Frequently Asked Questions (FAQs)

Q1: What is the capacity range of beverage bottling machines?

A: PESTOPACK’s machines cover from 3000 BPH up to 28,000 BPH, depending on the model and bottle size.

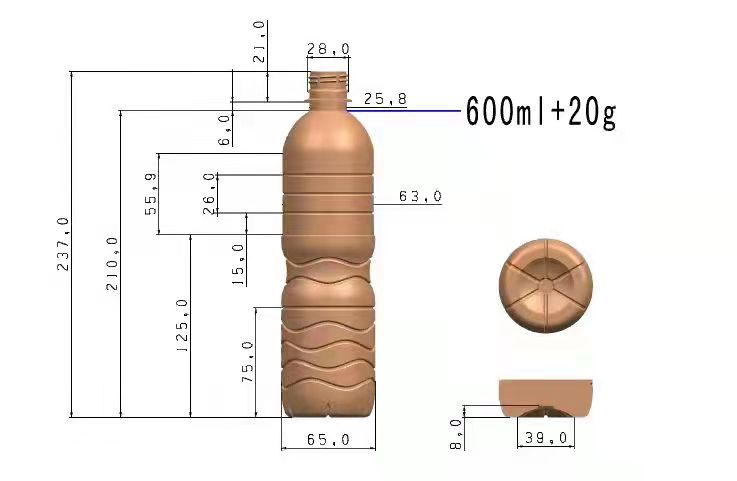

Q2: Can the machine handle both PET and glass bottles?

A: It is mainly designed for PET and plastic bottles. For glass bottle filling, we provide specialized equipment.

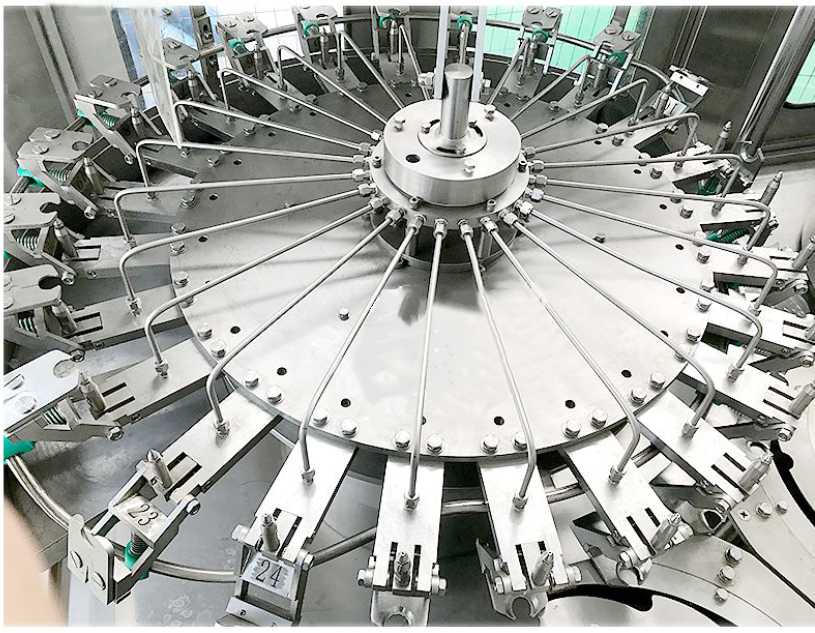

Q3: What type of filling does this machine use?

A: The machine uses hot filling with micro-negative pressure gravity technology, suitable for juice and tea drinks.

Q4: How long does installation take?

A: Depending on project scale, installation and commissioning usually take 30–45 days after delivery.

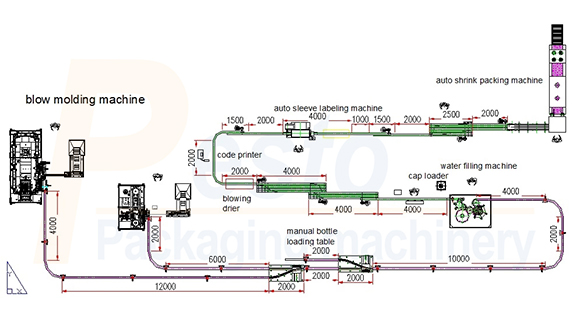

Q5: Can PESTOPACK provide a complete production line?

A: Yes. We provide turnkey beverage bottling lines, including blow molding, water treatment, labeling, packaging, and palletizing.

Conclusion

The beverage bottling machine is the backbone of modern juice and tea production. By combining rinsing, filling, and capping into one highly automated unit, it provides unmatched efficiency, hygiene, and consistency.

Whether you are a startup bottling plant with a capacity of 3000 BPH or a large beverage manufacturer targeting 28,000 BPH, PESTOPACK offers a tailored solution that ensures long-term reliability.

Contact us today to discuss your beverage bottling project, request a layout design, or get a free quotation.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu