What is a Pump Capping Machine?

A pump capping machine is specialized equipment designed to automatically cap containers with pump-style or trigger-style closures. It is widely used for detergents, shampoos, shower gels, and other liquid products where consistent, airtight, and secure capping is essential to protect product quality and customer satisfaction.

Key Features of Pump Capping Machine

1. Advanced Four-Claw Structure for Precise Capping

2. Servo System for Enhanced Precision

PLC + touch screen control

Adjustable torque for accurate tightening

Smooth operation and precise alignment

3. Integrated Cap Management System

Automatic elevator for cap sorting

Accurate cap grasping and placement

Adjustable torque to prevent damage

4. Safety and Diagnostic Functions

Alarms for bottle jams, cap shortages, overloads

Self-diagnostics with visual + audible alerts

Torque clutch device to prevent equipment damage

5. User-Friendly & Hygienic Design

Meets daily chemical hygiene standards

Simple parameter settings & memory for multiple bottles

Durable polyurethane capping wheels

Quick changeover for multiple cap/bottle types

Technical Advantages of Rotary Pump Capping Machine

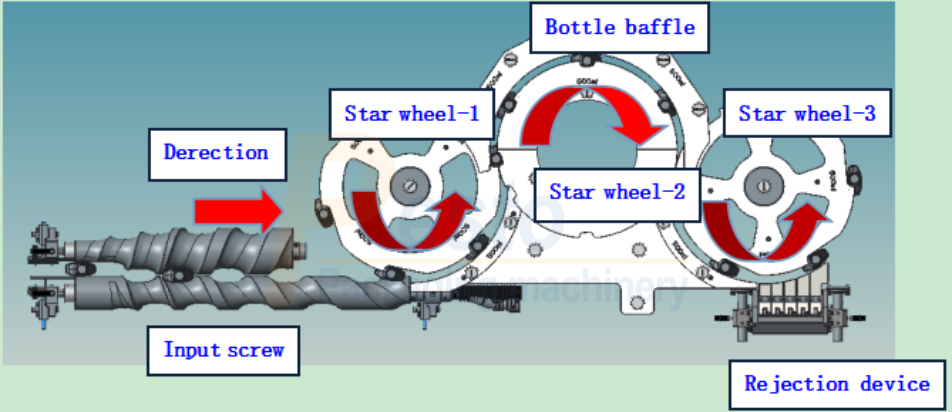

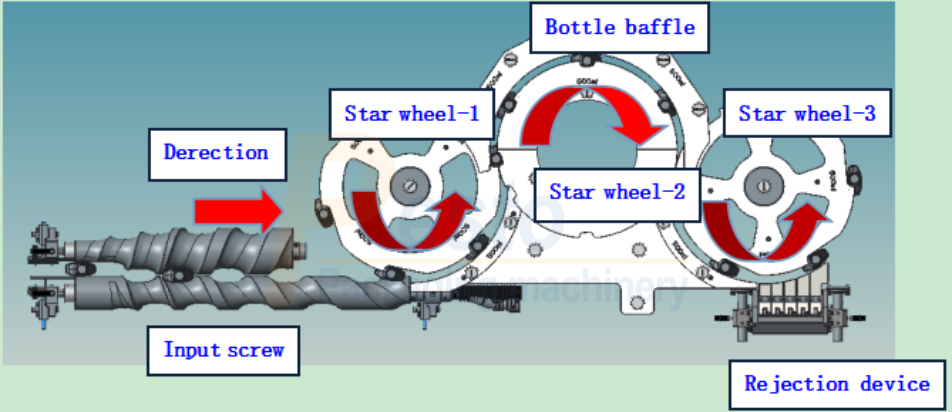

Flexible Inlet Screw Design

The rotary pump capping machine has an inlet screw that guides bottles smoothly, preventing breakage and ensuring high-speed production efficiency.

Detection and Rejection Devices

Bottles without caps, misaligned pumps, or NG caps are automatically rejected

An additional conveyor ensures only properly capped bottles enter packaging

Belt-Based Cap Feeding System

Compared with traditional wind-feeding, the belt system:

How Pump Capping Machine Improves Production Efficiency

A modern automatic capping machine not only replaces manual labor but also standardizes the entire capping process. By adopting servo-driven torque control and automatic cap sorting, manufacturers can achieve:

Higher production capacity with reduced operator fatigue

Stable performance in continuous 24-hour operations

Reduced error rates compared with manual capping

This is why the pump capping machine is a core component of detergent, cosmetic, and household chemical production lines.

Why Choose Our Pump Capping Machine

Improved Productivity – Reduces labor, boosts speed and accuracy

Consistent Capping Quality – Servo-driven torque avoids under/over-tightening

Versatile Applications – Works with PET, PP, PE, HDPE bottles

Reduced Downtime – Quick changeovers, intuitive touch-screen controls

Applications of Pump Capping Machines

Detergents – Leak-proof during transport

Shampoos & Shower Gels – Airtight, hygienic capping

Beauty & Skincare Products – Precision capping for premium look

Household Care Products – Strong, tamper-proof sealing

Industries Benefiting from Pump Capping Machines

Daily Chemical Industry

In detergent and cleaning product lines, pump capping machines ensure each bottle is sealed tightly, preventing leaks that could damage packaging or logistics.

Cosmetic & Skincare Industry

For high-value cosmetics, the rotary pump capping machine provides precise torque control, ensuring an elegant finish without damaging fragile bottles.

Food & Beverage Applications

While less common, pump-style closures are also used in sauces and syrups. A bottle capping machine guarantees freshness and tamper evidence.

Why This Pump Capping Machine Stands Out

Our rotary pump capping machine combines cutting-edge technology, reliability, and ease of use. Whether for detergents or high-end cosmetics, it ensures every bottle is securely capped to the highest industry

Comparison with Other Capping Machines

| Feature | Pump Capping Machine | Screw Capper | Press-on Capper |

Cap Type | Pump, trigger, dispenser | Screw caps | Snap-on caps |

Precision | High (servo torque) | Medium | Low |

Flexibility | Multiple bottle types | Mostly PET bottles | Limited |

Applications | Detergent, shampoo, skincare | Water, beverages | Jars, tubs |

Changeover | <30 min | 20–40 min | 15–25 min |

Compared to traditional automatic bottle capping machines, the pump capper is more versatile in handling irregular and complex cap shapes.

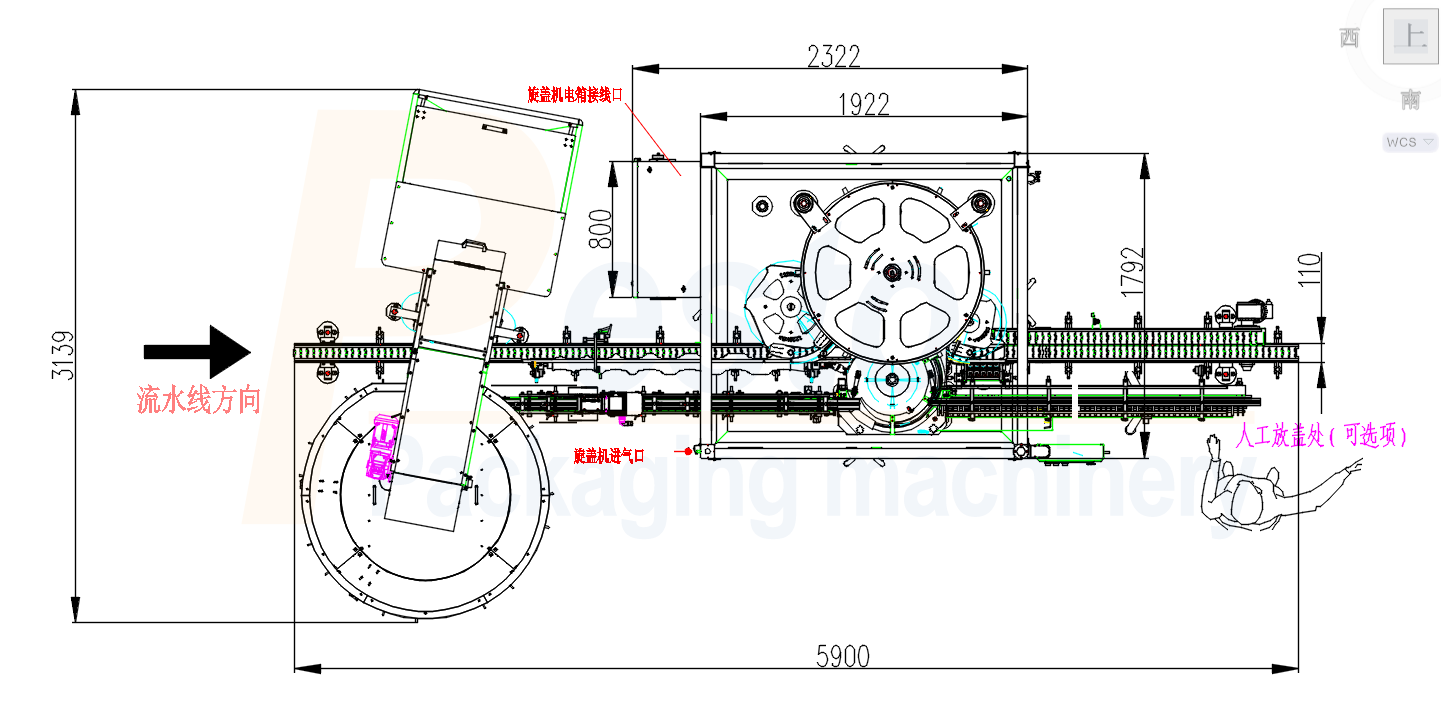

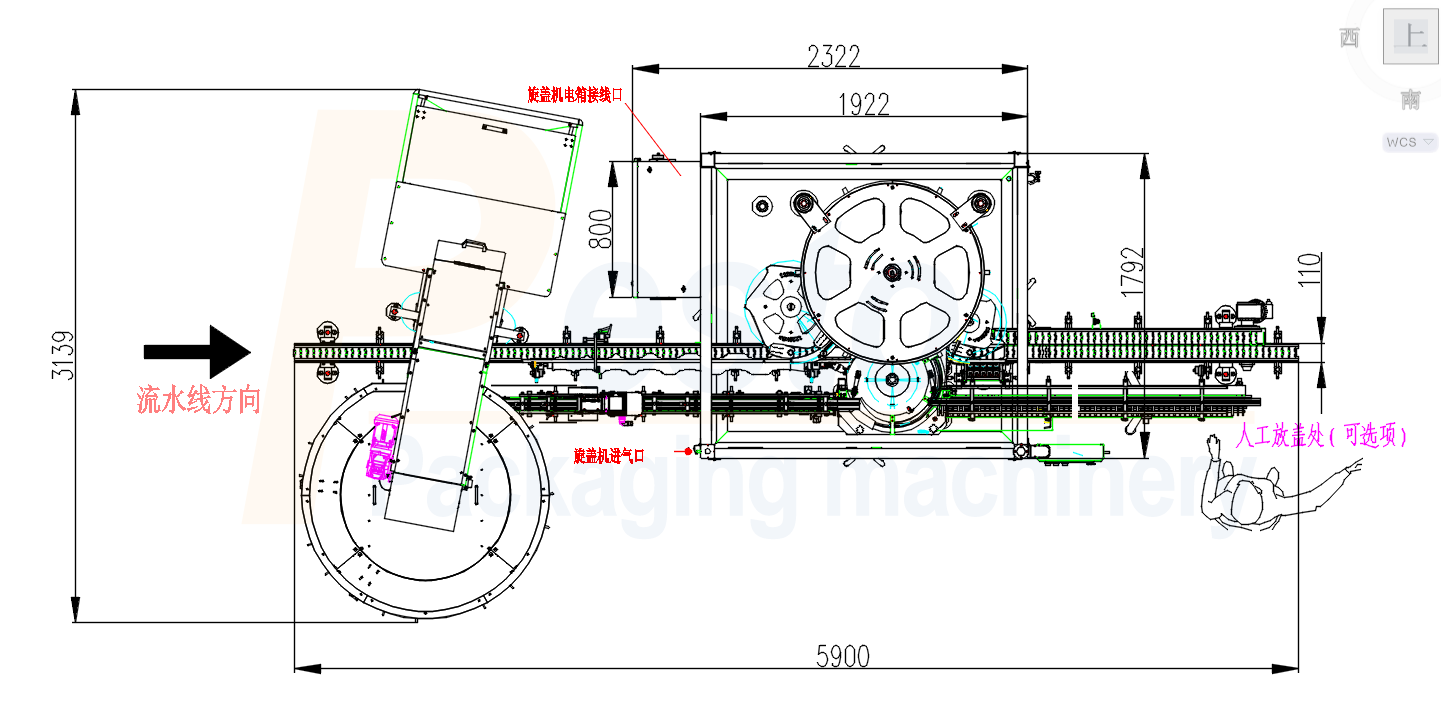

LAYOUT REFERENCE

Technical Parameters

Parameter | Specification |

Capping heads | 8 (customizable) |

Speed | ≥ 5000 BPH |

Bottle type | Customized |

Cap size | Customized |

Torque control | Permanent magnet clutch |

Qualified rate | ≥ 99% |

Total Power | 5 kW |

Power Supply | AC 380V / 50Hz |

Weight | 4000 kg |

Air Supply | ≥ 0.5 Mpa |

Air Consumption | 0.009 m³/min |

Noise | ≤ 80 dB (1m) |

Dimension (L×W×H) | 2000 × 1800 × 2900 mm |

Material | SUS304 stainless steel |

Conveyor Height | 900 ± 50 mm |

Cap Elevator Volume | 0.3 m³ |

Cap Sorter Diameter | ∅1000 mm |

FAQ

Q1. What bottle sizes and materials are supported?

Compatible with PET, PP, PE, and HDPE bottles in multiple sizes.

Q2. Can it handle different pump cap designs?

Yes — the four-claw structure and adjustable torque allow flexibility for different pumps.

Q3. How long is changeover time?

Less than 30 minutes, no special tools required.

Integration into a Complete Filling Line

The pump capping machine is often installed after filling and before labeling/packing. In a full detergent or shampoo line, the sequence is:

By combining these machines, manufacturers build a complete detergent filling line or cosmetic packaging line, ensuring both efficiency and product consistency.

Maintenance & After-Sales Service

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu