1. Ukuthuthukiswa Kwamandla

2. Ukukhanya nokuxuba

3. I-Emulsation

4. Ukupholisa kanye ne-homogenization

I-5. Ukungezwa kwezithako ezisebenzayo kanye nezinto zokugcina

6. Ukulawulwa kwekhwalithi

7. Ukugcwalisa

8. Ukubekwa uphawu

9. Ilebula

10. Ukupakishwa

Ukugcina

Ukukhiqiza ukhilimu wobuso kubandakanya inqubo yokucophelela ukuqinisekisa ikhwalithi yomkhiqizo, ukuphepha kanye nokusebenza kahle. Le nqubo ephelele idinga ukunaka imininingwane ngaso sonke isikhathi, ekukhetheni izinto ezinhle kakhulu ezingavuthiwe ukuze kuqinisekiswe umkhiqizo wokugcina upakishwe ngokuphelele. Isinyathelo ngasinye sidlala indima ebalulekile ekugcineni ubuqotho bukakhilimu wobuso, buqinisekisa ukuthi ihlangabezana namazinga aphezulu okusetshenziswa kwabathengi. Ngezansi umhlahlandlela onemininingwane yokuthi u-Foce Cream wenziwa kanjani, uqokomisa isigaba ngasinye kusuka ekukhetheni ngokucophelela kwezinto zokusetshenziswa okuqondile, ukulawulwa kwekhwalithi efanelekile, futhi ekugcineni inqubo yokupakisha esebenzayo nehlanzekile. Lo mhlahlandlela uhlose ukuhlinzeka ngokuqonda okujulile kwenqubo eyinkimbinkimbi ngemuva kokukhiqiza ukhilimu osezingeni eliphakeme ophephile, osebenzayo, futhi olungele imakethe.

1. Ukuthuthukiswa Kwamandla

Uhambo lokudala ukhilimu wobuso luqala ngokuthuthukisa ukwakhiwa okulungile, inqubo ebeka isisekelo somkhiqizo wonke. Lesi sinyathelo esibalulekile sibandakanya ukukhethwa ngokucophelela kanye nokuhlanganiswa kwezithako ezahlukahlukene, okukhethwe ngakunye kwezakhiwo zalo ezithile ezizuzisayo kanye nezimpawu ezifiselekayo zomkhiqizo wokugcina.

Kukhethwe ama-emulsifiers ukuqinisekisa izigaba zamafutha nezinziselo zamanzi zihlangana kahle, zinikeza ukuthungwa okuzinzile nokungaguquki. Abakhulu bangezwa ukufeza ukubonwa okufiselekayo kanye nokuthuthukisa umuzwa kakhilimu esikhunjeni. Ama-mesasants adlala indima ebalulekile ekudonseni nasekugcinweni komswakama, ukuqinisekisa ukuthi isikhumba sihlala sinamanzi. Ama-Emollients afakiwe ukuthambisa futhi athathe isikhumba, adale isithiyo esivikelayo esikhiya umswakama.

Izithako ezisebenzayo ezifana namavithamini, ama-antioxidants, kanye nokukhishwa kwe-botanical kukhethwa ngokucophelela ngezinzuzo zawo ezihlosiwe. Amavithamini, njengovithamini C kanye nevithamini e, angezwa ngezakhiwo zawo ze-antioxidant, asiza ukuvikela isikhumba ekulimaleni kwemvelo futhi athuthukise ukubukeka okunempilo. Ukukhishwa kwe-botanical, okutholwe kusuka ezitshalweni zemvelo, nikeza izinzuzo ezahlukahlukene zesikhumba, kusuka ekuvuvukeni okupholile ukuhlinzeka izakhi zomzimba ezibalulekile.

Isigaba Sokuthuthukiswa Kwamakhemikhali siwumzamo wokubambisana phakathi kwamakhemikhali, ama-dermatologists, kanye nabathuthukisi bomkhiqizo, baqinisekise ukuthi umkhiqizo wokugcina awuphumelelanga nje kodwa futhi uphephile futhi ukujabulisa ukusetshenziswa. Ngokuhlolwa okuqinile kanye nokuhlolwa, ukwakheka kuyacwengiswa kuze kube yilapho ihlangabezana nazo zonke izindlela ezifiselekayo, isetha isigaba sezinyathelo ezilandelayo kwinqubo yokukhiqiza.

2. Ukukhanya nokuxuba

Lapho ukwakhiwa sekuphothuliwe, inqubo yokukhiqiza iqhubekela esigabeni esibucayi sokuba nesisindo nokuxuba izithako. Lesi sinyathelo sibalulekile ukuze uqinisekise ukuthi i-batch ngayinye yobuso igcina ukuvumelana nekhwalithi. Izithako zisindwa ngokuqondile ngokuya ngeresiphi ethuthukiswe ngokucophelela, nengxenye ngayinye eyalinganiswa ku-gramu ngqo ukuqinisekisa inani elifanele.

Inqubo yokuxuba iqala ngokuhlanganisa ngokuhlukile ukuhlanganisa izithako ezingenamanzi. Izithako ezingenamanzi, ezingafaka ama-mulaimus, izinhlekisa, kanye nezithako ezithile ezisebenzayo, zixutshwe emkhunjini owodwa. Kwesinye isitsha, izithako ezincibilikayo kawoyela, njenge-emollients, uwoyela namavithamini athile, ahlanganisiwe. Lokhu kuhlukanisa kuyadingeka ngoba amanzi namafutha awahlanganisi ngokwemvelo; Badinga imibandela ethile namasu athile ukwakha inhlanganisela ezinzile.

Kokubili isigaba samanzi kanye nesigaba samafutha bese sifudunyezwa emazingeni okushisa athile, imvamisa cishe cishe ngo-70-80 degrees Celsius (158-176 degrees Fahrenheit). Ukushisa lezi zigaba kubalulekile njengoba kusiza ukuncibilikisa izithako ezithile futhi kusiza inqubo yokwenza i-emulsification. Lapho zombili izigaba zombili zifinyelela kumazinga okushisa afunekayo, zihlanganiswa kancane kancane. Lokhu kwenziwa kusetshenziswa ama-Mixers aphezulu-shear, asebenzisa amandla amakhulu emishini ukudiliza amaconsi kawoyela abe yizinhlayiya ezincane, zivumele ukuba zihlakaze ngokulinganayo kuzo zonke izigaba zamanzi.

Umphumela wale nqubo yi-emulsion ezinzile, ingxubevange enobungozi lapho izigaba zamafutha nezinzi zasolwandle zisatshalaliswa ngendlela efanayo. Le emulsion yilokho okunikeza ukhilimu wobuso obushelelezi, ukungaguquguquki okunethezeka. Ukulawulwa ngokucophelela kokushisa, isivinini sokuxuba, nesikhathi nesikhathi kubalulekile ukuze uqinisekise ukuthi umkhiqizo wokugcina awuzinzile kuphela kodwa futhi unokuthungwa okufunayo kanye nokusebenza kahle. Lesi sigaba sibeka isisekelo se-Cream esezingeni eliphakeme ehlangabezana namazinga afakiwe.

3. I-Emulsation

I-Emulsassification iyisinyathelo esibalulekile ekukhiqizeni ukhilimu wobuso, lapho izigaba zamafutha ezake zihlanganiswe ngaphambili kanye nezinhlanganisela zenhlanganisela. Le nqubo ibalulekile ukuqinisekisa ukuthi ukhilimu wobuso ugcina ukuthungwa kwawo okubushelelezi futhi akahlukanisi isikhathi, okuzohlehlisa ikhwalithi nokusebenza kwayo.

Inqubo ye-emulsation iqala ngokwazisa isigaba samafutha esigabeni samanzi. Lokhu ngokuvamile kwenziwa kusetshenziswa ama-mixers aphezulu-shear, okuyimishini ekhethekile eyenzelwe ukusebenzisa amandla amakhulu emishini engxube. Ama-Mixers aphezulu-shear asebenza ngesivinini esikhulu, akhiqiza amandla anele okubhidliza amaconsi kawoyela abe osayizi bemicroscopic. Lawa amaconsi amancane asatshalaliswa ngokulinganayo kulo lonke iSigaba Samanzi, adala i-emulsion efanayo.

Ukusebenza kwale nqubo kuthembela ekuphathweni okuqondile kwamapharamitha ahlukahlukene, kufaka phakathi ijubane lokuxuba, izinga lokushisa kanye nesikhathi sokuxuba. Amandla aphezulu we-shear aqinisekisa ukuthi amaconsi kawoyela mancane ngokwanele ukuba ahlale amiswe esigabeni samanzi, ebavimbela ekuhlanganiseni ukuhlanganisa futhi ahlukanise ngaphandle. Lokhu kuphumela emulsion ozinzile ngokuvumelana okubushelelezi nokunokhilimu, okubalulekile ku-cream osezingeni eliphakeme.

Ngaphezu kwalokho, ama-emulsifiers adlala indima ebalulekile ngalesi sinyathelo. Lezi zithako zengezwa engxube ukusiza ukuqinisa i-emulsion ngokunciphisa ukungezwani okungaphezulu phakathi kwezigaba zamafutha nezitha zamanzi. Ama-emulsifiers ajwayelekile asetshenziselwa ukwakhiwa ko-CHECE we-FACE afaka i-Lecithin, ama-polysorbetes, no-cytyl alcohol, phakathi kwabanye. Basebenza ngokwakha isithiyo esivikelekile esizungeze amaconsi kawoyela, bavimbela ukuba bahlangane futhi bahlukanise nesigaba samanzi.

I-Emulsassification iyibhalansi ebucayi yesayensi nezobuciko, edinga ukuqapha ngokucophelela kanye nezinguquko ukuze kufinyelelwe ukuvumelana okuphelele. Umphumela wokugcina ukhilimu wobuso ongeyona kuphela ubuhle kodwa futhi uphumelele ekuletheni izithako zawo ezizuzisayo esikhunjeni. Le emulsion ezinzile iqinisekisa ukuthi izithako ezisebenzayo zisatshalaliswa ngokulinganayo kulowo mkhiqizo, zinikeza imiphumela engaguquki ngakho konke ukusetshenziswa.

4. Ukupholisa kanye ne-homogenization

Ngemuva kwenqubo ebabayo, izinyathelo ezibalulekile ezilandelayo zokukhiqiza ukhilimu zipholile kanye nokupholisa. Lezi zinyathelo zibalulekile ukuze uqinisekise ukuthi umkhiqizo wokugcina ufinyelela ukuthungwa okufiselekayo, ukuvumelana, nokuqina.

Lapho nje izigaba zamafutha nezinzi zamanzi zikhuphuke ngempumelelo, inhlanganisela kancane kancane yaphonswa ekushiseni kwegumbi. Ukupholisa kwenziwa ngendlela elawulwayo ngenkathi kuqhubeka ukuxuba ukhilimu ukuze ulondoloze ukusatshalaliswa komfaniswano kwezithako futhi uvikele noma yikuphi ukwahlukana. Lokhu kuncishiswa kancane kancane kusiza ukuqinisa ukwakheka kwe-emulsion, ukukhiya endaweni ebushelelezi etholakele ngesikhathi kusizakala.

Ngesikhathi senqubo yokupholisa, ukuxuba okuqhubekayo kubalulekile ukuze uqinisekise ukuthi izinga lokushisa lisatshalaliswa ngokulinganayo kuyo yonke le ngxube. Lokhu kuvimbela ukwakheka kwezigaxa futhi kugcina ukuvumelana kokhilimu. Ukuxuba futhi kuyasiza ukuqeda noma yikuphi ukushisa okwenziwe ngesikhathi senqubo ye-emulsation, okuvumela ukhilimu ukuba apholile ngokufana.

I-Homogenization ivame ukwenzeka phakathi noma ngemuva kwesigaba sokupholisa ukuze uqhubeke nokuhlaziya ukuthungwa kukakhilimu. Le nqubo ifaka ukuphoqa le ngxube ngendawo emincane, esebenzisa ingcindezi ephezulu yokubhidliza noma yiziphi izinhlayiya ezinkulu ezisele namaconsi abe ngosayizi abancane. I-Homogenization ithuthukisa ubushelelezi be-ayisikhilimu futhi iqinisekise ukuthi izithako ezisebenzayo zisatshalaliswa ngokulinganayo kulowo mkhiqizo.

Umphumela we-homogenization ungumkhilimu wobuso onomfaniswano ophakeme futhi obushelelezi, mahhala kunoma yikuphi okudla okudla okudlayo noma ukungalingani. Lesi sinyathelo sibalulekile ekwakheni umuzwa wokunethezeka esikhunjeni nasekuqinisekiseni ukuthi ukhilimu usakazeka kalula futhi umuhle kahle. I-Homogenization ibuye isize ukuthuthukisa ukuqina kokhilimu, ivikele ukuhlukaniswa kwezigaba zamafutha nezinziselo zamanzi ngokuhamba kwesikhathi futhi iqinisekise ukuthi umkhiqizo uhlala uphumelele futhi uthande ubuhle bukabusuku bayo yonke impilo yakhe.

Ngokulawula ngokucophelela izinqubo zokupholisa kanye ne-homogenization, abakhiqizi bangakhiqiza ukhilimu osezingeni eliphakeme oletha ukusebenza okungaguquki, futhi ejabulisa isikhumba, futhi ahlangabezane nezindinganiso ezinzima zekhwalithi nokusebenza okudingekayo embonini ye-skincare.

I-5. Ukungezwa kwezithako ezisebenzayo kanye nezinto zokugcina

Lapho i-cream eyisisekelo isilungisiwe futhi sehlile emazingeni okushisa afanele, isinyathelo esilandelayo sifaka ukungezwa kwezithako ezisebenzayo, amakha, nezithonjana. Lesi sigaba sibalulekile ekuthuthukiseni ukusebenza ngempumelelo, isikhalazo, kanye nempilo eshalofle yekhilimu yobuso.

Izithako Ezisebenzayo:

Izithako ezisebenzayo zengezwa ukuletha izinzuzo ezithile esikhunjeni. Lokhu kungafaka amavithamini, ama-peptides, ama-antioxidants, kanye nokukhishwa kwe-botanical. Isibonelo, uvithamini C uvame ukungezwa ngokukhanyisa kwawo futhi anti-agen Properties, kuyilapho i-hyaluronic acid ifakiwe amakhono ayo amahle kakhulu anomswakama. Ngoba lezi zithako zivame ukuzwela ukushisa, zingezwa ngemuva kokuthi ingxube ipholile ukuze ilondoloze amandla nokusebenza kwayo.

Amakha:

Amakha angeniswa ukuthuthukisa ulwazi lokuzwa lokusebenzisa ukhilimu wobuso. Lokhu kungasukela kumafutha asemqoka wemvelo kumakhambi wokwenziwa. Ukukhetha iphunga kuncike kwiphrofayili yephunga elifunekayo lomkhiqizo wokugcina kanye nezintandokazi zabathengi. Ukungeza amakha kulesi sigaba kuqinisekisa ukuthi bahlangana kahle ngaphandle kokuwohloka ngenxa yokushisa okuphezulu.

Okulondoloziwe:

Ama-Proservatives aqakathekile ukuvimbela ukungcoliswa kwe-microbial futhi anwebe impilo yeshelufu kakhilimu wobuso. Izindawo ezijwayelekile zibandakanya amapharane, Phenoxyethanol, kanye nezinye izindlela zemvelo ezinjenge-rosemary extract. Lezi zingxenye zikhethwe ngokucophelela ukuze ziqinisekise ukuthi zisebenza ngokugxila okuphansi futhi ziyahambisana nezinye izithako ekwakhekeni.

Ukuxuba:

Ngemuva kokuhlanganiswa kwalezi zinto ezibucayi, ingxube ivuswe ngobumnene ukuqinisekisa ukusatshalaliswa okufanayo kulo lonke ukhilimu oyisisekelo. Lesi sinyathelo sidinga ukuphatha ngokucophelela ukugwema ukwethula ama-bubble omoya futhi ulondoloze ukuthungwa okubushelelezi komkhiqizo.

Ukungezwa ngokucophelela kwezithako ezisebenzayo, amakha, kanye nezinto zokugcina kuyisigaba esibucayi kodwa esibalulekile ekukhiqizweni kokhilimu wobuso. Kuqinisekisa ukuthi umkhiqizo wokugcina awugcini nje ngokunikeza izinzuzo ezithenjisiwe ze-skincare kepha futhi uhlinzeka ngesipiliyoni esimnandi somsebenzisi futhi uhlala ephephile futhi uzinzile ngokuhamba kwesikhathi.

6. Ukulawulwa kwekhwalithi

Ukhilimu wokugcina wobuso obukhona ocwaningweni lokuhlolwa kokulawulwa kwekhwalithi okuqinile ukuze uqinisekise ukuthi ihlangabezana nakho konke ukuphepha kanye namazinga asezingeni ngaphambi kokuthi kuvunyelwe ukufakwa. Lesi sinyathelo esibalulekile senzelwe ukuqinisekisa ukuthi umkhiqizo uphephile, uyasebenza, futhi uhambisana nezincazelo ozifunayo.

Ukuhlolwa kwe-PH:

I-PH ye-Cream yobuso ihlolwe ukuqinisekisa ukuthi ingaphakathi kwebanga elifanele lokuhambisana kwesikhumba. Izinga le-PH lithinta ukuqina komkhiqizo nokuxhumana kwalo nesikhumba. I-PH elinganiselayo iqinisekisa ukhilimu umnene futhi awucasuli, okwenza kufanelekile ukusetshenziswa kwansuku zonke.

Ukulinganiswa kwe-Viscosity:

Ukubonakala kukakhilimu kulinganiswa ukuze kuqinisekiswe ukuthi kunokuvumelana okulungile. I-Viscesity ithinta indlela ukhilimu asakazeka futhi amunca isikhumba. Ukuqinisekisa ukuthi i-viscosity efanele ibalulekile ekwanelisekeni komsebenzisi kanye nokusebenza kahle komkhiqizo.

Ukuhlolwa kwe-Microbial:

Ukuhlolwa kwe-microbial kwenziwa ukuze kuqinisekiswe ukuthi ukhilimu wobuso akhululekile kumagciwane ayingozi, imvubelo, nokubumba. Lesi yisinyathelo esibucayi ekuqinisekiseni umkhiqizo uphephile kubathengi. Ukhilimu uhlolelwa ukungcoliswa kwe-microbial zombili ngokushesha ngemuva kokukhiqizwa nangemva kokugcinwa ngaphansi kwezimo ezahlukahlukene ukulingisa ukusetshenziswa kwangempela komhlaba.

Ukuhlolwa kokuqina:

Ukuhlolwa kokuqina kuhlaziya ukuthi ukhilimu wobuso usebenza kanjani ngokuhamba kwesikhathi nangaphansi kwezimo ezahlukahlukene zezemvelo. Lokhu kufaka phakathi ukuhlola ukuqina komkhiqizo, kwamakhemikhali, kanye nokuqina kwe-microbiological. Ukhilimu ufakwa ngaphansi kwezimo zokuguga ezisheshayo ukubikezela impilo yazo eshalofini futhi uqinisekise ukuthi ihlala iqinile futhi isebenza kahle ngesikhathi esifanele sokusebenzisa okuhlosiwe.

Ukuhlolwa okwengeziwe:

Ngokuya ngokwakha nokusetshenziswa okuhlosiwe, kungenziwa ukuhlolwa okwengeziwe. Lokhu kungafaka ukuhlolwa kwemizwa, okuhlola ukubukeka komkhiqizo, ukuthungwa, kanye nephunga, kanye nokuhlolwa okusebenzayo, okulinganisa ukusebenza kwezithako ezisebenzayo.

I-batch ngayinye yobuso ukhilimu kufanele idlule zonke lezi zivivinyo zokulawula ezisezingeni eliphansi ngaphambi kokuthi ivunyelwe ukufakwa. Le nqubo yokuhlola kahle iqinisekisa ukuthi yonke imbiza yekhilimu yobuso ihlangabezana namazinga aphezulu okuphepha nekhwalithi, ukuhlinzeka abathengi ngomkhiqizo othembekile futhi osebenzayo we-skincare. Ngokunamathela kwimigomo yokulawula esezingeni elifanele, abakhiqizi bangagcina idumela labo lokugqama futhi baqinisekise ukwaneliseka kwamakhasimende.

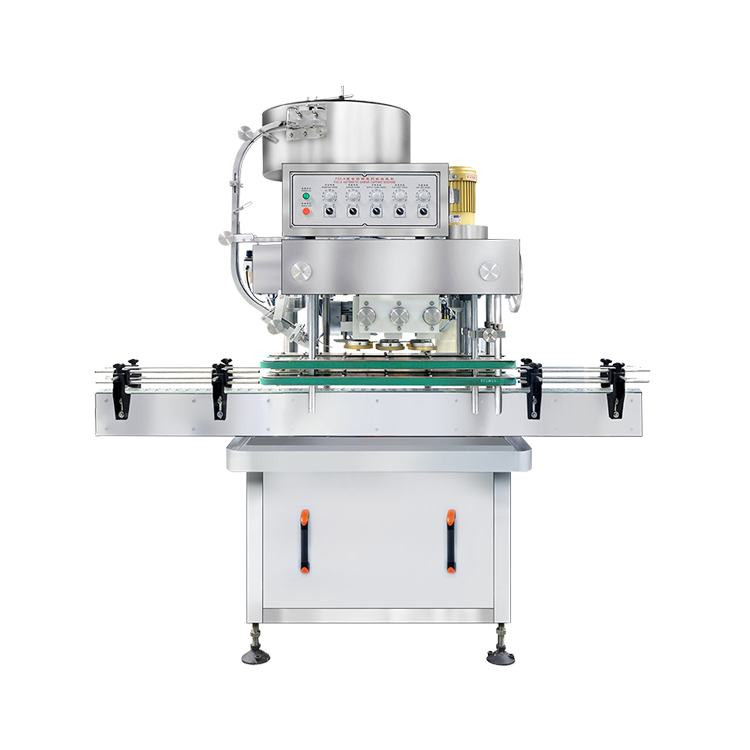

7. Ukugcwalisa

Lapho nje ukhilimu wobuso usudlulile konke ukuhlolwa kwekhwalithi, kudluliswa esiteshini sokugcwalisa. Lapha, ukhilimu uhanjiswa ezitsheni, amashubhu, noma amabhodlela usebenzisa imishini yokugcwalisa ekhethekile eyenzelwe ukuqinisekisa ukunemba nokungaguquguquki. Ukunemba kubaluleke kakhulu ngesikhathi kulesi sigaba ukugwema ukugcwala ngokweqile noma ukugcwaliswa, okungakwazi ukuthinta kuphela impilo yeshelufu yomkhiqizo kodwa futhi nesethulo sayo sonke. Imishini yokugcwalisa okuthuthukile, efana nesimo sethu-kwe-the-art Umshini wokugcwalisa ukhilimu , asetshenziselwa ukufeza amazinga okugcwalisa anembile, ukuqinisekisa ukuthi isitsha ngasinye sibambe inani elifanele lomkhiqizo. Lesi sinyathelo futhi sifaka ukugcina amazinga aqinile wokuhlanzeka ukuvikela ukungcoliswa kanye nokuqinisekisa ukuthi ukhilimu wobuso uhlala uphephile futhi usebenza ngokusetshenziswa kwabathengi.

8. Ukubekwa uphawu

Kamuva Umshini wokugcwalisa ibhodlela e-liquid Bottle , iziqukathi zihanjiswa esiteshini sokubopha uphawu. Lapha, imbiza ngayinye, ishubhu, noma ibhodlela livalwe ngokuphephile ukuvikela umkhiqizo ezicini zezemvelo futhi ugcine ubuqotho bayo. Ukufakwa uphawu kungafaka phakathi kwamabhodlela, ama-cap, noma izimbumbulu ze-tamper-ezibonakalayo, kuya ngohlobo lokupakisha olusetshenzisiwe. Lesi sinyathelo sibalulekile ukuqinisekisa ukuthi umkhiqizo uhlala ungonakalisiwe futhi musha, ugcina ikhwalithi yawo kuze kube yilapho ifinyelela kumthengi.

9. Ilebula

Ngemuva kwenqubo yokubekwa uphawu, iziqukathi ziqhubekela esiteshini samalebula. Amalebula asetshenziswa esitsheni ngasinye, enikeza imininingwane ebalulekile efana negama lomkhiqizo, izithako, imiyalo yokusetshenziswa, kanye nosuku lokuphelelwa yisikhathi. Inqubo yokulebula isebenza ngokuzenzakalela ukuqinisekisa ukunemba nokungaguquguquki, ukuqiniseka ukuthi wonke umkhiqizo ubukeka uchwepheshe futhi uhlangabezana nezidingo zokulawula. Ukulebula okunembile kubalulekile kuzo zombili ukuhambisana nokuthengiswa kwezomthetho, njengoba kwazisa abathengi ngomkhiqizo nokusetshenziswa kwayo okufanele.

10. Ukupakishwa

Isinyathelo sokugcina kwinqubo yokukhiqiza sifaka iziqukathi ezivalekile futhi ezibhalwe amabhokisi amabhokisi noma amabhokisi, alungele ukusatshalaliswa. Lokhu kufaka ukuhlela ngokucophelela imikhiqizo ukuvikela ukulimala ngesikhathi sokuhamba. Inqubo yokupakisha yakhelwe ukuthi isebenze kahle, iqinisekise ukuthi inqwaba yomkhiqizo ingaphathwa ngokushesha nangokuphepha. Kukhethwe izinto zokupakisha ukuhlinzeka ukuvikela okwanele ngenkathi futhi kube nobungani bemvelo noma nini lapho kungenzeka. Uma upakishwe, amabhokisi avaliwe futhi abhalwe ukuthi athunyelwa, aqinisekise ukuthi ukhilimu wobuso ufinyelela abathengi esimweni esifanele.

Ukugcina

Ukukhiqiza nokupakipha kobuso ukhilimu kubandakanya uchungechunge lwezinyathelo ezingezwa kahle zokuqinisekisa ikhwalithi yomkhiqizo kanye nokusebenza kahle. Isigaba ngasinye, kusuka ekuthuthukisweni kokwakheka kuya kwiphakheji yokugcina, kudinga ukunemba nokunaka imininingwane. Ngokufaka imishini esezingeni eliphezulu efana nomshini wethu wokugcwalisa ukhilimu, abakhiqizi bangathola ukunemba okukhulu, ukusebenza kahle, kanye nenhlanzeko ekusebenzeni kwabo. Lokhu kuholela emikhiqizweni ephakeme ehlangabezana namazinga aphezulu emakethe yanamuhla ye-skincare, enikeza abathengi abanamakhilimu wobuso obuthembekile, osezingeni eliphakeme aletha izithembiso.