The Importance of Accuracy and Consistency

Minimizing Contamination and Preserving Quality

Versatility and Adaptability

Efficiency and Productivity

The Role of the Lotion Filling Machine

Conclusion

The cosmetics industry is all about delivering beauty and self-care products that meet high standards of quality, consistency, and aesthetic appeal. To achieve this, precise and efficient manufacturing processes are essential. Liquid filling machines play a pivotal role in the cosmetics industry by ensuring that products like lotions, creams, serums, and perfumes are accurately and consistently filled into their containers. In this article, we will delve into the critical role of liquid filling machine for sale in cosmetics production and explore how they contribute to maintaining product quality and consistency.

The Importance of Accuracy and Consistency

Cosmetics consumers have high expectations when it comes to the products they use. They expect each bottle of lotion, jar of cream, or vial of perfume to contain the exact amount of product promised on the label. Deviations from this standard can lead to customer dissatisfaction and, in some cases, legal issues.

Liquid filling machines are designed to address these concerns. They are equipped with precision technology that ensures the accurate and consistent dispensing of cosmetics. This not only meets consumer expectations but also prevents product wastage and overfilling, which can be costly for manufacturers.

PESTOPACK, a liquid filling machine manufacturer, its machines are designed to address these concerns. We are equipped with precision technology that ensures the accurate and consistent dispensing of cosmetics. This not only meets consumer expectations but also prevents product wastage and overfilling, which can be costly for manufacturers.

Minimizing Contamination and Preserving Quality

Maintaining product quality is a top priority in the cosmetics industry. Contamination, even in minuscule amounts, can lead to product spoilage, safety concerns, and damage to a brand's reputation. PESTOPACK's liquid filling machines are equipped with features to prevent contamination, such as sterile filling environments and airtight sealing mechanisms. This helps preserve the quality and safety of cosmetics, especially for products like eye creams, serums, and other sensitive formulations.

Versatility and Adaptability

Cosmetic products come in various viscosities, from thin lotions to thick creams. Liquid filling machines are versatile and can be adapted to handle a wide range of product types. They can be configured to accommodate different container sizes and shapes, making them suitable for filling bottles, jars, tubes, and more. This adaptability is crucial in the cosmetics industry, where product diversity is a hallmark.

Efficiency and Productivity

Efficiency is a key driver of success in cosmetics manufacturing. Liquid filling machines help streamline the production process by automating the filling and capping of containers. This not only speeds up production but also reduces the potential for human error. As a result, manufacturers can meet demand more effectively and focus on other critical aspects of their business, such as research and development, marketing, and quality control.

The Role of the Lotion Filling Machine

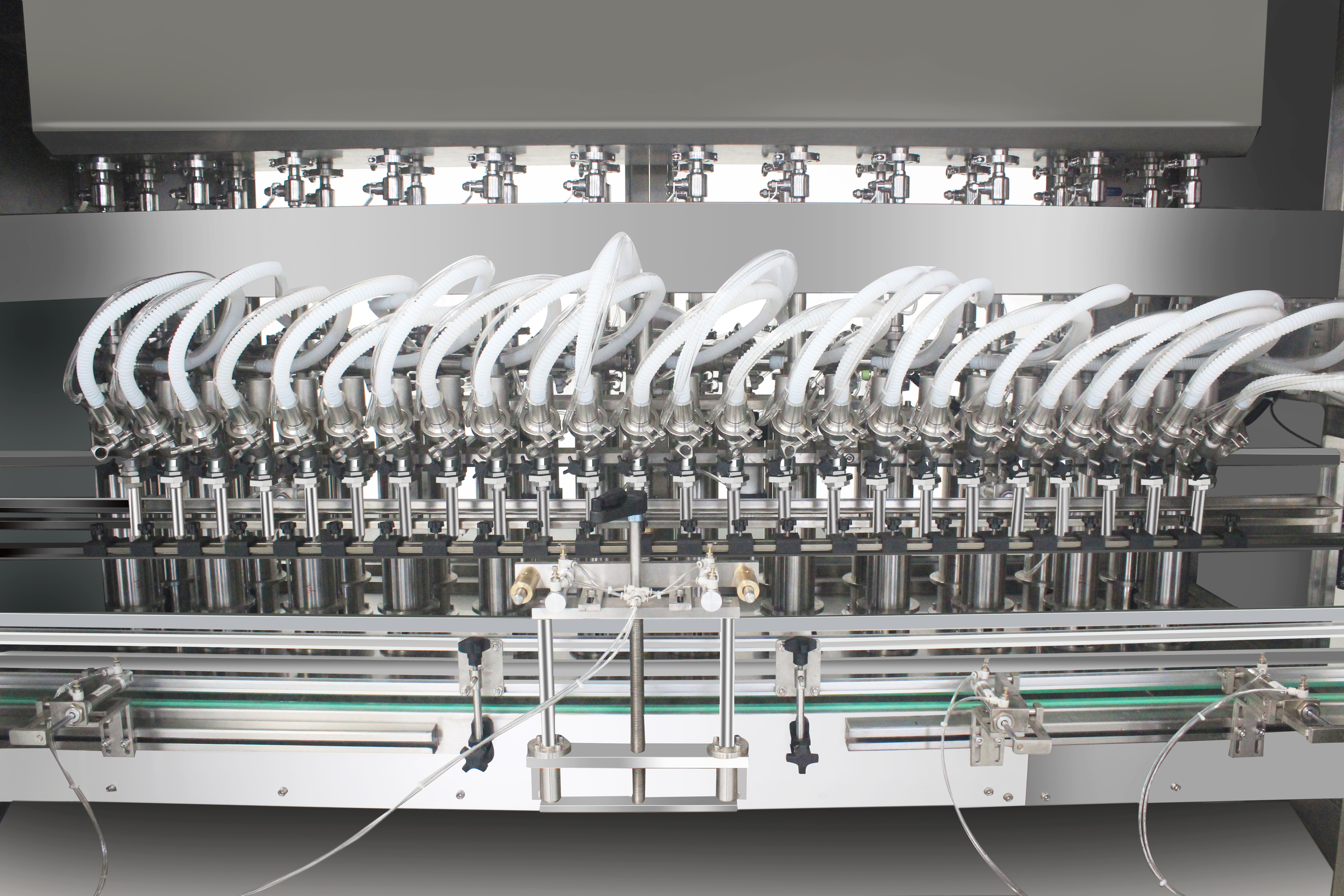

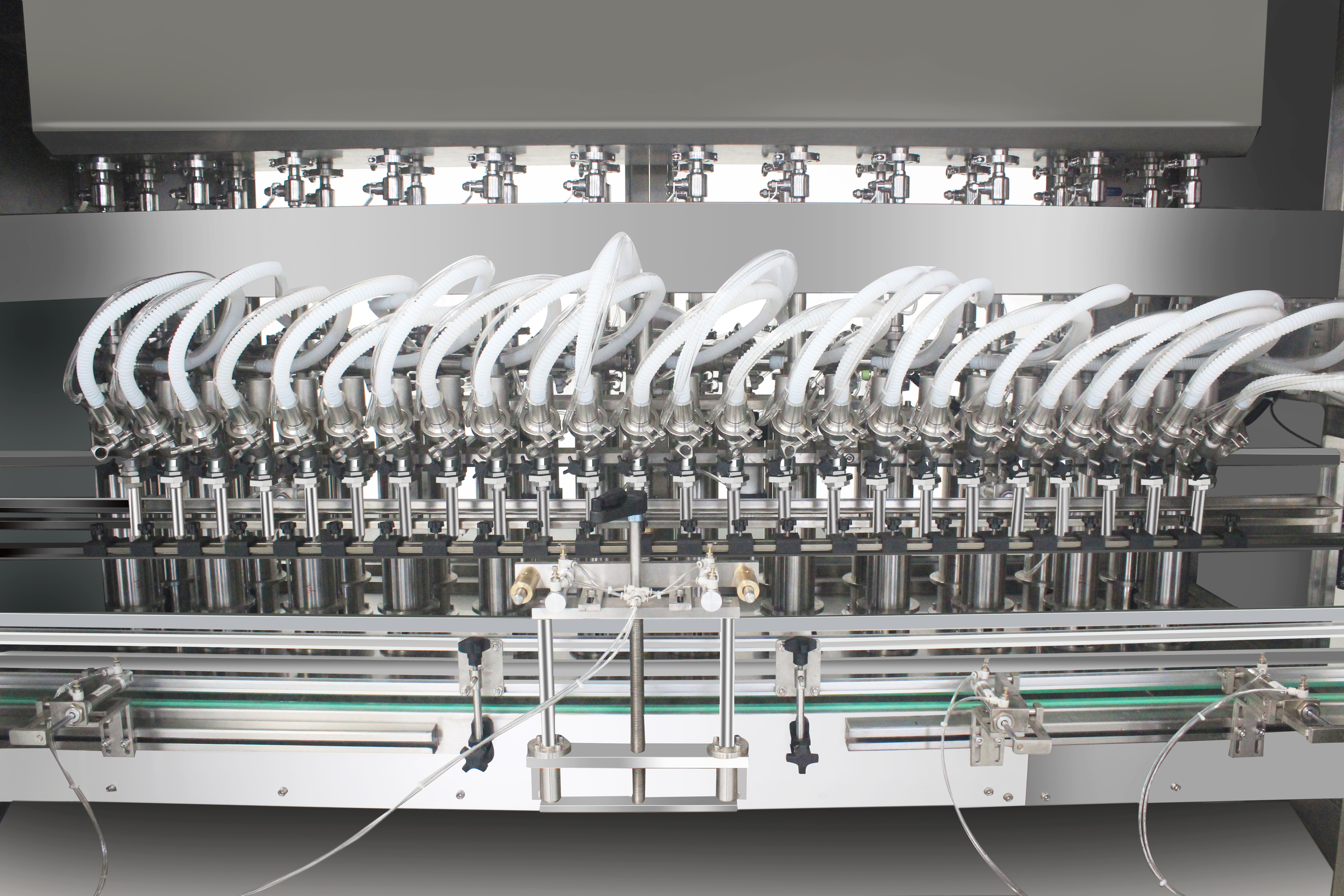

In the cosmetics industry, lotion is a staple product. Lotion filling machine and cream filling machine are specifically designed to handle this type of product. They come equipped with features such as:

Viscosity Control: Lotions vary in viscosity, and lotion filling machines are designed to handle this variety. They can adjust to ensure the smooth and consistent filling of bottles and containers, regardless of the lotion's thickness.

Airtight Sealing: To prevent contamination and maintain product freshness, lotion filling machines often include airtight sealing mechanisms. This is critical for preserving the quality of lotion products over time.

Accurate Measurement: Lotions are typically sold in various container sizes. A lotion filling machine must accurately measure and fill each container, meeting both regulatory standards and consumer expectations.

High Output: Lotion filling machines are designed to handle high production volumes, ensuring that cosmetics manufacturers can keep up with market demand.

Conclusion

In conclusion, liquid filling machines, including lotion filling machines, play an indispensable role in the cosmetics industry by ensuring accurate and consistent product filling, preserving quality, and enhancing overall manufacturing efficiency. They contribute significantly to maintaining the integrity of cosmetic products, which is essential for the industry's success. If you want to learn more about the specific features and benefits of lotion filling machines, please visit our "Lotion Filling Machine" page. Our commitment to innovation and excellence makes them a reliable partner in the cosmetics industry.

Incorporating liquid filling machines into cosmetics production processes is not just a convenience; it's a necessity for meeting the exacting standards of the industry and delivering top-quality products to consumers.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu