Ukuqonda imishini yokugcwaliswa kwebhodlela le-BOTSIOL BOTSLE

Izici ezibalulekile zemishini yezandla

Izinzuzo zemishini yezandla

Okubi kwemishini yezandla

Ihlola imishini yokugcwalisa yebhodlela elizenzakalelayo

Izici ezibalulekile zemishini ezenzakalelayo

Izinzuzo zemishini ezenzakalelayo

Okubi kwemishini ezenzakalelayo

Ukucatshangelwa okubalulekile lapho ukhetha phakathi kwemishini yezandla nezenzakalelayo

Isiphetho: Ukwenza ukukhetha okulungile kwebhizinisi lakho

Uma kukhulunywa ngokusetha umugqa wokukhiqiza ukuthola imikhiqizo ewuketshezi, ukukhetha umshini wokugcwalisa ebhodlela elifanele kubalulekile. Izinhlobo ezimbili eziphambili zemishini etholakalayo ziyincwajana futhi ezenzakalelayo umshini wokugcwalisa ibhodlela we-liquid Bottle . Ngayinye inezinzuzo zayo nobunzima bayo, ibenze balungele izinhlobo ezahlukene zamabhizinisi nezikali zokukhiqiza. Kulesi siqondisi esiphelele, sizohlola ukungezwani okusemqoka phakathi kwalezi zinhlobo ezimbili zemishini ukukusiza ekuboneni ukuthi iyiphi elungele kangcono izidingo zakho.

Ukuqonda imishini yokugcwaliswa kwebhodlela le-BOTSIOL BOTSLE

Imishini yokugcwalisa ibhodlela ye-Manual Liquid yenzelwe ngokuyinhloko ukusebenza kwezinga elincane, ukuqala, noma amabhizinisi akhiqiza imikhiqizo ekhethekile ngamanani aphansi. Le mishini idinga ukuthi opharetha balawule ngesandla zonke izinyathelo zenqubo yokugcwalisa, ukusuka endaweni ebeka phansi ibhodlela ngaphansi kokugcwalisa i-nozzle ukulawula ukuhamba koketshezi esitsheni.

Izici ezibalulekile zemishini yezandla

Ukusebenza okulawulwa ngumuntu

Imishini yokugcwalisa ibhodlela ye-Manual Liquid, kufaka phakathi Umshini wokugcwalisa kawoyela , ngokuyisisekelo uncike ekubhekaneni komuntu, okunikeza izinga lokuguquguquka okungekho amasistimu azenzakalelayo angahambelani. Njengoba abahlinzeki babambe iqhaza kuzo zonke izinyathelo zenqubo yokugcwalisa, bangashintsha kalula inani lamafutha noma ezinye iziphuzo ezisatshalaliswe ebhodleleni ngalinye. Lokhu kuvumelana nokuvumelana okuzuzisa ikakhulukazi amabhizinisi aphatha imikhiqizo ehlukahlukene, efana nezinhlobo ezahlukene zamafutha, ngamunye adinga amazinga athile wokugcwalisa.

Isibonelo, opharetha angakwazi ukuguqula ngokushesha ivolumu yokugcwalisa ukuze kuhlaliswe i-oda elikhethekile noma ukwakheka kwamafutha ahlukile ngaphandle kwesidingo sokuhlela kabusha okuyinkimbinkimbi. Le ndlela ye-Human-Huntir ibaluleke kakhulu ekusebenzeni kwamafutha okugcwalisa kawoyela, lapho ukubonakala kwamafutha ahlukene kungahluka, ukuvumela abahlinzeki ukuthi benze izinguquko zesikhathi sangempela ukuze baqinisekise ukunemba. Iphinde futhi inikeze amandla okubamba futhi alungise amaphutha lapho, eqinisekisa izinga eliphakeme lekhwalithi yomkhiqizo, elibalulekile ekugcineni ukuvumelana ekukhiqizeni uwoyela.

Usebenzisa umshini wokugcwalisa kawoyela we-Manual uvumela amabhizinisi ukuthi agcine ukulawulwa okugcwele kwenqubo yokugcwalisa, ukuqinisekisa ukuthi umkhiqizo ngamunye uhlangabezana namazinga athile futhi unikeze ukuguquguquka ukuze uvumelanise nezidingo zokukhiqiza.

Idizayini elula

Idizayini yemishini yokugcwalisa yezandla iqondile ngamabomu, igxile ekusebenzeni nasekusebenziseka kalula. Ngezingxenye ezimbalwa ezihambayo uma kuqhathaniswa nabalingani bazo ezenzakalelayo, le mishini ayithambekele kangako ukwehluleka kwemishini. Ukusebenziseka lula kokwakheka kusho ukuthi abaqhubi bangafunda ngokushesha ukuthi bawusebenzise kanjani umshini, behlisa isikhathi sokuqeqeshwa nezindleko ezihambisanayo. Ngaphezu kwalokho, uhlobo oluqondile lwale mishini lubenza kube lula ukululungisa nokulungisa. Amabhizinisi avame ukwenza ukulungiswa okujwayelekile endlini ngaphandle kwesidingo sabachwepheshe abakhethekile, ukonga isikhathi nemali. Lokhu kulula futhi kusho ukuthi umshini mancane amathuba okuthola isikhathi sokuphumula ngenxa yezinkinga zemishini, ezingase zibe zibucayi ukuze zigcine amashejuli wokukhiqiza aqinile.

Ukutshalwa Kwezimali Okuphansi

Enye yezinzuzo ezibaluleke kakhulu zemishini yokugcwalisa yezandla ukufinyeleleka kwayo. Ngamabhizinisi anemali ekhawulelwe noma lezo eziqala nje, izindleko ezingezansi zangaphansi zomshini wezandla zenza kube inketho ekhangayo. Lokhu kutshalwa kwemali okuphansi kuvumela amabhizinisi ukuthi abele izinsiza kwezinye izindawo ezibucayi, njengokumaketha, ukuthuthukiswa komkhiqizo, noma yokusungula. Naphezu kwezindleko zabo eziphansi, imishini yezandla yakhelwe ekugcineni, ukuhlinzeka ngemisebenzi ethembekile iminyaka enobulungiswa. Le nhlanganisela yokungabizeki nokuqina yenza imishini yezemibhalo ibe yisinqumo esihle kakhulu samabhizinisi abheke ukukhulisa ukubuya kwabo ekutshalweni kwemali.

Izinzuzo zemishini yezandla

Kuqiza kahle

Ukutshalwa kwezimali kokuqala emshinini wokugcwalisa webhodlela le-BOTSHEW BOTSLE kuphansi kunalokho okudingekayo kumshini ozenzakalelayo. Lokhu kwenza imishini yezandla ikhanga kakhulu amabhizinisi amancane, okokuqala, noma ukusebenza ngenani elilinganiselwe lokukhiqiza. Ukusebenza kwezindleko kwale mishini kufinyelela ngaphezu kwentengo yokuthenga. Njengoba imishini yokubhubha idinga ukulungiswa okuncane nokulungiswa okumbalwa, izindleko zesikhathi eside zokusebenza nazo ziphansi. Lokhu kungabizi kuvumela amabhizinisi ukuthi aqhubeke nokuncintisana, ikakhulukazi ezimakethe lapho ama-margins aqine khona. Ngaphezu kwalokho, ukonga izindleko kungavuselelwa kwezinye izici zebhizinisi, njengokukhulisa umugqa womkhiqizo noma ukuthuthukisa ikhwalithi yokufaka.

Ukuvumelana nezimo

Ukuvumelana nezimo kuwuphawu lwemishini yokugcwalisa ngesandla, kufaka phakathi umshini wokugcwalisa ukhilimu . Njengoba inqubo ilawulwa yi-opharetha, le mishini ingahlalisa kalula ukwakheka kwamabhodlela ahlukahlukene, osayizi, kanye nezinto zokwakha. Ukuthi ugcwalisa iziqukathi ezincane, eziyinkimbinkimbi noma amabhodlela amakhulu, anobukhulu, umshini wokugcwalisa ukhilimu ungaphatha umsebenzi ngokulungiswa okuncane. Lokhu kuguqulwa kufinyelela ezinhlotsheni zotshwala ezingahanjiswa, kusuka kuma-pure, kusuka ku-ketshezi oluncane, olufana namanzi ukuze lube lukhuni, izinto ezibonakalayo ezinjengezinto ezifana nokhilimu.

Imishini yezandla isebenza kahle ekuphatheni imikhiqizo emikhulu, ebonakalayo efana nokhilimu, ibenze ibe ukukhetha okuhle kwezimboni eziphatha imikhiqizo ye-skincare, i-lotions, nezinye izinto ezifanayo. Lokhu kuvumelana nezimo kuqinisekisa ukuthi amabhizinisi akhiqiza imikhiqizo ehlukahlukene, noma lezo ezishintsha kaningi phakathi kwemigqa ehlukene yomkhiqizo, zingenza kanjalo kalula nangesikhathi esincane. Amandla okuphatha izinhlobo zemikhiqizo ehlukahlukene, kufaka phakathi okhilimu obukhulu, enza imishini yokugcwaliswa kokhilimu ebhukwayo iyimpahla ebalulekile yabakhiqizi abafuna ukunemba nokuguquguquka kwenqubo yabo.

Izindleko zokulungiswa okuphansi

Ngomklamo wabo olula kanye nezingxenye ezimbalwa ezihambayo, imishini yokugcwalisa yezandla ilula ngokwemvelo futhi ibiza kakhulu ukuze ilondoloze. Imisebenzi yokulungisa ejwayelekile, njengokuhlanza nokuthambisa, imvamisa ingayenziwa ngabasebenza ngokwabo ngaphandle kwesidingo samathuluzi akhethekile noma ukuqeqeshwa. Ngokwengeziwe, ngoba imishini yezandla ayithembeli ezinhlelweni eziyinkimbinkimbi ze-elekthronikhi noma ezenzakalelayo, azithathiswe ukungasebenzi kahle kwezobuchwepheshe ezingabiza izindleko. Lesi sidingo esincishisiwe sezinsizakalo zokulungiswa kobungcweti futhi sinomthelela emalini yokonga yonke ehlotshaniswa nemishini yezandla. Kumabhizinisi afuna ukunciphisa izindleko zokusebenza, izindleko eziphansi zokulungiswa kwemishini yokugcwalisa yezandla ziyithuba elikhulu, zibavumela ukuba babele izinsiza ngempumelelo.

Okubi kwemishini yezandla

I-Labour-ibanzi

Enye yezingqinamba eziyinhloko zemishini yokugcwalisa yamabhodlela e-Manual liquid uwuhlobo olusebenzayo lokuhlinzwa kwabo. Njengoba le mishini incithe ngokuphelele ekufakweni komuntu, opharetha kumele ahlanganyele kakhulu kwinqubo yokugcwalisa isikhathi sokukhiqizwa. Lokhu kubandakanyeka okuqhubekayo kungafuneka emzimbeni, ikakhulukazi ngesikhathi sokushintsha okunwetshiwe noma lapho ugcwalisa amabhodlela amakhulu. Ama-opharetha angathola ukukhathala, okungaholela ekunciphiseni umkhiqizo kanye namathuba akhuphukile amaphutha. Izimfuno ezibonakalayo zokusebenza komshini wezandla nazo zingafaka isandla ekuguqukeni kwabasebenzi, njengoba uhlobo oluphindaphindwayo lomsebenzi kungaholela ekugculiseni isikhathi ngesikhathi. Ngokwengeziwe, isidingo sokusebenza okwenziwa njalo ngamamabhizinisi sisho ukuthi amabhizinisi kufanele anikeze izinsizakusebenza ezinele zabasebenzi ukuze alondoloze amazinga okukhiqiza angaguquki, angaba yinselele yemisebenzi emincane noma ngesikhathi sokukhiqizwa kwe-Peak.

Ukugcwaliswa okungahambelani

Ngoba imishini ebhaliwe, kufaka phakathi Umshini wokugcwalisa owuketshezi omncane , kuncike ekusebenzeni kwabantu, kunengozi ephezulu yokuhlukahluka kwinqubo yokugcwalisa. Izici ezifana necebo le-opharetha, isivinini, nokunaka imininingwane ethile ingathinta inani loketshezi olukhishwe ebhodleleni ngalinye. Lokhu kuhluka kungaholela ekungathobeki emkhiqizweni wokugcina, namabhodlela athile athola uketshezi oluningi futhi amanye ancane kakhulu.

Ukungahambisani okunjalo kungaba yinkinga ikakhulukazi ezimbonini lapho izilinganiso eziqondile zibucayi, ezinjengemithi, izimonyo eziphakeme kakhulu, noma ukukhiqizwa koketshezi okuncane. Ukugcwaliswa okungahambelani kungathinta kuphela ikhwalithi yomkhiqizo kepha kungaholela ekugculiseni kwamakhasimende kanye nokwengeza imfucuza. Amabhizinisi ancike emishini emincane yokugcwaliswa koketshezi kumele atshale imali ekuqeqeshweni okufanele kubahlinzeki bawo ukuqinisekisa inqubo yokugcwalisa engaguquki. Kodwa-ke, noma ngabe nokuqeqeshwa, ezinye izinga lokuhlukahluka akunakugwenywa ngenxa yento yomuntu. Lokhu kwenza umsebenzi ngokucophelela nokwengamela kubalulekile lapho usebenzisa imishini emincane yokugcwalisa ngoketshezi ukugcina ukunemba nekhwalithi.

Ijubane lokukhiqiza kancane

Imishini yokugcwalisa ibhodlela ye-Manual lihamba kancane kancane kunabalingani babo abazenzakalelayo. Ijubane lapho amabhodlela angagcwaliswa khona ngokuphelele ekusebenzeni kahle kwe-opharetha kanye nobubi. Ngenkathi opharetha onolwazi bengasebenza ngokushesha, imishini yezandla imane nje ayikwazi ukufanisa umphumela wezinhlelo ezenzakalelayo, ezingagcwalisa namakhulu amabhodlela noma izinkulungwane zamabhodlela ngehora. Lesi sivinini sokukhiqiza esihamba kancane singaba umkhawulo obalulekile wamabhizinisi anezidingo eziphezulu zokukhiqiza noma labo abafuna ukukala imisebenzi yabo. Emakethe yokuncintisana lapho izikhathi eziguquguqukayo zibalulekile khona, zincike emishini yezandla zingaholela ekubambeni kokuhleleka kokugcwaliswa ngoku-oda futhi kuncishiswe umkhiqizo ophelele. Ngaphezu kwalokho, ijubane elihamba kancane lokugcwaliswa kwencwajana lisho ukuthi amabhizinisi angadinga ukusebenzisa abasebenzi abengeziwe ukuze ahlangabezane nezindlela zokukhiqiza, ezengeziwe ezandayo zabasebenzi futhi zikwazi ukuhambisa imali yokonga izindleko ezihlotshaniswa nemishini yezezimali.

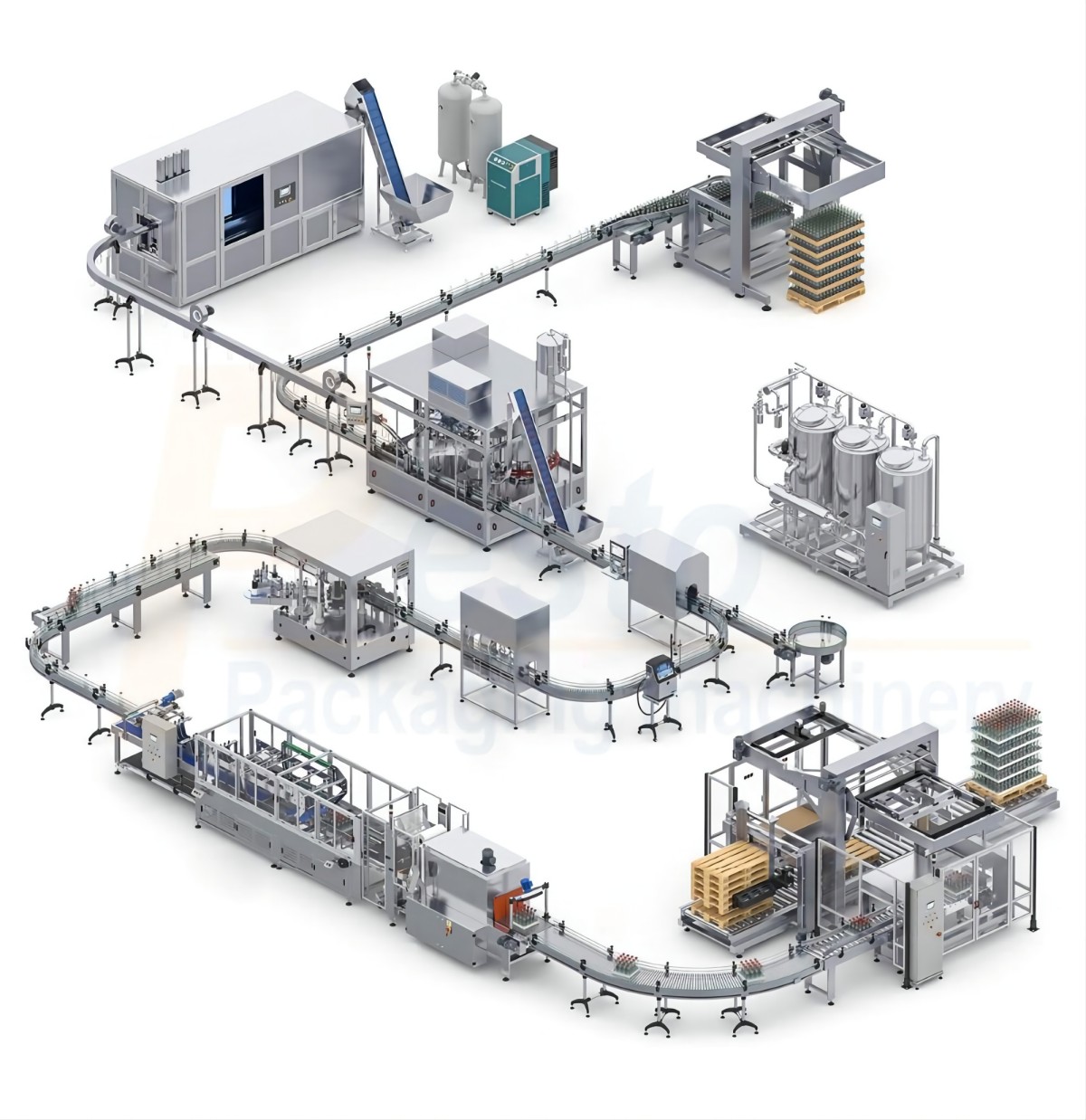

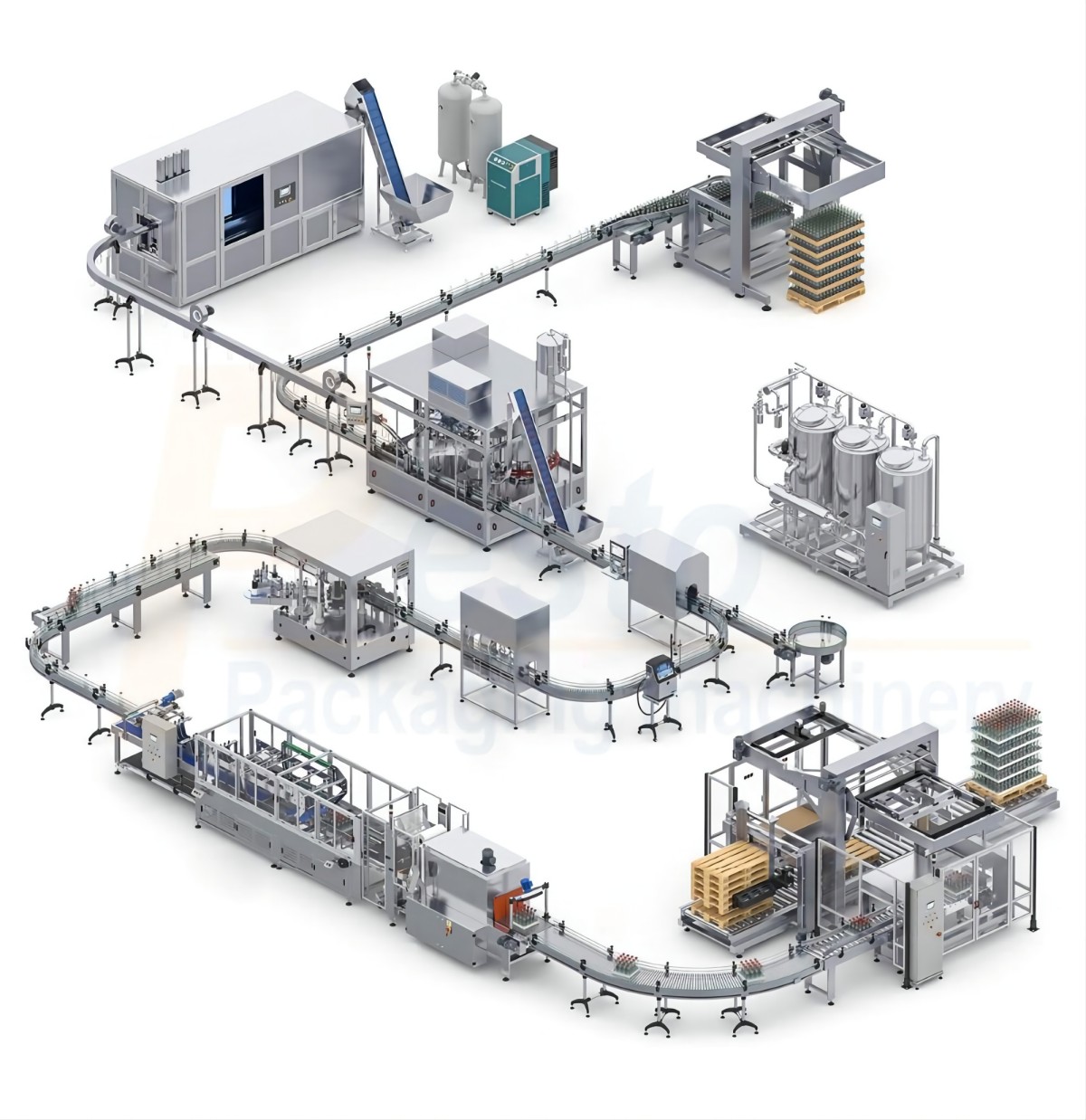

Ihlola imishini yokugcwalisa yebhodlela elizenzakalelayo

Imishini yokugcwalisa e-othomathikhi yebhodlela le-othomathikhi ifanekisela inqwaba yokusebenza kahle kanye nokunemba ezindaweni zesimanje zokukhiqiza. Yakhelwe ngokuqondile ukuthi i-Medium kuya kokuqina okuphezulu, le mishini iye yathuthukiswa ukuphatha amavolumu aphezulu ngejubane nokunemba okungenakuqhathaniswa. Ukudluliswa kwezikhalazo okuzenzakalelayo kwemishini yokugcwalisa okuzenzakalelayo kutholakala emandleni abo okusebenzisa yonke inqubo yokukhiqiza, kusukela ebhodleleni lokuqala ebhodleleni kukopela kokugcina nokubekwa uphawu. Lokhu okuzenzakalelayo kunciphisa kakhulu isidingo sokungenelela okwenziwa ngesandla, okuvumela amabhizinisi ukufezekisa ukuvumelana okukhulu namazinga okukhishwa aphezulu anokusebenza okuncane.

Izici ezibalulekile zemishini ezenzakalelayo

Ukusebenza okuzenzakalelayo ngokuphelele

Imishini yokugcwalisa yamabhodlela azenzakalelayo, kufaka phakathi Umshini wokugcwalisa weSauce , wenzelwe ukuhambisa yonke inqubo yokugcwalisa, eqeda isidingo sokungenelela okwenziwa ngesandla. I-automation iqala ekuqaleni komugqa wokukhiqiza, lapho amabhodlela angenalutho enziwa ngokuzenzakalelayo ohlelweni lokuhambisa. Ukusuka lapho, amabhodlela ahamba esigabeni ngasinye senqubo yokugcwalisa - esenziwe kahle ngaphansi kokugcwaliswa kwama-nozzles, agcwele inani eliqondile lesoso, eliboshwe, eliboshwe, elivaliwe, futhi noma elibhalwe ngesandla.

Ukusebenza kwawo wonke emishini yokugcwalisa yeSauce kulawulwa yi-software eyinkimbinkimbi nezinhlelo zehardware, njengezilawuli ze-logic ezihlekisayo (ama-PLCs) nezindawo zomshini wabantu (HMIS). Lezi zinhlelo zivumelanisa izigaba ezahlukahlukene zenqubo ukuqinisekisa ukukhiqizwa okubushelelezi nokusebenzayo. Lokhu kusebenza okuzenzakalelayo ngokuphelele akugcini ngokusheshisa inqubo yokukhiqiza kepha futhi kunciphisa amathuba okuba nephutha lomuntu, okungaholela ekungathobekisweni, ukuchitheka, noma ukungcoliswa, ikakhulukazi esigabeni sezinto ezinkulu ezinjengesoso.

Ngokushintsha le misebenzi, amabhizinisi asebenzisa imishini yokugcwalisa yeSauce angathola umkhiqizo ophakeme, gcina amazinga aphezulu ekhwalithi, futhi anciphise izindleko zabasebenzi. Le mishini ilungele izimboni ezidinga ukuphatha imikhiqizo ebonakalayo efana nososo, lapho ukugcwaliswa okunembile nokungaguquki kubalulekile ukuze kuqinisekiswe ubuqotho bomkhiqizo nokwaneliseka kwamakhasimende.

Ukunemba okuphezulu

Enye yezinto zokusukuma zemishini yokugcwalisa ezenzakalelayo yikhono labo lokuletha ukunemba okuphezulu kuwo wonke amabhodlela agcwele. Le mishini ifakwe izinzwa ezithuthukile, amamitha okugeleza, kanye nezinhlelo zokulawula ezibheka futhi zilawule inani loketshezi olukhishwe ebhodleleni ngalinye ngokunemba kwenkomba. Izinzwa ziqinisekisa ukuthi uketshezi luhanjiswa ngenani elifanele nokuthi ibhodlela ngalinye lithola inani eliqondile elishiwoyo, noma ngabe kuyinto encane yoketshezi lwezemithi noma isitsha esikhulu sokuhlanza. Ukunemba okuphezulu kwale mishini kunciphisa imfucuza yomkhiqizo, ngoba kunengozi encane yokugcwala noma amabhodlela angaphansi komhlaba. Lokhu akusizi nje kuphela ekugcineni ukuguquguquka komkhiqizo kepha futhi nokunamathela kumazinga alawulayo lapho i-dosing eqondile ibaluleke kakhulu. Ngaphezu kwalokho, ukucaca okuphezulu kunciphisa isidingo sokulungiswa kwangemva kokugcwalisa noma amasheke asezingeni, okuvumela ukugcwala ngokushesha kanye nokusebenza kahle okuphezulu.

Inkalala

I-Scalability iyisici esibalulekile semishini yokugcwalisa ibhodlela e-othomathikhi, ibenze babe ukukhetha okuhle kwamabhizinisi akhulayo noma imisebenzi emikhulu. Le mishini yenzelwe ukuhlanganiswa kalula emigqeni yokukhiqiza ekhona, ivumela ukunwetshwa komthungo njengoba ukukhiqizwa kwezidingo zokwenyuka. Noma ngabe udinga ukwengeza amakhanda wokugcwalisa amaningi ukwandisa inani lamabhodlela agcwaliswe ngomzuzu noma ahlanganise amamojula angeziwe wokugcwala, ukulebula, noma imishini esebenza ngokuzenzakalela kunikeza ukuguquguquka kokubhekana nokuphazamiseka okukhulu kwinqubo yokukhiqiza. Idizayini evumelanayo yemishini eminingi yokugcwalisa ezenzakalelayo isho ukuthi amabhizinisi angaqala ukusetha okuyisisekelo futhi kancane kancane athuthukise uhlelo njengoba izidingo zabo zivela. Lokhu kukhubazeka kuyinzuzo ikakhulukazi ezimbonini lapho kukhiqizwa khona ukukhiqizwa kungashintshashintsha ngenxa yesidingo sonyaka noma ukukhula kwemakethe. Ngokwengeziwe, amandla okuphatha amavolumu amakhulu amabhodlela anokuphumula okuncane aqinisekisa ukuthi amabhizinisi angahlangabezana nemigomo yokukhiqiza ephezulu ngenkathi egcina ukusebenza kahle nekhwalithi yomkhiqizo. Ukukhululeka kwesikali nakho kubuye kube ngekusasa - ubufakazi bokutshala imali, njengoba umshini ungakhula eceleni kwebhizinisi ngaphandle kwesidingo semishini emisha ngokuphelele.

Izinzuzo zemishini ezenzakalelayo

Ijubane lokukhiqiza elikhulayo

Enye yezinzuzo eziphoqelelayo kakhulu zemishini yokugcwalisa e-othomathikhi yebhodlela le-othomathikhi amandla abo okusebenza ngesivinini esikhulu kakhulu, okuphelelwe yincwajana noma okuzenzakalelayo. Ngokuya ngomshini womshini nohlobo lomkhiqizo olugcwalisiwe, imishini ezenzakalelayo ingacubungula amakhulu ezinkulungwaneni zamabhodlela ngehora. Lokhu kunamandla kubalulekile kumabhizinisi adinga ukufeza ama-oda amakhulu ngokushesha nangendlela efanelekile, ikakhulukazi ezimbonini lapho ukufunwa khona kungashintsha kungazelelwe, njengasesikhathini se-Precist. Ukusebenza okusheshayo kwemishini ezenziwe nge-othomathikhi kutholakala ngokuhlanganiswa kwezinhlelo ezithuthukile zokuhambisa, iziteshi zokugcwaliswa kwekhanda eliningi, nokukhokhwa okuvumelanisiwe kanye nokulebula amamojula, wonke umsebenzi wokuvumelana kokwandisa ukukhishwa. Leli jubane lokukhiqizwa okusheshayo alisize nje kuphela amabhizinisi agcine izikhathi zokuhola ancintisanayo kodwa futhi abenze bakwazi ukukala imisebenzi yabo ngaphandle kwesidingo semishini noma yabasebenzi. Ngenxa yalokhu, amabhizinisi angahlangabezana nesikhathi esiphansi, afeze ama-oda amakhulu, futhi ekugcineni akhulise isabelo sawo semakethe ngokukwazi ukuletha imikhiqizo ngokushesha kunabantu abancintisana nabo phansi, izinqubo eziningi ezenziwa ngesandla.

Isimo esivumelanayo

Ukungaguquguquki kwekhwalithi yomkhiqizo kuyitshe lesisekelo sanoma yikuphi ukusebenza ngempumelelo kokukhiqiza, kanye nemishini yokugcwalisa okuzenzakalelayo, kufaka phakathi Umshini wokugcwalisa iLotioon , u-Excel kule ndawo ngokuqinisekisa ukuthi ibhodlela ngalinye ligcwele inani eliqondile le-ketshezi, i-batch ngemuva kwe-batch. Ukunemba kwemishini yokugcwaliswa kwe-lotion kusekelwe ekusebenziseni kwabo izinzwa ezithuthukisiwe, amamitha okugeleza, nezinhlelo zokulawula ezenzakalelayo ezibheka futhi zilungise inqubo yokugcwalisa ngesikhathi sangempela. Le automation iqeda ukuhlukahluka okukhona ekugcwalisweni kwesandla, lapho ukungafani ngendlela ye-opharetha noma ukukhathala kungaholela ekungathobeki emazingeni okugcwalisa.

Ngomshini wokugcwalisa we-lotion othomathikhi, wonke amabhodlela agcwele ukucaciswa okuqondile, ehlisa ubungozi bokugcwala ngokweqile noma ukugcwala ngokweqile, okungaholela ekungcoleni komkhiqizo, izindaba zokulawula, noma ukunganeliseki kwamakhasimende. Ikhwalithi engaguquki ibaluleke kakhulu ezimbonini ezinjengezimonyo, lapho i-dosing eqondile ye-lotions nokhilimu ibalulekile ekuqinisekiseni ukusebenza komkhiqizo nokuhlangana okulindelwe kwamakhasimende.

Ngokugcina ukufana kuyo yonke imikhiqizo, imishini yokugcwaliswa kwe-lotion okuzenzakalelayo isiza amabhizinisi ukwakha nokugcina idumela labo lomkhiqizo ukuze lithembeke nekhwalithi, ekugcineni liholela ekuthembekeni kwamakhasimende okukhulu kanye nokwethembeka. Le mishini idlala indima ebalulekile ekugcineni ubuqotho bomkhiqizo kanye nokuqinisekisa ukuthi iyunithi ngalinye lihlangabezana nezindinganiso eziphakeme ezilindelwe embonini yezimonyo.

Ukusebenza kahle kwezabasebenzi

Ukusebenza kahle kwezabasebenzi kungenye inzuzo ebonakalayo yemishini yokugcwalisa yamabhodlela azenzakalelayo. Ngokushintsha inqubo yokugcwalisa, amabhizinisi anganciphisa kakhulu ukuthembela kwawo emsebenzini wezandla, okungagcini nje ngokuphuza izindleko ezisebenzayo kodwa futhi kunciphisa ubungozi obuhambisana nephutha lomuntu. Kwisethaphu yencwajana noma i-semi-othomathikhi, abahlinzeki babhekele imisebenzi efana namabhodlela okuma, abalawula ivolumu yokugcwalisa, kanye nokukhonkotha imisebenzi ngayinye-imisebenzi ephindaphindwayo, edla isikhathi, futhi ithambekele emaphutheni. Imishini ezenzakalelayo, ngakolunye uhlangothi, phatha le misebenzi ngokuzimela, ukuvumela amabhizinisi ukuthi ahlele kabusha abasebenzi abo ezindimeni zamasu athe xaxa, njengokulawulwa kwekhwalithi, ukulungiswa, noma inqubo yokwenza inqubo. Lokhu kuncishiswa kwabasebenzi akugcini nje ngokunciphisa izindleko ezikhokhelwa kepha futhi kuthuthukisa ukusebenza kahle emsebenzini ngokunciphisa isikhathi sokuphumula esihambisana nokungenelela komuntu. Ngaphezu kwalokho, njengoba izindleko zabasebenzi ziyaqhubeka ukukhuphuka ezingxenyeni eziningi zomhlaba, imali ekhokhwayo yesikhathi eside etholwe nge-automation ingaba yinto enkulu. Ngokwengeziwe, ukuncishiswa kokuphathwa komuntu kunciphisa ubungozi bokungcola, ikakhulukazi ezindaweni ezinyumba noma ezihlangethwe egumbini lokuhlanza, ukuthuthukisa ikhwalithi yomkhiqizo nokuphepha.

Okubi kwemishini ezenzakalelayo

Izindleko Eziphezulu Zokuqala

Ububi obuseduze kakhulu futhi obunzima kakhulu bemishini yokugcwalisa yamabhodlela azenzakalelayo yizindleko zabo eziphakeme zokuqala. Le mishini ifakwe ubuchwepheshe obuthuthukisiwe, kufaka phakathi izinzwa ezizenzakalelayo, abalawuli abahlekisayo (ama-PLCs), iziteshi zokugcwaliswa ezinamakhanda amaningi, nokukhonkotha okuhlangene kanye nokulebula kwezinhlelo. Leli zinga lobuciko kanye ne-automation liza nethegi elibalulekile lentengo, okwenza ukutshalwa kwemali okuphezulu kakhulu kunalokho kwemishini yezandla noma ye-semi-othomathikhi. Ngamabhizinisi amancane, ama-Startups, noma izinkampani ezine-capital elilinganiselwe, lokhu kungaba yisithiyo esikhulu ekungeneni. Ukuzibophezela kwezezimali okudingekayo ukuthenga umshini othomathikhi kufaka hhayi kuphela izindleko zoMshini uqobo kodwa nezindleko ezingaba khona ezihlobene nokufakwa, ukuhlanganiswa nemigqa yokukhiqiza ekhona, kanye nokuqeqeshwa komqhubi wokuqala. Ngokwengeziwe, i-ROI (Buyela ekutshalweni kwemali) ngomshini onjalo kungathatha isikhathi ukubona, ikakhulukazi uma ukukhiqizwa kungamandla kangako kungavumeli ngokushesha isikali sotshalomali. Amabhizinisi amancane kufanele ahlole ngokucophelela izidingo zabo zokukhiqiza isikhathi eside kanye nezinsizakusebenza zezezimali ngaphambi kokuzibophezela ekuthengeni okubaluleke kakhulu, njengoba izindleko eziphezulu zokuqala zingahle zizincine ukuqina kwezimali.

Ukusebenza okuyinkimbinkimbi nokulungiswa

Ubunzima bemishini yokugcwalisa okuzenzakalelayo, kufaka phakathi Umshini wokugcwalisa amanzi , kungenye into ephawuleka kahle, ikakhulukazi ngokuya ngokusebenza nokunakekelwa. Ngokungafani nemishini ebhaliwe, eqondile futhi okulula ukuyisebenzisa, imishini yokugcwalisa kwamanzi okuzenzakalelayo idinga opharetha abanamakhono abaqeqeshelwe ukuphatha izilawuli ezithuthukile nezinhlelo zesoftware elawula imisebenzi yomshini. Lokhu kuvame ukubandakanya ijika lokufunda eliphakeme, lapho abasebenza khona kufanele babe nekhono ekuxazululeni inkinga, uhlelo, kanye nokwenza kahle umshini wokuqhuba ukukhiqiza okuhlukile.

Ngaphezu kobunzima bokusebenza, ukugcinwa kwemishini yokugcwalisa amanzi kuyadingeka kakhulu. Ukulungiswa okujwayelekile kubalulekile ukuze kuqinisekiswe ukuthi umshini usebenza ekusebenzeni okuphezulu, futhi lokhu kuvame ukudinga ulwazi namathuluzi akhethekile. Izakhi ezithuthukile, njengezinzwa, ama-PLC, nezingxenye zezimoto, zidinga ukulinganisa ngokucophelela nokusebenza njalo ukuvikela ukungasebenzi kahle. Noma yisiphi isikhathi sokulungiswa noma ukulungisa kungabizi nangesikhathi sokudla, njengoba amabhizinisi angadinga ukuletha ochwepheshe abakhethekile noma athenge izingxenye zokubuyiselwa ezibizayo.

Ngaphezu kwalokho, ukwephuka okungalindelekile emishini yokugcwalisa amanzi kungaholela ekubambezeleni okubalulekile kokukhiqiza, okungaba yingozi ikakhulukazi kumabhizinisi asebenza amashejuli aqinile noma afeze ama-oda amakhulu. Ukuqinisekisa ukuthi umshini ugcinwe kahle futhi usebenza kubalulekile ukugwema ukuphazamiseka okubiza izindleko futhi uqhubeke nokukhiqiza kusebenza kahle.

Izidingo zesikhala

Imishini yokugcwalisa e-othomathikhi ye-othomathikhi ngokuvamile ikhudlwana futhi iyinkimbinkimbi kakhulu kunabalingani babo bencwadi ebhaliwe noma okuzenzakalelayo, okuholela ezifulekeni zesikhala. Le mishini ivame ukuza namamojula angezekile emisebenzi efana nokukhonkotha, ilebula, kanye nokupakipha, okubuye kukhulise ngaphezulu kwezinyawo zazo. Kumabhizinisi anendawo yokukhiqiza elinganiselwe, indawo yokuhlala umshini othomathikhi kungaba inselelo yokungena. Isidingo sesikhala esanele sidlulela ngale kwezindlu nje kuphela umshini uqobo; Kubandakanya nokucatshangelwa kokusebenza okuphephile, ukufinyelela kwesondlo, kanye nokunyakaza kwezinto ezizungeze indawo yokukhiqiza. Kwezinye izimo, amabhizinisi angadinga ukukhipha kabusha phansi kwawo ukukhiqiza, athumele eminye imishini, noma andise izindawo zawo ukudala isikhala esidingekayo somshini ozenzakalelayo. Lokhu kungaholela ezindlekweni ezengeziwe kanye nokuphazamiseka okungaba khona ekukhiqizweni ngesikhathi soguquko. Izinkampani ezisebenza ezindaweni zasemadolobheni lapho impahla yangempela isendaweni yeprimiyamu, noma yalabo abanezingqinamba zesikhala ezikhona, okwenza kube nzima ukucacisa ukutshalwa kwemali naphezu kwezinzuzo ezingaba khona ukusebenza kahle nokukhiqiza.

Ukucatshangelwa okubalulekile lapho ukhetha phakathi kwemishini yezandla nezenzakalelayo

Ukukhetha umshini wokugcwalisa we-liquid Bottle Feging kuyisinqumo esibalulekile esingathinta kakhulu ukusebenza kahle kwebhizinisi lakho, isakhiwo sezindleko, kanye nekhono lokukala. Noma ngabe ukhetha umbhalo noma umshini ozenzakalelayo uncike ezicini eziningana, ngalinye lidlala indima ebalulekile ekuvumelaniseni amakhono omshini wakho ngezidingo zebhizinisi lakho. Ngezansi kucatshangelwa okusemqoka okufanele ukukhumbula lapho unquma phakathi kwencwadi yomshini wokugcwalisa webhodlela othomathikhi.

1. Ivolumu yokukhiqiza

Low to movilevolute, uma ibhizinisi lakho likhiqiza ama-batches amancane noma linemininingwane ephansi yokukhiqiza, umshini wokugcwalisa wemanyuki uvame ukukhetha okusebenzayo kakhulu. Imishini yesandla ilungele imisebenzi lapho izimfuno zokukhiqiza zithobekile, futhi kugxilwe kakhulu ekuguqulekeni nasekulawuleni. Le mishini ivumela abahlinzeki ukuthi baphathe ukukhiqizwa okuncane kwe-Scale kusebenza kahle ngaphandle kwesidingo samakhono aphezulu we-Systems ezenzakalelayo. Lokhu kwenza imishini ebhaliwe ilungele ukuqalwa, abakhiqizi be-artisalal, noma izimakethe ze-niche lapho ikhwalithi nokwenza kubekwe phambili ngevolumu enkulu.

IVolumu ephezulu: Yamabhizinisi anezidingo eziphezulu zokukhiqiza, lapho kudingeka khona amavolumu amakhulu amabhodlela ngokushesha futhi ngokungaguquguquki, umshini wokugcwalisa othomathikhi uyindlela ekhethwayo. Imishini ezenzakalelayo yenzelwe ukubhekana nobunzima bokukhiqizwa kwevolumu ephezulu, enikeza isivinini kanye nokusebenza kahle okudingekayo ukuze kuhlangatshezwane nama-oda amakhulu futhi kugcinwe izikhathi zokuhola. Amandla okugcwalisa amakhulu noma izinkulungwane zamabhodlela ngehora ngalinye kuqinisekisa ukuthi amabhizinisi angahambisana nesidingo semakethe, anciphise isikhathi sokuhola, futhi andise ukuphuma kwawo okuholayo. Lokhu kubaluleke kakhulu ezimbonini ezinjengezimboni ezinjengeziphuzo, amakhamishini kanye nezimonyo, lapho ukukhiqizwa okuphezulu okuvame ukudingekile ukufeza imfuno yabathengi.

2. Isabelomali

Isabelomali Esilinganiselwe: Kumabhizinisi anezabelomali eziqinile noma lezo ziqala nje, imishini yokubhubha inikeza isixazululo esingabizi kakhulu. Ukutshalwa kwemali okuphansi okuphansi okudingekayo kumshini wokugcwalisa wemanyuwali kuvumela amabhizinisi ukuthi abele izinsizakusebenza ngokwezentengiso, njengokumaketha, ukuthuthukiswa komkhiqizo, noma ukuphathwa kokusungula. Imishini yokubhukelwa ibuye ibe nezindleko eziphansi zokulungiswa futhi ilula ukusebenza, okungaqhubeka nokunciphisa izindleko. Lokhu kubenza babe inketho ekhangayo yamabhizinisi amancane noma asebenza ezimakethe anezinzuzo zenzuzo encane.

Esikhulu Isabelomali Ngenkathi ukutshalwa kwezimali kokuqala kuphakeme, i-ROI ingaba yinto enkulu, ikakhulukazi amabhizinisi anezinhlobo eziphakeme zokukhiqiza. Imishini ezenzakalelayo yehlisa isidingo sabasebenzi bezandla, izinqubo zokukhiqiza ezihamba phambili, futhi iqinisekise ikhwalithi yomkhiqizo engaguquki, konke okunomthelela ekuzuzeni inzuzo ephezulu ngokuhamba kwesikhathi. Kumabhizinisi anezifiso zokukhula, ukutshala imali ngomshini ozenzakalelayo kusukela ekuqaleni kungavimba nesidingo sokuvuselelwa okubizayo noma ukushintshwa kwezikali.

3. Izinhlobonhlobo zemikhiqizo

Izinhlobonhlobo eziphakeme: Uma ukukhiqizwa kwakho kubandakanya uhla olubanzi lwamabhodlela, amajamo, noma izinhlobo zomkhiqizo, umshini wezandla ungahlinzeka ukuguquguquka okuphezulu. Imishini yokubhukwa ivumela abasebenza ngokushintshana kalula phakathi kwemikhiqizo ehlukene kanye nokulungisa ukugcwalisa amavolumu njengoba kudingeka ngaphandle kokuthola kabusha okuningana. Lokhu kuvumelana nalokhu kuzuzisa ikakhulukazi amabhizinisi akhiqiza imikhiqizo yangokwezifiso noma enqunyelwe, lapho amasayizi we-batch kanye nemininingwane yomkhiqizo ingahluka kakhulu. Amandla okuvumelana ngokushesha nezidingo ezihlukile zokukhiqiza enza imishini yezandla ibe inketho eguquguqukayo yamabhizinisi anemigqa yomkhiqizo ehlukahlukene.

Izinhlobo eziphansi: Ngemikhiqizo esezingeni elifanele ngosayizi webhodlela ongaguquki kanye nokugcwalisa izidingo, umshini othomathikhi ungahambisa kahle inqubo yokukhiqiza. Lapho setha, imishini ezenzakalelayo ingagcwalisa ngokungaguquki kwamabhodlela amakhulu afanayo ngokuhluka okuncane, ukuqinisekisa ukufana nokunciphisa isidingo sokulungiswa. Lokhu kuvumelana kubalulekile ekugcineni kwekhwalithi yomkhiqizo kanye nokuhlangana namazinga okulawula, ikakhulukazi ezimbonini ezinjengezimboni kanye nokudla kanye nesiphuzo. Imishini ezenzakalelayo futhi ivumela izikhathi zokukhiqiza ezisheshayo, ukuzenza zilungele amabhizinisi akhiqiza amavolumu amakhulu omkhiqizo owodwa noma abe nohlobo olulinganiselwe lweminikelo.

4. Ukutholakala Kwezabasebenzi

Ukutholakala Kwezabasebenzi: Uma ibhizinisi lakho lithola umsebenzi onokwethenjelwa futhi amakhono, umshini wezandla kungaba inketho ephumelelayo. Imishini yesandla incike kubahlinzeki ngabantu ukwenza inqubo yokugcwalisa, ngakho-ke ukuba nokuhlinzekwa okuqhubekayo kwabasebenzi abaqeqeshiwe kubalulekile ukuze kugcinwe ukusebenza kahle kokukhiqiza. Ezifundeni lapho izindleko zabasebenzi ziphansi, noma lapho kunesiko lobuciko obunamakhono, imishini yezandla ingaba yindlela ebiza kakhulu futhi esebenzayo. Ngokwengeziwe, imishini yezandla ingadala amathuba emisebenzi, okungenzeka ukuthi kucatshangelwa amabhizinisi anakalisayo asekela umsebenzi wendawo.

Abasebenzi abalinganiselwe: Uma izindleko zabasebenzi ziphezulu, noma uma ibhizinisi lakho lilwa nokutholakala kwabasebenzi, umshini othomathikhi ungasiza ukunciphisa ukuncika kwakho kubasebenzi bezandla. Imishini ezenzakalelayo idinga abaqhubi abambalwa futhi ingaqhubeka nokugijima kahle ngokugadwa okuncane. Lokhu kuzuzisa kakhulu ezifundeni lapho ukushoda kwabasebenzi kuvame, noma lapho izindleko zokuqashwa nokuqeqesha abasebenzi zibiza kakhulu. Ngokunciphisa isidingo sabasebenzi bezandla, imishini ezenzakalelayo nayo ingasiza ekunciphiseni ubungozi obuhambisana nenhlawulo yabasebenzi, ukungahambi kahle, kanye nokuhlukahluka kokusebenza, okuholela emiphumeleni yokukhiqiza engaguquki.

5. Ukunwetshwa okuzayo

Izidingo zesikhashana zesikhashana: Uma ibhizinisi lakho lisezigabeni zokuqala zentuthuko noma uma ukukhula okuzayo kungaqinisekile, kucatshangelwa a Umshini wokugcwalisa uketshezi othengiswayo , ikakhulukazi incwadi yezandla, kungaba ukutshalwa kwezimali okuphephile, okuyingozi. Imishini yokubhukelwa ngokuvamile ibiza kakhulu futhi inikezela ukuguquguquka kokuphatha imikhiqizo ehlukahlukene ngaphandle kwesidingo sokuvuselelwa okuyinkimbinkimbi. Lokhu kuvumela amabhizinisi ukuthi agxile ekwakheni ubukhona bemakethe abo futhi acwengeke imikhiqizo yawo ngaphandle kokuzibophezela kwizindleko ezibalulekile zohlelo oluzenzakalelayo. Kumabhizinisi ahlola amamaki amasha noma imikhiqizo, umshini wokugcwalisa uketshezi owukuthengiswa okuthengiswayo kunikeza ukuguquguquka okuhlukahlukene ukuze uvumelane nezidingo ezishintshayo ngaphandle kwengcindezi yokulinganisa ngokushesha okukhulu.

Ukukhula kwesikhathi eside: Uma ucabanga ukuthi ukukhula okubalulekile kumandla akho okukhiqiza noma ukufunwa kwemakethe, ukutshala imali emshinini othoma othomathikhi othengiswayo kusukela ekuqaleni kungagcina isikhathi sebhizinisi lakho. Imishini ezenzakalelayo yenzelwe ukukala, okuvumela amabhizinisi ukukhulisa amandla okukhiqiza ngaphandle kwesidingo semishini eyengeziwe noma yabasebenzi. Lokhu kukhubazeka kubaluleke kakhulu kumabhizinisi anamasu omude wokukhula, ngoba kubenza bakwazi ukufeza ukufunwa okwandayo ngaphandle kokuphazamiseka. Ngokutshala imali e-automation kusenesikhathi, amabhizinisi angazibeka empumelelweni yesikhathi esizayo, aqinisekise ukuthi amakhono abo okukhiqiza angahambisana nezinhloso zawo zokunwebeka.

Ngokuhlola umshini wokugcwalisa owuketshezi ofanele wokuthengisa ohambelana nezidingo zakho zamanje nezebhizinisi lakho, ungaqinisekisa ukulingana phakathi kweziguqukinhlobo nasekusebenzeni kahle, ukubeka inkampani yakho ukukhula okuqhubekayo.

Isiphetho: Ukwenza ukukhetha okulungile kwebhizinisi lakho

Isinqumo phakathi komshini wokugcwalisa ibhodlela we-audiol othomathikhi awusiwona usayizi owodwa. Kuya ngezici ezahlukahlukene kufaka phakathi ivolumu yakho yokukhiqiza, isabelomali, izinhlobonhlobo zomkhiqizo, kanye nezinhloso zebhizinisi lesikhathi eside. Imishini yokubhukwa inikeza ukufinyeleleka, ukuguquguquka, kanye nokulungiswa kalula, okwenza kube yinto elungele amabhizinisi amancane noma lezo ezinezidingo ezikhethekile. Ngakolunye uhlangothi, imishini ezenzakalelayo ihlinzeka ngesivinini, ukunemba, kanye nokusebenza kahle, kubenza babalulekelwe imisebenzi emikhulu ngezidingo eziphezulu zokukhiqiza.

Ngokuhlola ngokucophelela izidingo zakho ezithile nezinhlelo zesikhathi esizayo, ungakhetha umshini ongeke uhlangabezane nezidingo zakho zamanje kodwa futhi usekele ukukhula kwebhizinisi lakho nempumelelo. Noma ngabe ukhetha ukufakwa kwezandla noma okuzenzakalelayo, ukutshala imali emshinini wokugcwalisa we-liquid Bottle Bottle kuyisinyathelo esibalulekile ekwakheni inqubo yakho yokukhiqiza futhi ulethe imikhiqizo esezingeni eliphakeme kumakhasimende akho.

Ngemininingwane engaphezulu ngemishini yokugcwalisa ibhodlela ye-Liquid Bottle noma ukuhlola uhla lwethu lwemikhiqizo, thintana Pestpack namuhla. Ochwepheshe bethu bakhona ukukusiza ekutholeni ikhambi elifanele lezidingo zakho zebhizinisi.