Namathisela ukusetshenziswa komshini wokugcwalisa

Namathisi wokugcwalisa wokugcwalisa yimishini ekhethekile yokugcwalisa iziqukathi ezinama-pastes aminyene, ama-viscous kanye nama-semi-ketshezi. Le mishini yokunamathisela ye-paller yenzelwe ukuhambisa ngokunembile futhi igcwalise iziqukathi ngezinto ezinjengezinto ezinjengamakhilimu, ama-gels, ama-pastes, ama-pastes, nemikhiqizo efanayo. Namathisela yinto enobukhulu, ewuketshezi ngokujwayelekile inokuvunywa okuphezulu. Kubalulekile ukuqaphela ukuthi amanani we-viscosity angahluka kakhulu ngokususelwa ezintweni ezifana nokushisa, izinga lokugunda, kanye nokwakhiwa okuthile. Amabanga alandelayo ahlinzeka ngombono ojwayelekile wokuhlukaniswa kwe-viscosity kwama-pastes ahlukahlukene okudla.

I-Viscusity ephansi:

Amasoso amancanyana: I-Viscosity ebangeni le-5 - 100 CP (centipoise). Izibonelo zifaka isoso elishisayo kanye nokugqoka kwesaladi elikhanyayo.

I-Salsas: Ukuvunywa kububanzi obungu-50 - 500 cp. Ama-Salsas anama-chunks amancane athambekele ekupheleni kwalolu banga.

I-DIPS: I-Viscosity ebangeni le-100 - 1000 cp. I-Creamy Dips efana ne-yogurt-based dips dips fall kuleli banga.

I-Contiments: I-Viscosity ebangeni le-100 - 2000 cp. Amacebiso ajwayelekile afana ne-ketchup kanye nesinaphi kufanelekile lapha.

Ama-viscosity aphakathi:

Ama-Curry Mathses: I-Viscosity ebangeni le-1000 - 5000 CP. Lawa ma-pastes akhulu futhi agxile kakhulu.

I-Pesto: I-Viscosity ebangeni le-1000 - 5000 cp. Okuqukethwe kwe-nati kanye no-kayela kunomthelela kulolu banga.

Ama-Fruit Compotes: I-Viscosity ebangeni le-1000 - 10,000 CP. Izithelo eziphekiwe ku-syrup ziwela ngaphakathi kwalesi sigaba.

Ukugcwalisa ama-pastes: I-Viscosity ebangeni le-1000 - 10,000 CP. Lokhu kungafaka i-alimond paste kanye nokugcwaliswa kwezithelo.

I-Visposity ephezulu:

I-NAT Butter: I-Viscosity ebangeni le-10,000 - 100,000 CP. Amantongomane aphansi emhlabathini anikela ngokuguquguquka okuminyene nokusabalaleki.

Ukusakazwa koshokoleti: Ukuvunywa kububanzi be-10,000 - 100,000 CP. Ukusakazwa koshokolethi kubukhulumane ngenxa yenhlanganisela ye-chocolate namafutha.

I-Miso Paste: I-Viscosity ebangeni le-10,000 - 100,000 CP. Inqubo yokuvutshelwa inomthelela ekuboneni okuphezulu.

I-Fish Paste: I-Viscosity ebangeni le-10,000 - 100,000 CP. I-Fish Paste esetshenziswe emigqeni yase-Asia iwubukhulu obukhulu ngenxa yenhlanganisela yezinhlanzi nezinye izithako.

Ukuqondanisa ama-Ingteents kanye nokubonana kwe-passe ne- Umshini wokugcwalisa weSauce ubalulekile ekukhiqizweni okusebenzayo nokunembile. Kuqinisekisa ukuthi ukunamathisela kusatshalaliswa kahle emabhodleleni, kunciphise ukungcola nokugcina ikhwalithi yomkhiqizo.

Imishini ehlukile yokugcwalisa ukuthengisa

Namathisela imishini yokugcwalisa ethengiswa yimishini ebalulekile emikhakheni ehlukahlukene yezimboni ezinemikhiqizo elungiselelwe ngokunembile enemikhiqizo emikhulu, ebonakalayo, kanye ne-semi-ketshezi. Le mishini yokugcwalisa okuzenzakalelayo ingena ezinhlotsheni ezahlukahlukene kanye nokucushwa ukuze kubhekwe kwi-viscosities ehlukene yomkhiqizo, osayizi beziqukathi, amavolumu okukhiqiza, kanye nezidingo ezithile zohlelo lokusebenza.

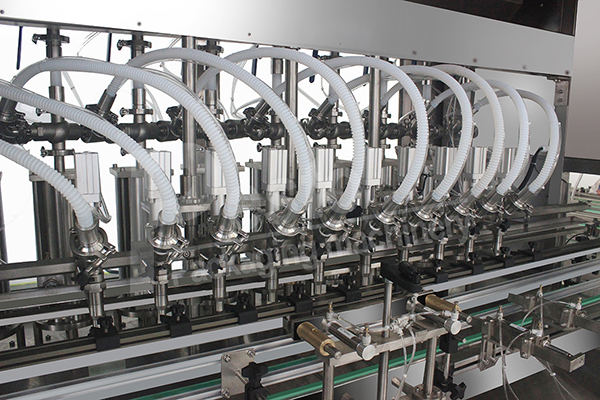

1. Ukugcwalisa umshini wokunamathisela uketshezi

Namathisela imishini yokugcwalisa uketshezi Sebenzisa indlela ye-piston ne-cylinder ukudweba nokukhipha umthamo oqondile womkhiqizo ezitsheni. I-piston iqhutshwa amandla e-pneumatic noma kagesi. Kuyinto imishini efanelekile yemikhiqizo ebonakalayo efana namasoso, okhilimu, ama-gels, kanye ne-lotions. Umshini wokugcwalisa owuketshezi we-pneumatic unama-paste une-ulls enembile futhi ephindaphindwayo, efanelekile yemikhiqizo ephezulu ye-viscosity, kulula ukuyihlanza nokugcina. Thanda Umshini wokugcwalisa uju usebenzisa ubuchwepheshe be-piston.

Umshini wokugcwalisa piston

Ukugcwalisa amakhanda: 4-20 nozzles

Umthamo Wokukhiqiza: 1000-5000bph (500ml)

Ukugcwalisa ivolumu: 50ml-5000ml

Ukugcwalisa ukunemba: ≤0.5%

Phansi ukugcwalisa ukunciphisa igwebu

I-Servo Motor Drayivu

Ukuhlukaniswa okulula nokuhlanza

Okwesoso le-Meduim-Viscosity

2. Ukugcwalisa umshini wokunamathisela okuminyene

Uma kukhulunywa ngokupakisha ama-pastes aminyene futhi aphezulu aphezulu, umshini wokugcwalisa amaphampu we-rotor aqhamuka njengokukhetha okuphezulu. Lo mshini wokugcwalisa wokunamathisela obukhulu unikeza ukunemba, ukusebenza kahle, kanye nokuguquguquka ekusingatheni imikhiqizo esukela kokhilimu kanye nososo kuya kuma-adhesives kanye nama-sealants. Umgomo wokusebenza uhilela i-rotor ephenduke i-stator, edala umgodi oqhubekayo. Le ndlela ephumelelayo futhi idonsa futhi idlulisela ivolumu eqondile yokunamathisela ngokuhluka okuncane. I-viscosity ephezulu yokunamathisela ukunamathisela imishini yokugcwalisa imikhiqizo nge-viscosities ephezulu kakhulu. Ama-pastes abukhulu, ama-gels, kanye nemikhiqizo equkethe izinhlayiya ingagcwaliswa ngempumelelo ngaphandle kokuvalwa noma ukuphazamiseka.

Umshini wokugcwalisa amaphampu e-rotor

Ukugcwalisa amakhanda: 4-12 nozzles

Umthamo Wokukhiqiza: 1000-4000bph (500ml)

Ukugcwalisa ivolumu: 50ml-5000ml

Ukugcwalisa ukunemba: ≤1%

Ukwakhiwa Kwensimbi Engagqwali

Phansi ukugcwalisa ukunciphisa igwebu

Ukuhlukaniswa okulula nokuhlanza

Ngesoso elisindayo-elisindayo

Ukuthi umshini wethu wokugcwalisa we-paste ulungele kanjani umkhiqizo wakho

Umshini wethu wokugcwalisa othomathikhi ozenzakalelayo wholesale Wholesale Wholesale Isixazululo Esithuthukile, Esinembile Sokuhlolisisa Esilungiselelwe Ukuqondisa kanye Nokuthuthukisa Inqubo Yokugcwalisa Yobubanzi Bokuthola Imikhiqizo Ehlukahlukene Nama-Semi-ketshezi. Ngobuchwepheshe be-state-of-the-art kanye nokuzibophezela kwekhwalithi, lo mshini oguquguqukayo uqinisekisa ukugcwaliswa okunembile, okungaguquki, okusebenzayo, okwenza kube yindlela efanelekile yezimboni ezinjengokudla, izimonyo, ezemithi, nokuningi.

Ububanzi

Umshini wethu wokugcwalisa ukunamathisela wenzelwe ukwamukela imikhiqizo ehlukahlukene, kufaka phakathi amasoso, okhilimu, ama-lotion, ama-gel, amafutha, nokuningi. Kuyahluka ngokwanele ukufeza izidingo zezimboni ezahlukahlukene.

Ukunemba nokunemba

Umshini wokugcwalisa we-paste filler womshini oqhutshwa uqinisekisa ukugcwaliswa okungaguquki futhi okunembile, ukunciphisa imfucumfucu yomkhiqizo kanye nokuqinisekisa ukulawulwa kwekhwalithi.

Ukwenza ngokwezifiso

Siyaqonda ukuthi umkhiqizo ngamunye uhlukile. Okokusebenza kwethu okufuywayo koketshezi kungenziwa ngokwezifiso ukufanisa izici ezithile zomkhiqizo wakho, kufaka phakathi izinhlobo zezitsha, osayizi, nezidingo zokugcwalisa.

Ukuhlanzeka nokuhambisana

Yakhelwe ngokuhambisana nengqondo, uhlelo lwethu lokugcwalisa uketshezi kulula ukuluhlanza nokugcina, ukubhekana namazinga okuhlanzeka aqinile ezimboni ezinjengemithi nokudla.

Inkalala

Noma ngabe uyisiqalo ngamabheji amancane noma umenzi osunguliwe onomkhiqizo ophakeme, umshini wethu ungalinganiswa ukuze uhambisane nezidingo zakho zokusebenzisa.

Imininingwane yoMshini Wokugcwalisa Uketshezi

Lokhu kunamathisela uketshezi umshini wokugcwalisa umshini we-PLC Placents PLC, okuhlanganisa ukukhanya, umshini, ugesi, ukuzwela nokubulawa kwe-pneumatic. Umshini wokugcwalisa othomathikhi othomathikhi wamukela i-piston noma i-culor yensimbi engenasici ngaphandle kokulawulwa kwe-servo motor, engathola ukulinganisa okunembile. Ukulungisa ukugcwaliswa kwemininingwane nokufakwa metering kumane nje kuwukuthinta esibukweni. Umshini wokugcwalisa ibhodlela webhodlela unesakhiwo esilula, ukusebenza okulula nokuhlanza.

Izinzuzo zokunamathisela umshini wokugcwalisa

Ukusebenza kahle okuthuthukisiwe

Sakaza inqubo yakho yokukhiqiza futhi unciphise umsebenzi wezandla ngomshini wethu wokugcwalisa okuzenzakalelayo, ukonga isikhathi nezindleko zabasebenzi.

Ikhwalithi yomkhiqizo ethuthukisiwe

Finyelela ukugcwaliswa okungaguquki nokunembe, okuholela kwikhwalithi yomkhiqizo ephakeme nokwaneliseka kwamakhasimende.

Ukulondolozwa Kwezindleko

Nciphisa imfucumfucu yomkhiqizo, yehlisa izindleko zokulungisa, kanye nezindleko eziphansi eziphelele, okufaka umthelela omuhle emugqeni wakho ongezansi.

Ukuhambisana nokuphepha

Hlangana nemithethonqubo eqondene nomkhakha kanye namazinga okuphepha ngomshini owenzelwe ukuhambisana nokwethembeka komkhiqizo.

Umngcele wokuncintisana

Thola umngcele wokuncintisana emakethe ngokunikeza imikhiqizo ephakeme enekhwalithi engaguquki nokupakisha.

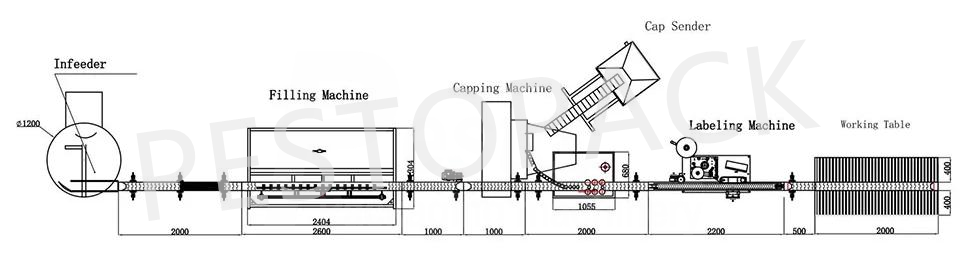

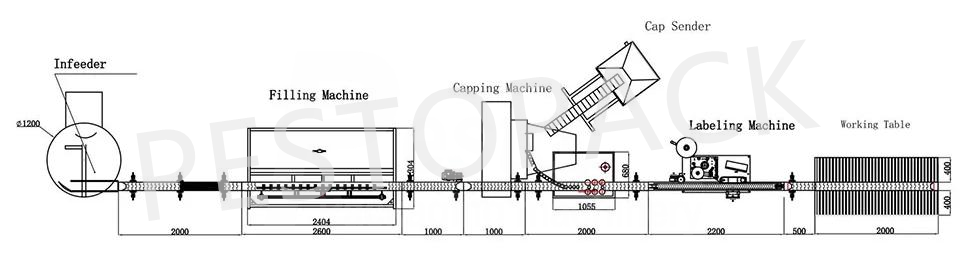

Hlanganisa umugqa wokugcwalisa okuphelele wokunamathisela

E-Pestpack, siyaqonda ukuthi inqubo yokugcwalisa engenamthungo neyosebenza kahle ibalulekile ngezidingo zakho zokukhiqiza. Kungakho sinikezela okungaphezu kokugcwaliswa kwamanzi okugcwaliswa koketshezi ngakunye. Sinikezela ngemigqa yokugcwalisa ephelele ehambisana nezidingo zakho ezithile. Nge-Pestpack, ungathola ikhambi le-turnkey eliqondisa inqubo yakho yokupakisha yokunamathisela, kusukela ekuqaleni kuze kube sekupheleni.

1. Ukubonisana ngokwezifiso:

Inqubo yethu iqala ngokubonisana kahle ukuze uqonde izidingo zakho ezihlukile, ukucaciswa komkhiqizo, nezinhloso zokukhiqiza. Sisebenzisana kakhulu nawe ukuthola imishini efanelekile, ukucushwa kanye nokwakheka kokugcwaliswa kwakho kokugcwaliswa kanye nomshini weplip.

2. Ikhwalithi ephezulu yokugcwalisa imishini:

I-Pestpack inikeza uhla lwemishini yokugcwalisa ewuketshezi ephezulu eyenzelwe ukuphatha izinhlobonhlobo zokunamathisela kwe-viscosities kanye nezinhlobo zezitsha. Kusuka kuma-piston filler kuma-rotor pump fillers, siqinisekisa ukuthi unemishini efanelekile yemikhiqizo yakho ethile.

3. Izinhlelo zokuhambisa:

Ukwenza lula ukugeleza okubushelelezi kweziqukathi ngomugqa wakho wokugcwalisa unamathisela, sinikeza amasistimu wokuhambisa ngokwezifiso. Abahambisi bethu be-veniors benzelwe ukuphatha osayizi abahlukahlukene bezitsha, okwenza inqubo yakho yokukhiqiza isebenze kangcono.

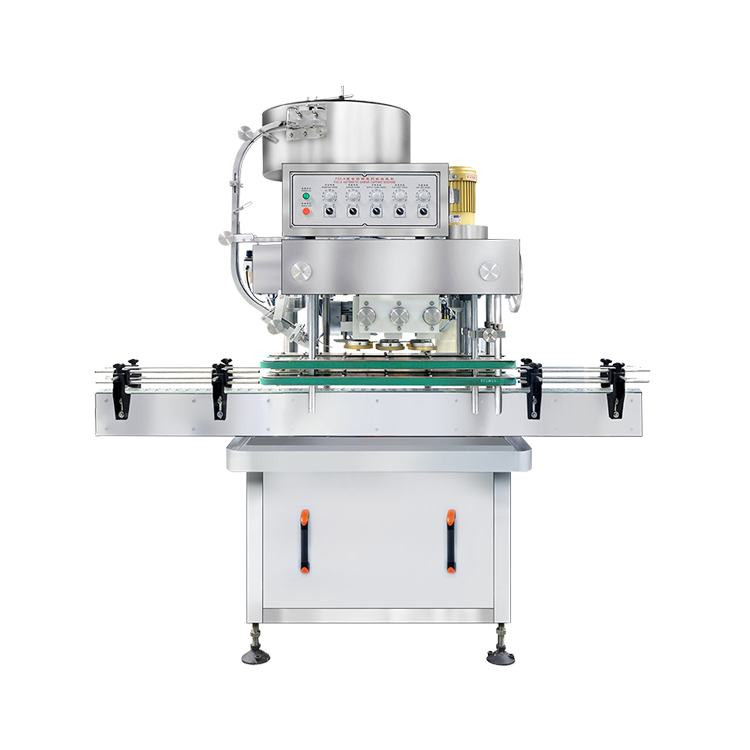

4. Ukugcwala nokubopha:

Ngaphezu kokugcwalisa, imigqa yethu yokugcwalisa yokunamathisela yokunamathisela ingafaka ukugcwala kanye neziteshi zokubopha ukuhlinzeka ngesisombululo esiphelele sokufaka. Sinikeza ngezinto ezahlukahlukene zokukhonkotha kanye nemishini yokubopha uphawu ukuze uhlangabezane nezidingo zakho, uqinisekise ubuqotho bomkhiqizo nokuphepha.

.

5. Ukulebula nokupakisha:

Ukuze uthole ikhambi eliphelele ngempela, i-pestopack ingahlanganisa ilebula kanye nemishini yokupakisha kumugqa wakho wokugcwalisa uketshezi. Lokhu kuqinisekisa ukuthi imikhiqizo yakho ayigcwaliswe ngokunembile kodwa futhi ifakwe amalebula kahle futhi ifakwe ukusatshalaliswa.

I-6. Izinhlelo ezizenzakalelayo kanye nokulawula:

Isixazululo sethu sokugcwalisa ukunamathisela sibonisa ama-automation ashubile kanye nokulawula amasistimu, avumela ukulawulwa okuqondile kwenqubo yokugcwalisa, ukuhlanganiswa okungenamthungo neminye imishini, nokuqapha kwangempela kokukhiqizwa.