Introduction

Rising Consumer Demand and Competitive Pressures

Why Efficiency and Technology Are Now the Biggest Differentiators

Challenge #1: Water Source and Quality Variability

Challenge #2: High Energy and Water Consumption

Challenge #3: Complex Packaging and Frequent Changeovers

Challenge #4: Labor Skill Gap and Maintenance Downtime

Challenge #5: Quality Regulations and Certification Pressure

Challenge #6: Sustainability and Plastic Reduction

Why Pestopack Machinery Leads the Way in Smart Filling Solutions

Case Example – How a Turkish Factory Boosted Output by 30%

Key Benefits of Smart Bottled Water Filling Machines

How to Choose the Right Bottled Water Filling Machine

Conclusion

Introduction

Türkiye is one of the largest bottled water markets in Europe. With rising health awareness, strong tourism, and a growing population, demand for purified and mineral water keeps climbing. Yet, behind this impressive growth lie real challenges that many factories face daily — from water source instability to high energy costs and sustainability pressures.

So how can Turkish producers keep pace with the competition while ensuring product quality and profitability? The answer lies in adopting smart, efficient bottled water filling machines designed for modern demands.

Rising Consumer Demand and Competitive Pressures

Consumers in Türkiye are shifting toward healthier lifestyles. They expect safe, crisp, and well-packaged water in every size — from 0.33 L to 19 L. Dozens of local and international brands fight for shelf space, pushing manufacturers to produce faster, cleaner, and more efficiently than ever before.

Why Efficiency and Technology Are Now the Biggest Differentiators

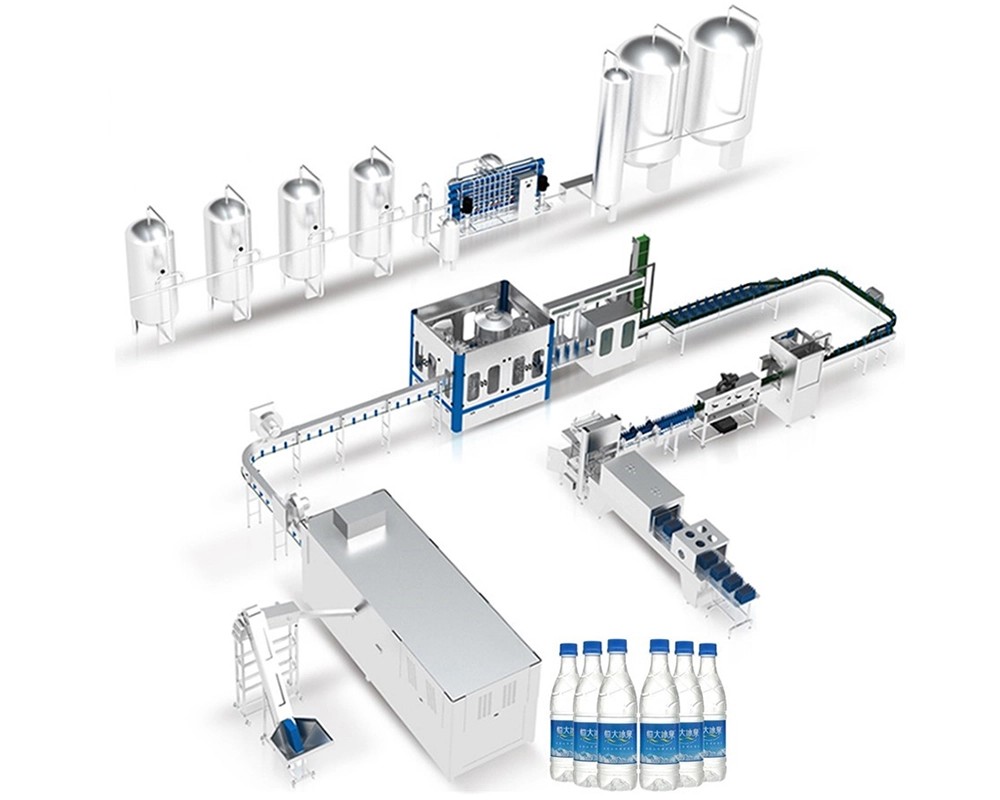

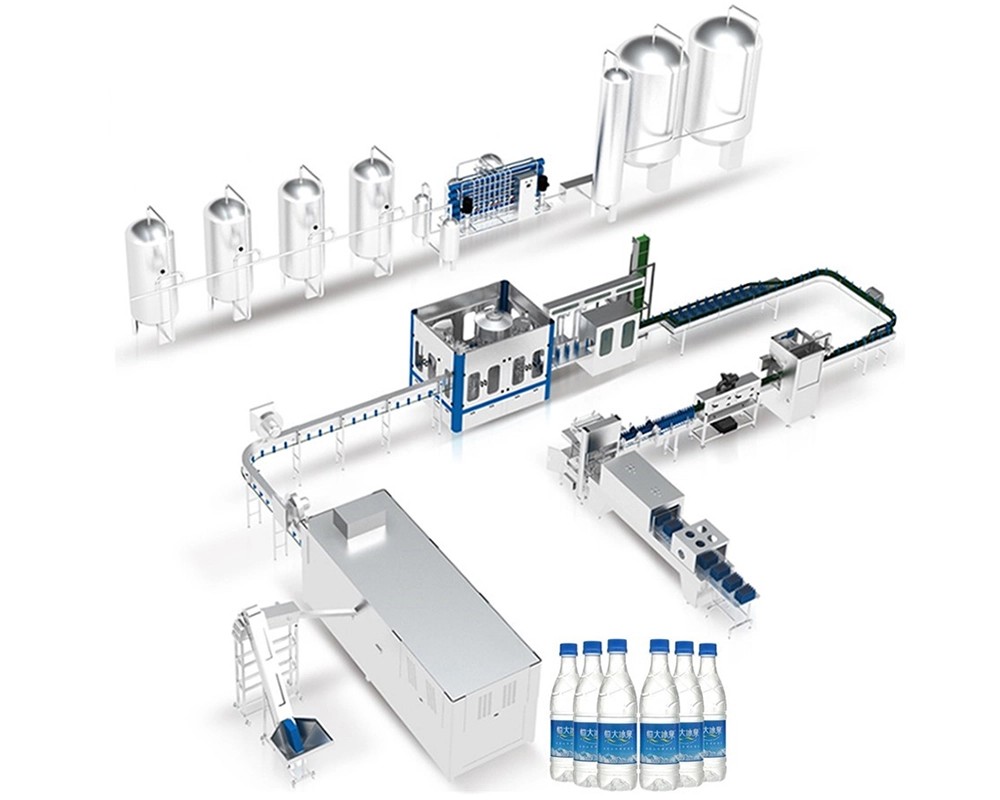

While the market once relied on manual or semi-automatic lines, today’s winners invest in automated bottled water filling lines that minimize losses and reduce costs per bottle. Automation, precision dosing, and hygienic design have become not just luxuries — they’re the new baseline for competitiveness.

Challenge #1: Water Source and Quality Variability

Seasonal Fluctuations and Purity Concerns

Many Turkish factories depend on natural springs or municipal sources. During dry seasons, water flow drops or the mineral balance shifts, impacting taste and quality. Without advanced filtration, factories risk inconsistencies that damage consumer trust.

Smart Solution – Advanced RO and Filtration Integration

Smart plants integrate multi-stage filtration — including sand, activated carbon, reverse osmosis (RO), UV, and ozone sterilization — ensuring stable purity throughout the year. Pestopack’s solutions allow automated back-flushing and online monitoring of conductivity and pH, keeping every drop crystal-clear.

Challenge #2: High Energy and Water Consumption

How Outdated Lines Waste Energy and Resources

Older fillers consume excessive electricity, compressed air, and rinse water. A single inefficient rinser can waste thousands of liters daily — a major issue in regions facing water stress.

Smart Solution – Energy-Efficient Motors and Closed-Loop Systems

Modern lines adopt variable-frequency drives, air recovery systems, and water recirculation loops. Pestopack’s automatic rinsers use filtered recycled water for pre-rinsing, cutting water use by up to 25%. Its energy-optimized servo motors also reduce power consumption by 15–20%, slashing overall operating costs.

Challenge #3: Complex Packaging and Frequent Changeovers

Multi-Bottle Formats and Material Challenges

Turkish producers often bottle multiple SKUs — 0.5 L, 1.5 L, 5 L — sometimes even in glass and PET. Changing molds and formats on conventional lines takes hours, slowing productivity.

Smart Solution – Modular Design and Quick Change Features

Pestopack’s bottled water filling machines feature modular components and tool-free neck-handling adjustments, enabling a complete format change in under 20 minutes. Operators can switch between PET and glass without compromising hygiene or output rate.

Challenge #4: Labor Skill Gap and Maintenance Downtime

Lack of Skilled Technicians in Regional Areas

Some Turkish regions lack experienced maintenance staff. When machines fail, downtime extends as factories wait for specialists or spare parts.

Smart Solution – User-Friendly Controls and Remote Support

Pestopack integrates intuitive touch-screens, self-diagnosis systems, and IoT connectivity. Through remote access, engineers can troubleshoot issues instantly — minimizing line stoppages. Preventive maintenance reminders keep performance at its peak, even with new operators.

Challenge #5: Quality Regulations and Certification Pressure

Meeting EU-Aligned Standards and Traceability

Türkiye aligns closely with European quality and hygiene regulations. Water producers must maintain full traceability, from source to cap seal. Manual records are no longer enough.

Smart Solution – Integrated CIP and Data Tracking

Pestopack’s automatic CIP (clean-in-place) systems ensure flawless sanitation without manual intervention. Every wash cycle is digitally recorded and traceable. Integrated PLC data logging provides real-time production records that auditors can easily verify — helping factories achieve ISO and CE compliance faster.

Challenge #6: Sustainability and Plastic Reduction

Lightweight Bottle Design and Eco-Pressure from Consumers

As the world moves toward eco-friendly consumption, Turkish brands feel pressure to cut plastic use and adopt recyclable materials. But lightweight bottles often deform under traditional filling pressure.

Smart Solution – Flexible Neck Handling and rPET Compatibility

Pestopack’s machines handle lightweight and rPET bottles through neck-handling technology that avoids stress points. Precision servo control adjusts fill speed and pressure for stability, so even ultra-thin bottles keep their shape. This lets brands achieve sustainability goals without sacrificing aesthetics.

Why Pestopack Machinery Leads the Way in Smart Filling Solutions

Chinese Factory, Global Service, Factory-Direct Pricing

With its 20,000 m² manufacturing facility in China, Pestopack offers factory-direct pricing without middlemen. The company exports to over 30 countries, including Türkiye, delivering competitive costs and European-grade quality.

Decades of Experience Across 30+ Countries

Since 2010, Pestopack has installed lines for 900+ clients worldwide — from small start-ups to large multinationals. Each project benefits from custom engineering and localized after-sales service.

Tailor-Made Solutions for Türkiye’s Water Producers

Whether you produce mineral, spring, or RO purified water, Pestopack customizes the line based on your bottle size, cap type, and production volume. Its design team understands local logistics and regulations, making installation and operation seamless.

Case Example – How a Turkish Factory Boosted Output by 30%

A regional water producer in Ankara upgraded its aging line with a Pestopack 12-12-4 Rinser-Filler-Capper. By integrating servo motors and automatic CIP, the factory reduced changeover time from 45 minutes to 10 minutes and cut water wastage by 22%. Within six months, their production output grew by 30%, and ROI was achieved in under two years.

Key Benefits of Smart Bottled Water Filling Machines

Precision, Speed, and Hygiene

Each bottle is filled with ±0.2% accuracy at high speed, ensuring uniform product quality. All contact parts are made of food-grade SS 316L, meeting global sanitation standards.

Digital Monitoring and Predictive Maintenance

IoT-based sensors monitor valve pressure, temperature, and flow. When any parameter drifts, alerts are triggered before issues escalate — preventing unscheduled shutdowns.

How to Choose the Right Bottled Water Filling Machine

Define Capacity, Bottle Type, and Budget

Start by defining your target output (BPH – bottles per hour). Whether you need 2,000 BPH for a start-up or 12,000 BPH for a national brand, Pestopack offers models that fit your scale and budget.

Check details on the Water Bottling Machine for Sale page.

Verify After-Sales Support and Spare Parts

Choose a partner with local technicians and fast spare-parts delivery. Pestopack provides remote assistance, on-site installation guidance, and training for Turkish operators to ensure smooth operation from day one.

Learn more about complete lines on the Water Bottling Line page.

Conclusion

Türkiye’s bottled water sector is evolving fast. Factories that embrace automation, energy efficiency, and data-driven quality control will dominate the next decade. By addressing the core pain points — water quality, energy, flexibility, skills, and sustainability — manufacturers can turn challenges into opportunities.

With Pestopack Machinery’s smart bottled water filling machines, Turkish producers gain not only top-tier technology but also a global partner committed to their growth. Efficiency is no longer optional — it’s the key to staying ahead in Türkiye’s competitive water market.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu