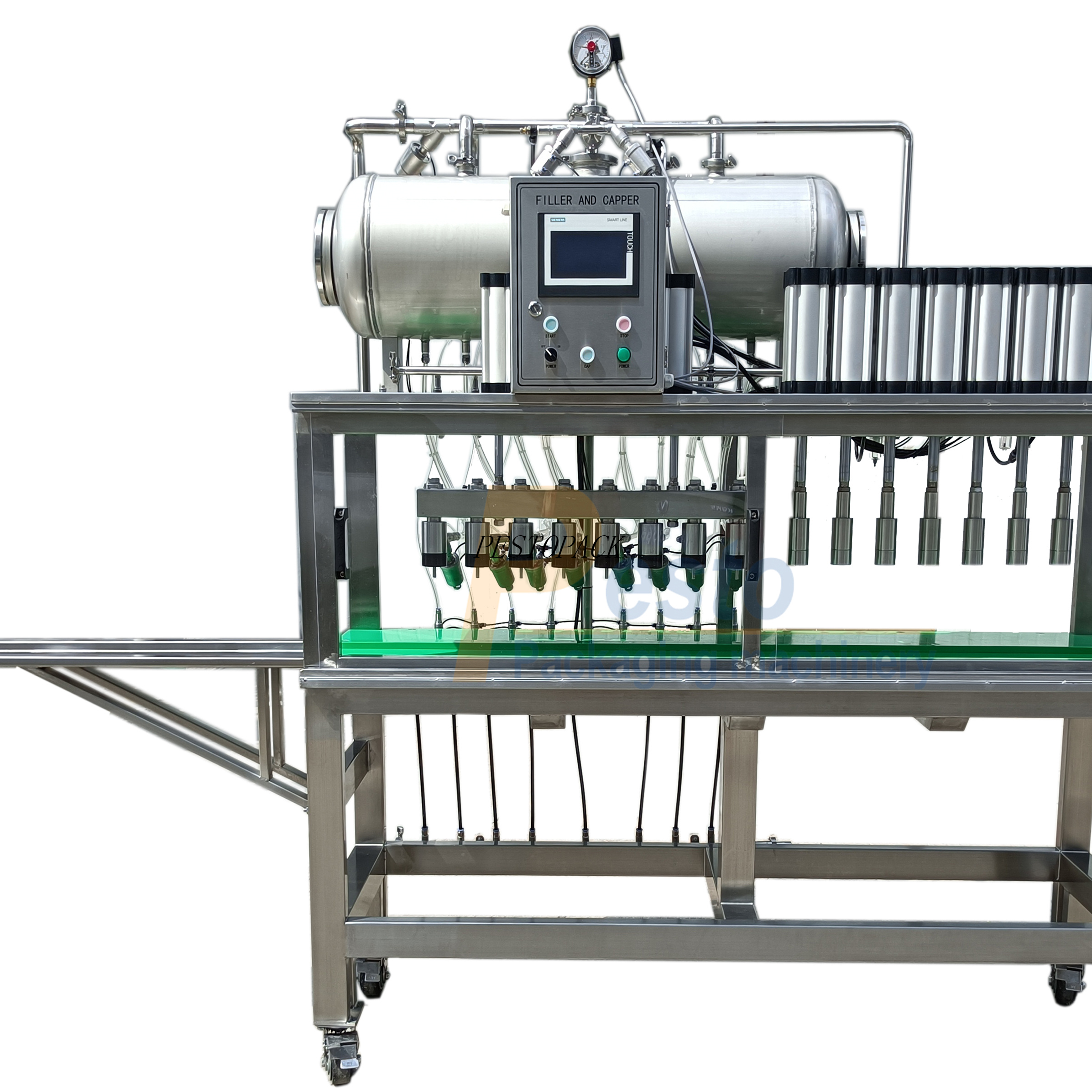

3. Ukucindezelwa

Ngaphambi kokugcwalisa, amabhodlela acindezelwa ngegesi ye-carbon dioxide (CO2). Lesi sinyathelo sisiza ukudala imvelo elawulwayo ngaphakathi kwebhodlela, ukuvimbela ukonakala ngokweqile kanye nokulahleka kwe-carbonation ngesikhathi sokugcwaliswa.

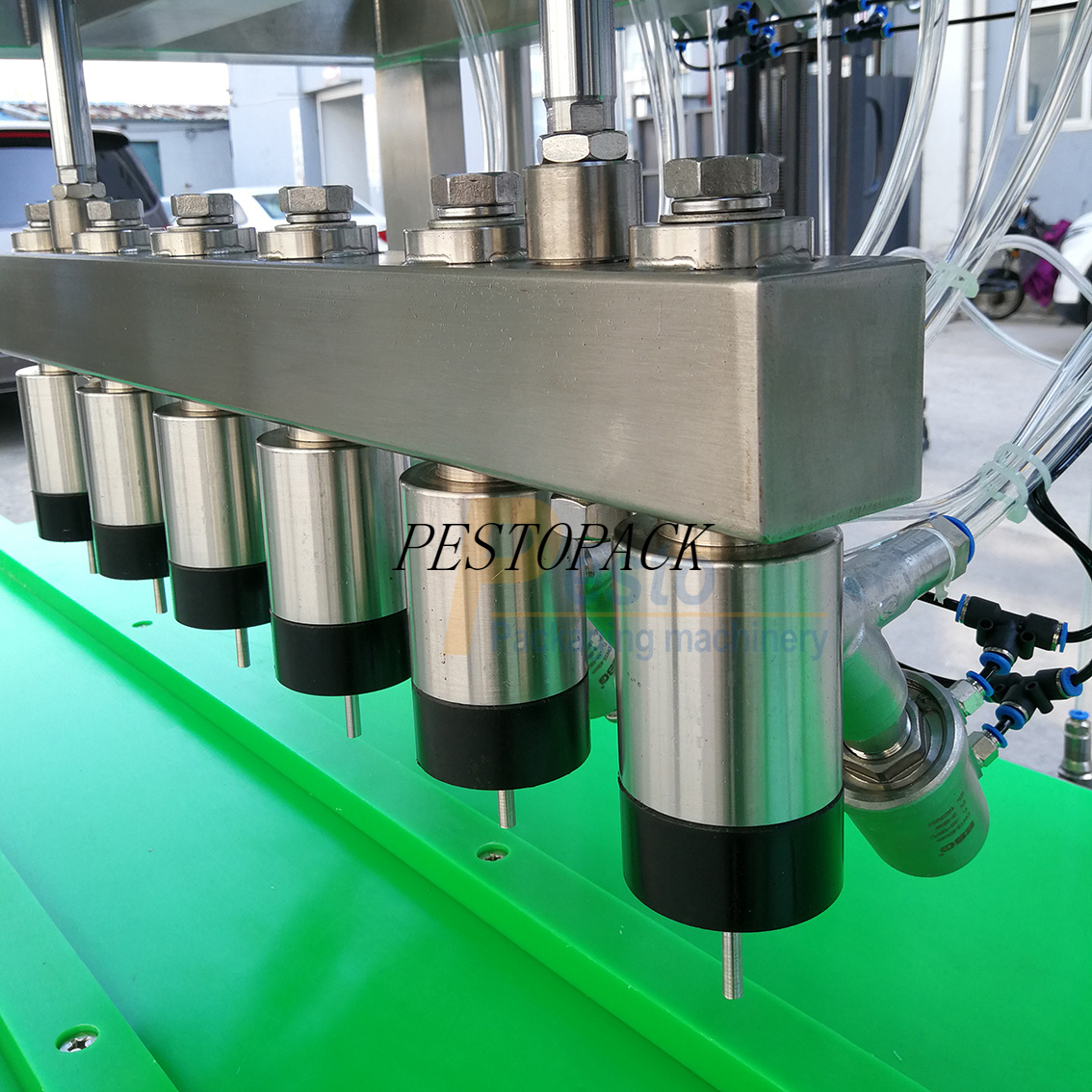

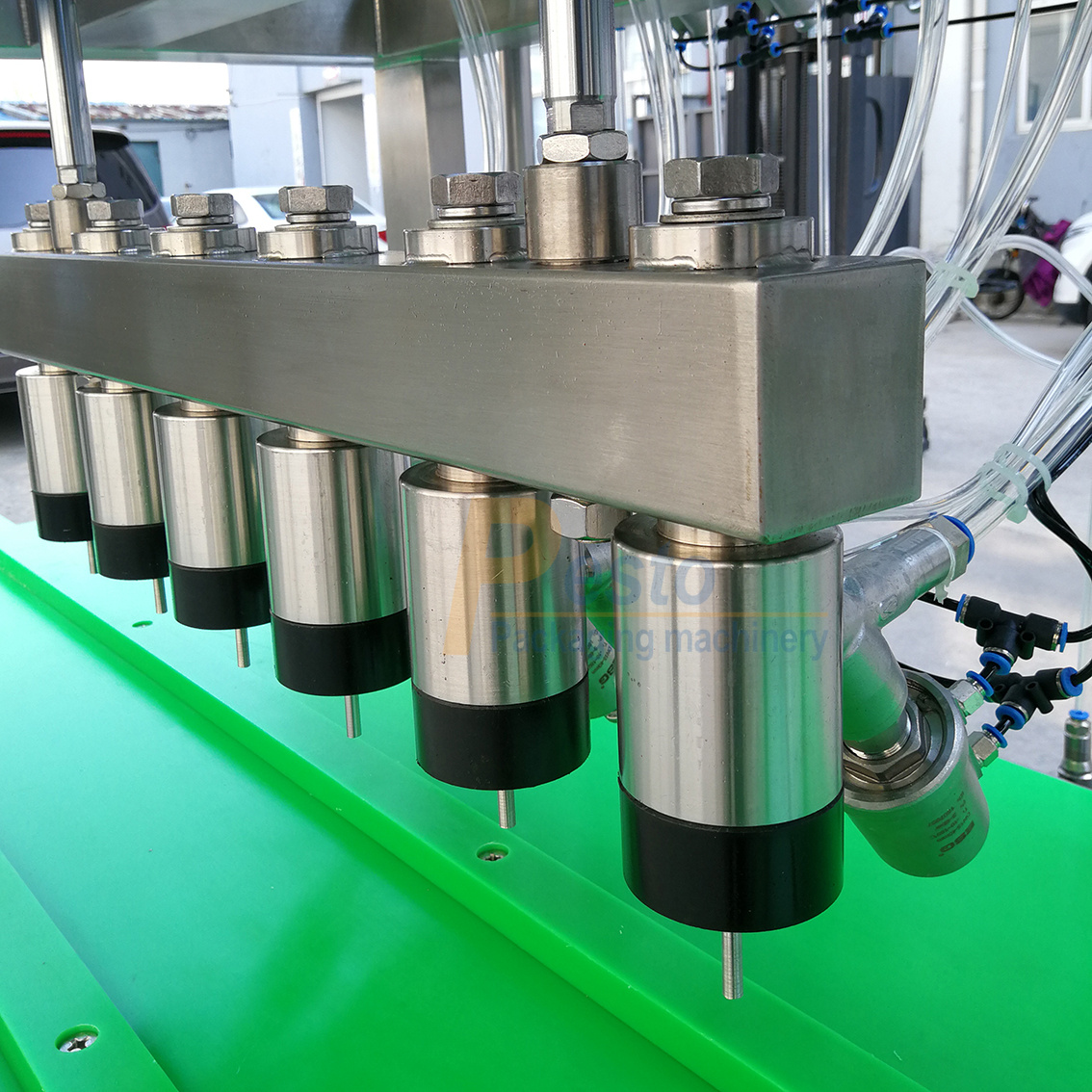

4. Ukugcwaliswa kwebhodlela likabhiya

Inqubo ye-isobaric yokugcwalisa iyaqala. Umshini wokugcwalisa ibhodlela we-Manual ufaka isiteshi sokugcwalisa esifakwe amakhanda ama-4-10 okugcwalisa.Izinhloko zemisebenzi emibili eyinhloko: zikhipha igesi emibili eyinhloko: zikhipha igesi ecindezelwe ye-CO2 ebhodleleni, zidale i-vacuum, futhi ngasikhathi sigcwalise ibhodlela ngobhiya. Lesi senzo esimbaxambili sivimbela amagwebu ngokweqile futhi sigcina izinga lokugcwalisa elingaguquki.

