Frequently Asked Questions (FAQs)

1. What is the capacity range of PESTOPACK glass bottle filling machines?

From 2,000 BPH to 18,000 BPH, depending on the model selected.

2. Can the machine handle different bottle sizes?

Yes, machines can be customized to fit various glass bottle heights and diameters.

3. How is hygiene maintained?

Each machine is equipped with CIP cleaning, stainless steel construction, and food-grade components.

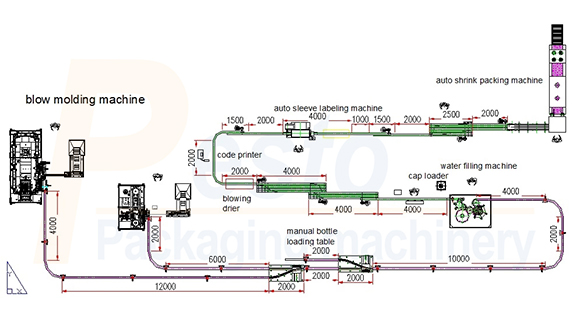

4. Do I need auxiliary equipment?

Yes, for a complete line you will need a drink mixer, bottle loader, cooling system, labeling, and packaging machine.

5. How much does a soda glass bottle filling machine cost?

Prices vary depending on capacity, configuration, and customization. Contact PESTOPACK for a tailored quotation.

Conclusion

The rotary glass bottle filling machine for soda drinks is a vital solution for modern beverage manufacturers seeking efficiency, precision, and premium packaging. With PESTOPACK’s advanced technology, global expertise, and reliable after-sales service, you can build a production line that delivers consistent quality while reducing operational costs.

Ready to upgrade your soda production? Contact PESTOPACK today for a customized solution.

Explore related machines:

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu