In the realm of chemical packaging, our cutting-edge corrosive filling machine stands as a testament to innovation and efficiency. Designed to handle a variety of corrosive substances, this corossive filling machine incorporates some key features that set it apart.

1. Corrosion-Resistant Construction

At the heart of our corrosive filling machine lies a robust structure crafted from premium materials like corrosion-resistant PP material. This ensures not only the longevity of the equipment but also guarantees the purity of the substances it handles, safeguarding product integrity.

2. Specialized Chemical-Resistant Components

Our machine boasts components designed specifically to combat the corrosive nature of the chemicals it manages. Corrosion-resistant seals, gaskets, and tubing play a pivotal role in preserving the machine's functionality, even when handling the most aggressive substances.

3. Advanced Precision Filling Technology

Precision is the bedrock of our machine's design. With advanced filling technology, we guarantee accuracy and consistency, reducing product wastage and minimizing the risk of errors. This ensures that every container is filled to the exact specifications required.

4. Comprehensive Safety Containment Systems

Safety is ingrained in every aspect of our corrosive filling machine. Robust containment systems are integrated to prevent leaks and spills, prioritizing the well-being of operators and maintaining environmental safety standards.

5. Rapid Emergency Shutdown Protocols

Anticipating the unexpected, our machine features rapid emergency shutdown protocols. This ensures swift responses to any unforeseen issues, minimizing potential risks and maintaining a secure filling process.

6. Customizable Configurations for Diverse Corrosive Liquids

Understanding the diverse nature of corrosive liquids, our machine offers customizable configurations. Whether handling acids, bleaches, or toilet cleaners, this adaptability ensures optimal performance, meeting the unique requirements of various chemical applications.

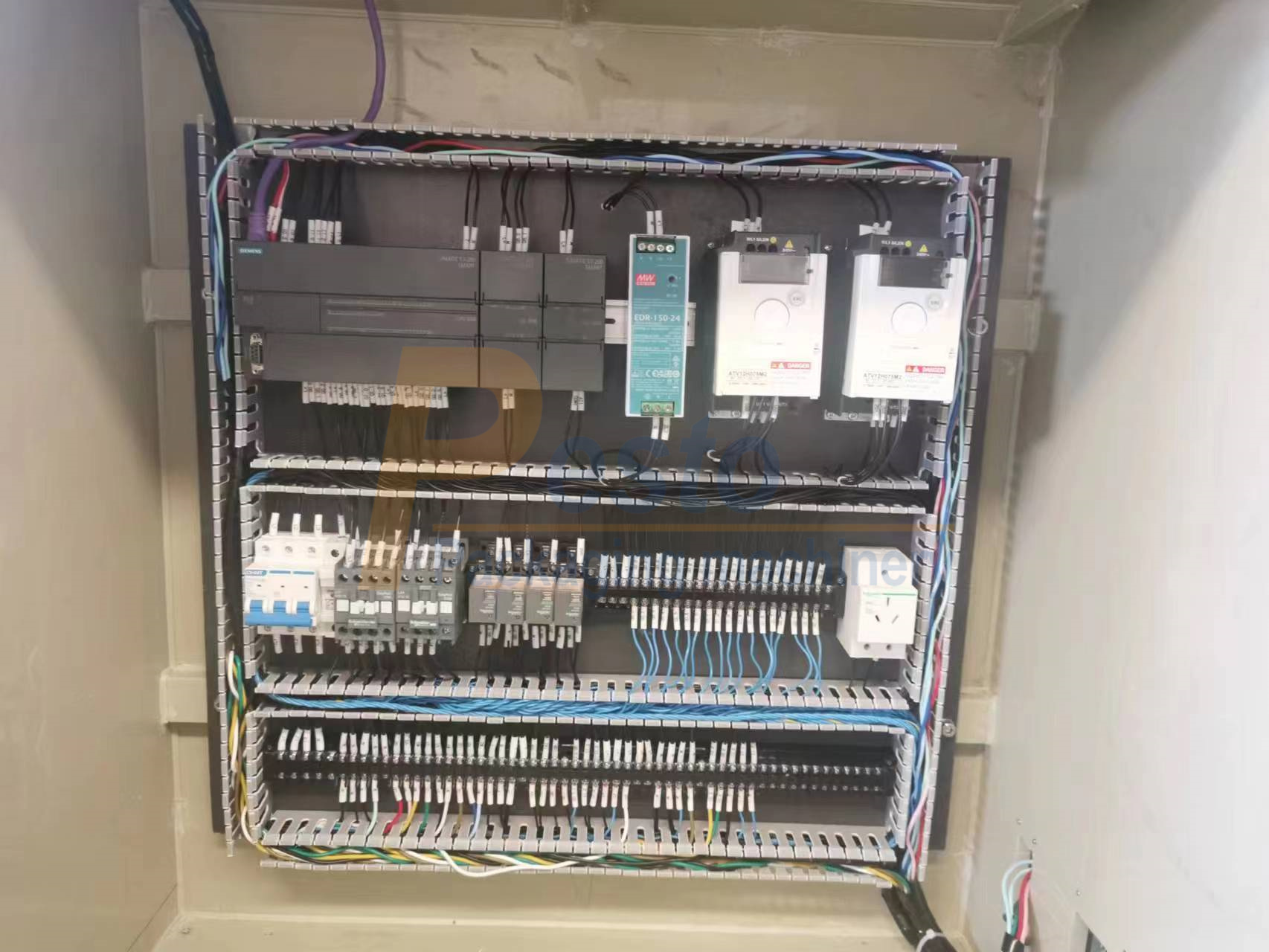

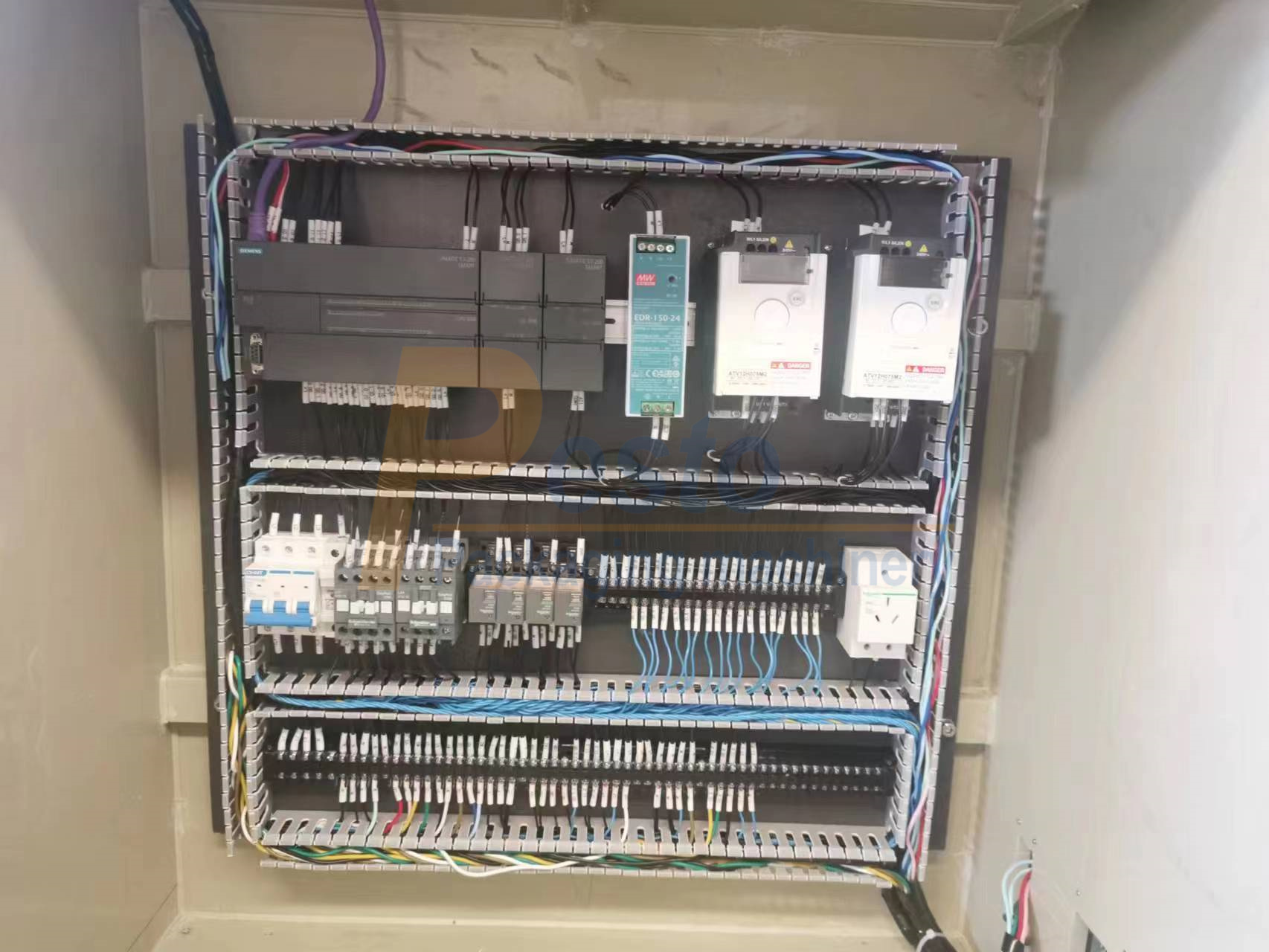

7. User-Friendly Interface

Our corrosive filling machine is designed with the end-user in mind. A user-friendly interface simplifies operation, reducing the learning curve for operators and enhancing overall efficiency.

8. Easy Maintenance and Cleaning

Streamlining maintenance, our machine is designed for easy access and cleaning. This not only prolongs the machine's lifespan but also ensures that every filling process is conducted with the highest standards of hygiene.

9. Compliance with Industry Standards

Our corrosive filling machine aligns with and often exceeds industry standards. This commitment to compliance ensures that our customers receive a product that not only meets expectations but also adheres to the highest safety and quality benchmarks.

10. Wide Application

Acid Filling Machine

Acidic substances demand specialized handling to prevent equipment corrosion and ensure operator safety. Learn more about the dedicated features of our acid filling machine designed to meet the challenges posed by corrosive acids.

Bleach Filling Machine

Bleaches, renowned for their corrosive properties, require precise handling during the filling process. Discover the intricacies of our bleach filling machine and how they contribute to the safe and efficient packaging of these chemical products.

Toilet Cleaner Filling Machine

Toilet cleaners often contain strong acids, presenting unique challenges in the filling process. Delve into the details of our toilet cleaner filling machine and their specialized features to ensure the accurate and safe packaging of these corrosive substances.

Conclusion

In the realm of corrosive filling machines, ours stands as a pinnacle of excellence. With a focus on durability, precision, and safety, our liquid filling machine for sale is not just a piece of equipment but a testament to our commitment to innovation and customer satisfaction. Each feature is meticulously crafted to redefine industry standards, making our corrosive filling machine a trusted partner in chemical packaging.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu