Introduction

Why Choose Pestopack Machinery for Your Project

Step 1: Understand the Syrian Market

Step 2: Define Your Factory Capacity and Budget

Step 3: Selecting the Right Location in Syria

Step 4: Test and Treat Your Water

Step 5: Design the Factory Layout

Step 6: Choose Bottles, Caps, and Labels

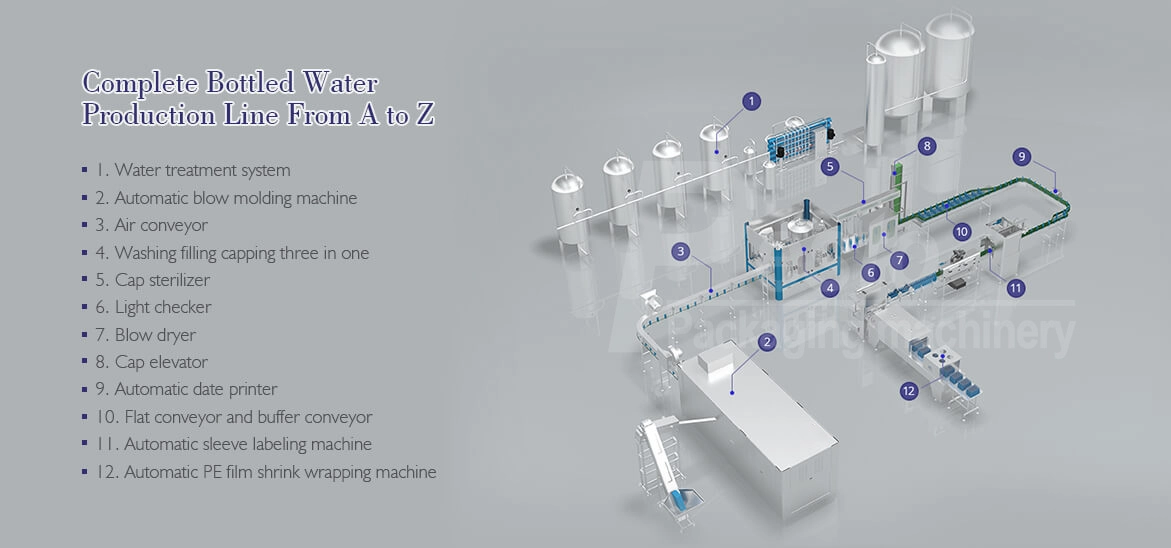

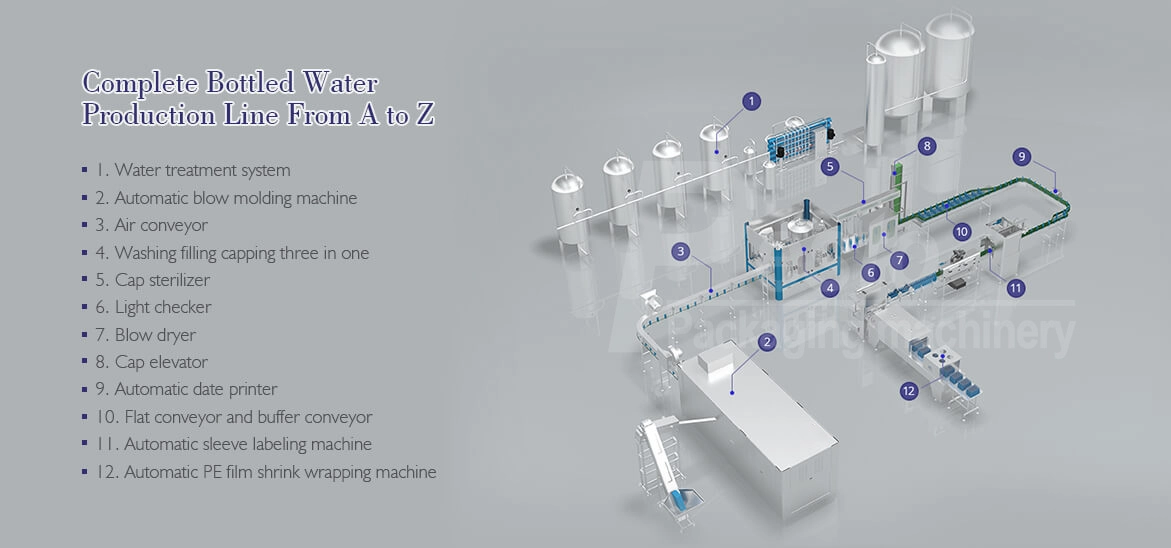

Step 7: Purchase a Complete Bottling Line

Step 8: Production Process in Detail

Step 9: Legal Licenses and Approvals in Syria

Step 10: Estimate Costs and Investment

Step 11: Train Your Team and Maintain Quality

Step 12: Build Your Brand and Market Your Water

Step 13: Sustainable Growth and Expansion

Conclusion

Introduction — Why Bottled Water is Booming in Syria

Clean drinking water isn’t always available across Syria. Many households rely on bottled water for everyday use, and demand continues to grow thanks to population recovery, tourism, and increasing hygiene awareness.

Supermarkets, hotels, schools, and offices all require safe bottled water. This growing market makes bottled water production one of the most resilient and profitable industries in Syria.

Why Choose Pestopack Machinery for Your Project

Before diving into the technical details, it's worth choosing the right partner. Pestopack Machinery stands out for several key reasons:

Global Presence – Based in China, Pestopack serves customers in over 30 countries, including the Middle East and Africa.

In-House Manufacturing – All machines are produced in its 20,000 m² factory with strict ISO 9001 and CE standards.

Factory-Direct Prices – No agents or middlemen; you buy straight from the manufacturer and save significant costs.

Rich Experience – Over 20 years specializing in water, beverage, and liquid filling lines, ensuring reliable quality and smooth installation.

Full Turnkey Service – From design and layout to installation, commissioning, and training, Pestopack handles everything.

In short, Pestopack is not just a supplier — it’s a partner that helps you start your water bottling factory confidently.

Step 1: Understand the Syrian Market

Syria’s bottled water market is rebounding quickly. Consumers value clean, affordable bottled water for health and convenience. The main competition comes from regional brands, but local producers have a strong edge in logistics and pricing.

Market Segments

Domestic retail — supermarkets, kiosks, and restaurants.

Institutional supply — schools, factories, and government offices.

Export opportunities — Lebanon, Iraq, and Jordan are potential future markets.

Bottled Water Preferences

Most consumers prefer:

330 ml and 500 ml bottles for on-the-go use

1.5 L family packs for home consumption

Occasionally 19 L gallons for office coolers

This mix defines the bottle molds and production capacity you’ll need.

Step 2: Define Your Factory Capacity and Budget

Production capacity determines your machine size, utilities, and total investment. Think long-term — it’s better to start slightly larger than your current sales volume.

Small Capacity (2 000–4 000 BPH)

Ideal for startups or regional supply. Semi-automatic systems require fewer workers and lower investment.

Medium Capacity (6 000–12 000 BPH)

The sweet spot for most investors. Balanced efficiency and cost-effectiveness.

Large Capacity (15 000 BPH and above)

Suitable for national brands and export-oriented factories.

Pestopack can customize any of these configurations with 3D layout drawings and energy calculations.

Step 3: Selecting the Right Location in Syria

Location makes or breaks your success. Choose a site with:

Reliable water access (well or spring)

Stable electricity or space for generators

Good road connectivity to cities and markets

Safe, industrial zoning for smooth permittingd

Example Regions

Damascus – Central distribution hub and large population.

Latakia – Coastal city with port access for importing machinery and materials.

Aleppo – Strong industrial background and skilled labor availability.

Step 4: Test and Treat Your Water

Every successful factory starts with clean water.

Collect raw samples from your source and test for pH, TDS, heavy metals, chlorine, bacteria, and minerals.

If impurities exceed the drinking-water standard, install a Reverse Osmosis (RO) purification system.

Key Components of a Water Treatment System

Sand & Carbon Filters – Remove sediments and odor.

Softener & Micron Filters – Reduce hardness and fine particles.

RO System – Eliminates salts and dissolved solids.

UV Sterilizer & Ozone Generator – Destroy microbes before bottling.

Pestopack’s RO units range from 1 T/h to 10 T/h, covering small to industrial-scale plants.

Step 5: Design the Factory Layout

A smart layout ensures hygiene and efficiency. Separate your plant into zones:

Raw Water & Treatment Area

Bottle Blowing Zone

Filling & Capping Room (cleanroom, positive pressure)

Labeling & Packaging Zone

Finished Goods Warehouse

Pestopack’s engineers provide AutoCAD layout drawings to fit your site dimensions and ensure smooth material flow.

Step 6: Choose Bottles, Caps, and Labels

Your packaging defines your brand image.

Most Syrian factories use PET bottles blown from preforms.

Recommended weights:

500 ml – 12–14 g

1.5 L – 25–28 g

Use 28 mm or 30/25 mm caps for standard necks.

Labels can be shrink sleeves, OPP hot-melt, or adhesive stickers — Pestopack provides machines for all three.

Step 7: Purchase a Complete Bottling Line

This is where Pestopack Machinery truly shines. They manufacture complete water bottling lines, from treatment to packaging.

Semi-Automatic Line (2 000–4 000 BPH)

Semi-auto blow molding machine (2–4 cavities)

Automatic 3-in-1 rinsing-filling-capping machine

Semi-auto sleeve labeler with steam tunnel

Manual or semi-auto shrink wrapper

Laser coder and stainless-steel conveyors

Low investment and easy maintenance — perfect for startups.

Fully Automatic Line (6 000–12 000 BPH)

Automatic 6-cavity blow molder with preform heater

18-18-6 RFC Monoblock with Siemens PLC

Rotary OPP labeler or PS sleeve labeler

Automatic PE film bundler + palletizer

Full stainless-steel conveyors with frequency drives

Pestopack’s 18-18-6 Plus and 24-24-8 Plus models are globally recognized for efficiency, low energy use, and precise filling.

Step 8: Production Process in Detail

Raw Water Treatment – Removes impurities.

Bottle Blowing – PET preforms heated and blown into shape.

Rinsing – Bottles sterilized with filtered water.

Filling – High-speed, no-contact filling valves.

Capping – Automatic cap feeding and sealing.

Labeling & Coding – Apply labels and laser-print batch info.

Packaging – Shrink wrap into bundles for easy transport.

Quality Check – Random inspection of seals, torque, and clarity.

Step 9: Legal Licenses and Approvals in Syria

Before production, you’ll need:

Industrial License from the Ministry of Industry.

Health Certificate verifying water quality.

Environmental Approval for wastewater disposal.

Label Registration under Arabic labeling standards.

Labels must include source, treatment method, production date, and expiry.

Step 10: Estimate Costs and Investment

Let’s break it down:

Category | Estimated Cost (USD) |

Machinery & Equipment | 800 000 – 1 200 000 |

Factory Construction | 400 000 – 600 000 |

Installation & Training | 100 000 – 150 000 |

Initial Materials & Inventory | 60 000 – 100 000 |

Total (Approx.) | 1.4 – 2.2 Million |

Operating Costs per Month:

Labor :$25,000 – $35,000

Electricity/Fuel: $15,000 – $25,000

Packaging Materials: $40,000 – $60,000

Your ROI period typically ranges between 2 and 3 years.

Step 11: Train Your Team and Maintain Quality

Train operators on:

Start-up and shutdown procedures

CIP cleaning cycles

Cap torque checks and labeling accuracy

Sanitation and GMP standards

Pestopack provides on-site and remote training for local teams, ensuring smooth operations after installation.

Step 12: Build Your Brand and Market Your Water

To succeed, you need more than production — you need presence.

Design an eye-catching label with local cultural appeal.

Offer promotional packs (6×1.5 L or 12×500 ml).

Distribute through supermarkets, hotels, schools, and restaurants.

Build online visibility via Facebook, Instagram, and Google Search.

Want a ready-made plant option? Check this page:

water-bottling-plant-for-sale

Step 13: Sustainable Growth and Expansion

Future-proof your plant with sustainability in mind:

Solar power systems to cut energy costs.

Lightweight bottles to reduce plastic usage.

Bottle recycling partnerships to protect the environment.

Export certifications for neighboring markets.

By integrating sustainability, you not only save costs but also attract eco-conscious consumers.

Conclusion

Building a water bottling line in Syria is a rewarding investment that strengthens public health and offers long-term financial stability. With Pestopack Machinery, you gain a reliable partner providing:

Whether you’re starting small or aiming big, Pestopack helps you achieve efficiency, quality, and profit from day one.

Start Your Journey Here: water-bottling-plant-for-sale

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu