The cost of an oil filling machine can vary widely based on several factors such as the type of machine, its capacity, the technology it uses, and the specific features required for your operations. Here is a breakdown to help understand how pricing work:

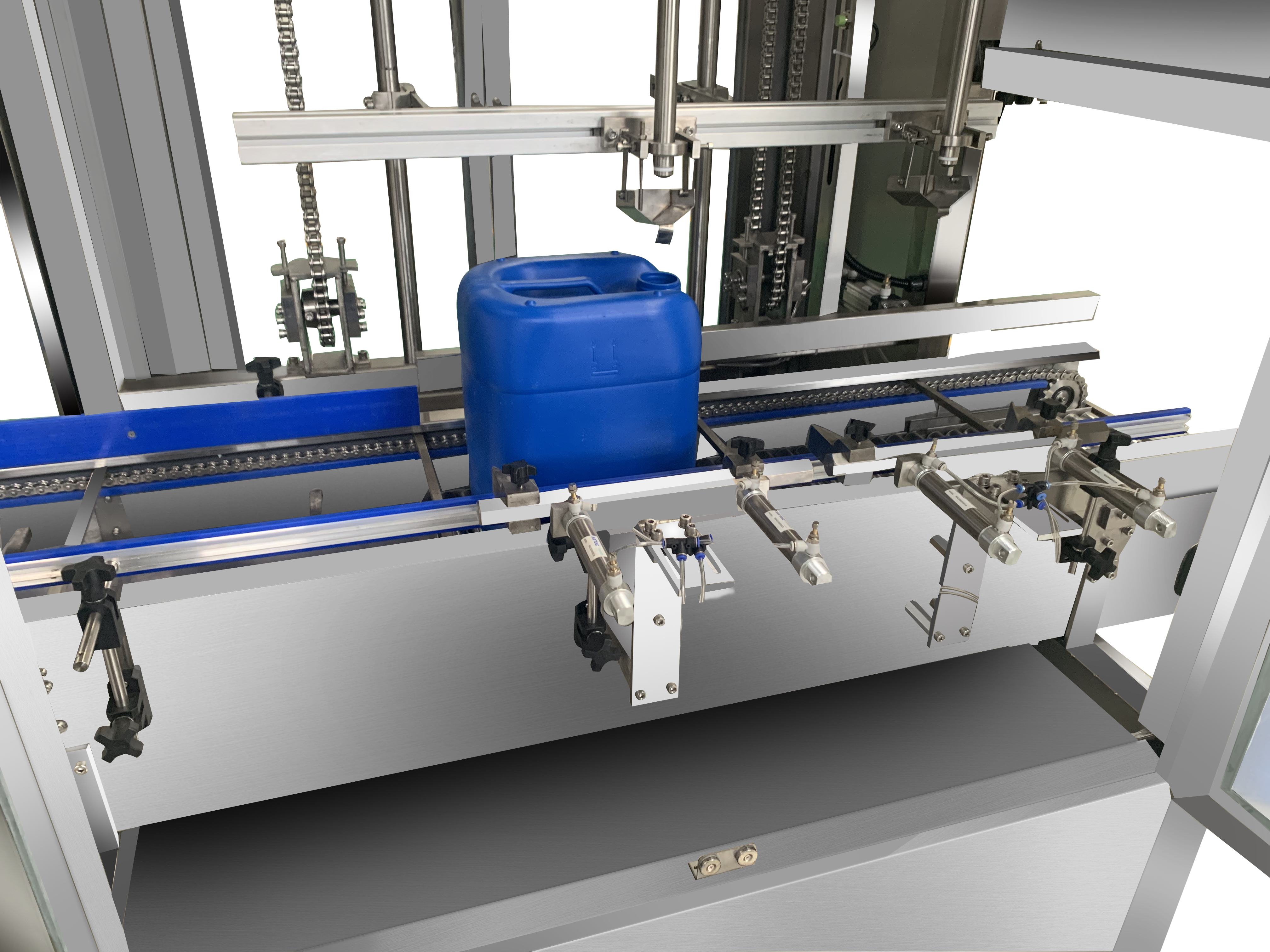

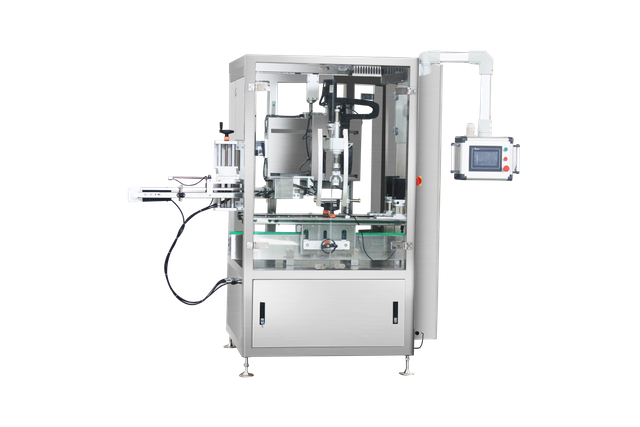

Machine Type: Basic manual or semi-automatic machines can be less expensive, while fully automated, high-speed machines with advanced features like servo motors and PLC control systems will cost more.

Capacity: Oil filling machines designed for high-volume production will generally be more expensive than those intended for smaller-scale operations due to the larger and more durable components required.

Customization: Custom features such as the ability to handle multiple bottle sizes, integration with existing production lines, or specialized filling systems for highly viscous oils or precise dosing can add to the cost.

Price Range

Low-end oil filling machines typically manual or semi-automatic, start from a few thousand dollars (e.g., $1,000 to $5,000).

Mid-range oil filling machines are usually more automated and robust, suitable for medium-sized businesses, and cost between $10,000 and $50,000.

High-end oil filling machines which are fully automated and capable of handling large-scale operations efficiently, can range from $50,000 to over $100,000.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu