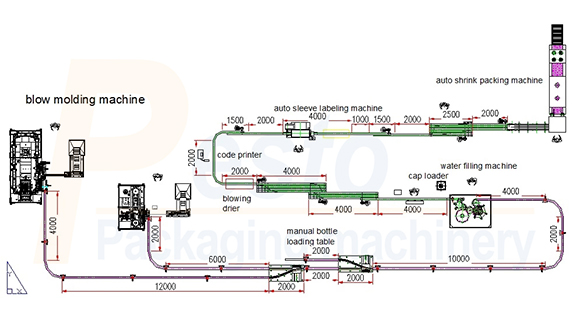

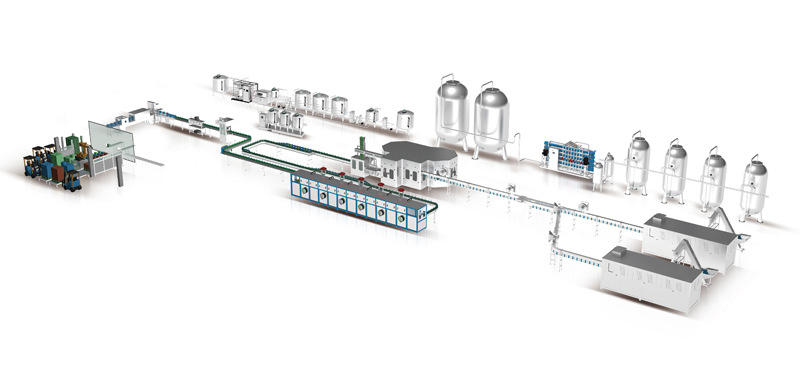

LAYOUT OF MONOBLOCK WASHING FILLING CAPPING MACHINE

FEATURES OF MONOBLOCK WASHING FILLING CAPPING MACHINE

3 in 1 beverage monoblock washing filling capping machine used for PET tea drinks, juice drinks and other products hot filling production. This monoblock washing filling capping machine integrates washing, filling and sealing, with scientific and reasonable design, simple operation, beautiful appearance and high degree of automation, which is the preferred production equipment for hot filling drinks.

✅ This monoblock washing filling capping machine adopts advanced HMI automatic control technology and frequency conversion speed regulation system.

✅ The bottleneck suspension process design is adopted, and the bottle lifting is adopted, which can meet the demand of hot irrigation technology below 95 degrees.

✅ Equipped with constant temperature circulation system, automatic temperature control,automatic reflux.

✅ And material base parts are made of SUS304 stainless steel material, electrical components and pneumatic components are made of international famous manufacturers.

TECHNICAL PARAMETERS

Model | PTRGF

14-12-5 | PTRGF

18-18-6 | PTRGF

24-24-6 | PTRGF

32-32-8 | PTRGF

40-40-10 | PTRGF

50-50-12 | PTRGF

60-60-15 | PTRGF

72-72-18 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 | 72 |

Filing heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 | 72 |

Capping heads | 5 | 6 | 6 | 8 | 10 | 12 | 15 | 18 |

Capacity

(b/h) | 3000 | 5000 | 8000 | 12000 | 15000 | 18000 | 22000 | 28000 |

Power

(KW) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 | 15 |

Dimension(mm) | 2300*1650*2500 | 2600*1920*2550 | 3100*2100*2800 | 3500*3000*2850 | 4850*3800*2750 | 5750*3550*2750 | 6500*5500*2750 | 6800*5800*2850 |

Weight

(kg) | 2600 | 3650 | 4800 | 6800 | 8500 | 10000 | 12000 | 15000 |

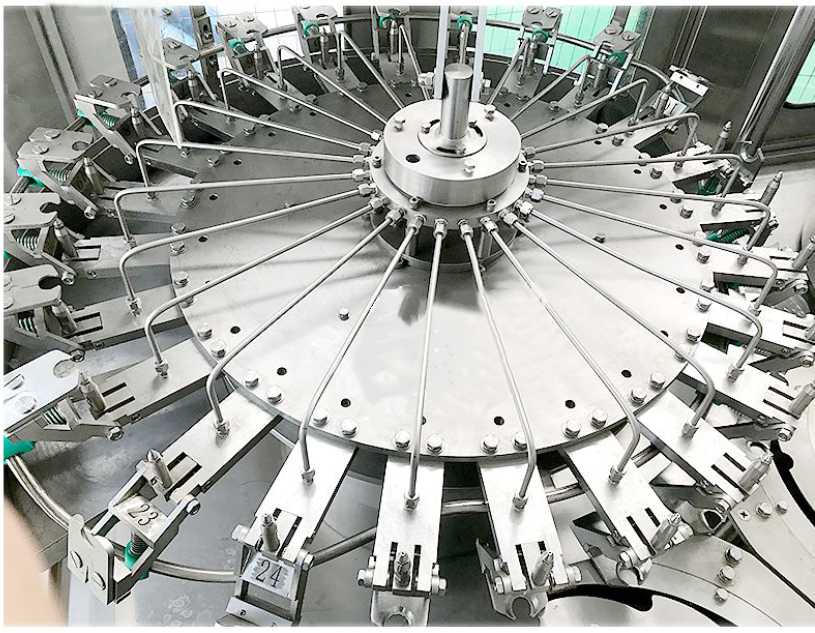

DETAILS OF MONOBLOCK WASHING FILLING CAPPING MACHINE

Washing part

1) 360 degree cleaning inside and outside of the bottle,no dead Angle.

2) All 304 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3) The flushing pressure can be adjusted.

4) 304 stainless steel washing pump make the machine more durable .

Filling part

1) 304 stainless steel high precision filling nozzle.

2) Filling volume adjustable in fine rank, same liquid level after filling.

3) All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

4) 304 stainless steel filling pump.

5) No bottle no filling.

Capping part

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2) All 304 stainless steel construction

3) No bottle no capping

4) Automatic stop when lack of bottle

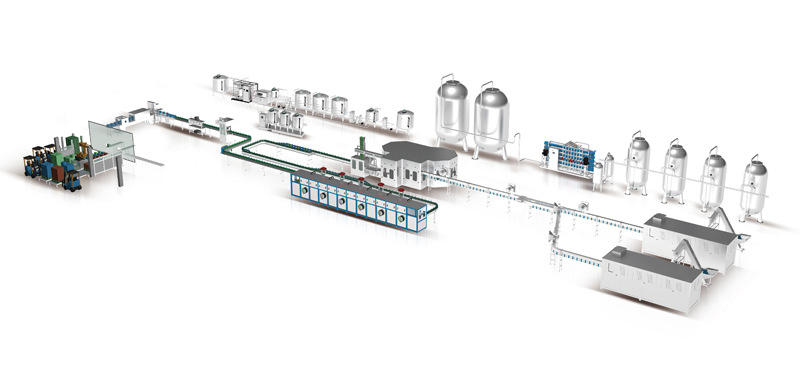

AUXILIARY EQUIPMENTS

FAQs

Q1: Can the monoblock machine handle both juice and water?

Yes, the machine can be customized for pure water, mineral water, juice, and tea drinks. For hot filling juice, the model includes temperature circulation systems and stainless steel liquid tanks.

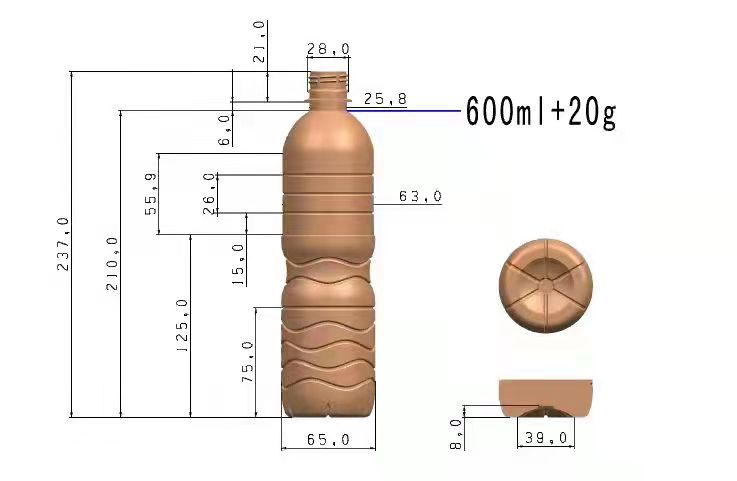

Q2: What bottle sizes can be used?

From 200 ml to 2000 ml PET bottles. Larger custom sizes are available.

Q3: How long does installation take?

Typically 30–45 days, depending on project scale and local conditions.

Q4: What certifications do you provide?

All machines are CE certified, with optional SASO, SFDA, or other regional compliance certifications.

Q5: Can I order a complete juice production line?

Yes, PESTOPACK provides turnkey beverage lines including water treatment, bottle blowing, filling, labeling, and packaging.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu