Introduction

The global demand for carbonated drinks such as soda, cola, sparkling water, flavored beverages, and energy drinks continues to rise. To meet this demand, beverage manufacturers need reliable, efficient, and hygienic equipment that can handle high-speed production without compromising product quality.

A carbonated beverage filling machine is the centerpiece of any soda bottling line. It integrates bottle rinsing, CO₂ beverage filling, and capping into one streamlined monoblock system. By automating these processes, manufacturers can reduce labor costs, improve filling accuracy, and ensure consistent carbonation levels for every bottle.

This in-depth guide will explain how carbonated beverage filling machines work, their technical specifications, benefits, applications, and how they compare with other filling technologies. If you are planning to invest in a carbonated drink production line, this article will help you make the right decision.

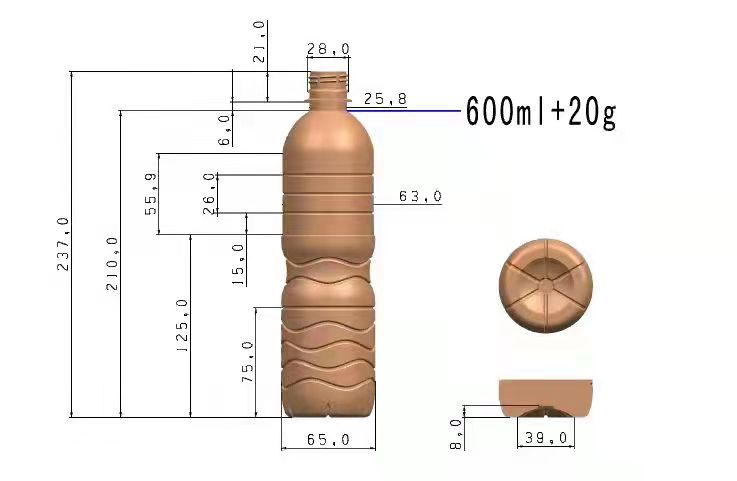

FINAL PRODUCTS

FAQs

Q1: Can the machine handle glass bottles?

A: Yes, with customized design. PET is standard, but glass bottle filling is possible.

Q2: What is the lifespan of the machine?

A: With proper maintenance, more than 10 years.

Q3: Can I start with a small model and upgrade later?

A: Yes. Many clients start with 2000–5000 bph models and expand to larger capacity machines as their business grows.

Q4: How much CO₂ is used in production?

A: It depends on beverage formulation, but the machine is designed to optimize CO₂ usage with minimal waste.

Q5: Is it easy to change bottle sizes?

A: Yes, changeover parts are available, and adjustment takes less than 30 minutes.

Conclusion

A carbonated beverage filling machine is an essential investment for any soda or sparkling drink manufacturer. It combines high-speed production, consistent carbonation, and advanced automation to ensure reliable beverage quality.

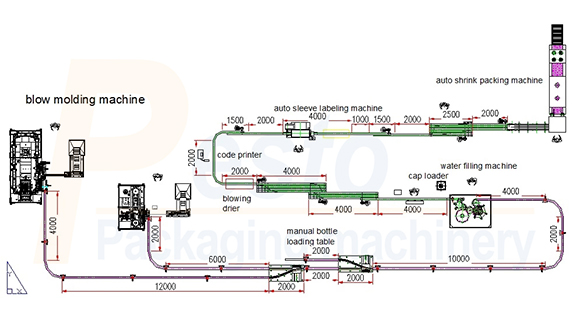

At PESTOPACK, we design and supply complete carbonated beverage production lines, including water treatment, mixing, blowing, filling, labeling, and packaging. With over 14 years of industry experience and installations in more than 30 countries, we guarantee cost-effective solutions tailored to your needs.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu