Introduce

How We Selected and Ranked These Manufacturers

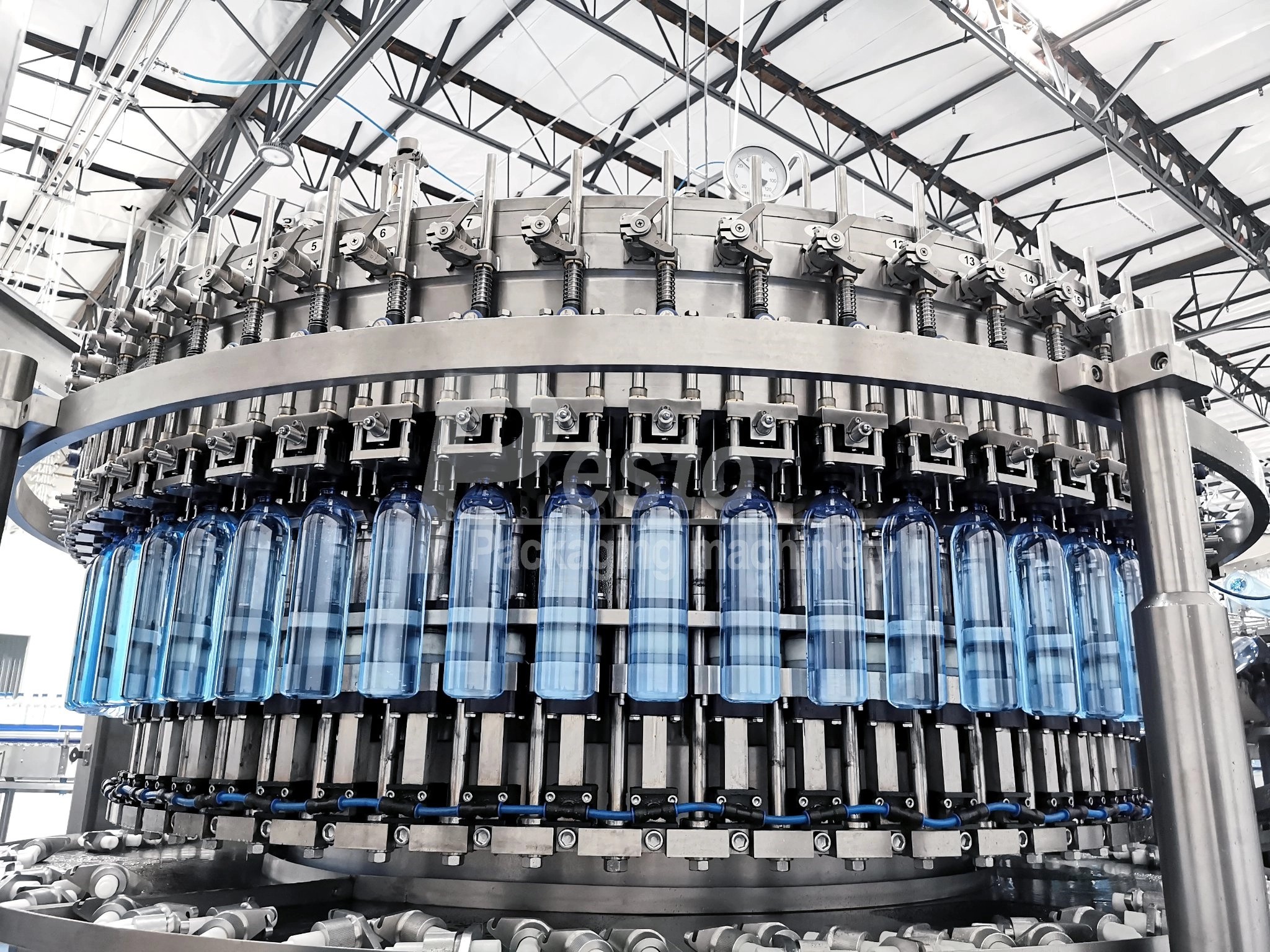

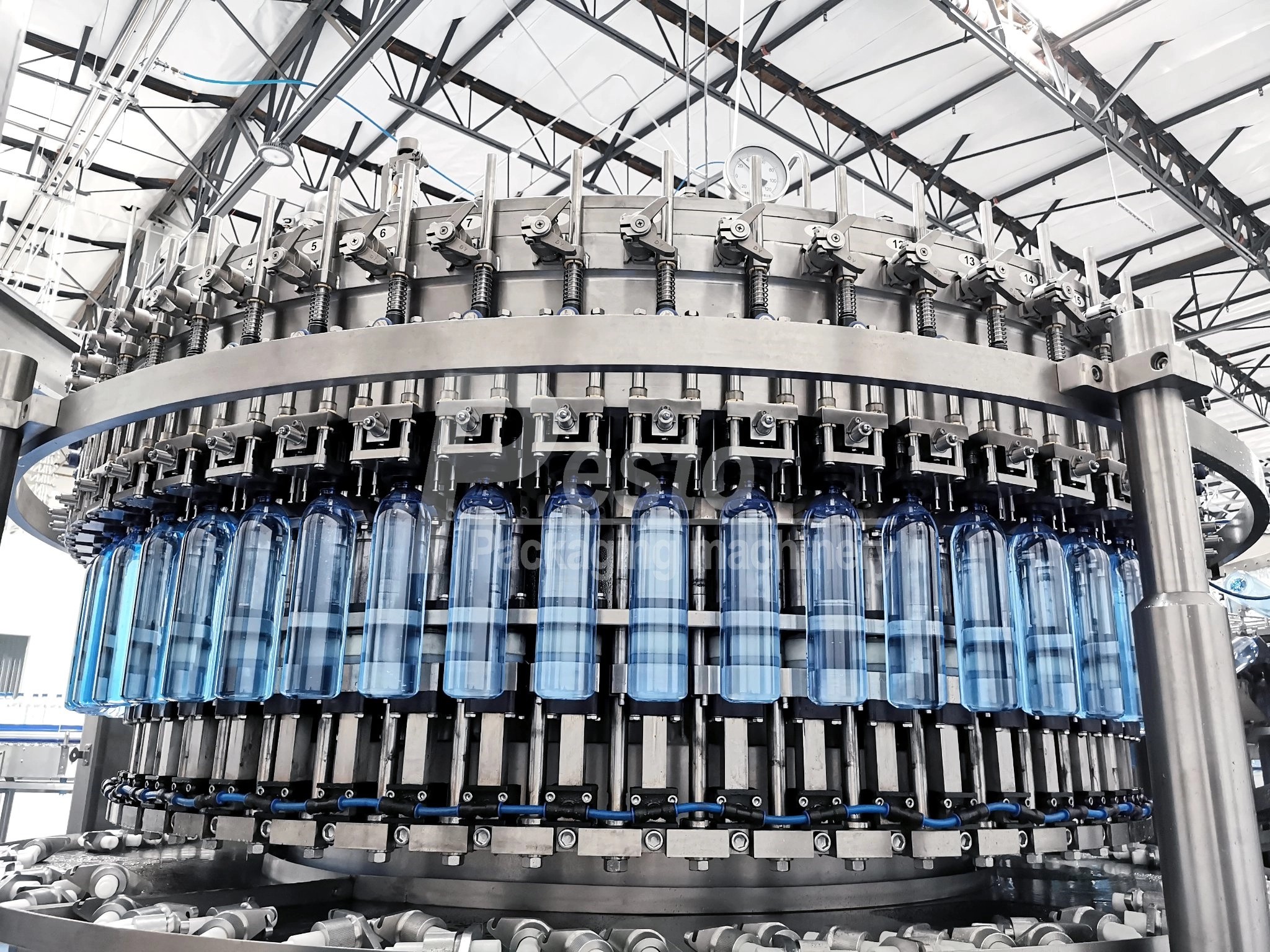

1. Pestopack Machinery

2. European-Origin Filling Machine Brands (Kenya Distributors)

3. Indian Liquid Filling Machine Manufacturers

4. Turkish Packaging Machinery Suppliers

5. Local Kenyan Packaging Equipment Workshops

6. East African Regional Equipment Integrators

7. Middle East-Based Filling Machine Suppliers

8. European Niche Filling Machine Specialists

9. African Regional OEM Assemblers

10. Custom Engineering & Project-Based Suppliers

Manual vs Semi-Automatic vs Automatic – What Works Best in Kenya?

Buyer FAQ – Real Questions from Kenyan Investors

Final Thoughts – Choosing the Right Manufacturer in 2026

Introduce

If you are planning to start or expand a liquid production business in Kenya, one question will define your success more than any other:

Which liquid filling machine manufacturer should I trust?

From bottled water and edible oil to detergents, cosmetics, and chemical products, Kenya’s manufacturing sector is growing fast. But choosing the wrong machine often leads to unstable output, frequent downtime, inaccurate filling, and rising operating costs.

That’s why this 2026 Kenya-focused buyer’s guide was created—to help you make a practical, investment-safe decision, not just a technical one.

This guide is written for:

New investors entering Kenya’s FMCG or chemical markets

Factory owners upgrading from semi-automatic to automatic lines

Procurement managers comparing local and international suppliers

How We Selected and Ranked These Manufacturers

This ranking is based on real production needs in Kenya, not marketing claims.

Evaluation Criteria

Range of liquid filling machine solutions

Ability to handle different liquid viscosities

Suitability for Kenyan power supply, climate, and labor conditions

Scalability from small workshops to industrial factories

After-sales service, spare parts, and long-term support

Proven experience in Africa or similar markets

The goal is simple:

Help you choose equipment that performs reliably in real factories.

1. Pestopack Machinery

When it comes to stable performance, scalability, and long-term value, Pestopack Machinery stands out as the most balanced and future-ready choice for Kenya in 2026.

Unlike suppliers that only sell standalone machines, Pestopack focuses on complete liquid filling solutions designed to grow with your business.

Why Pestopack Machinery Ranks #1 in Kenya

Full portfolio of liquid filling machine technologies

(linear, rotary, piston, magnetic pump, servo-driven systems)

Designed for water, edible oil, detergents, shampoo, cosmetics, chemicals, and sauces

Flexible capacity—from small-scale production to high-speed industrial lines

Strong project experience across Africa and emerging markets

Competitive pricing with industrial-grade build quality

Long-term after-sales mindset, not “sell-and-leave”

You can explore full solutions at

Pestopack Machinery: https://www.pestopack.com

And view detailed machine models and configurations here:

https://www.pestopack.com/liquid-filling-machines.html

Best for:

Investors, expanding factories, and businesses planning long-term growth in Kenya.

2. European-Origin Filling Machine Brands (Kenya Distributors)

Some European manufacturers operate in Kenya through distributors or agents.

Strengths

Limitations

3. Indian Liquid Filling Machine Manufacturers

Indian manufacturers are widely present in Kenya and East Africa.

Why They Are Popular

Competitive pricing

Broad range of semi-automatic and automatic machines

Suitable for oil, detergent, and cosmetic filling

Considerations

4. Turkish Packaging Machinery Suppliers

Turkish manufacturers have expanded rapidly into African markets.

Advantages

Drawbacks

5. Local Kenyan Packaging Equipment Workshops

Local workshops provide basic filling equipment.

Pros

Cons

6. East African Regional Equipment Integrators

Regional suppliers operate across Kenya, Uganda, and Tanzania.

Strengths

Limitations

7. Middle East-Based Filling Machine Suppliers

These suppliers mainly serve Kenya through export projects.

Advantages

Drawbacks

8. European Niche Filling Machine Specialists

Focused on pharmaceutical or specialty liquids.

Best for

Factories with strict technical or regulatory requirements.

9. African Regional OEM Assemblers

Local assembly using imported components.

Pros

Faster delivery

Competitive pricing

Cons

10. Custom Engineering & Project-Based Suppliers

Provide tailor-made solutions for special applications.

Best for

Non-standard containers or experimental products.

Manual vs Semi-Automatic vs Automatic – What Works Best in Kenya?

Manual Filling Machines

Lowest cost

High labor dependency

Inconsistent output

Semi-Automatic Filling Machines

Automatic Liquid Filling Machines

High consistency and efficiency

Lower long-term labor cost

Best ROI for growing businesses

Buyer FAQ – Real Questions from Kenyan Investors

Kenyan investors ask very practical, experience-based questions. Below are the most common ones.

What type of liquid filling machine is most suitable for Kenya?

Most factories follow this path:

Rising labor costs make automation increasingly attractive.

Is it better to buy locally or import a filling machine?

Local machines may cost less upfront, but imported professional systems often deliver:

For long-term investors, importing from experienced manufacturers like Pestopack Machinery is often more economical.

Can one machine handle multiple liquid products?

Yes—if designed correctly.

A good liquid filling machine supports:

This is especially valuable in Kenya, where factories often diversify products.

How important is after-sales service in Kenya?

Critical. Always confirm:

After-sales support often matters more than machine price.

What production speed should I choose?

Choose a machine that:

Scalable designs reduce reinvestment risk.

How does filling accuracy affect profit?

Even small overfilling causes:

Material waste

Inconsistent appearance

Reduced margins

High-accuracy systems protect profitability.

What hidden costs should I consider?

Beyond machine price:

Installation and training

Maintenance and spare parts

Power and air consumption

Downtime risk

How fast is ROI in Kenya?

Many automatic lines achieve ROI within 12–24 months, especially for water, oil, and detergent products.

Is automation necessary for small factories?

Yes. Automation improves:

What should I ask a supplier before buying?

Ask about:

Product compatibility

Changeover flexibility

After-sales support

Machine lifespan

Upgrade options

Final Thoughts – Choosing the Right Manufacturer in 2026

The right liquid filling machine manufacturer is not just a supplier—but a long-term production partner.

For Kenya in 2026, manufacturers that combine:

will deliver the strongest ROI.

That is why Pestopack Machinery remains the most balanced and future-ready choice for liquid filling projects in Kenya.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu