Uyini umshini wokugcwalisa wevolumetric

Izinhlobo zemishini yokugcwalisa yevolumetric

Imishini yokugcwalisa yevolumetric isebenza kanjani

Izinzuzo zemishini yokugcwalisa yevolumetric

Imikhiqizo yemishini yokugcwalisa yevolumetric egcwalisa

Ungawukhetha kanjani umshini wokugcwalisa we-volumetric ongakwesokudla

Intengo yomshini wokugcwalisa wevolumetric

I-Pestopack ngumshini womshini wevolumetric wokugcwalisa

Ukugcina

Ukukhetha umshini wokugcwalisa we-volumetric ongakwesokudla kuyisinqumo esibucayi esingathinta kakhulu ukusebenza kwakho kahle kokukhiqiza, ikhwalithi yomkhiqizo, nezindleko zokusebenza jikelele. Noma ngabe usembonini yokudla kanye nophuzo, ama-cosmetics, izimonyo noma amakhemikhali, umshini wokugcwalisa ofanele ofanele uqinisekisa imikhiqizo yakho enembile, engaguquki, futhi esebenza kahle. Lo mhlahlandlela ophelele uzokuhamba ngezinto ezibalulekile okufanele ucabangele, izinhlobo zemishini yokugcwalisa yevolumetric etholakalayo, amabanga amanani, namathiphu ukukusiza wenze isinqumo esinolwazi. Ngokuqonda ubunzima bemishini yokugcwalisa ye-volumetric, ungakhetha isixazululo se-volumetric sokugcwalisa esihlangabezana nezidingo zakho ezithile futhi isekela ukukhula kanye nempumelelo yebhizinisi lakho.

Uyini umshini wokugcwalisa wevolumetric

Umshini wokugcwalisa we-volumetric ucezu oluyinkimbinkimbi lwemishini eyenzelwe ukunikela ngenani elinembile, elinqunyelwe kusengaphambili loketshezi ezitsheni zezimo ezahlukahlukene nosayizi. Lolu hlobo lomshini wokugcwalisa wevolumetric lubalulekile ezimbonini ezifunwa ukunemba okuphezulu nokuvumelana ekugcwalisweni kwezinqubo.

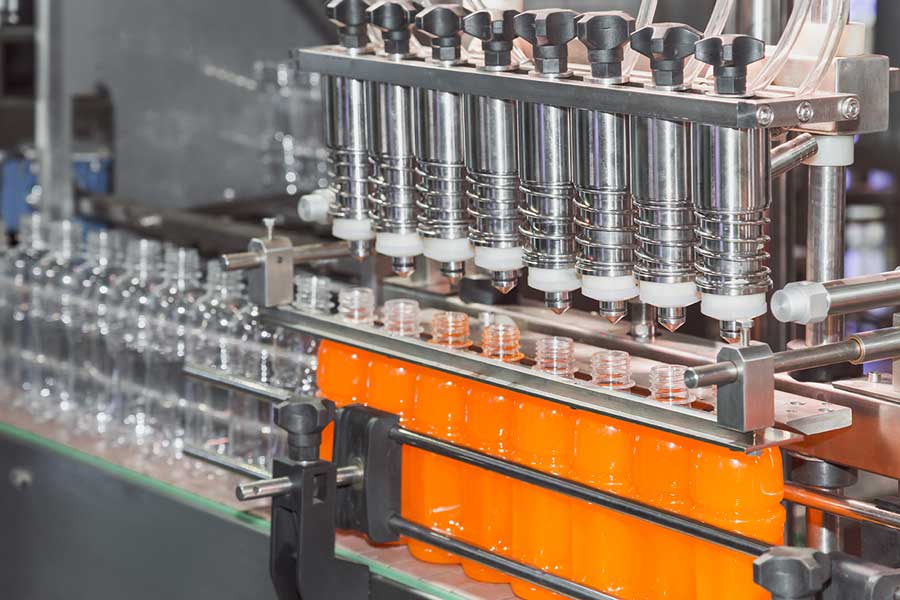

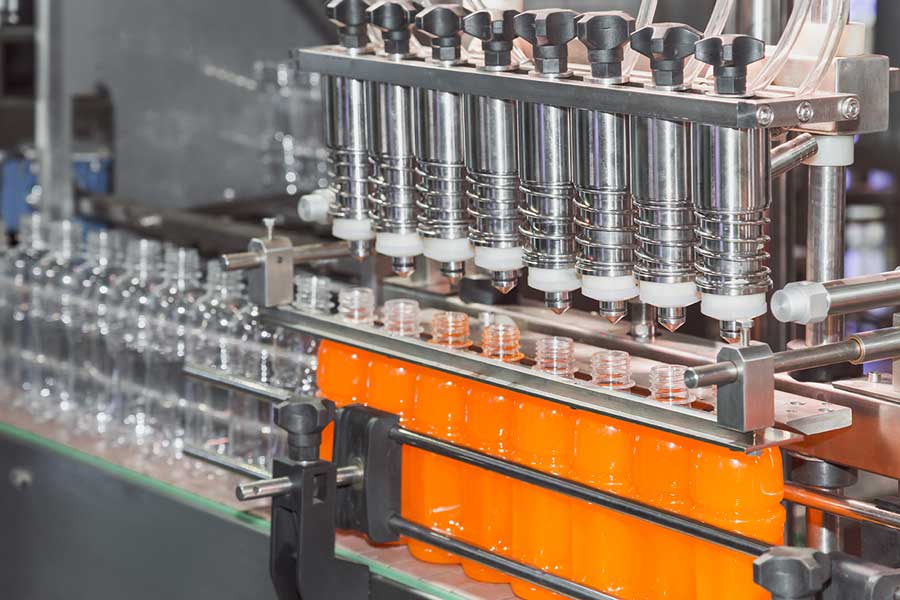

Embonini yokudla nokuphuza, imishini yokugcwalisa i-volumetric isetshenziselwa ukugcwalisa amabhodlela, izimbiza kanye nezipuni ezinemikhiqizo efana nama-juices, amasoso, ukugqoka kanye nama-syrups. Lokhu kuqinisekisa ukuthi isitsha ngasinye sibambe inani eliqondile elishiwo kwilebula, ukugcina ubuqotho bomkhiqizo nokwaneliseka kwamakhasimende. Emkhakheni wezemikhakha, le mishini yokugcwalisa yevolumetric ibalulekile ekugcwaliseni imithi ewuketshezi, isiraphu, nezinye izindlela, lapho ukunemba kubalulekile ukuqinisekisa ukuthi i-dosing efanelekile.

Abakhiqizi bezimonyo bathembela emishini yokugcwalisa ye-volumetric ukuze bakhiphe okhilimu, ama-lotion, ama-shampoos, kanye nezimo ezimoshini ezihlukene zokupakisha, ukuqinisekisa ukufana emkhiqizweni ngamunye. Embonini yamakhemikhali, lezi zinhlelo zokugcwalisa zevolumetric zisetshenziselwa ukugcwalisa iziqukathi ngezixazululo zokuhlanza, okokuhlanza, kanye noketshezi lwezimboni, lapho ukunemba kwevolumu kungawuthinta kakhulu ukusebenza komkhiqizo nokuphepha.

Imishini yokugcwalisa yevolumetric isebenza emgomeni wokulinganisa ivolumu ewuketshezi usebenzisa izindlela ezinjengamaPumps, amaphampu, noma amandla adonsela phansi. I-volumetric filler ilinganiselwe ukuhambisa ivolumu ethile isikhathi ngasinye, esinciphisa ukuhlukahluka futhi ithuthukise ukusebenza kahle kokukhiqiza. Leli zinga eliphakeme lokunemba linciphisa imfucuza ngokuvimbela ukugcwala ngokweqile noma ukugcwaliseka, zokwehlela ukusetshenziswa kwezinsiza kanye nokwehlisa izindleko zokukhiqiza.

Ngaphezu kwalokho, imishini yokugcwalisa yevolumetric ingahlanganiswa emigqeni yokukhiqiza ezenzakalelayo, ukuthuthukisa okunye ukusebenza kahle ngokunika amandla izinqubo zokugcwalisa eziqhubekayo nezisheshayo. Lokhu okuzenzakalelayo kunciphisa umsebenzi wezandla, kunciphisa iphutha lomuntu, futhi kwandise ukukhishwa okuphelele, okwenza lokhu Imishini yokugcwalisa ibhodlela e-Liquid Bottle itshalwe imali ebalulekile yabakhiqizi okuhlose ukukala imisebenzi yabo.

Izinhlobo zemishini yokugcwalisa yevolumetric

Imishini yokugcwalisa ye-Volumetric iza ngezinhlobo ezahlukahlukene, injini ngayinye ibhekane nezidingo ezithile kanye nezicelo ezikhona ezimbonini ezahlukene.

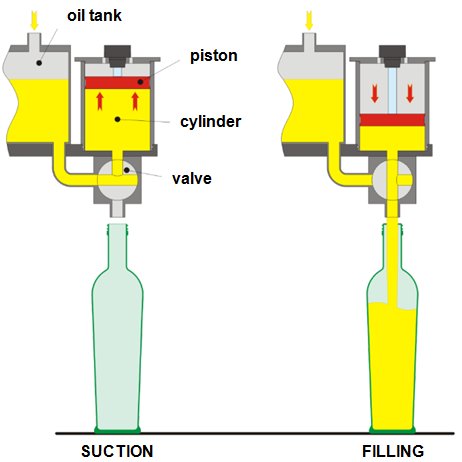

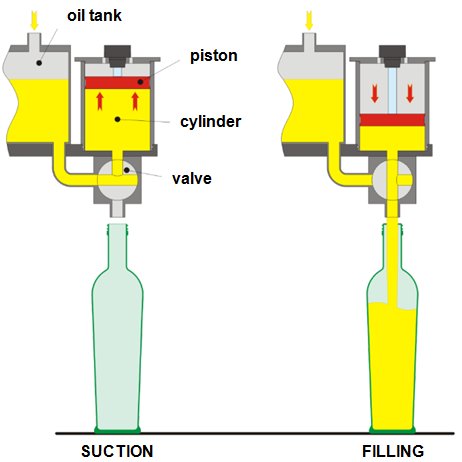

1. I-Piston Fisfers

Umshini wokugcwalisa uPiston usebenzisa umshini we-piston ukuze udwebe futhi unikeze umthamo oqondile woketshezi. I-piston ihamba ngaphakathi kwesilinda, idonsa uketshezi ekuhlaselweni kokudla futhi ilucindezele ekuchitheni. Le mishini yokugcwalisa yevolumetric isebenza ngokukhethekile ukugcwalisa imikhiqizo ebonakalayo ne-semi-viscous, njengamasoso, okhilimu, ama-gels, kanye nama-pastes. Isenzo se-piston siqinisekisa ukuthi ngisho nemikhiqizo emincane, e-chunky, noma enama-laden akhishwe ngokunembile nangokungaguquki.

Izinzuzo:

Ukunemba okuphezulu ekulawulweni kwevolumu.

Iyakwazi ukuphatha uhla olubanzi lwe-viscosities, kufaka phakathi imikhiqizo emikhulu kakhulu.

Ilungele imiqulu emincane nenkulu yokukhiqiza.

2. Ama-Gravity Fiffers

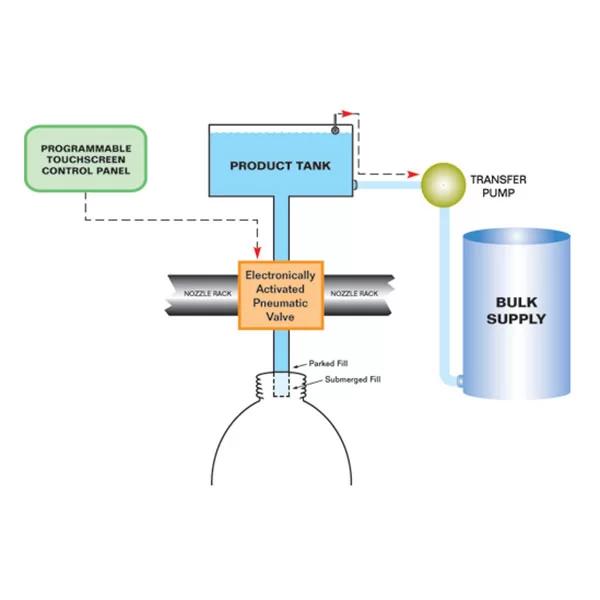

Umshini wokugcwalisa amandla adonsela phansi usebenza ngokusekelwe kunqubomgomo elula yamandla adonsela phansi. Umkhiqizo owuketshezi ubanjwa endaweni yokugcina amanzi ngenhla kwama-nozzls agcwalisa, namandla adonsela phansi avumela uketshezi ukuba lugeleze ezitsheni ezingezansi. Lezi zinhlaka ze-volumetric zilungele kangcono uketshezi oluncane, olugeleza mahhala olungadingi amandla okuhamba. Imikhiqizo ejwayelekile ifaka amanzi, ama-juices, imimoya, izixazululo zokuhlanza, kanye nezinye iziphuzo ezingezona ezibonakalayo.

Izinzuzo:

Elula futhi elibiza kakhulu.

Ilungele uketshezi olungelona olungabonakali.

Ukulungiswa okuncane okudingekayo ngenxa yezingxenye ezimbalwa ezihambayo.

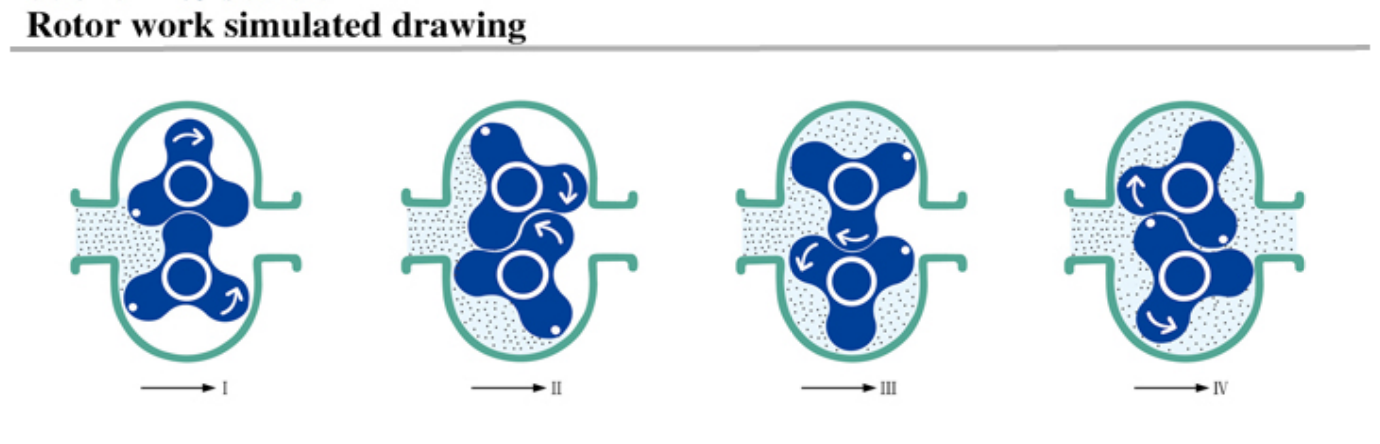

3. Ama-Pump Ficlers

Ama-filler wepompo asebenzisa izinhlobo ezahlukahlukene zamaphampu, njengamaphampu wegiya, amaphampu we-peristaltic, amaphampu we-diaphragm, noma Umshini wokugcwalisa amaphampu e-rotor pump , ukukala nokukhipha uketshezi. Ukukhethwa kwephampu kuya ngohlobo loketshezi kanye nezidingo ezithile zohlelo lokusebenza. Ama-fillers wepompo aguquguqukayo kakhulu futhi angakwazi ukuphatha izinhlobonhlobo ze-viscosities ewuketshezi, kusuka kokuncane kanye ne-foamy kuya ezintweni ezinamathelayo nezinamathelayo. Zivame ukusetshenziswa ekudleni, emikhakheni yezemithi kanye nezimboni zamakhemikhali zemikhiqizo efana nesiraphu, ama-lotion, ama-ejenti wokuhlanza, nokuningi.

Izinzuzo:

Ukuguquguquka ekusingatheni ama-viscosities ahlukene nezinhlobo ze-liquid.

Ukunemba okuphezulu nokulawula ivolumu yokugcwalisa.

Ingahlanganiswa kalula emigqeni yokukhiqiza ezenzakalelayo.

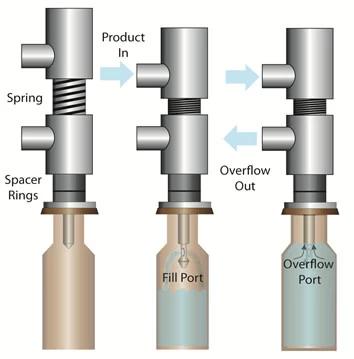

4. Ukuchichima ama-filler

Ama-fillers achichime aklanyelwe ukugcwalisa iziqukathi ezingeni elingaguquguquki. Uketshezi uphonswa esitsheni kuze kube yilapho ufinyelela ezingeni elithile, futhi noma yiluphi uketshezi olwedlulele lubuyele emuva ku-reservoir. Lokhu kuqinisekisa ukuthi isitsha ngasinye sivela ngokufana, okubaluleke kakhulu kwimikhiqizo ethengiswayo ekuphangethweni okusobala. Le mishini yokugcwalisa yevolumetric isetshenziselwa kakhulu imikhiqizo efana nama-shampoos, amafutha, kanye nezinye iziphuzo lapho izinga lokugcwaliswa komfaniswano lapho kubaluleke kakhulu khona. Zilungele ukuncipha okungcolile ku-visosity aphakathi.

Izinzuzo:

Iqinisekisa izinga lokugcwalisa elingaguquki kuzo zonke iziqukathi.

Ilungele iziqukathi ezisobala noma ezicacile lapho ukubukeka okufanayo kubalulekile.

Iyakwazi ukuphatha ukuhlukahluka okuncane ngosayizi wesitsha ngaphandle kokuthinta izinga lokugcwalisa.

Imishini yokugcwalisa yevolumetric isebenza kanjani

Imishini yokugcwalisa ye-Volumetric yenzelwe ukukala nokukhipha umthamo oqondile we-ketshezi ezitsheni, uqinisekise ukunemba nokuvumelana kwenqubo yokugcwalisa. Ukusebenza kwalezi zinhlelo zokugcwalisa amavolumetric kubandakanya izinyathelo ezimbalwa ezibalulekile, kubalulekile ngamunye wokugcina ivolumu yokugcwalisa oyifunayo kanye nokuqinisekisa ukukhiqizwa okusebenzayo.

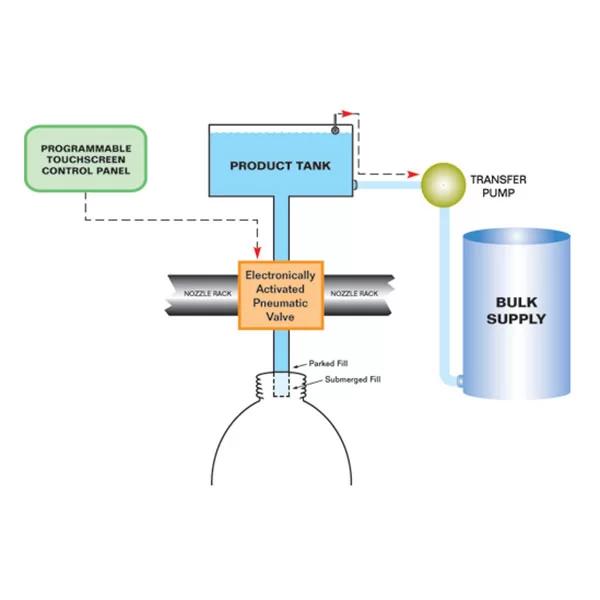

1. Ukunikezwa komkhiqizo

Inqubo iqala ngokuhlinzekwa komshini woketshezi emshinini wokugcwalisa wevolumetric. Uketshezi lugcinwa ethangi lokubamba noma i-reservoir, edla umkhiqizo emshinini. Ithangi lokubamba liqinisekisa ukulethwa okungaguquki futhi okuqinile koketshezi ohlelweni lokugcwalisa. Ihlome ngokuqothuka noma izici zokuphinda zisebenze ukuze zilondoloze i-homogeneity yomkhiqizo, ngoketshezi oluvame ukuhlukanisa noma ukudinga ukuxubana njalo.

2. Ukulinganiswa kwevolumu

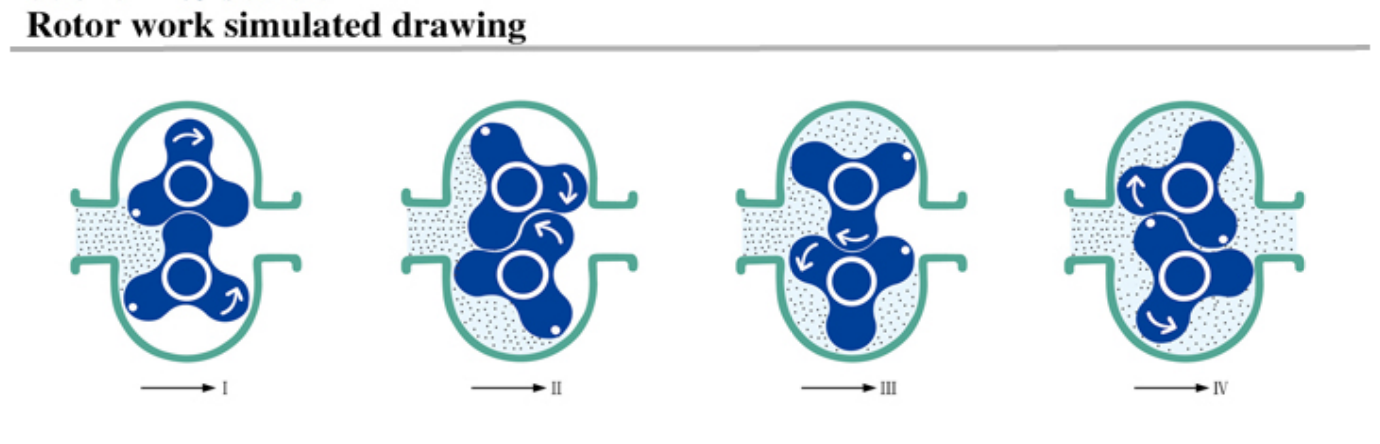

Umsebenzi oyisisekelo wemishini yokugcwalisa yevolumetric ukukala inani eliqondile loketshezi oluzokwalulwa. Lokhu kutholakala ngezindlela ezahlukahlukene ngokuya ngohlobo lwe-Volumetric Filer Machine-piston, iphampu, noma amasistimu asuselwa ku-gravity.

I-Piston Fiblers: I-piston ihamba ngaphakathi kwesilinda ukudweba ivolumu ebekiwe ye-liquoke yokudla bese uyihambisa ekuhlazenisweni. IVolumu ilawulwa ngokulungisa ubude be-stroke yepistoni.

Ama-Pump Ficlers: Lokhu kusebenzisa izinhlobo ezahlukahlukene zamaphampu (amaphampu wegiya, amaphampu we-peristaltic, amaphampu we-pepragm) ukulawula ukugeleza nokukala umthamo woketshezi. Ukujikeleza kwepompo noma ukugeleza kwempompo kulawulwa ngokunembile ukuhambisa ivolumu ngqo edingekayo.

Ama-Gravity Fiffers: Izinhlelo ezisuselwa ku-Gravity zisebenzisa amandla wemvelo wamandla adonsela phansi ukugcwalisa iziqukathi. IVolumu ilawulwa yisikhathi sokugeleza kwe-ketshezi kusuka kudamu esitsheni.

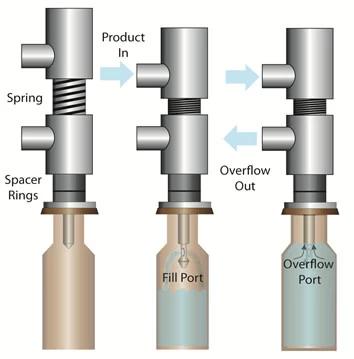

3. Ukusabalalisa

Lapho ivolumu ilinganiswe, uketshezi luyahanjiswa ezitsheni. Indlela yokuhambisa yenzelwe ukuqinisekisa ukulethwa okubushelelezi nokunembile koketshezi esitsheni ngasinye. Umshini wokugcwalisa wevolumetric ungashintshwa ukuze ugcwalise amavolumu ahlukene ngokususelwa kusayizi wesitsha kanye nezidingo zomkhiqizo. Ama-nozzles noma amakhanda okugcwalisa ahlelwe ngokunembile phezu kwezitsha zokunciphisa ukuchitheka futhi aqinisekise ukugcwaliswa okunembile.

Umklamo we- nozzle Ama-nozzles akhethekile angafaka amakhanda adonswayo afaka esitsheni ukuze anciphise igwebu kanye nesiphithiphithi ngesikhathi sokugcwaliswa.

Izilungiselelo eziguqukayo: Umshini wokugcwalisa ibhodlela we-volumetric uvumela abahlinzeki ukuthi balungise amanani okugcwalisa, isivinini, namanye amapharamitha ukuze bakwazi ukwamukela izidingo ezahlukahlukene zokukhiqiza kanye nosayizi wokukhiqiza ahlukahlukene.

4. Ukuphathwa kwesiqukathi

Ukusingathwa kahle kweziqukathi kubalulekile ekugcineni inqubo yokugcwalisa ebushelelezi neqhubekayo. Iziqukathi zihanjiswa zibe sesikhundleni ngaphansi kwama-nozzles okugcwalisa kusetshenziswa uhlelo lokuhambisa.

Uhlelo lokuhambisa: Iziqukathi zithuthwa ngebhande lokuhambisa, elibashukumisela ukuba babe sezikhundleni eziqondile ngaphansi kwamakhanda okugcwalisa. Ijubane lokuhambisa nokunyakaza kuvumelaniswa nomjikelezo wokugcwalisa ukuze kuqinisekiswe ukusebenza komthungo.

Ukubeka: Iziqukathi ziqondaniswe kahle futhi zibekwe ngaphansi kwama-nozzles okugcwalisa zisebenzisa ujantshi wemihlahlandlela, izinzwa nezinhlelo zokukhomba. Lokhu kuqinisekisa ukuthi isitsha ngasinye sithola umthamo oqondile woketshezi.

Ukugcwalisa ngemuva: Ngemuva kokugcwaliswa, iziqukathi zisuswa kude nesiteshi sokugcwalisa futhi zithuthelwe ezigabeni ezilandelayo zomugqa wokukhiqiza, njengokukhonkotha, ilebula, kanye nokupakisha.

5. Ukuhlanganiswa ne-automation

Imishini yokugcwalisa ye-Volumetric ivame ukuhlanganiswa kwimigqa yokukhiqiza ezenzakalelayo ngokugcwele, ukuthuthukisa ukusebenza kahle kanye nokusebenzisa. I-automation inciphisa ukungenelela kwencwajana, inciphisa amaphutha, futhi ikhulisa ijubane eliphelele lenqubo yokugcwalisa. Lezi zinhlelo zingafaka izici ezinjengokuhlanza okuzenzakalelayo kanye nezilawuli ezithuthukile zokulungiswa okuqondile.

Izinzuzo zemishini yokugcwalisa yevolumetric

Ukunemba:

Imishini yokugcwalisa ye-volumetric inikeza ukulawula okuqondile ngaphezulu kwevolumu ye-liquid esetshenzisiwe, ukuqinisekiswa ukuguquguquka nokunciphisa imfucuza yomkhiqizo.

Okuhlukahlukene:

Lezi zinhlelo zokugcwalisa zevolumetric zingaphatha ama-viscosities ahlukahlukene ahlukahlukene, ukuzenza zilungele imikhiqizo ehlukahlukene.

Ukusebenza kahle:

Ama-volumetric filler angafinyelela isivinini esiphezulu sokugcwalisa, ethuthukisa ukusebenza kahle kokukhiqiza.

Ukusebenziseka kalula:

Imishini yokugcwalisa ye-volumetric kulula kakhulu ukusetha futhi isebenze, ngezilawuli kanye nokulawulwa okusebenziseka kalula.

Ikhwalithi yokulawula:

Ngokugcina amazinga okugcwalisa angaguquki, imishini yokugcwalisa yevolumetric isiza ukuqinisekisa ikhwalithi yomkhiqizo nokwaneliseka kwamakhasimende.

Imikhiqizo yemishini yokugcwalisa yevolumetric egcwalisa

Imishini yokugcwalisa ye-Volumetric iyakwazi ukuguquguquka ngendlela emangalisayo, ekwazi ukuphatha imikhiqizo ehlukahlukene kuyo yonke imboni ehlukahlukene. Amandla abo okulinganisa ngokunembile nokukhipha amavolumu aqondile ka-ketshezi abenza balungele izinhlelo eziningi.

1. Ukudla neziphuzo

Embonini yokudla kanye nophuzo, imishini yokugcwalisa yevolumetric isetshenziselwa ukugcwalisa imikhiqizo ehlukahlukene ewuketshezi kanye noketshezi, iqinisekisa ivolumu engaguquki kanye nokugcina ikhwalithi yomkhiqizo.

Amasoso nokugqoka: I-Ketchup, lwesinaphi, ukugqoka isaladi, imayonnaise, kanye neminye imiyalezo edinga ukugcwaliswa okuqondile ukuze kuqinisekiswe ukufana nokunciphisa imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucuza futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise imfucumfucu futhi kunciphise ukungcola. A Umshini wokugcwalisa weSauce ulungele ukuphatha le mikhiqizo, ukuhlinzeka ngokugcwaliswa okungaguquki futhi okunembile kuwo womabili ama-sauces amnyama nowamathe.

Amajusi neziphuzo: amajusi wezithelo, ama-smoothies, ama-egceme apholile, namanzi asebhodleleni, lapho ukulondolozwa kwamazinga okugcwaliswa khona okunembile kubalulekile ekuguquguqukeni komkhiqizo nokwaneliseka kwamakhasimende.

Isiraphu: Isiraphu yeMaple, uju, isiraphu ye-chocolate, nezinye iziramu ezi-vischups ezidinga ukulinganisa okuqondile ukuze ugweme ukugcwala nokuchitheka.

Amafutha: Amafutha okupheka, amafutha omnqumo, namanye amafutha adliwayo adinga ukugcwaliswa okunembile ukuze kugcinwe ubuqotho bomkhiqizo futhi uhlangane namazinga alawulayo. A Umshini wokugcwalisa kawoyela uqinisekisa ukunemba nokusebenza kahle ekugcwaliseni le mikhiqizo, ukunamathela kwikhwalithi eqinile kanye nezidingo zokulawula.

2. Amakhemikhali

Ukunemba kubaluleke kakhulu embonini yezemithi, okwenza imishini yokugcwalisa ye-volumetric ibalulekile ekugcwaliseni imithi ewuketshezi neminye imikhiqizo yezemithi.

Imithi ewuketshezi: Isiraphu yokukhwehlela, izixazululo zomlomo, kanye nokumiswa okudinga imithamo eqondile ukuze kuqinisekiswe ukusebenza kahle nokuphepha.

Izisombululo ze-Topical: Izisombululo ze-antiseptic, okhilimu olungiselelwe, kanye namajeli adinga ukugcwaliswa okunembile ukuhlinzeka umthamo ofanele futhi ulondoloze inzalo.

Ama-Syrups: Ama-Vitamin Syrups, izithasiselo zokudla okunempilo, kanye nezinye iziraphu zokwelapha ezidinga ukulawulwa kwevolumu okuqondile kwe-dosing efanele.

3. I-COSMETICS

Embonini yezimonyo, imishini yokugcwalisa yevolumetric isetshenziselwa ukugcwalisa imikhiqizo ehlukahlukene yobuhle futhi i-semi-liquid ubuhle ubuhle, ukuqinisekisa ukuguquguquka nokwethulwa okuthandekayo.

Okhilimu kanye ne-lotions: okhilimu bobuso, ama-lotion omzimba, kanye nokhilimu wesandla obudinga ukugcwaliswa okuqondile ukuqinisekisa ukubukeka komkhiqizo nekhwalithi. A Umshini wokugcwalisa ukhilimu wenzelwe ngokukhethekile ukuphatha le mikhiqizo, uqinisekise ukunemba nokuvumelana kokugcwaliswa kokugcwaliswa konke.

Ama-Shampoos kanye nezimo: Imikhiqizo yokunakekelwa kwezinwele edinga ukugcwaliswa okunembile ukuze ilondoloze ukungaguquguquki komkhiqizo futhi ihlangabezane nokulindelwe kwabathengi. A Umshini wokugcwalisa iShampoo wenzelwe ukuphatha le mikhiqizo, uqinisekise ukugcwaliswa okuqondile nokugcina ikhwalithi nokungaguqulwa okulindelwe abathengi.

Ama-Serums nama-Oils: Ama-Beauty Serums, Amafutha Abalulekile, kanye nezinye izimonyo ezidinga ukulinganisa okuqondile ukuze kuqinisekiswe ukusebenza kahle nokwaneliseka kwamakhasimende.

4. Amakhemikhali

Imboni yamakhemikhali idinga izixazululo zokugcwalisa eziqondile nezinokwethenjelwa zemikhiqizo ehlukahlukene ewuketshezi, kubahlanza basekhaya kumakhemikhali wezimboni.

Izixazululo Zokuhlanza: Abahlanza Abasendlini, Ama-Disinfectants, kanye Nokuhlanza Okudinga Ukugcwaliswa Okunembile Ukuqinisekisa Ukusebenza Okusebenzayo Ukuhlanza Nokuphepha. A Umshini wokugcwalisa we-Detergent ulungele lezi zinhlelo zokusebenza, enikeza ukugcwaliswa okunembile futhi okunokwethenjelwa ukuthola uhla lwemikhiqizo yokuhlanza.

Ama-liquid wezimboni: Ama-lubricial, ama-solvents, namakhemikhali wezimboni adinga ukulinganisa okuqondile ukuze alondoloze ubuqotho bomkhiqizo futhi ahlangabezane nezidingo zokulawula.

Amakhemikhali ezolimo: ama-pesticides, ama-herbicides, kanye nomanyolo odinga ukugcwaliswa okuqondile ukuze kuqinisekiswe uhlelo lokusebenza kanye nokusebenza kahle. A Umshini wokugcwalisa amakhemikhali ubalulekile kule mikhiqizo, enikeza ukunemba nokuphepha ekuphatheni izinto ezingaba yingozi.

Ungawukhetha kanjani umshini wokugcwalisa we-volumetric ongakwesokudla

Ukukhetha umshini wokugcwalisa we-volumetric ongakwesokudla kubalulekile ekwakheni inqubo yakho yokukhiqiza kanye nokuqinisekisa ikhwalithi kanye nokusebenza kahle kwemisebenzi yakho. Izici ezimbalwa ezibalulekile kufanele zibhekwe ukwenza isinqumo esinolwazi.

1. Izici zomkhiqizo

Uhlobo lomkhiqizo oludingayo ukuze ugcwalise iqhaza elibalulekile ekunqumeni uhlobo lomshini wokugcwalisa we-volumetric ofaneleka kangcono uhlelo lwakho lokusebenza.

I-Viscosity: Ubukhulu noma izici zokugeleza koketshezi. Imikhiqizo ebonakalayo enjenge-GELS nokhilimu ingadinga ama-piston fillers, kuyilapho amancane, uketshezi lwamahhala njengamanzi noma amajusi angahle aphathwe kahle ngama-gravity fillers.

Izakhiwo ze-Foaming: ezinye iziphuzo, ezinjenge-shampoos kanye neziphuzo ezithile, zivame ukugcwala. Kule, imishini eno-nozzles okhethekile noma amakhanda e-diving angasiza ukunciphisa igwebu futhi aqinisekise ukugcwaliswa okunembile.

Ukuqukethwe okuqukethe: Uma uketshezi luqukethe ama-companiuletes (isib.

2. Izidingo Zokukhiqiza

Ukuqonda izidingo zakho zokukhiqiza kubalulekile ekukhetheni umshini wokugcwalisa wevolumetric ohlangabezana nezidingo zakho zevolumu nezidingo ngenkathi uvumelanisa nezinhloso zakho ezenzakalelayo.

Gcwalisa i-Provuct: Thola ububanzi be-Volumes okudingeka uligcwalise. Eminye imishini ingaphatha amavolumu ahlukahlukene okugcwalisa, kanti amanye akhethekile kakhulu.

Ijubane lokukhiqiza: Hlola ijubane lapho udinga ukusebenza khona. Imigqa yokukhiqiza yejubane eliphezulu idinga imishini ekwazi ngokushesha, ukugcwaliswa okungaguquki ukuze uhambisane nesidingo.

Izinga le-automation: nquma ngezinga le-automation oyidingayo. Izinhlelo ezizenzakalelayo ezizenzakalelayo zevolumetric zokugcwalisa zingandisa ukusebenza kahle futhi zinciphise izindleko zabasebenzi kepha zingadinga ukutshalwa kwezimali okuphezulu.

3. Izinhlobo zeziqukathi

Idizayini kanye nokuqukethwe kweziqukathi osebenzisayo kungathonya ukukhetha komshini wokugcwalisa wevolumetric.

Usayizi nokwakheka: Qinisekisa ukuthi umshini we-filler wevolumetric ungahlalisa ubukhulu nobukhulu beziqukathi zakho. Ezinye izinhlelo zokugcwalisa zevolumetric zinikeza izilungiselelo eziguqukayo ukuphatha osayizi abahlukahlukene bezitsha.

Izinto ezibonakalayo: Cabanga ngezinto ezibonakalayo, njengepulasitiki, ingilazi noma ngensimbi. Umshini wokugcwalisa we-volumetric kufanele uhambisane nezinto ezibonakalayo ukuvikela ukulimala ngesikhathi senqubo yokugcwalisa.

Izinhlobo ze-Cap: Uma iziqukathi zidinga izinhlobo ezithile zama-cap noma ukuvalwa, qiniseka ukuthi umshini wokugcwalisa wevolumetric ungahlanganisa nezinhlelo zokukhonkotha ezihlalisa lezi zidingo.

4. Isabelomali

Ukuhlola isabelomali sakho kukusiza ukulinganisa ukutshalwa kwezimali kokuqala ngezindleko zesikhathi eside zokusebenza kanye nezinzuzo.

Ukutshala imali okuqala: Cabanga ngentengo ephambili yomshini wokugcwalisa wevolumetric, kufaka phakathi noma yikuphi ukwenza ngokwezifiso okudingekayo noma imishini eyengeziwe.

Izindleko zokulungiswa: Factor ngezindleko zokugcina njalo, izingxenye ezisele, kanye nokulungiswa okungaba khona. Imishini yokugcwalisa ye-Volumetric enezindleko eziphakeme zokuqala inganikeza izindleko zokulungiswa okuphansi ngokuhamba kwesikhathi.

Izindleko zokusebenza: Hlola izindleko eziqhubekayo ezihambisana nokusebenza kwe-volumetric filler, njengokusetshenziswa kwamandla, ukunakekelwa kanye nokudla.

5. Ukuxhaswa komkhiqizi

Izinga lokusekelwa kanye nensizakalo enikezwe ngumakhi we-Volumetric wokugcwalisa umshini angathinta kakhulu impumelelo yesikhathi eside nokuthembeka kokusebenza kwakho kokugcwalisa.

Idumela: Khetha umenzi womshini we-volumetric wokugcwalisa ngerekhodi elifakazelwe kanye nedumela elihle lemboni ukuze uthembeke nekhwalithi.

Ukuxhaswa Kwamakhasimende: Ukuxhaswa Kwamakhasimende Okuthembekile kubalulekile ekuxazululeni inkinga, ukuqeqeshwa kanye nokunakekelwa. Qinisekisa ukuthi umenzi womshini wokugcwalisa wevolumetric unikeza izinsiza zokusekelwa ezisheshayo nezisebenzayo.

Ukuqeqeshwa: Bheka abakhiqizi be-volumetric wokugcwalisa abahlinzeka ngokuqeqeshwa okuphelele kwabasebenzi bakho ukuqinisekisa ukuthi bangasebenza futhi balondoloze umsebenzi kahle.

Ukutholakala kwezingxenye: Qinisekisa ukuthi izingxenye ezisele zitholakala kalula ukuze zinciphise isikhathi sokuphumula uma kwenzeka kuphuka umshini noma izidingo zokulungisa.

Ukukhetha umshini wokugcwalisa we-volumetric ongakwesokudla kubandakanya ukucubungula ngokucophelela kwezimpawu zomkhiqizo wakho, izidingo zokukhiqiza, izinhlobo zezitsha, isabelomali, kanye nezinga lokusekelwa elinikezwe ngumenzi. Ngokuhlola kahle lezi zinto, ungakhetha umshini wokugcwalisa we-volumetric ongahlangabezananga nje kuphela ngezidingo zakho kodwa futhi uvumela ukuqina okuzayo kanye nokwenza ngcono ukuthuthuka. Ukutshala imali emshinini wokugcwalisa ebhodleleni okulungile kwesokudla kuzothuthukisa amandla akho okukhiqiza, ukunciphisa imfucuza, futhi kuqinisekiswe ikhwalithi yomkhiqizo engaguquki, kufaka isandla empumelelweni nasekukhuleni kwebhizinisi lakho.

Intengo yomshini wokugcwalisa wevolumetric

Intengo yale mishini yokugcwalisa yevolumetric ingahluka kakhulu ngokusekelwe ezicini eziningana, kufaka phakathi uhlobo lomshini, izici zalo.

Izici ezithonya intengo

Izinto ezahlukahlukene zinomthelela ezindlekweni eziphelele zomshini wokugcwalisa wevolumetric. Lezi zinto zingakusiza ekuboneni ukuthi iyiphi i-volumetric filler efanelana nesabelomali sakho nezidingo zakho.

Uhlobo lomshini:

Izinhlobo ezahlukahlukene zemishini yokugcwalisa yevolumetric (ama-piston fillers, ama-fillers adonsela phansi, ama-filler pump, ama-filler amaningi) eza namathegi entengo ahlukahlukene. Imishini eyinkimbinkimbi futhi eguquguqukayo, njenge-Pump Ficlers, ivame ukubiza kakhulu.

Umthamo Wokukhiqiza:

Imishini yokugcwalisa ye-Volumetric yakhelwe ngejubane lokukhiqiza eliphakeme kanye namanani amakhulu abiza ngaphezulu. Umthamo owudingayo uzoncika kwizidingo zakho zokukhiqiza.

Ikhwalithi yokwakha neyakha:

Izinto ezisezingeni eliphakeme kanye nokwakhiwa okuqinile kukhulisa ukuqina kanye nokuphila komshini wokugcwalisa wevolumetric kodwa futhi kufaka isandla ezindlekweni eziphakeme.

Izinga le-automation:

Izinhlelo ezizenzakalelayo ngokuphelele zibiza kakhulu kunemishini ezenzakalelayo noma ebhukwayo ngenxa yezakhi ezengeziwe nobuchwepheshe obuhilelekile.

Ukwenza ngokwezifiso:

Izici ezenziwe ngokwezifiso noma ukuguqulwa okuhambisana nezidingo zakho ezithile kungangeza intengo. Lokhu kufaka phakathi ama-nozzles akhethekile, izici ezengeziwe zokuphepha, noma ukuhlanganiswa nemigqa yokukhiqiza ekhona.

Ububanzi bentengo

Imishini yokungena:

Umshini wokugcwalisa owuketshezi omncane ulungele ukuqalwa noma amabhizinisi amancane angaqala kusuka kumadola ayizinkulungwane ezimbalwa. Le mishini yokugcwalisa ye-volumetric iyincwajana noma i-semi-automated futhi ilungele ukukhiqizwa okuphansi kwemiphakathi.

Imishini Yama-Mid-Range:

Imishini ethuthukisiwe yokugcwalisa ye-volumetric enekhono eliphakeme lokukhiqiza kanye nezici ezingeziwe zingasukela ku- $ 5,000 kuya ku- $ 50,000. Lokhu kufanelekile ekusebenzeni okuphakathi kwemigwaqo emikhulu edinga izixazululo ezithembekile, ezisebenza kahle, kanye nezixazululo ezizenzakalelayo.

Imishini ephezulu yokuphela:

Izinhlelo ezizenzakalelayo ezisetshenziselwa ijubane eliphezulu, ukukhiqizwa okuphezulu kakhulu kungabiza ngaphezulu kwama- $ 50 000 kuye kwama-dollar ayizinkulungwane ezingamakhulu amaningana. Le mishini yokugcwalisa yevolumetric inikela ngezici ezithuthukile, ukunemba okuphezulu, kanye namakhono wokuhlanganisa neminye imishini yomugqa wokukhiqiza.

Inani lemali

Ukuhlola izindleko maqondana nezinzuzo nezici ezinikezwa nguSuloumetric Filling System kusiza ekuqinisekiseni ukuthi uthola inani elihle kakhulu lokutshala kwakho imali.

Ukusebenza kanye nokusebenza kahle:

Imishini ephakeme ephakeme ye-Volumetric Figing imishini inikezela ukusebenza okungcono, ukusebenza kahle okuphezulu, kanye nezici ezisezingeni eliphakeme ezingaholela emalini yesikhathi eside yezindleko.

Isikali:

Cabanga ukuthi umshini wokugcwalisa wevolumetric ungakwazi ukukala nebhizinisi lakho. Ukutshala imali emishini yokugcwalisa yevolumetric engakwazi ukuphatha ukukhula okuzayo kunganikeza inani elingcono ngokuhamba kwesikhathi.

I-Pestopack ngumshini womshini wevolumetric wokugcwalisa

I-Pespopack ngumkhiqizi oholayo wemishini yokugcwalisa ye-volumetric, edume ngokuhlinzeka ngezixazululo ezisezingeni eliphakeme, ezithembekile, nezisebenzayo zokugcwalisa ezisebenzayo kuyo yonke imboni ehlukahlukene. Ngolwazi olunzulu nokuzibophezela okuqinile kokuhle, siqinisekisa ukuthi umshini ngamunye wokugcwalisa wevolumetric yakhelwe ukufeza izidingo ezithile zamakhasimende alo, ukuletha ukunemba, ukuguquguquka nokusebenza kahle.

Iminyaka yesipiliyoni

I-Pestpack yakhele idumela eliqinile elingaphezu kweminyaka eyi-14, lifaka okuhlangenwe nakho kwalo okubanzi ukuthuthukisa izixazululo ezintsha nezingathembekile zokugcwalisa izixazululo. Ngeminyaka eyi-14 yokuhlangenwe nakho kwezimboni, i-pestopack iye yahlonipha ubuchwepheshe bayo ekwakheni nasekukhiqizeni imishini yokugcwalisa yevolumetric enakekela izidingo zomkhiqizo nezindawo zokukhiqiza. Imishini yethu yokugcwalisa yevolumetric ithelwa ngamabhizinisi amaningi emhlabeni wonke, ekhombisa ukuthembeka kwethu nokusebenza kwezicelo ezahlukahlukene.

Ukuzibophezela kwikhwalithi

Ikhwalithi isemgogodleni wemisebenzi yethu. Sizinikezele ekukhiqizeni imishini yokugcwalisa yevolumetric ehlangabezana namazinga aphezulu okunemba nokuqina. I-Pestopack isebenzisa izinto zokwenziwa ze-premium kanye namasu okukhiqiza athuthukile ukuqinisekisa isikhathi eside nokuqina kwezinhlelo zayo zokugcwalisa zevolumetric. Umshini ngamunye uhlolwe ukuhlolwa okuqinile kanye nokuhlolwa kwekhwalithi ukuqinisekisa ukuthi ihlangabezana namazinga aqinile adingekayo ekugcwalisweni kwe-Precision. Imishini yethu yokugcwalisa yevolumetric iqinisekisiwe ukuthi ihlangabezana namazinga embonini, ukuhlinzeka amakhasimende ethu ngokuzethemba ekutshalweni kwemali.

Ububanzi bezixazululo

Sinikeza uhla oluphelele lwemishini yokugcwalisa ye-volumetric, ehambisana nokuhlangabezana nezidingo ezithile zezimboni ezahlukahlukene kanye nezicelo. Umugqa wethu womkhiqizo ufaka ama-piston fillers, ama-gravity fillers kanye nama-filler wepompo, ngalinye liklanyelwe ukuphatha izinhlobo eziningi zoketshezi kanye ne-viscosities. Sinikeza ngezixazululo ezenziwe ngokwezifiso ukuze zilungele izidingo ezihlukile zokukhiqiza, ukuqinisekisa ukuthi umshini wokugcwalisa ngamunye wevolumetric ungashintshwa nezidingo ezithile nezingqinamba. Ukusuka ekusebenzeni kwezilinganiso ezincane kuya emigqeni emikhulu yezimboni, sinikezela ngezixazululo ze-volumetric zokugcwalisa ezikhulayo ezikhula nebhizinisi lakho.

Ukwethembeka nokusebenza kahle

Imishini ye-Pestopack's Volumetric Figning yezonjiniyela ukuletha ukusebenza okuthembekile nokusebenzayo, ukuthuthukisa amandla okukhiqiza kanye nokunciphisa isikhathi sokuphumula. Yakhelwe ukucaciswa okuphezulu nokuphindaphindwa, imishini yethu yokugcwalisa yevolumetric iqinisekisa amavolumu wokugcwalisa okungaguquki kanye nekhwalithi yomkhiqizo.

Ukuphatha izinhlobo ezahlukene zotshwala

Imishini yethu yokugcwalisa yevolumetric iguquguqukayo ngokwanele ukuphatha uhla olubanzi lwamatshe, kusuka emikhiqizweni emincane, egeleza mahhala kwizinto eziwugqinsi, ezibonakalayo. Ama-propack's Volumetric Fichers alungele ukugcwalisa imikhiqizo ehlukahlukene, kufaka phakathi ukudla neziphuzo, amakhambi, izimonyo namakhemikhali.

Ukugcina

Imishini yokugcwalisa ye-Volumetric ingamathuluzi adingekayo ezimboni eziningi, enikeza izixazululo eziqondile nezisebenzayo zokugcwalisa ngemikhiqizo ehlukahlukene. Ukutshala imali emshinini wokugcwalisa we-volumetric ongakwesokudla kubalulekile ekwakheni izinqubo zakho zokukhiqiza kanye nokuqinisekisa amazinga aphezulu kakhulu wekhwalithi yomkhiqizo nokuvumelana. Ngokucabanga ngokucophelela izici zomkhiqizo, izidingo zokukhiqizwa, izinhlobo zezitsha, isabelomali kanye nokwesekwa komenzi, ungenza isinqumo esinolwazi esivumelana nezinhloso zakho zebhizinisi.