Video Of Glass Bottle Beer Filling Machine

Introduction to Beer Bottling Solutions

Beer bottling is a critical step for breweries—whether small craft brewers or large industrial producers. Packaging beer into glass bottles not only preserves freshness but also enhances product branding, shelf life, and consumer appeal.

Traditional manual or semi-automatic bottling methods often struggle with:

Inconsistent filling levels

High foam generation and product loss

Contamination risks

Limited production capacity

To address these issues, breweries turn to automatic glass bottle beer filling machines, which ensure speed, accuracy, and efficiency while maintaining product quality.

Different Solutions for Beer Bottle Filling Machines

At PESTOPACK, we design different automatic beer bottle filling machine solutions based on:

Production capacity

Budget

Automation level

Workshop size

Whether you operate a small craft beer brewery, a medium-scale regional brand, or a large industrial beer plant, we provide the right beer bottling solution for you.

1. Small-Scale Beer Bottle Filling Machine (2000–4000 BPH)

Perfect for microbreweries and start-up beer businesses, these machines provide higher automation compared to manual or semi-automatic systems.

Key Features:

Automatic bottle feeding table

Integrated rinsing, filling, and capping

Moderate output capacity (2000–4000 bottles/hour)

User-friendly touchscreen control system

Conveyor integration for smooth transfer

Adjustable settings for different bottle sizes

Optional labeler and date coding machine

Ideal for breweries upgrading from manual to automatic production.

2. Middle-Scale Beer Bottle Filling Machine (6000–10000 BPH)

For breweries with growing market demand, this range balances speed and flexibility.

Key Features:

Semi-automatic depalletizer for bottle loading

Fully automatic rinsing, filling, and capping

Higher capacity (6000–10000 bottles/hour)

Advanced PLC control systems

Integration with labeling, date coding, and packaging machines

Reduced downtime and quick bottle changeovers

Best suited for regional beer producers targeting supermarkets and wider distribution.

3. Large-Scale Beer Bottle Filling Machine (15000–18000 BPH)

For industrial-scale breweries, where efficiency and automation are paramount.

Key Features:

Fully automatic depalletizer system

Advanced rinsing, filling, and capping stations

Very high output capacity (15,000–18,000 bottles/hour)

Programmable logic controllers (PLC) with operator interface

Integrated labeling, packaging, and palletizing system

High-speed bottle size changeover capabilities

Designed for global beer brands and export-oriented production.

Technical Parameters of Glass Bottle Beer Filling Machines

Model | BGF 16-12-6 | BGF 18-18-6 | BGF 24-24-8 | BGF 32-32-10 | BGF 40-40-12 | BGF 50-50-15 |

Washing Heads | 16 | 18 | 24 | 32 | 40 | 50 |

Filling Heads | 12 | 18 | 24 | 32 | 40 | 50 |

Capping Heads | 6 | 6 | 8 | 10 | 12 | 15 |

Capacity (BPH) | 2000 | 4000 | 6000 | 10000 | 15000 | 18000 |

Power (kW) | 3.5 | 4.0 | 4.8 | 7.6 | 8.3 | 9.6 |

Dimension (mm) | 2200×1600×2400 | 2450×1900×2400 | 2750×2250×2400 | 4000×2300×2400 | 4550×2650×2400 | 5450×3210×2400 |

Features of Glass Bottle Beer Filling Machine

Fully Automatic Operation – Rinsing, filling, capping, and bottle transfer with minimal manual input.

Separate Cleaning Function – Allows bottle washing only, useful as a pre-washing stage.

Reliable Mechanical Transmission – Bending rod linkage ensures smooth, stable operation.

Advanced Detection Systems – Flow, pressure, liquid residue, and spear opening monitoring with alarms.

CO2 Back Pressure Filling – Low-foam, precise filling using differential pressure technology.

Automated Temperature Control – Water tank auto-refill, heating, and constant temperature system.

Touchscreen Adjustment – Filling volume and error calibration with real-time bottle/liter count.