5. Ukulingana kwengcindezelo

Ngemuva kokugcwaliswa, umshini wokufaka amabhodlela webhiya we-automatic uphinde ubuyisele ingcindezi yangaphakathi ngaphakathi kwebhodlela ukufanisa ingcindezi yangaphandle. Lesi sinyathelo sokulinganisa sisiza ekuqinisekiseni amazinga afanele we-carbonation kubhiya futhi avimbele ukwakheka ngokweqile kwebhodlela.

6. Ukugcwala kwebhodlela likabhiya

Lapho ukulingana kwengcindezi sekuqediwe, amabhodlela athuthela esiteshini se-caple. Umshini we-Manual Beer Bottling unesimo sokukhotha esikwazi ukuphatha izinhlobo ezahlukene zamabhodlela caps, njenge-crown cheps noma ama-twist-off cap. I-caplic mechanism ibeka amabhodlela ama-cap, iqinisekisa ukubekwa uphawu okufanele ukuze kugcinwe ukubekelwa amakhandla nokusha.

7. Ukususwa kwebhodlela likabhiya

Lapho amabhodlela agcwalisiwe futhi ahlanganiswe, asuswe ngesandla emshinini we-semi auto beer Botting.

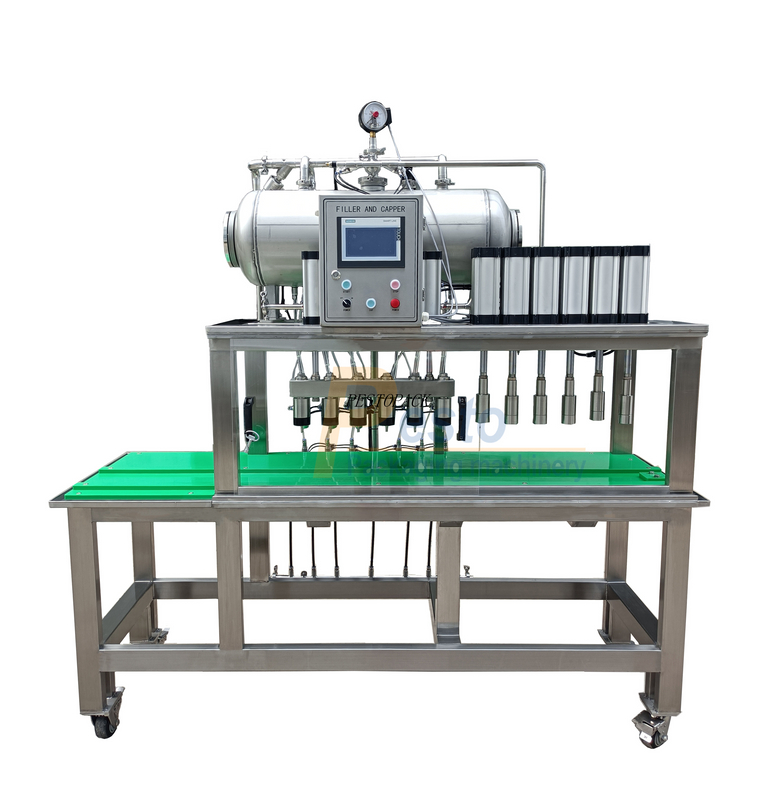

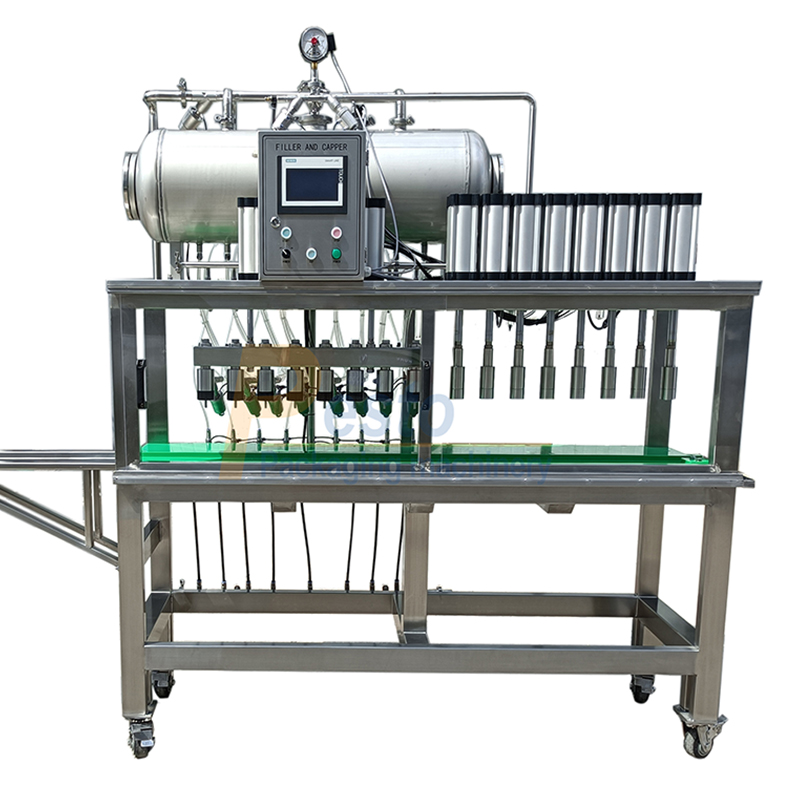

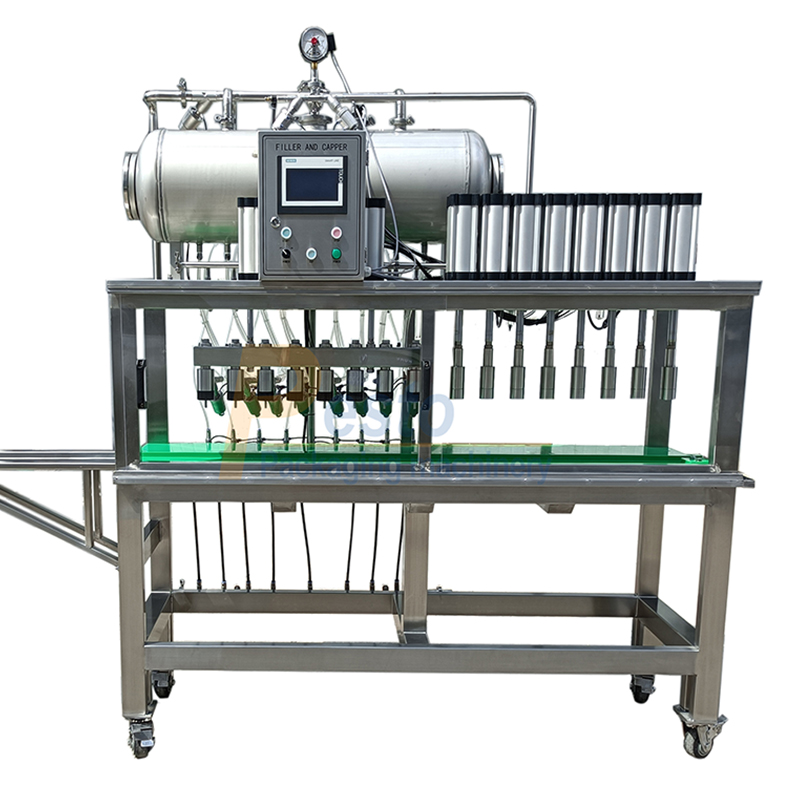

Umshini we-automatic othomathikhi webhilidi othengiswayo

Umthamo wokukhiqiza |

Amabhodlela angama-300-600 / hr |

Amabhodlela asebenzayo |

I-330ML-2L-2L |

Iziteshi Zokusebenza |

4, 6, 8, 10 |

| Amandla okuhlinzekwa kwamandla |

I-AC 220V 50HZ (eyenziwe ngezifiso) |

Ubukhulu |

I-1800 * 800 * 2200mm (Izinhlobo ezahlukahlukene Izinhlobo Zizohluka) |

Isisindo sengqikithi |

I-300kg (Izinhlobo Ehlukile Isisindo Sizohluka) |

I-4 ikhanda le-Semi-Auto Beer Botting Machine

I-6 ikhanda le-semi-auto beer botting machin

I-8 Heads Semi-Auto Beer Botining Machine

I-10 Heads Semi-Auto Beer Botining Machine

Izici zomshini wokubopha ibhodlela le-automatic othomathikhi

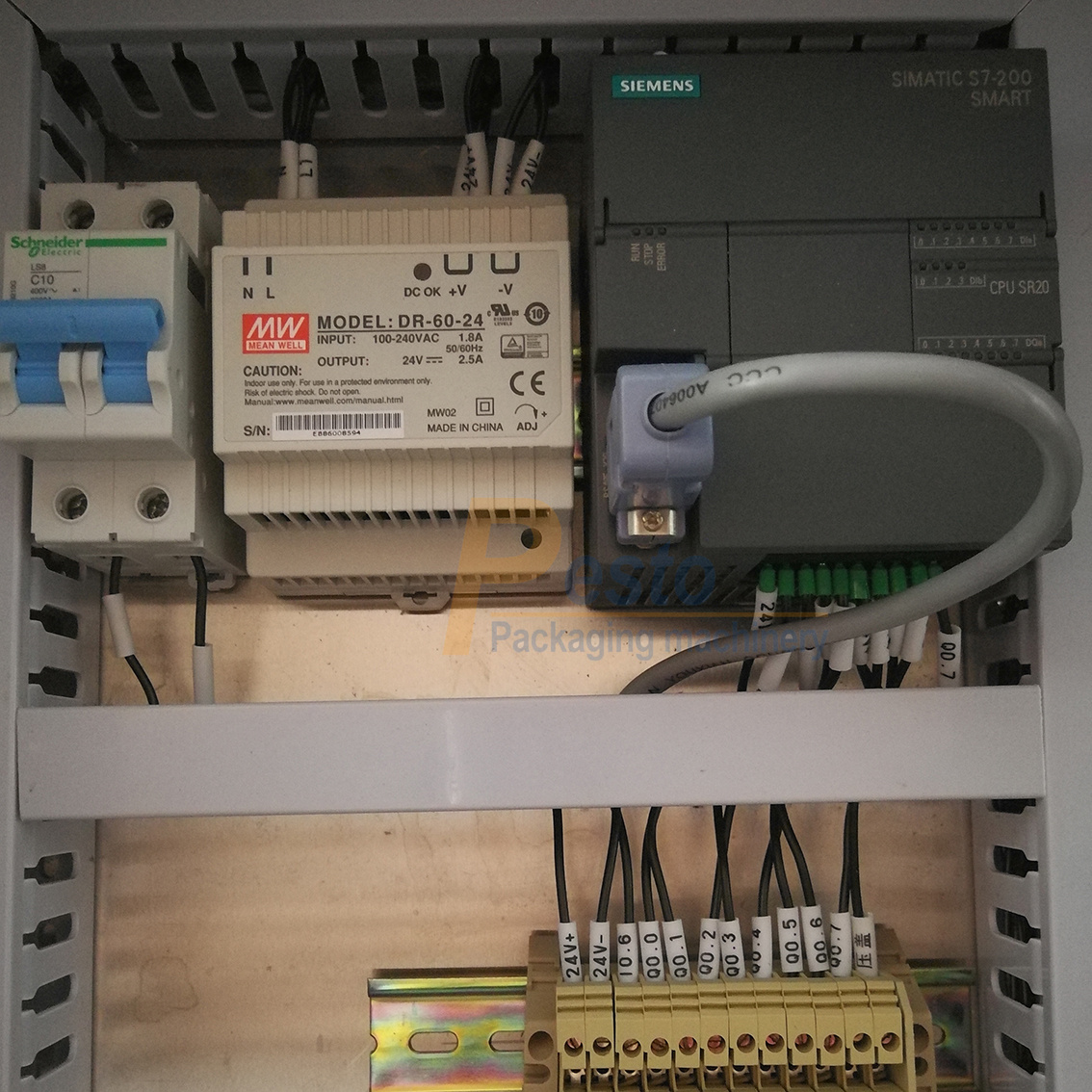

Ukusebenza okuzenzakalelayo okuzenzakalelayo:

Umshini wethu weBhotishani we-Mini Mini uhlanganisa izinzuzo ze-automation ngokuguquguquka kokulawulwa kwezandla. Isebenzisa inqubo yokugcwalisa ngenkathi ihlinzeka ngotshwala ngokulawula amapharamitha abucayi, ukuqinisekisa ukufakwa okuguqukayo nokunembile.

Ukusetha okulula nokusebenza:

Ngokusebenzisana kwayo okusebenziseka kalula, umshini wokugcwalisa ibhodlela webhodlela le-semi-othomathikhi angahlelwa futhi asebenze ngokuzikhandla ekutholeni isikrini.Izinto zokuqeqeshwa ze-touch.

Ukusebenza kahle:

Ngokwenza imisebenzi ephindaphindwayo ebandakanyeka ebhishini likabhiya, ibhukwana lethu Umshini webhiya webhiya ukhulisa kakhulu umkhiqizo wakho we-Brewery. Kunciphisa isikhathi esidingekayo sokupakisha, okuvumela ukuthi uhlangabezane nokufunwa okukhulayo ngaphandle kokuyekethisa ngekhwalithi. Ukugcwalisa kanye nenqubo yokuthwebula kungaqedwa kulo mshini.

Amazinga wokugcwalisa angaguquki:

Ukugcina ukugcwalisa okungaguquki kubalulekile ekwanelisekeni kwamakhasimende. Umshini wethu wokugcwalisa we-semi wakho othomathikhi usebenzisa izinhlelo eziqondile zokulinganisa ukuqinisekisa amazinga okugcwalisa aqondile kuwo wonke amabhodlela, ukuqeda ukungahambisani nomkhiqizo nokunciphisa imfucumfucu.

Ngokwezifiso okwenziwe nge-Brewery yakho:

Njalo i-Brewery inezidingo zayo ezihlukile. Umshini wethu weBottoling Bottoring wethu unikeza izinketho zokwenza ngokwezifiso ukwamukela osayizi abahlukahlukene bebhodlela, amajamo, kanye nezitayela zikabhiya. Ivumelana nezidingo zakho ezithile, ikuvumela ukuthi uhlukanise uhla lomkhiqizo wakho futhi uhlangabezane nezimakethe ngempumelelo.

Kungani ukhethe umshini wethu webhoti likabhiya

1. Isikhathi kanye nokonga izinsiza:

Ezenzakalelayo inqubo yakho yebhilidi Umshini wokugcwalisa ubhiya usindisa isikhathi esibalulekile nezinsizakusebenza. Yehlisa izindleko zabasebenzi, nciphisa imfucumfucu yomkhiqizo, futhi uthuthukise ukusebenza kahle kwe-Brewery.

2. Ukunemba nokulawulwa kwekhwalithi:

Ngokulawulwa kokugcwaliswa okunembile nokungaguquguquki, umshini wethu wesibhoti wobhiya uqinisekisa ukuthi wonke amabhodlela ahlangabezana namazinga aphezulu kakhulu. Ukuhambisa umkhiqizo omuhle kakhulu kusiza ukwakha ukwethembeka kwamakhasimende futhi kuthuthukise idumela lakho lomkhiqizo.

3. Ukuqina nokukhula:

Njengoba ukwenziwa kwakho kunwebeka, isikali sethu semishini ye-ser-othomathikhi yebhiya yakho. Ikuvumela ukuthi uhlangane nokwanda kokukhiqiza ngenkathi ugcina izinga lokulawula nokuvumelana okufunwayo.

4. Ukusebenza okuthuthukile kwe-Brewery:

Ngokwenza lula futhi kuqondiswe inqubo yakho yokupakisha ubhiya, umshini wethu webhiya we-Manual Bottoring ukhulula isikhathi sakho, ukubenza bagxile kweminye imisebenzi ebucayi, njengokuthuthukiswa kweresiphi, ukuqinisekiswa kwekhwalithi, nokuzibandakanya kwamakhasimende.

Xhumana nathi namuhla ukuthola inani lomshini webhishi

Ukulungele ukuthatha inqubo yakho yokupakisha kabhiya we-Brewery kuya ezingeni elilandelayo? Xhumana nathi namhlanje ngomshini wethu webhiya ozenzakalelayo we-automatic. Izwa izinzuzo zokusebenza okuqondiswe kahle, i-Effect ethuthukisiwe yekhwalithi nekhwalithi engaguquki. Vumela umshini wethu uvuse amakhono akho okupakisha we-Brewery wakho. Cela isilinganiso manje! Ngaphandle kwemishini ye-water kanye ne-beverage, futhi sinayo Umshini wokugcwalisa kawoyela , umshini wokugcwalisa we-sauce, umshini wokugcwalisa owohlaseli wokukhetha. Sicela uxhumane nathi ukuthola eminye imininingwane.