PESTOPACK-YOUR TRUSTED CREAM FILLING MACHINE MANUFACTURER

At PestoPack, we take immense pride in being your trusted partner for cream filling solutions. As a leading cream and detergent filling machine manufacturer, we have established a reputation for excellence and innovation in the industry.

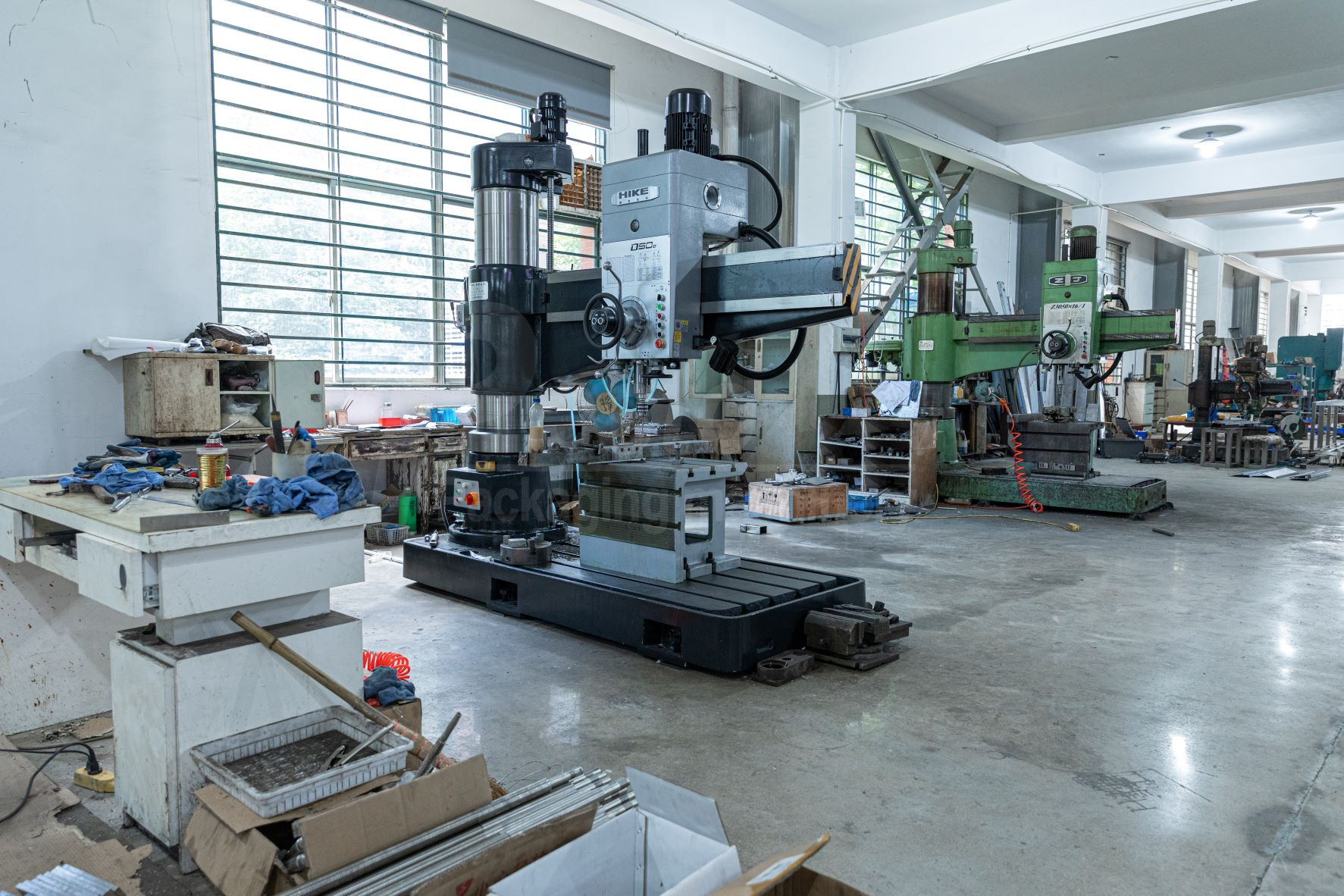

Expertise and Experience

With years of experience under our belt, we bring a wealth of knowledge and expertise to the table. Our team comprises skilled engineers and industry experts who understand the nuances of cream filling technology.

Cutting-Edge Technology

We stay at the forefront of technology, consistently innovating and improving our cream paste filling machines. You can count on us to provide state-of-the-art solutions that meet the demands of modern production.

Versatility and Customization

We recognize that every production process is unique. That's why we offer versatile wholesale cream filling machines or lotion filling machine that can be tailored to your specific needs. From container types to cream viscosities, we can customize our machines to suit your requirements.

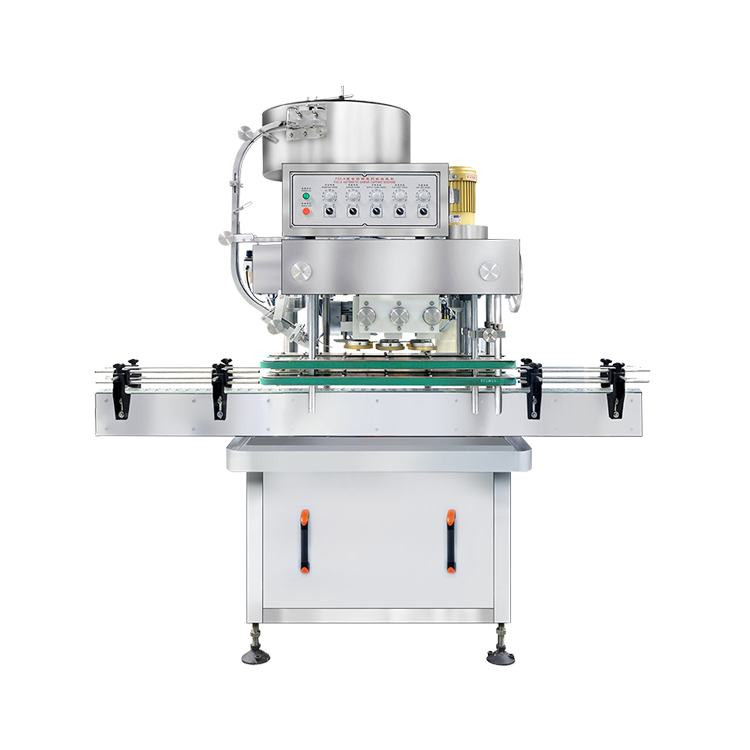

Quality and Precision

When you choose PestoPack, you're choosing precision. Our cream filling machines are engineered for accuracy, ensuring that each container is filled consistently and to your exact specifications.

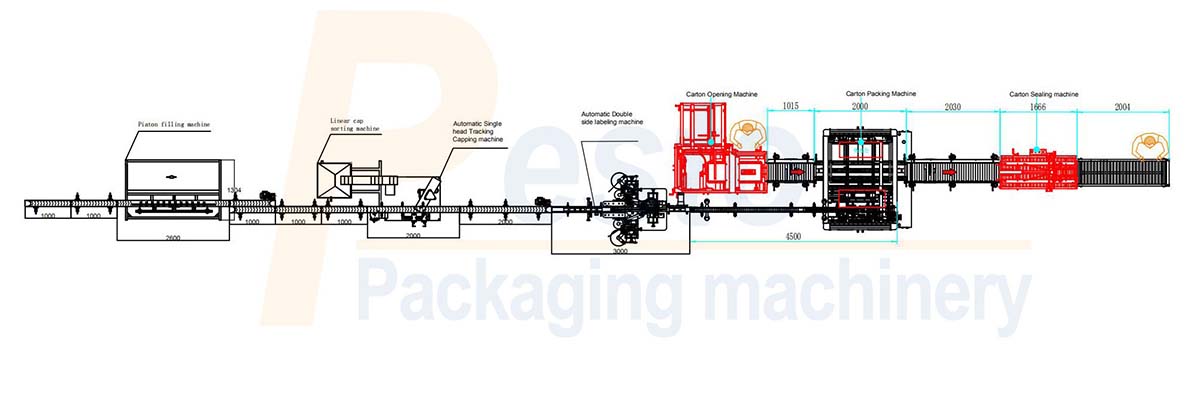

Comprehensive Solutions

We don't stop at providing machines; we offer complete solutions. Whether you need a standalone small cream filling machine or a full cream filling line, we have the expertise to deliver and install the entire system.

Reliability and Durability

We design our cream filling machines to be reliable workhorses that can withstand the rigors of daily production. The robust construction and quality components minimize downtime and maintenance costs.

Personalized Support

When you partner with PestoPack, you're not just another customer; you're a valued partner. We provide hands-on support, training, and guidance to ensure that you get the most out of our machines.

Cost-Effective Solutions

Our cream filling machines offer cost-effective production benefits. From reduced labor costs to minimized product waste, choosing PestoPack is a smart investment for your business.

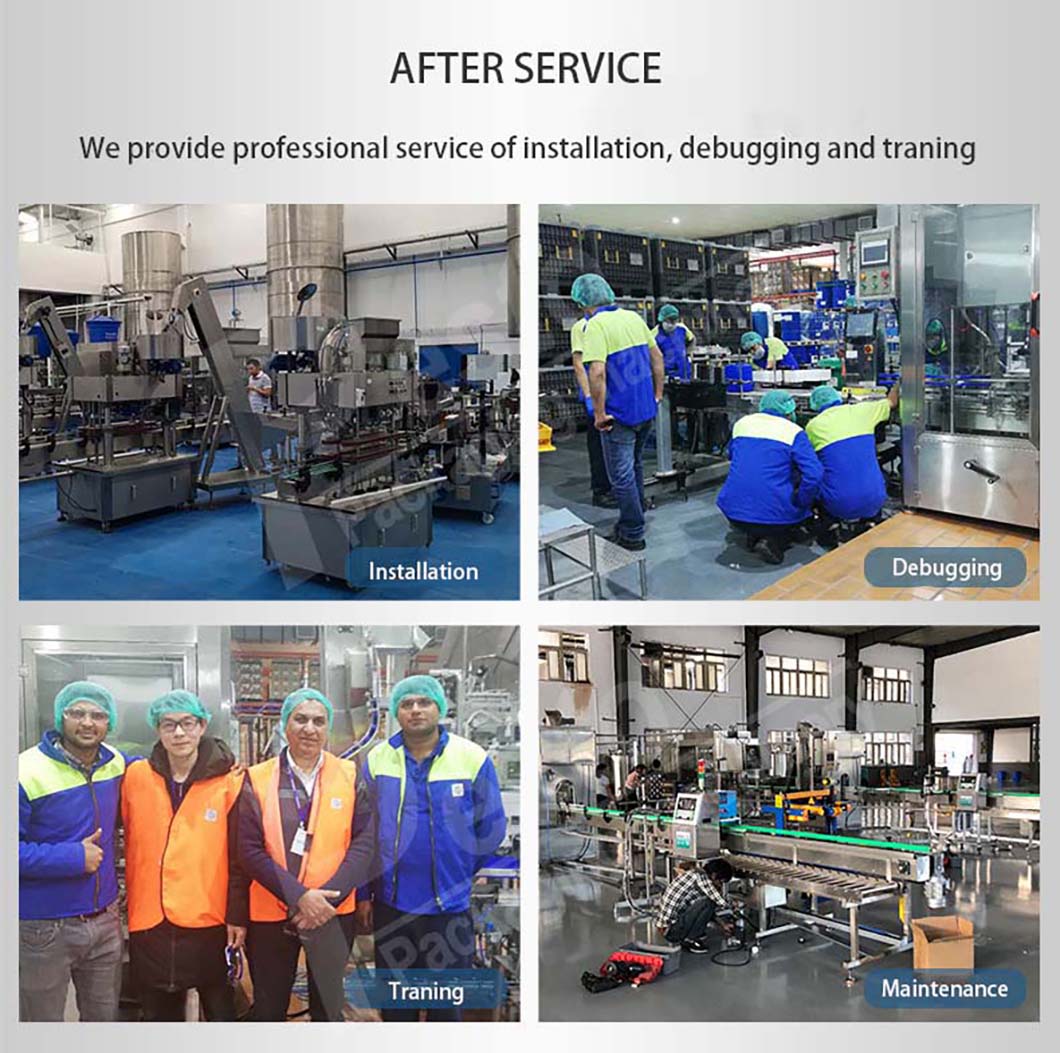

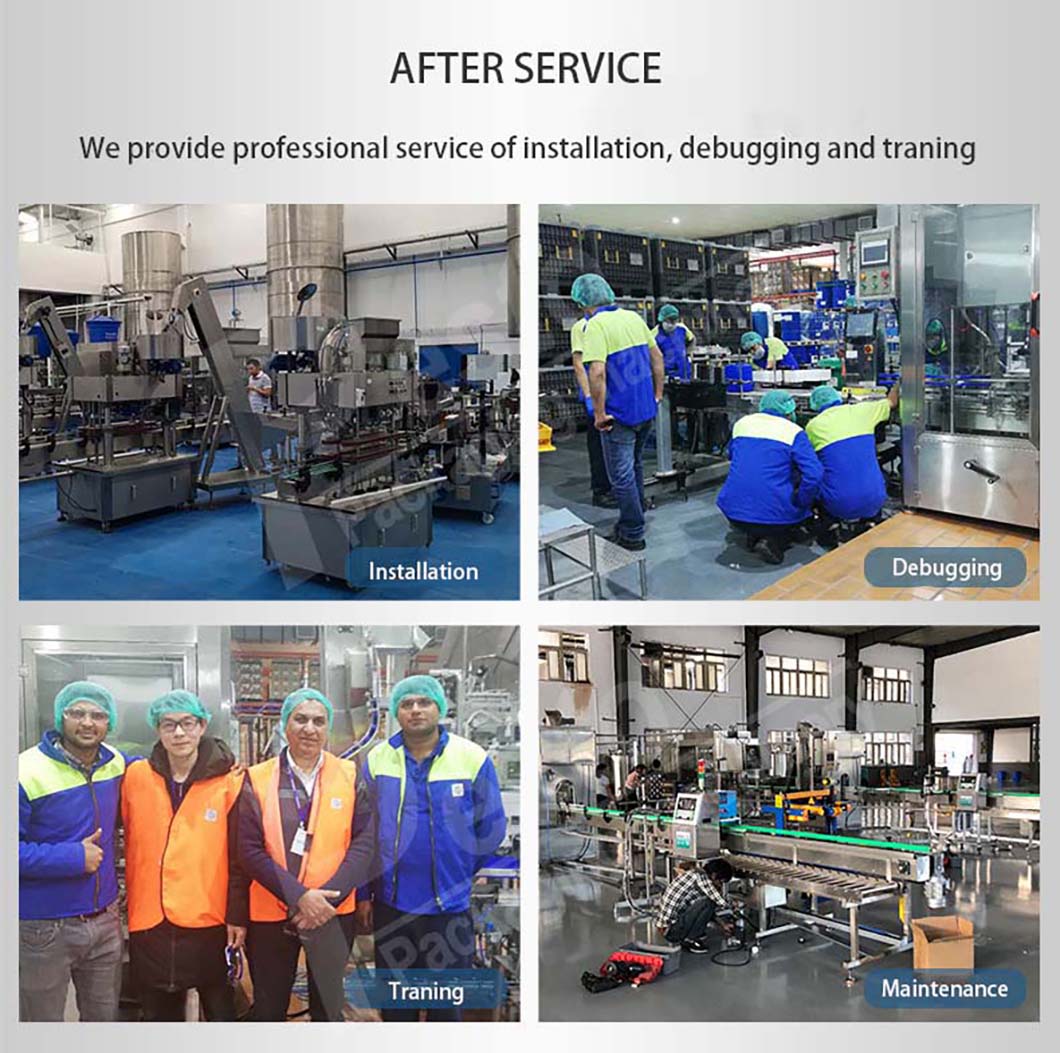

After Sales

1. Installation and Training

Our expert technicians will ensure the proper installation and setup of your cream filling machine. We provide comprehensive training for your staff to operate the equipment efficiently and safely.

2. Technical Support

Pestopack offers round-the-clock technical support to address any questions or issues you may encounter during the operation of your cream filler machine. Our team is just a phone call or email away, ready to assist you.

3. Maintenance

Regular maintenance is essential to keep your cream filling machine in optimal condition. Pestopack offers preventive maintenance packages to extend the life of your equipment and minimize unexpected downtime.

4. Spare Parts Availability

We maintain an inventory of genuine spare parts to ensure quick replacements when needed. Using genuine parts guarantees the continued reliability of your cream filling machine.

5. Custom Solutions

If your needs change or your production process evolves, Pestopack can provide custom solutions to adapt your cream filling equipment to your new requirements.

Customer Testimonial

Lisa, USA

"We've had Pestopack's cosmetic cream filling equipment for a while now. It's a practical piece of equipment that's made our beauty product production smoother. It may not be fancy, but it's reliable and does the job."

Carlos, Moxico

"We started using Pestopack's cream filler machine last year for our skincare line. It's practical and doesn't require a lot of fuss. The fills are consistent, and it's made our production a bit more efficient. It's working out well for us."

Olivia, Australia

"We use Pestopack's cream filling machine in our production. It's pretty straightforward, and it's effective. It's easy to handle, and we've seen an improvement in our product quality. "

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu