Introduction

In the bottled water and beverage packaging industry, the demand for large-capacity containers such as 3 gallon and 5 gallon PET bottles continues to grow rapidly. Businesses supplying purified water, mineral water, or commercial beverage distribution all require reliable, efficient, and cost-effective solutions to produce these large bottles.

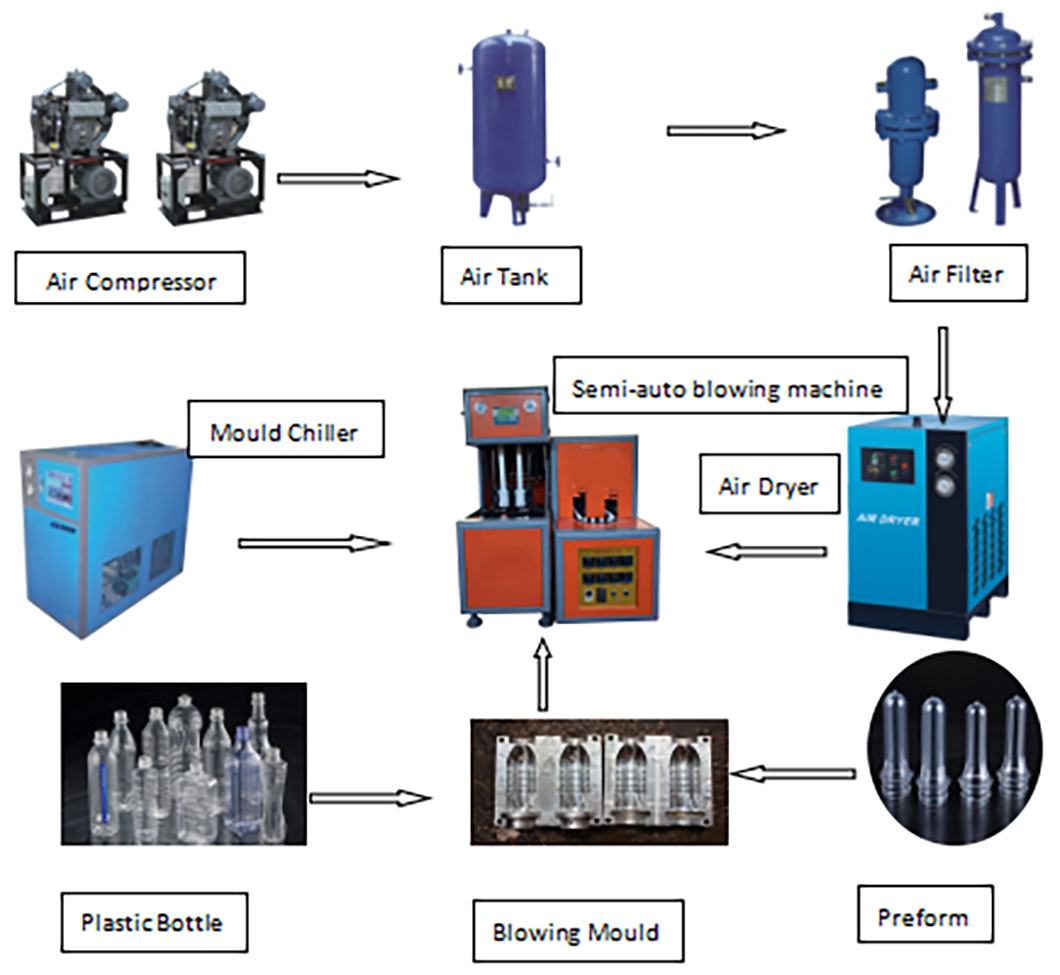

The Semi Automatic 5 Gallon Bottle Blowing Machine (Model YD-5-1 cavity) is specially engineered to meet this demand. Compact, energy-saving, and designed for easy operation, it is one of the most practical investments for small to medium-scale bottled water plants. In this article, we will walk you through everything you need to know: machine features, working process, technical parameters, after-sales service, and turnkey solutions.

What is a 5 Gallon Bottle Blowing Machine?

A 5 gallon bottle blowing machine is a piece of packaging equipment designed to produce large PET bottles—typically 3 gallon (11.3L) and 5 gallon (18.9L) containers. These bottles are widely used in:

Water plants (purified water, mineral water, spring water)

Office & home water dispenser bottles

Food & beverage packaging

Industrial and commercial container supply

Unlike small-size PET bottle blowers, these machines must handle larger preforms, higher clamping forces, and greater stretching strokes. The semi-automatic type strikes a balance between low investment cost and good production efficiency, making it ideal for startups or mid-capacity operations.

Key Features of the Semi Automatic 5 Gallon Bottle Blowing Machine

The YD-5-1 cavity model is designed with both functionality and affordability in mind. Let’s explore its main highlights:

1. Specialized for 3 and 5 Gallon Bottles

This model can produce a variety of PET containers from 7 liters up to 22 liters, with neck finishes ranging from 50mm to 330mm. It’s versatile enough to manufacture water dispenser bottles, commercial gallon jugs, and other large containers.

2. Compact & Space-Saving Design

With a footprint of only 210 × 73 × 190 cm, the machine is small in size, compact in construction, and eliminates unnecessary space waste. This makes it easy to install in workshops of different scales.

3. Easy Operation

The semi-automatic system is designed to be operated by a single person, reducing labor costs. Operators can easily load preforms, manage the heating process, and initiate blowing with minimal training.

4. Energy-Efficient & Durable

Uses new double crank four-bar mold locking system for stability.

High pressure blowing system ensures strong and uniform bottle formation.

The design minimizes wear and tear, ensuring a long service life and low maintenance.

5. Complete Mold & Preform Solutions

The supplier can also provide custom preforms, bottle molds, and cap molds to meet different customer needs. Whether you want standard 5 gallon round bottles or branded customized shapes, this machine can adapt.

Technical Parameters

Here is a detailed technical breakdown of the YD-5-1 cavity semi-automatic 5 gallon bottle blowing machine:

General Information | Specification |

Machine Name | Semi Automatic 5 Gallon Bottle Blowing Machine |

Model | YD-5-1 cavity |

Clamping Force | 22T |

Clamping Stroke | 450mm |

Max. Stretching Stroke | 660mm |

Number of Cavity | 1 |

Output | 90BPH (Bottles Per Hour) |

Max. Mould Thickness | 400mm |

Electrical System |

|

Voltage Standard | 380V / 3PH / 50Hz (customizable) |

Total Power | 10–25 KW |

Min. Air Pressure | 1.6m³/min, 3.0MPa |

Plastic Container Specifications |

|

Container Volume | 7–22L |

Neck Diameter Range | 50–330mm |

Max. Container Diameter | 400mm |

Container Height | 640mm |

Machine Dimensions |

|

Machine Size | 210 × 73 × 190 cm |

Net Weight | 2.5T |

This makes it suitable for stable production up to 90 large bottles per hour—a strong output for semi-automatic operations.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu