Introduction to Automatic Beverage Filling Machines

In today’s fast-paced beverage industry, automatic beverage filling machines have become the backbone of production lines worldwide. These machines integrate the three most critical processes—rinsing, filling, and capping—into a single streamlined system. By automating these steps, beverage manufacturers save time, reduce labor costs, and ensure consistent product quality.

At PESTOPACK, our PTRGF series automatic beverage filling machines are designed to meet the needs of both small and large beverage factories. From 3,000 bottles per hour (BPH) up to 28,000 BPH, our machines provide flexible capacity options. Built with SUS304 stainless steel and manufactured using CNC precision machining, our machines are durable, hygienic, and built to last.

Whether you are producing bottled water, fruit juices, teas, or carbonated soft drinks, PESTOPACK machines ensure that every bottle meets international standards for safety and quality.

How Automatic Beverage Filling Machine Works

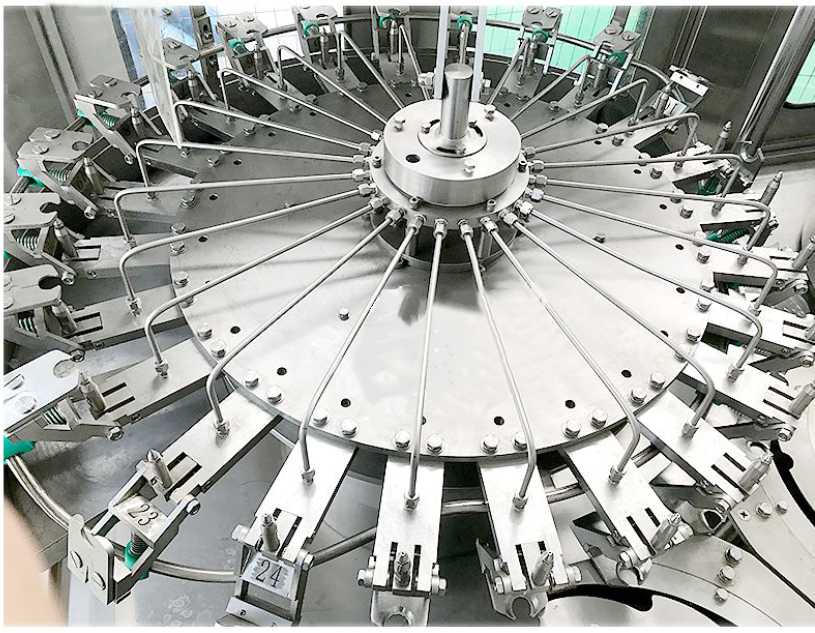

One of the main advantages of the PTRGF 18-18-6 beverage filling machine is its ability to combine three essential functions into one compact machine:

1. Bottle Rinsing

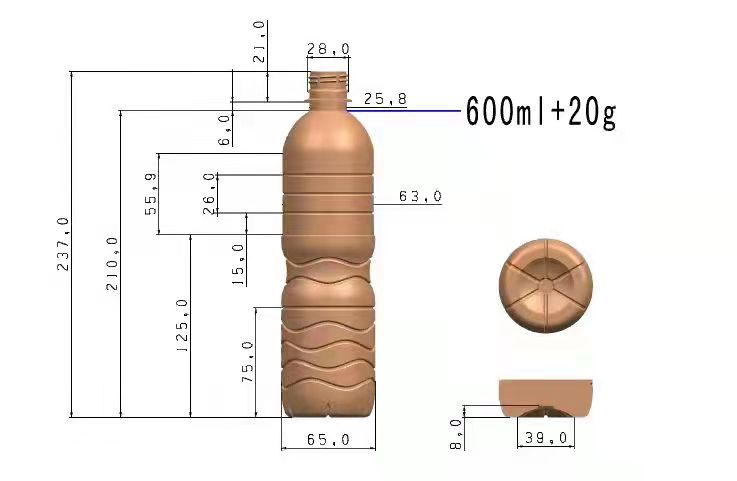

Empty PET bottles are fed into the machine using an air conveyor system, which gently moves them into position without causing deformation. Each bottle is held securely by the neck hanger—a method that reduces contact with the bottle’s threaded mouth and ensures hygienic processing. Multiple rinsing heads spray the bottles with sterilized water, ensuring they are fully cleaned before filling.

2. Filling Process

The heart of the machine lies in its micro-pressure filling technology. This method ensures accurate, spill-free filling, whether you are bottling water, juice, or tea. The filling valves are designed to handle both hot filling (for juices and teas) and cold filling (for pure and mineral water). The valve lifting mechanism ensures each bottle is filled to the precise level, maintaining uniformity across thousands of bottles per hour.

3. Capping

Once filled, bottles move seamlessly to the capping section. Here, automatic capping heads securely fasten caps without damaging the bottle or the thread. The precision ensures leak-proof sealing, which is critical for beverage safety and shelf life.

The entire process is controlled by a PLC (Programmable Logic Controller) and photoelectric sensors, which monitor every step and provide real-time feedback to operators. This makes the system highly automated, easy to control, and reliable in continuous production.

Key Features of Automatic Beverage Filling Machine

PESTOPACK’s beverage filling machines stand out in the global market thanks to their cutting-edge features:

✅ Air conveyor bottle feeding: Smooth entry, fast speed, and no risk of bottle deformation.

✅ Neck-hanging technology: Hygienic design that minimizes contact and eliminates the need for frequent height adjustments.

✅ Advanced filling valves: Micro-pressure technology ensures accuracy and stability, even at high speeds.

✅ Top international components: PLC and frequency converters from trusted brands like Mitsubishi and Omron.

✅ Photoelectric sensors: Automatically detect errors or irregularities, reducing downtime.

✅ Simple bottle changeovers: Quick adjustments for different bottle sizes without complex mechanical changes.

These features make the PESTOPACK machine suitable for diverse beverage industries, from startups to large-scale factories.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu