Our honey filling machine is designed to automate the process of filling containers, such as jars or bottles, with honey. The operation of the honey filling machine involves several key steps:

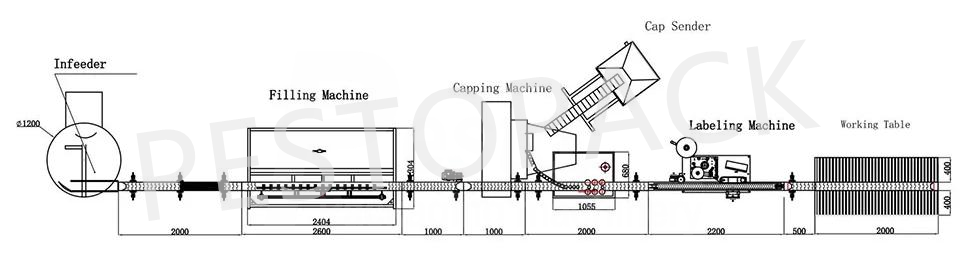

1. Container Placement: Empty containers are loaded onto a conveyor or feeding mechanism that transports them to the filling station.

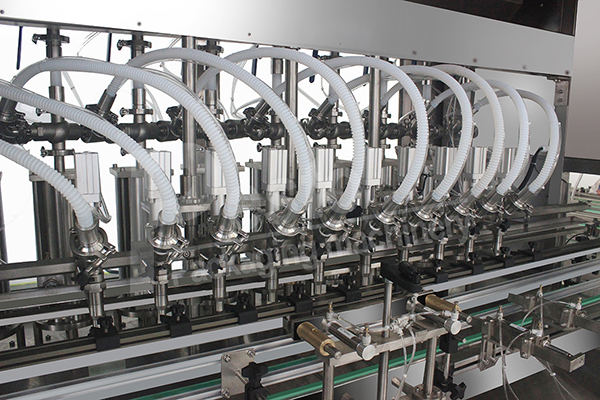

2. Filling Nozzle Setup: At the filling station, the honey filling machine is configured with the appropriate filling nozzles.

3. Honey Reservoir: Honey is stored in a reservoir or holding tank, located above the filling station.

4. Filling Process: The filling nozzles descend to the predetermined fill level inside the containers with pistion filling. A piston within each filling nozzle withdraws to create a vacuum, drawing honey into the nozzle.

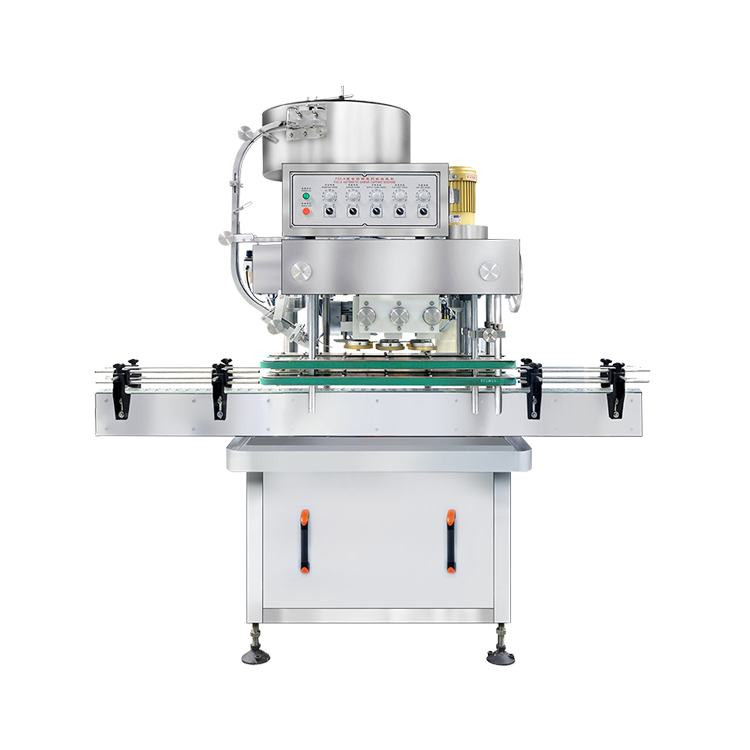

5. Sealing (Optional): If the honey containers require sealing, a capping station can be integrated into the production line. T

6. Labeling and Packaging (Optional): Depending on the production line setup, labeling and packaging processes may follow, where labels are applied, and containers are packed into boxes or cartons for distribution.

Can honey filling machines handle different container sizes?

Yes, honey filling machines are designed to handle different container sizes. They are versatile and can be adjusted or customized to accommodate various container sizes and shapes based on your specific production needs.

What is the cost of a honey filling machine?

The cost of a honey filling machine can vary widely depending on several factors, including the machine's type, capacity, features, brand, and whether it's a standard or customized model. Here are some general price ranges to provide an idea of the cost:

1. Semi-Automatic Honey Filling Machines:

These machines typically start at a few thousand dollars and can range up to several thousand dollars. The cost depends on factors such as capacity and features.

2. Automatic Honey Filling Machines:

Automatic filling machines with higher production capacities and advanced features can range from several thousand dollars to tens of thousands of dollars.

3. Customized Solutions:

If you require a honey filling machine tailored to your specific needs, the cost can vary significantly depending on the level of customization and complexity. Customized machines may have higher price points due to engineering and design considerations.

4. Brand and Quality:

The reputation and quality of the manufacturer can also impact the price. Well-known and reputable manufacturers may offer higher-priced machines due to their reliability and performance.

It's essential to consider your specific production requirements, budget, and long-term goals when choosing a honey filling machine. Keep in mind that while upfront costs are a consideration, the efficiency, reliability, and quality of the machine are equally important factors to evaluate.

Are honey filling machines easy to clean?

Our honey filling machines are designed with ease of cleaning in mind to ensure hygiene and maintain the integrity of the honey.

1. Stainless Steel Construction

Our honey filling machines are constructed with stainless steel, typically SUS304 or SUS316 grade materials. Stainless steel is corrosion-resistant and easy to clean, making it ideal for equipment that handles sticky substances like honey.

2. Quick Clamps and Disassembly

Our honey filling machines feature quick clamps and easy-to-disassemble components. This allows for rapid access to parts that come into contact with honey, such as filling nozzles, valves, and pipes. Quick disassembly simplifies the cleaning process.

3. Sanitary Piping

Our honey filling machines are designed with sanitary piping, reducing the risk of honey residue buildup. Sanitary fittings and tubing are easy to clean and maintain.

4. Smooth Surfaces

The absence of sharp edges, crevices, or corners in the design minimizes the potential for honey to get trapped, making cleaning more thorough and efficient.

Can honey filling machines handle different honey viscosities?

Yes, our honey filling machines are designed to handle a wide range of honey viscosities, from runny to thick.

What is the warranty for your honey filling machine?

The warranty for our honey filling machine is 12 months.

Can honey filling machines be customized for specific requirements?

Yes, our honey filling machines can be customized to meet specific requirements and production needs. We offer customization options to tailor the machine to the unique demands of your honey packaging process.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu