1. I-Pestpack - uNdunankulu wakho ogcwalisa kanye nomkhiqizi womshini we-capping

2. Ukugcwaliswa kwebhodlela kanye nomshini we-cap webhodlela

3. I-jar ukugcwalisa kanye nomshini weplip

4. Ukugcwaliswa koketshezi kanye nomshini weplipha

I-5. Ukugcwalisa okuzenzakalelayo nomshini we-cap

6. Ukugcwalisa, ukukhonkotha, kanye nokulebula komshini

7

8. Ukugcwaliswa kwe-Rotary kanye nomshini weplip

9. Ukugcwaliswa kwebhodlela elincane kanye nomshini webhoji

10. Ukugeza, ukugcwalisa, kanye nomshini weplip

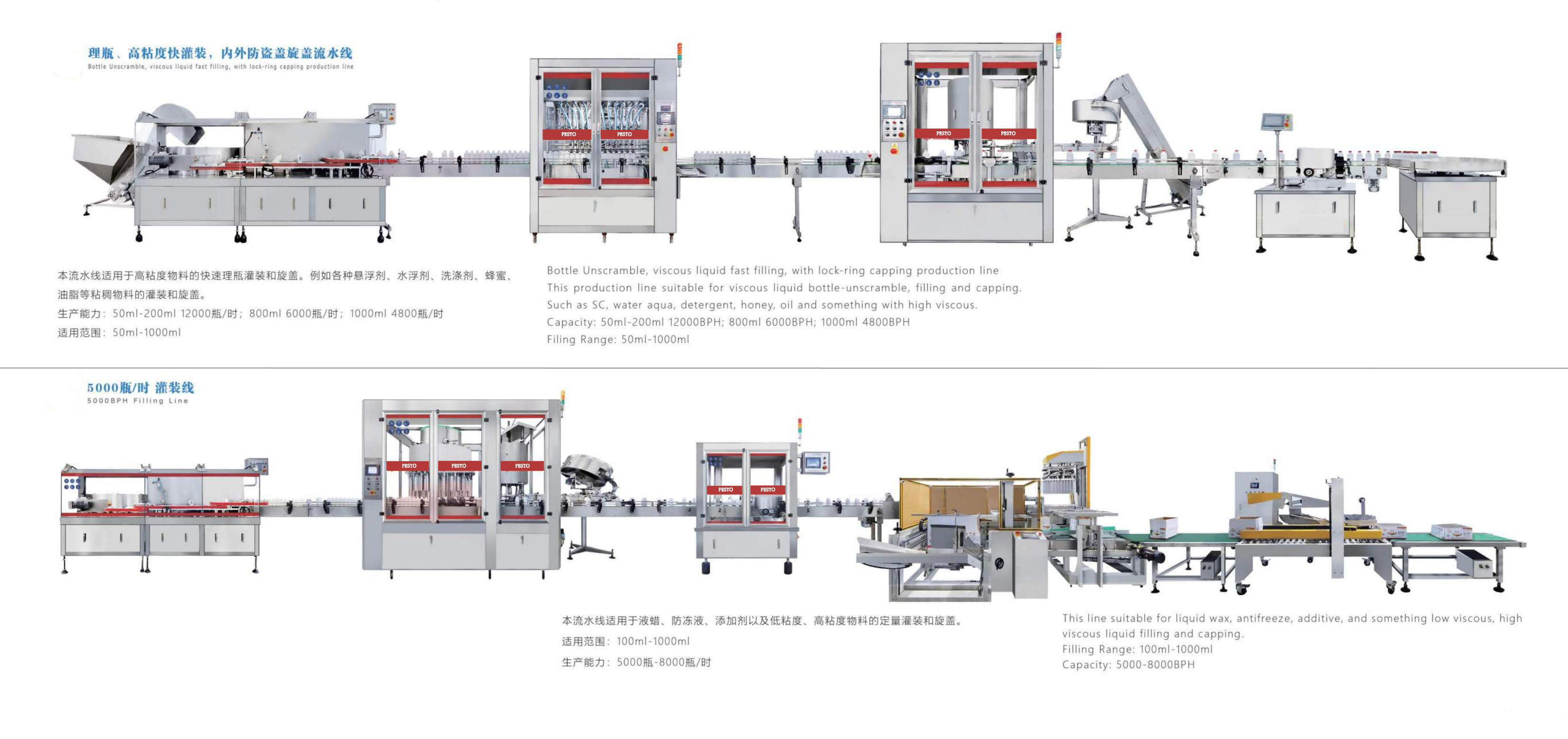

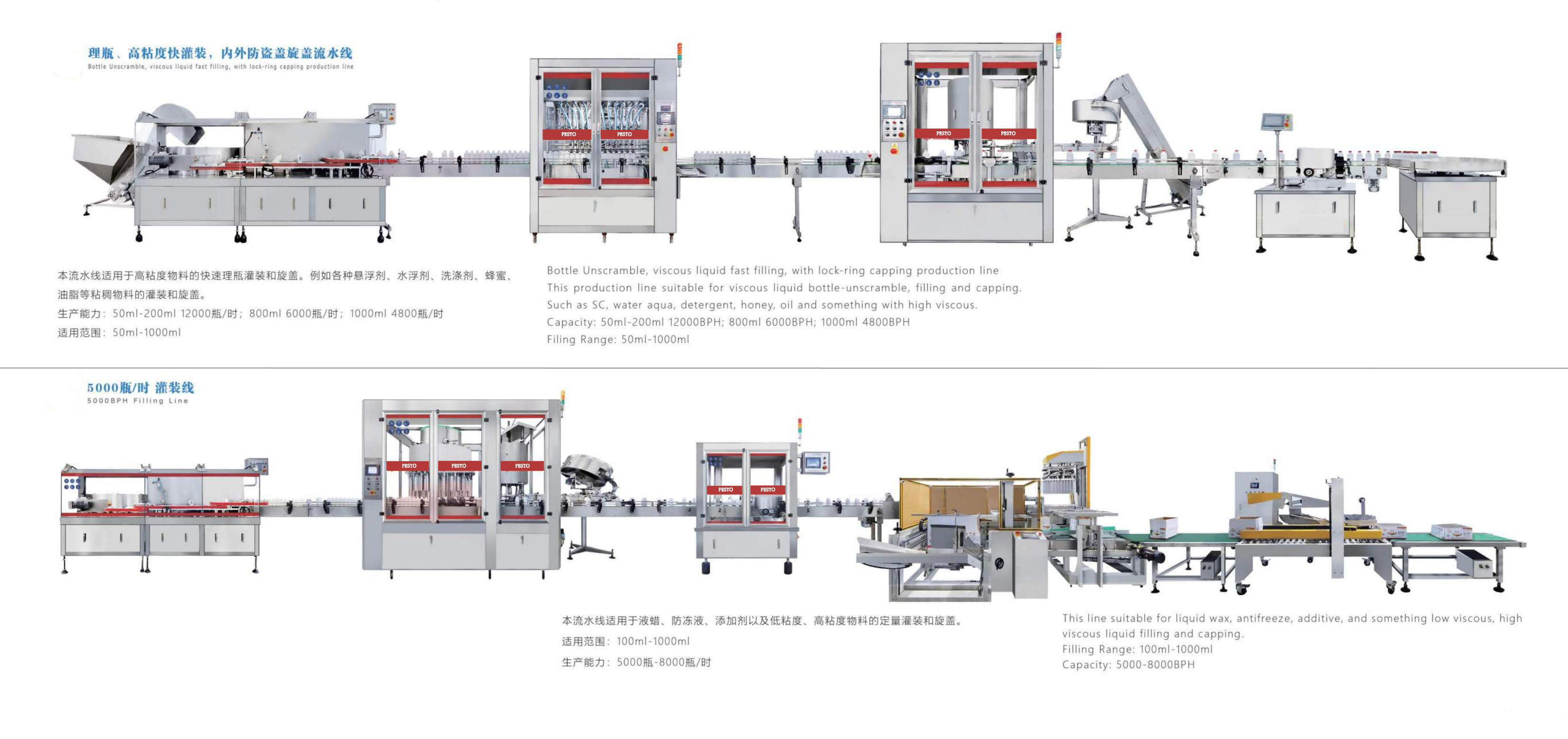

Esikhathini sanamuhla sokukhiqiza amandla okukhiqiza, ukusebenza kahle kanye nokunemba kubaluleke kakhulu. Ukugcwalisa imishini yokuqopha kuqhamuke njengabadlali abasemqoka, kubuye kabusha imboni yokufaka kuyo yonke imikhakha ehlukahlukene. Kulesi sihloko, sizohlola uhla oluhlukahlukene lokugcwalisa imishini yokugcwala, ngayinye inezimiso zayo, izici ezihlukile, izinzuzo, kanye nezinhlelo zokusebenza ezibanzi kakhulu.

1. I-Pestpack - uNdunankulu wakho ogcwalisa kanye nomkhiqizi womshini we-capping

Njengomenzi oholayo wokugcwalisa nemishini yokuqopha, sinikezelwe ekuletheni imishini yokusika onqenqemeni eqondisa izinqubo zakho zokukhiqiza, ithuthukise ukusebenza kahle, futhi iqinisekise ukuthembeka kwemikhiqizo yakho. E-Pestpack, siyagqamisa ekwakheni nasekukhiqizeni imishini yokugcwaliswa komhlaba kanye nokugcwaliswa kobuciko okuphathelene nokwahlukahlukana kwezimboni. Imishini yethu yokugcwalisa kanye ne-cap ye-cap nge-ntererision yokuhlangabezana nezidingo eziqinile zemigqa yanamuhla yokukhiqiza. Ukuthi ufuna ukugcwaliswa koketshezi, ukukhonkotha kwebhodlela, noma zombili, i-pestopack inekhambi elihambisana nezidingo zakho.

Kungani ukhethe i-pestopack?

Ubunjiniyela obuqondile

Imishini yethu yokugcwalisa nokukhonkotha isebenza kwimigomo yokunemba ngokunemba nokunemba, ukuqinisekisa ukuthi umkhiqizo ngamunye ugcwele ngokungaguquki nangokunemba.

Ukusebenza kahle kuchazwe kabusha

Khulisa amandla akho okukhiqiza kanye nokusebenza kahle ngemishini yethu. I-automation inciphisa ukuthembela emsebenzini wezandla, okuvumela iqembu lakho ukuthi ligxile emisebenzini ebucayi kakhulu.

Izisombululo Eziguquguqukayo

Shintshana nezimo ezahlukahlukene zemikhiqizo kanye nosayizi wezitsha. -Kwethu imishini yokugcwalisa ewuketshezi futhi Imishini yokuqopha iyavumelana ngezifiso ukwamukela izidingo ezahlukahlukene zomkhiqizo nezidingo zokupakisha.

Ikhwalithi engaphenduki

Ikhwalithi iyinto ebaluleke kakhulu kuwe. Sinamathela ezinqubweni zokulawula ezisezingeni elifanele, siqinisekise ukuthi wonke umshini ushiya indawo yethu ihlangabezana nezindinganiso eziphakeme kakhulu zomkhakha.

Uzakwethu nge-pestopack futhi uhlangabezana nobunjiniyela bokucacisa bokucacisa abangakwenza ekusebenzeni kwakho kokupakisha. Noma ngabe uyisidlali semboni evezwa noma ukuqala nje, ubuchwepheshe bethu kanye nezixazululo zombuso ezingaguqula izinqubo zakho zokukhiqiza. Hlola uhla lwethu oluhlukahlukene lokugcwalisa nemishini yokukhapha njengokulandelayo, ngalinye liklanyelwe ukufeza izidingo ezithile zemboni.

2. Ukugcwaliswa kwebhodlela kanye nomshini webhodlela

Isimiso:

Umshini webhodlela kanye nomshini we-capling ucezu olukhethekile lwemishini esetshenziswa kwizimboni ezahlukahlukene ukuze uguqule inqubo yokugcwalisa amabhodlela anomkhiqizo othize (njengoketshezi, noma ama-granules) futhi uvale. Le mishini yokugcwalisa ibhodlela kanye nemishini yokushayela embonini ivame ukuqashwa embonini yokufaka kanye nokukhiqiza ukwandisa ukusebenza kahle kokukhiqiza futhi kuqinisekiswe ikhwalithi yomkhiqizo. Ngokwesibonelo, Umshini wokugcwalisa kawoyela uhlobo lokugcwalisa ibhodlela kanye nomshini we-capling ogcwalisa uwoyela wamabhodlela.

Nakhu ukuwohloka kwezakhi ezisemqoka nemisebenzi yokugcwalisa ibhodlela ezenzakalelayo kanye nomshini weplip:

1

2. Ukugcwalisa: esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo owuthandayo ebhodleleni ngalinye. Lokhu kungenziwa kusetshenziswa izindlela ezahlukahlukene, kufaka phakathi ukugcwaliswa kwe-volumetric (ukukala ivolumu ethile yomkhiqizo) noma ukugcwaliswa kwe-gravimetric (ukulinganisa ngesisindo).

3. Ukugcwala: Ngemuva kokugcwaliswa, umshini usebenza ngokuphephile ama-cap noma ukuvalwa emabhodleleni. I-caplic mechanism ingahluka, ngezinketho ezinjengezikulumo ezinjenge-screw cap, snap cap, ama-cork stop, noma ezinye izinhlobo, ngokuya ngomkhiqizo nezidingo zomkhiqizo.

4. Ukufaka uphawu: Umshini uqinisekisa ukuthi ama-cap avalwe ngokuqinile ukuvikela ukuvuza noma ukuphazamisa. Lesi sinyathelo sibalulekile ekugcineni ubuqotho bomkhiqizo.

I-5

I-6. Ukulebula nokupakisha: Kwezinye izimo, le mishini iyingxenye yomugqa ophelele wokufaka okubandakanya ukulebula, ukufaka amakhodi wedethi, nokupakipha emabhokisini noma ezitsheni.

Izici:

Ijubane lokukhiqiza elikhulayo kanye nokusebenza kahle, ukunciphisa izindleko zabasebenzi.

Ukugcwaliswa okungaguquki nokunembile, kunciphisa imfucumfucu yomkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Ukuguquguquka kwamasayizi ahlukene amabhodlela nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Lokhu kugcwalisa ibhodlela ezenzakalelayo kanye nemishini yokushayela kusetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi i-Pharmaceutical, ukudla kanye nesiphuzo, izimonyo, izimboni zomkhiqizo wamakhemikhali, phakathi kwabanye. Beza ngosayizi abahlukahlukene kanye nokucushwa ukufeza izidingo ezithile zemigqa yokukhiqiza ehlukene, kusuka ekusebenzeni kwezinga elincane kuya ngesivinini esikhulu, ukukhiqiza okukhulu.

3. I-jar ukugcwalisa kanye nomshini webhoji

Isimiso:

Umshini wokugcwalisa we-jar kanye ne-capping ucezu olukhethekile lwemishini eyenzelwe ukuguqula inqubo yokugcwalisa izimbiza ngemikhiqizo ehlukahlukene, njengama-okhilimu, nama-powdes, kanye nezinye izinto ezibonakalayo, futhi zibebeka uphawu ngokuphephile ngama-cap noma ukuvalwa. Ngokwesibonelo, Umshini wokugcwalisa iLotiont uwuhlobo lokugcwalisa i-jar kanye nomshini wokugcwala ogcwalisa u-lotion ezitsheni.

Nasi sibukezo sezakhi ezibalulekile nemisebenzi yokugcwalisa i-jar kanye nomshini weplip:

I-Jar feed: Izimbiza ezingenalutho zivame ukulayishwa ohlelweni lokuhambisa noma lokudla, oluzithutha esiteshini sokugcwalisa.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo embizeni ngayinye. Indlela yokugcwalisa yenzelwe ukuphatha uhla olubanzi lwe-product conpenction, kusuka okhilimu obukhulu kuya kuma-powders. Ngokuya ngomkhiqizo, ukugcwaliswa kungenzeka kwenziwe kusetshenziswa ama-piston fillers, ama-filler auger, noma ezinye izindlela ezikhethekile.

Ukukhonkotha: Ngemuva kokugcwalisa, umshini usebenza ngokuphepha izigqoko noma ukuvalwa ezitsheni. I-caplic mechanism ingahluka, ithola izinhlobo ezahlukahlukene ze-cap, njengama-screw cap, ama-lug cap, ama-cap-on cheps, noma okunye ukuvalwa.

Ukubekwa uphawu: Umshini uqinisekisa ukuthi ama-cap avalwe ngokuqinile ukuvikela ukuvuza komkhiqizo noma ukungcoliswa. Ukubekwa uphawu okufanele kubalulekile ukuze kugcinwe ikhwalithi yomkhiqizo nokuphepha.

Ukulawulwa kwekhwalithi: Imishini eminingi ye-jar kanye ne-capping ifaka izici zokulawula ikhwalithi, njengokuhlola i-cap torque noma ukugcwalisa ukuhlolwa kwezinga, ukuqinisekisa ukuthi imbiza ngayinye igcwaliswe kahle futhi ivalwe kahle.

Ukulebula nokupakisha: Kwezinye izimo, le mishini ihlanganiswe emgqeni ophelele wokufaka okubandakanya ukulebula, ukufaka amakhodi wedethi, kanye nokupakishwa kwezimbiza emabhokisini noma ezitsheni.

Izici:

Ukwanda kokusebenza kokukhiqizwa kokukhiqizwa, ukunciphisa izindleko zabasebenzi nokuphathwa ngesandla.

Ukugcwaliswa okunembile nokungaguquki, kunciphisa ukuchithwa komkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Ukuzivumelanisa nezimo kusayizi ahlukahlukene e-jar nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Le mishini yokugcwalisa ye-jar kanye ne-capping isetshenziswa kakhulu ezimbonini lapho imikhiqizo igcwele khona izimbiza, kufaka phakathi ukucubungula ukudla, izimonyo, amakhamishini, nokuningi. Imishini yokugcwalisa ye-jar kanye ne-capping iguquguqukayo futhi ingenziwa ngokwezifiso ukufeza izidingo ezithile zemikhiqizo ehlukene nezidingo zokukhiqiza. Beza ngokucushwa okuhlukahlukene, kufaka phakathi amamodeli azenzakalelayo azenzakalelayo futhi azenzakalelayo, ukwamukela uhla olubanzi lwezikalo zokukhiqiza kanye nokuhlukahluka komkhiqizo.

4. Ukugcwaliswa koketshezi kanye nomshini weplipha

Isimiso:

Umshini wokugcwalisa owuketshezi kanye nokwelashwa ucezu olukhethekile lwemishini eyenzelwe ukuguqula inqubo yokugcwalisa iziqukathi ngemikhiqizo ewuketshezi, njengeziphuzo zemithi, bese ubeka uphawu ngokuphepha kwalezo zitsheni ezinama-cap noma ukuvalwa. Ngokwesibonelo, Umshini wokugcwalisa uju uhlobo lokugcwaliswa koketshezi kanye nomshini weplip ogcwalisa futhi uphawu oju lwamabhodlela.

Nazi izingxenye ezisemqoka nemisebenzi yokugcwalisa okuwuketshezi kanye nomshini weplip:

Isitsha sokudla: iziqukathi ezingenalutho, njengamabhodlela noma ama-vials, zilayishwa ohlelweni lokuhambisa noma lokudla, oluzithutha esiteshini sokugcwalisa.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo owuketshezi esitsheni ngasinye. Ukugcwaliswa koketshezi kuvame ukwenziwa kusetshenziswa enye yezindlela eziningana, njengokugcwaliswa kwevolumetric (ukukala ivolumu ethile ye-ketshezi) noma ukugcwaliswa kwe-gravimetric (ukulinganisa ngesisindo). Umgomo ukuqinisekisa ukugcwaliswa okunembile futhi okungaguquki kwesitsha ngasinye.

Ukukhonkotha: Ngemuva kokugcwalisa, umshini usebenza ngokuphepha izigqoko noma ukuvalwa ezitsheni. Indlela yokukhonkotha iyahlukahluka ngokuya ngohlobo lwe-cap esetshenzisiwe futhi ingahle ifake ukubhoboza isikulufu, ukubhoboza i-snap, ukugcwala kwe-capping, noma ezinye izindlela zokuvalwa.

Ukubekwa uphawu Ukubekwa uphawu okufanele kubalulekile ekugcineni ubuqotho bomkhiqizo nokuphepha.

Ukulawulwa kwekhwalithi: Imishini eminingi yokugcwalisa ewuketshezi kanye nemishini yokuthwebula ifaka izici zokulawula ikhwalithi, njengokuhlola i-cap torque noma ukugcwalisa ukuhlolwa kwezinga, ukuqinisekisa ukuthi isitsha ngasinye sigcwaliswe kahle futhi sivaliwe.

Ukulebula nokupakisha: Eminye imigqa yokukhiqiza, ukugcwaliswa koketshezi kanye nemishini yokushayela kuhlanganiswe ohlelweni oluphelele lokupakisha olubandakanya ukulebula, ukufaka amakhodi wedethi, nokupakisha iziqukathi emabhokisini noma ezitsheni zokusatshalaliswa.

Izici:

Ijubane lokukhiqiza elikhulayo kanye nokusebenza kahle, ukunciphisa izindleko zabasebenzi.

I-Uquid Doosing ye-Liquid engaguquki futhi eqondile, ukunciphisa imfucumfucu yomkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Ukuzivumelanisa nezimo kusayizi ohlukile wesitsha kanye ne-visosities ewuketshezi.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Lokhu kugcwalisa okuwuketshezi kanye nemishini yokuqopha kuvame ukusetshenziswa ezimbonini lapho kubalulekile khona ukufakwa koketshezi nokubekwa uphawu, kufaka phakathi ukudla neziphuzo, izimboni zemithi kanye nezimboni zezekhemikhali. Le mishini iguquguqukayo kakhulu futhi iza ngosayizi ahlukahlukene kanye nokucushwa ukuze kuhlaliswe esikalini sokukhiqiza, izinhlobo zezitsha, kanye nemikhiqizo ewuketshezi. Noma ngabe ekusebenzeni okukuncane noma indawo yokukhiqiza ngesivinini esikhulu, ukugcwaliswa koketshezi kanye nemishini yokuqopha idlala indima ebalulekile ekuqinisekiseni izinqubo zokupakisha ezisebenzayo nezithembekile.

I-5. Ukugcwalisa okuzenzakalelayo nomshini we-cap

Isimiso:

Umshini wokugcwalisa othomathikhi nokukhonkotha ucezu oluyinkimbinkimbi lwemishini eyenzelwe ukuguqula inqubo yokugcwalisa iziqukathi ngemikhiqizo ehlukahlukene, efana nama-ketshezi, ama-powders, okhilimu, noma ukuvalwa. Ngokwesibonelo, Umshini wokugcwalisa weSauce uluhlobo lokugcwalisa okuzenzakalelayo nokugcwaliswa komshini ogcwalisa futhi uphawu lwe-sauce emabhodleleni ngokuzenzakalelayo.

Nazi izingxenye ezisemqoka nemisebenzi yokugcwalisa okuzenzakalelayo nomshini wepliphu:

Isitsha sokudla: iziqukathi ezingenalutho, njengamabhodlela, izimbiza, noma ama-vials, zilayishwa ohlelweni lokuhambisa noma indlela yokudla, ezithutha eziteshini zokugcwalisa kanye nokukhonkotha.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo esitsheni ngasinye. Izindlela ezahlukahlukene zokugcwalisa, ezinjenge-volumetric, i-gravimetric, noma ukugcwaliswa kwe-piston, kungaqashwa ukuze kuqinisekiswe ukugcwaliswa okunembile futhi okungaguquki.

Ukukhonkotha: Ngemuva kokugcwalisa, umshini usebenza ngokuzenzakalelayo ama-cap noma ukuvalwa ezitsheni. I-CAPP yakhelwe ukusebenza ngejubane eliphezulu, ithola izinhlobo ezahlukene ze-cap, kufaka phakathi ama-screw cap, cindezela izigqoko, noma okunye ukuvalwa.

Ukubekwa uphawu

Ukuhlolwa kweCap: Imishini eminingi yokugcwalisa okuzenzakalelayo nemishini yokuthwebula ifaka izinhlelo zokuhlola i-CAP ukubheka ukubekwa kwe-cap efanele ne-torque ukuqinisekisa ukulawulwa kwekhwalithi.

Ukulebula nokupakisha: Eminye imishini ihlanganiswe emugqeni ophelele wokufaka, kufaka phakathi ukulebula, ukufaka amakhodi wedethi, kanye neziqukathi zokupakisha emabhokisini noma amabhokisi okusatshalaliswa.

Izici:

Ijubane eliphezulu kanye nokukhiqizwa okuphezulu kwevolumu, okwandisa kahle ukusebenza kahle.

Ukugcwaliswa okungaguquki nokunembile, kunciphisa imfucumfucu yomkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Izindleko ezincishisiwe zabasebenzi kanye nephutha lomuntu elincishisiwe.

Ukuzivumelanisa nezimo kusayizi ohlukahlukene wesitsha nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Le mishini yokugcwalisa ezenzakalelayo nemishini esetshenziswayo isetshenziswa kakhulu ezimbonini lapho ukukhiqizwa okuphezulu nokungaguquki kubalulekile, njengokudla neziphuzo, izimonyo namakhemikhali namakhemikhali. Imishini yokugcwalisa ezenzakalelayo kanye nemishini yokukhahlela iza ngokucushwa okuhlukahlukene ukuze ihlangabezane nezidingo ezihlukile zokukhiqiza, kusuka emishini ecwebezelayo efanelekile yokusebenza kwezimali ezincane ukuze isebenze ngokuzenzakalela, izinhlelo eziphezulu zesivinini esikwazi ukusingatha inqwaba yemikhiqizo ngomzuzu. Le mishini idlala indima ebalulekile ezinhlelweni zokukhiqiza eziqondisayo kanye nokuqinisekisa ikhwalithi yomkhiqizo engaguquki.

6. Ukugcwalisa, ukukhonkotha, kanye nokulebula komshini

Isimiso:

Umshini wokugcwalisa, wokugcwala, nowokubhala, ovame ukubizwa ngokuthi umshini wokulebula wokugcwalisa, kuyingxenye yemishini ehlukahlukene futhi ehlanganisiwe eyenzelwe ukushintsha izigaba eziningi zenqubo ehlukahlukene. Lo mshini uhlehlisa izinqubo zokugcwalisa iziqukathi ngomkhiqizo othile, ukukhokha ngokuphepha noma ukubeka uphawu lezo ziqukathi, nokusebenzisa amalebula kubo bonke ekusebenzeni okukodwa, okungenamthungo. Ngokwesibonelo, Umshini wokugcwalisa we-shampoo ungahlanganisa ukubhoboza nokulebula ngomshini kulayini wokugcwalisa we-shampoo ophelele.

Nazi izinto ezisemqoka nemisebenzi yokugcwaliswa koketshezi, ukugcwala, kanye nomshini wokulebula:

Isitsha sokudla: iziqukathi ezingenalutho, njengamabhodlela noma izimbiza, zilayishwa ohlelweni lokuhambisa noma indlela yokudla, ezithutha eziteshini ezihlanganisiwe zokugcwaliswa, ukukhokha, kanye nokulebula.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo esitsheni ngasinye, uqinisekise ukugcwaliswa okunembile futhi okungaguquki. Izindlela ezahlukahlukene zokugcwalisa zingasetshenziswa, kuya ngohlobo lomkhiqizo.

Ukugcwala: Ngemuva kokugcwalisa, umshini usebenza ngokuzenzakalelayo ama-cap noma ukuvalwa ezitsheni, ukuwabopha ngokuphephile. I-cappap mechanism ingaphatha izinhlobo ezahlukahlukene ze-cap, kufaka phakathi ama-screw cap, snap cap, noma okunye ukuvalwa.

Ukubekwa uphawu

Ukulebula: Uma sekugcwalisiwe futhi kugcwalisiwe, iziqukathi zithuthela esiteshini sokulebula, lapho amalebula asetshenziswa ngokunembile futhi afane. Ukulebula kungafaka imininingwane yomkhiqizo, uphawu, ama-barcode, neminye imininingwane edingekayo.

Ukulawulwa kwekhwalithi: Imicibisholo eminingi yafaka izici zokulawula ikhwalithi, njengokuhlola i-cap torque, gcwalisa ukuhlolwa kwezinga, bese uqinisekisa ukuthi isitsha ngasinye sigcwaliswe kahle, sibekwe uphawu.

Ukupakisha: Ukugcwaliswa okuthile, ukugcwala, kanye nemishini yokulebula kuyingxenye yomugqa omkhulu wokupakisha futhi kungafaka nezinqubo ezengeziwe ezifana nokufaka amakhodi wedethi, ukuhlolwa komkhiqizo, kanye neziqukathi zokupakisha zibe ngamabhokisi noma amabhokisi okusatshalaliswa.

Izici:

Ukuncishiswa okuphambili kwezindleko zabasebenzi kanye nokuphathwa ngesandla.

Ukusebenza kahle kokukhiqiza kanye nesivinini.

Ukugcwaliswa okunembile nokungaguquki, ukukhokha, kanye nokulebula, kunciphisa ukuchithwa komkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

I-Versicility ukwamukela osayizi abahlukahlukene bezitsha kanye nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Lokhu kugcwalisa okuzenzakalelayo kwelebula kusetshenziswa kabanzi ezimbonini lapho kusebenza khona futhi okunembile ukufakwa kubalulekile, njengokudla neziphuzo, izimonyo, izimonyo namakhemikhali namakhemikhali. Baza ngokucushwa okuhlukahlukene, benikeza ukuguquguquka ukuze bahlangabezane nezikali ezihlukile zokukhiqiza kanye nokwahlukahluka komkhiqizo, kubenza bayimpahla ebalulekile yezinqubo zokufaka ezihleliwe nezisezingeni eliphakeme.

7

Isimiso:

Ukugcwaliswa kwebhodlela lengilazi kanye nomshini we-caple kuyingxenye ekhethekile yemishini eyenzelwe ukuguqula inqubo yokugcwalisa amabhodlela engilazi agcwalisa imikhiqizo ehlukahlukene enezimpawu noma ukuvalwa ngokuphephile. Le mishini yenzelwe ukuphatha iziqukathi ezibucayi zeglasi ngokunakekela ukuvikela ukwehla ngesikhathi sokugcwalisa kanye nokukhonkotha. Ngokwesibonelo, Umshini wokugcwalisa ubhiya uhlobo lokugcwalisa ibhodlela lengilazi nomshini wokukhonkotha ogcwalisa ubhiya emabhodleleni engilazi.

Nazi izingxenye ezisemqoka nemisebenzi yokugcwalisa ibhodlela yengilazi kanye nomshini weplip:

Ukuphaka Kwebhodlela: Amabhodlela e-Glass angenalutho alayishwa ohlelweni lokuhambisa noma indlela yokudla, ewuthutha eziteshini zokugcwalisa kanye nokukhonkotha.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo owuketshezi ebhodleleni ngalinye lengilazi. Izindlela zokugcwalisa zingahluka futhi zingafaka amavolumetric, ama-gravimetric, noma izindlela zokugcwalisa ama-piston ukuqinisekisa ukugcwaliswa okunembile nokungaguquki.

Ukukhonkotha: Ngemuva kokugcwalisa, umshini usebenza ngobunono futhi uvikele ngokuphephile ama-cap noma ukuvalwa emabhodleleni engilazi. I-Capling Mechanism yakhelwe ukuphatha iziqukathi zengilazi ezimnandi ukuvikela ukuqhekeka.

Ukubekwa uphawu

Ukulawulwa kwekhwalithi: Ukugcwaliswa kwamabhodlela amaningi we-glass kanye nemishini yokuqopha kwekhwalithi kuhlanganisa izici zokulawulwa kwekhwalithi, njengokuhlola i-cap torque bese ugcwalisa ukuthi ibhodlela ngalinye ligcwaliswe kahle futhi livaliwe.

Ukulebula nokupakisha: Amanye ama-Machines ayingxenye yomugqa omkhulu wokupakisha futhi angafaka izinqubo ezengeziwe njengokulebula, ukufaka amakhodi amadethi, kanye nokupakisha amabhodlela engilazi emabhokisini noma amabhokisi okusatshalaliswa.

Izici:

Ukulondolozwa kwekhwalithi yomkhiqizo nokunambitha, njengoba ingilazi ingasebenzi futhi ingafinyeleleki ezintweni ezingaphandle.

Ukuphathwa ngobumnene kwamabhodlela ezingilazi ezintekenteke, kunciphisa ubungozi bokuqhekeka.

Ukugcwaliswa okunembile nokungaguquki kanye nokugcwala, ukunciphisa imfucumfucu yomkhiqizo.

Ukuhlanzeka komkhiqizo okuthuthukisiwe nokuphepha nge-automation.

Ukuzivumelanisa ngezimo eziguqukayo ngosayizi wamabhodlela e-glass kanye nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yezimboni, ikakhulukazi ezimbonini ezinezidingo zekhwalithi eqinile.

Isicelo

Ukugcwaliswa kwebhodlela le-Glass kanye nemishini esetshenziswayo kuvame ukusetshenziswa ezimbonini lapho ikhwalithi yomkhiqizo kanye nokuthembeka kokupakishwa kwengilazi kubaluleke kakhulu, njengezimboni ze-beverage, kanye nezimboni. Imishini yokugcwalisa ibhodlela ye-glass kanye ne-caple ibalulekile ezimbonini lapho isethulo somkhiqizo nekhwalithi zibalulekile, njengokuphuza okuphezulu, amakha, amakhamishini kanye nemikhiqizo yezimonyo. Zizokwengeza ukuqinisekisa ukufakwa okuphephile futhi okusebenzayo kwemikhiqizo ewuketshezi ezitsheni zeglasi, ukugcina amazinga aphezulu kakhulu wekhwalithi yomkhiqizo nobuqotho.

8. Ukugcwaliswa kwe-Rotary kanye nomshini weplip

Isimiso:

Umshini wokugcwalisa we-rotary kanye nokwelashwa ucezu olukhethekile lwemishini eyenzelwe ukuguqula inqubo yokugcwalisa iziqukathi ngemikhiqizo ehlukahlukene, njengoketshezi, noma ukubopha noma ukukhokha lezo ziqukathi. Le mishini ibonakala ngokujikeleza kwabo okuguqukayo noma kwe-carousel design, evumela ijubane eliphezulu kanye nokukhiqizwa okuqhubekayo. Ngokwesibonelo, Umshini wokugcwalisa iziphuzo ze-carbonated uluhlobo lokugcwaliswa kwe-rotary kanye nomshini we-capling ogcwalisa futhi uphawu isiphuzo.

Nazi izinto ezisemqoka nemisebenzi yokugcwaliswa kwe-rotary kanye nomshini we-capling:

Isitsha sokudla: Iziqukathi ezingenalutho, njengamabhodlela, izimbiza, noma ama-vials, zilayishwe etafuleni lokukhonjiswa e-rotary noma uhlelo lokuhambisa olubashukumisela eziteshini ezahlukahlukene zomshini.

Ukugcwaliswa: Esiteshini sokugcwalisa, umshini udlulisela umkhiqizo esitsheni ngasinye. Ama-nozzles amaningi wokugcwalisa noma amakhanda ahlelwe etafuleni elijikelezayo, avumela iziqukathi eziningi ukuthi zigcwaliswe ngasikhathi sinye. Izindlela zokugcwalisa zingafaka amavolumetric, ama-gravimetric, noma izindlela ezenzelwe ama-piston.

Ukugcwala: Ngemuva kokugcwaliswa, iziqukathi zithuthela esiteshini se-caple, lapho kufakwa khona ama-cap noma ukuvalwa futhi kuqiniswe ngokuphephile. Amakhanda okukhomba avumelaniswa ngokujikeleza kwe-turntable ukuphatha iziqukathi eziningi ngasikhathi sinye.

Ukubekwa uphawu

Ukulawulwa kwekhwalithi: Ukugcwaliswa okuningi okujikelezayo kanye nemishini yokuthwebula ifaka izici zokulawula ezisezingeni eliphakeme, njengokuhlola i-cap torque bese ugcwalisa ukuhlolwa kwezinga, ukuqinisekisa ukuthi isitsha ngasinye sigcwaliswe kahle futhi sivaliwe.

Ukulebula nokupakisha: Kwezinye izimo, le mishini ihlanganiswe emugqeni ophelele wokupakisha futhi ingafaka izinqubo ezengeziwe njengokulebula, amakhodi amadethi, futhi ukupakisha iziqukathi zibe ngamabhokisi noma amabhokisi okusatshalaliswa.

Izici:

Ijubane eliphezulu kanye nokukhiqizwa okuphezulu kwevolumu, okwandisa kahle ukusebenza kahle.

Ukugcwaliswa okunembile nokungaguquki kanye nokugcwala, kunciphisa ukuchithwa komkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Izindleko ezincishisiwe zabasebenzi kanye nephutha lomuntu elincishisiwe.

Ukuzivumelanisa nezimo kusayizi ohlukahlukene wesitsha nezinhlobo zomkhiqizo.

Ukuhambisana namazinga nemigomo yemboni.

Isicelo:

Ukugcwaliswa kwe-Rotary Ukugcwaliswa kwemishini kuvame ukusetshenziswa ezimbonini lapho kushesha khona, ukusebenza kahle, futhi okuqondile ukufakwa kubalulekile, kufaka phakathi isiphuzo, amakhambi, izimonyo, izimonyo namakhemikhali namakhemikhali. Imishini yokujikeleza okujikelezayo kanye ne-cap ye-cap nge-Industries enezidingo ezinkulu zokukhiqiza, lapho ijubane nokusebenza kahle kubaluleke kakhulu. Zenzelwe ukuphatha uhla olubanzi lwamasayizi aqukethe kanye nezinhlobo, okwenza babe yimpahla ebalulekile yamabhizinisi abheke ukwenza izinqubo zazo zokupakisha.

9. Ukugcwaliswa kwebhodlela elincane kanye nomshini webhoji

Isimiso:

Umshini wamabhodlela amancane nokukhonkotha ucezu olukhethekile lwemishini eyenzelwe ukuguqula inqubo yokugcwaliswa nokuvimbela ngokuphepha, njengamabhodlela amancane, nemikhiqizo emincane, kufaka phakathi iziphuzo, okubandakanya nezimonyo, nokuningi. Le mishini yenzelwe ngokukhethekile ukuphatha iziqukathi ezinosayizi amancane ngokunemba nokunakekelwa, ukuqinisekisa ukugcwaliswa okunembile nokubopha ukubopha okuqinile. Ngokwesibonelo, Uma umshini wokugcwalisa uketshezi uluhlobo lokugcwaliswa kwamabhodlela amancane kanye nomshini we-capling ogcwalisa futhi unamathiselwe uketshezi ebhodleleni elincane kusuka ku-10ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml kuya ku-100ml.

Nazi izinto ezisemqoka nemisebenzi yokugcwaliswa kwamabhodlela amancane kanye nomshini we-capping:

Isitsha sokudla: Amabhodlela amancane angenalutho noma ama-vials alayishwe ohlelweni lokuhambisa noma indlela yokudla, ewuthutha eziteshini zokugcwalisa kanye nokukhonkotha.

Ukugcwalisa: Esiteshini sokugcwalisa, umshini udlulisela ngokunembile umkhiqizo esitsheni ngasinye esincane. Izindlela zokugcwalisa zingahluka futhi zingafaka amavolumetric, ama-gravimetric, noma izindlela ezenzelwe ama-piston zenzelwe amavolumu amancane.

Ukugcwala: Ngemuva kokugcwaliswa, iziqukathi ezincane zithuthela esiteshini se-TIPICE, lapho kusetshenziswa khona ama-cap noma ukuvalwa futhi kuqiniswe ngokuphephile. I-Capling Mechanism yakhelwe ama-cap-sheshes amancane neziqukathi.

Ukubekwa uphawu

Ukulawulwa kwekhwalithi: Ukugcwaliswa kwamabhodlela amancane kanye nemishini yokuqopha kwe-cap kufaka phakathi izici zokulawula ikhwalithi, njengokuhlola ama-cap torque futhi ugcwalise ukuhlolwa kwezinga, ukuqinisekisa ukuthi isitsha ngasinye esincane sigcwaliswe kahle futhi sivaliwe.

Ukulebula nokupakisha: Kwezinye izimo, le mishini ihlanganiswe emugqeni ophelele wokupakisha futhi ingafaka izinqubo ezengeziwe njengokulebula, amakhodi wedethi, nokupakipha iziqukathi ezincane emabhokisini noma amabhokisi okusatshalaliswa.

Izici:

Ukugcwaliswa okunembile nokungaguquki kanye nokugcwala, ukunciphisa imfucumfucu yomkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko nge-automation.

Ukuzivumelanisa nezimo kosayizi abancane bezitsha kanye nezinhlobo zomkhiqizo.

Izindleko ezincishisiwe zabasebenzi kanye nephutha lomuntu elincishisiwe.

Ukuhambisana namazinga wezimboni nemigomo yokupakishwa okuncane kwesitsha.

Isicelo:

Ukugcwaliswa kwebhodlela elincane kanye nemishini yokushayela kuvame ukusetshenziswa ezimbonini lapho kudingeka khona ukufakwa kwezilinganiso ezincane, njengezemithi, izimonyo kanye nama-laboratories. Imishini yokugcwaliswa kwebhodlela elincane kanye nemishini yokushayela ibalulekile ezimbonini lapho ukuhlanganiswa okuhlangene kuvame, njengemithi yamakhemikhali yama-vials, izimonyo zamabhodlela amancane, noma ama-laboratories weziqukathi zesampula ezincane. Zenzelwe ukuhlangabezana nezidingo ezihlukile zokupakishwa kwezilinganiso ezincane ngenkathi kuqinisekisa ikhwalithi yomkhiqizo kanye nokusebenza kahle.

10. Ukugeza, ukugcwalisa, kanye nomshini weplip

Isimiso:

Ukugeza, ukugcwalisa, kanye nomshini wepring, okuvame ukubizwa ngokuthi ngumshini we-WFC, kuyingxenye eyinkimbinkimbi yemishini esetshenziswa embonini nasembonini epakisha. Lo mshini wenza inqubo yokuhlanza, ukugcwalisa, kanye nokukhonkotha iziqukathi, ngokujwayelekile amabhodlela, ngendlela eqhubekayo futhi ephumelelayo. Ngokwesibonelo, Umshini wokugcwalisa amanzi uluhlobo lokugcwaliswa kwe-rinsing yokugcwalisa kanye nomshini we-capling ogeza, ugcwalise futhi ulise amanzi emabhodleleni ngokuzenzakalelayo.

Nakhu ukuwohloka kwezakhi ezisemqoka nemisebenzi yokuvutha, ukugcwalisa, kanye nomshini weplipha:

Isitsha sokugeza: Iziqukathi ezingenalutho (imvamisa amabhodlela) zithuthwa okokuqala esiteshini sokuwasha. Lapha, iziqukathi zibhekana nenqubo ephelele yokuhlanza, ezingahilela ukugcwala, ukubulawa inzalo, futhi zomiswa ukususa noma yikuphi ukungcola noma izinsalela.

Ukugcwaliswa: Ngemuva kokugeza, iziqukathi ezihlanzekile ziye esiteshini sokugcwalisa, lapho umshini usakaza ngokuqondile umkhiqizo owufunayo (isib., Isiphuzo, noma isixazululo semithi) esitsheni ngasinye. Inqubo yokugcwalisa ingaqasha izindlela ezahlukahlukene, kufaka phakathi amavolumetric, ama-gravimetric, noma izindlela ezenzelwe ama-piston.

Ukugcwala: Ukulandela ukugcwalisa, iziqukathi ziqhubekisela esiteshini se-COPIPE. Umshini usebenza ngokuzenzakalelayo ama-cap noma ukuvalwa esitsheni ngasinye bese uqinisa ngokuphephile. Lesi sinyathelo siqinisekisa ukuthi umkhiqizo uhlala uvaliwe futhi uvikelekile.

Ukubekwa uphawu

Ukulawulwa Kwekhwalithi: Ukugeza okuningi, ukugcwalisa, kanye nemishini yokuthwebula kufaka phakathi izici zokulawula ezisezingeni, njengokuhlola iziqu, ukugcwalisa ukuhlolwa kwezinga, ukuqinisekiswa kwesitsha ngasinye kugcwaliswe kahle, kwabhalwa.

Ukulebula nokupakisha: Amanye ama-Machines ahlanganiswe emugqeni ophelele wokupakisha futhi angafaka izinqubo ezengeziwe, njengokulebula, ukufaka amakhodi wedethi, kanye nokupakisha iziqukathi emabhokisini noma amabhokisi okusatshalaliswa.

Izici:

Ijubane eliphezulu kanye nokukhiqizwa okuphezulu kwevolumu, okwandisa kahle ukusebenza kahle.

Ukugcwaliswa okunembile nokungaguquki, ukukhokha, nokubekwa uphawu, kunciphisa ukuchithwa komkhiqizo.

Ikhwalithi yomkhiqizo ethuthukisiwe nenhlanzeko ngokusebenzisa ukuhlanza okuzenzakalelayo nezinqubo zokubopha uphawu.

Izindleko ezincishisiwe zabasebenzi kanye nephutha lomuntu elincishisiwe.

Ukuhambisana namazinga wezimboni kanye nemigomo yokupakishwa komkhiqizo nekhwalithi.

Isicelo:

Umshini wokugcwalisa nokugcwaliswa kwe-cap we-cap ejwayele ukusetshenziselwa izimboni ezinjengeziphuzo (isib. Amanzi amabhodlela, iziphuzo ezithambile), ubisi (isib. Ubisi, i-yogurt), kanye nemithi. URinsing, ukugcwalisa, kanye nemishini yokushaya kubalulekile ezimbonini lapho kugcwele ibhodlela nokupakishwa. Zenzelwe ukuqinisekisa ukufakwa okusebenzayo, okuthembekile, kanye nenhlanzeko kwemikhiqizo ehlukahlukene ngenkathi kugcinwa amazinga aphezulu kakhulu wekhwalithi nokuphepha.

Ekuphetheni, ukugcwalisa kanye nemishini yokushaya nge-linchpin yezixazululo zesimanjemanje zokupakisha, ukuhlinzeka ngokuhlukahluka, ukusebenza kahle, kanye nobuqotho bomkhiqizo kuyo yonke imboni ehlukahlukene. Ukusuka ekutholeni okunembile okuzenzakalelayo kuya ezishintshayo okuphezulu, le mishini ivumelanisa nezidingo ezahlukahlukene zokukhiqiza. Ukutshala imali emshinini wokugcwalisa kwesokudla wokugcwalisa imali kungathuthukisa kakhulu ukusebenza kokukhiqiza, ukunciphisa izindleko, futhi kuqinisekise ikhwalithi yomkhiqizo, ekugcineni impumelelo ekumeni komhlaba okusebenzayo.