DETAILS OF GLASS BOTTLE BEER FILLING MACHINE

Filling part

Capping part

Washing part

Cap elevator

Depalletizer

Touch screen

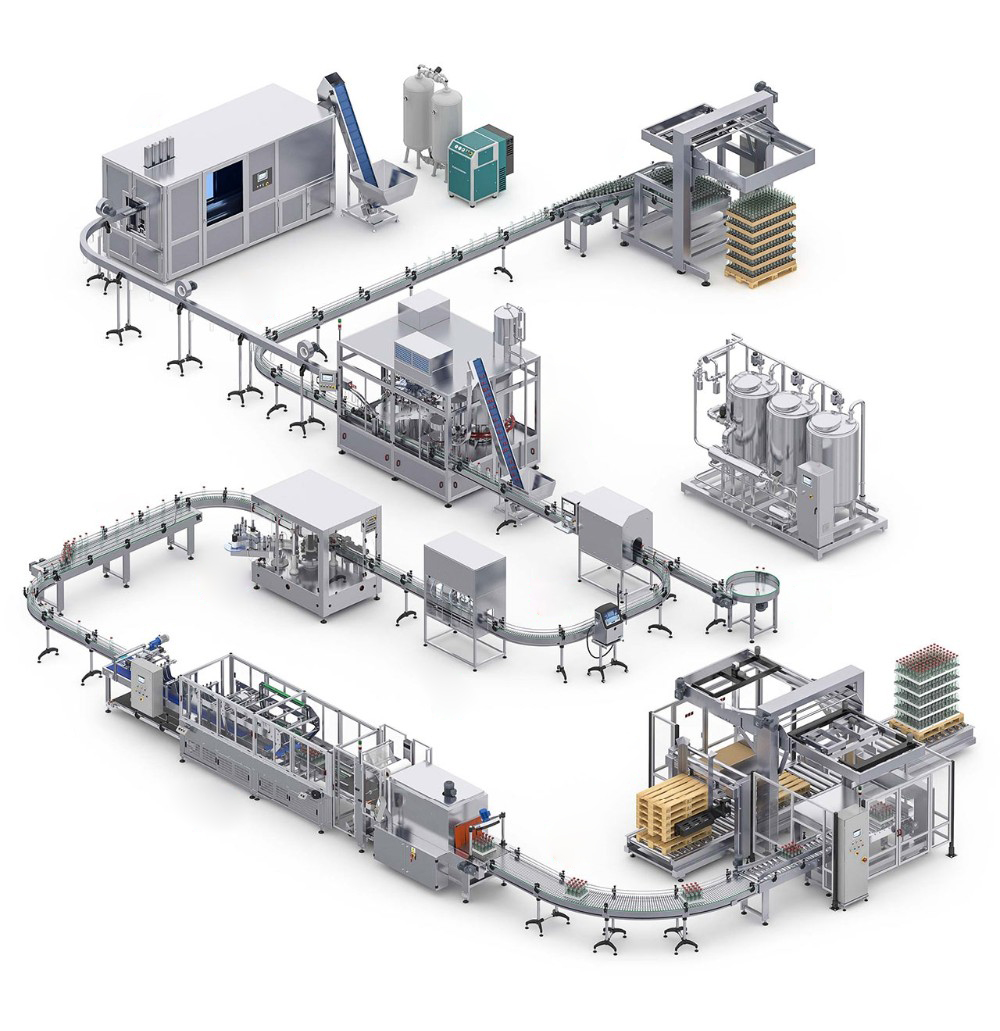

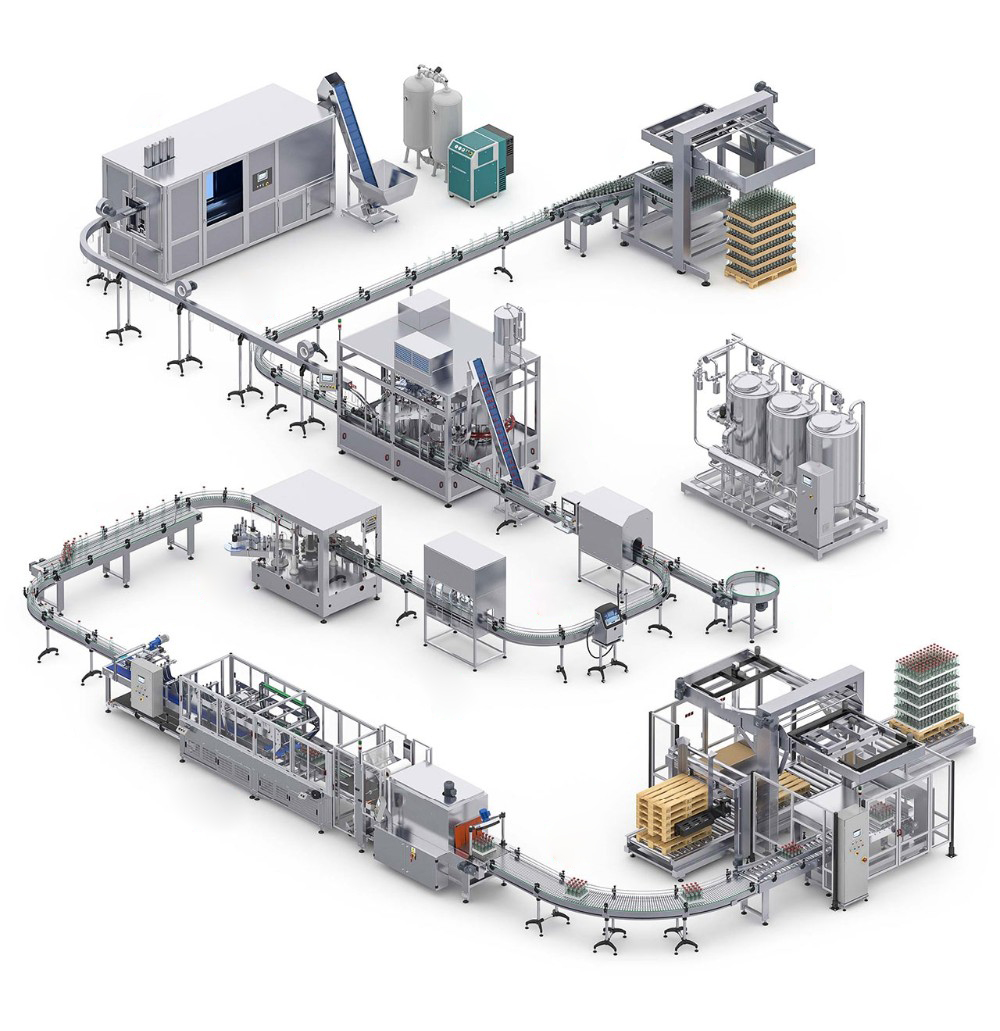

3D LAYOUT OF GLASS BOTTLE BEER FILLING LINE

AUXILIARY EQUIPMENT FOR BEER BOTTLE FILLING MACHINE

A complete glass bottle beer filling line consists of several interconnected machines and equipment designed to automate the process of filling beer into glass bottles.

1. Depalletizer

This machine uploads the empty glass bottles from pallets and feed them into the glass bottle beer filling line.

2. 3 in 1 Beer Filling Machine:

3-in-1 beer filling machine is a specialized piece of equipment designed to handle three functions in the beer bottling process: rinsing, filling, and capping. This machine integrates these three functions into a single unit, providing a compact and efficient solution for smaller-scale beer bottling operations. The 3-in-1 beer bottle filling machine streamlines the beer bottling process by eliminating the need for separate machines for rinsing, filling, and capping. It offers advantages such as space-saving, improved efficiency, simplified operation, and reduced labor requirements.

3. Beer pasteurization tunnel:

It is a specialized equipment used in the beer production industry to pasteurize packaged beer. The pasteurization process involves heating the beer to a specific temperature for a set period to eliminate harmful microorganisms and extend the beer's shelf life.

4. Bottle drying machine:

It is a specialized piece of equipment used in the beverage industry to dry bottles after they have been rinsed or washed. The purpose of the machine is to remove any residual water or moisture from the bottles before they are filled with beverages or further processed.

5. Labeling Machine:

Once the bottles are sealed, they pass through a labeling machine that applies labels with product information, branding, and other required details. This machine can handle different label types, including front and back labels, neck labels, or wraparound labels.

6. Date Coding Machine:

A date coding machine is often integrated into the line to print batch numbers, expiration dates, or other relevant information on the bottles. It ensures traceability and regulatory compliance.

7. Packaging Machine:

The filled and labeled bottles are then grouped into packaging units, such as cartons, trays, or crates. Packaging machines can automate the process of assembling, loading, and sealing these units.

8. Case Packer:

In some cases, a separate machine called a case packer is used to pack the filled bottles into larger shipping cases or cartons for transportation and storage.

9. Conveyors:

Throughout the line, conveyors are used to transport the bottles between different machines and stages. They ensure a smooth and continuous flow of bottles, minimizing manual handling.

RECOMMEND PRODUCTS

Besides glass bottle beer filling machine for sale, we also have kinds of different bottling equipment for water and beverage. Like 5 gallon water bottling plant, carbonated drinks filling line, water bottling equipment, juice filling line ect.

Frequently Asked Questions (FAQs)

Q1: Can this machine handle different glass bottle sizes?

Yes, our machines support multiple glass bottle sizes with quick changeover features.

Q2: How do you reduce beer foaming during filling?

We use CO2 back-pressure technology to maintain low foam and precise filling.

Q3: Can the line integrate labeling and packaging systems?

Absolutely. Our beer filling lines connect seamlessly with labelers, date coders, and case packers.

Q4: What capacity should I choose for my brewery?

2000–4000 BPH → small craft breweries

6000–10000 BPH → medium breweries

15000–18000 BPH → large breweries

Q5: Do you provide installation and after-sales service?

Yes, we provide on-site installation, operator training, spare parts, and lifetime technical support.

Conclusion

PESTOPACK’s glass bottle beer filling machines are built for efficiency, reliability, and flexibility. From 2000 BPH microbrewery lines to 18000 BPH industrial bottling plants, our solutions cover all brewery sizes.

With automated rinsing, filling, capping, and packaging, our beer bottling machines help breweries:

Contact us today to design your custom beer bottling line or explore our full range of liquid filling machines.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu