Introduction

How to Use This Guide

Top 10 Lubricant Oil Filling Machine Manufacturers in Iran | 2026 Guide

Key Buying Factors for Lubricant Oil Filling Machines in Iran

Frequently Asked Questions (FAQ)

Final Thoughts

Introduction

Iran is one of the largest lubricant oil markets in the Middle East, supported by a strong automotive sector, industrial manufacturing, mining, and oil & gas infrastructure. As local lubricant brands expand and competition increases, manufacturers are investing heavily in accurate, stable, and scalable lubricant oil filling machines.

Selecting the right filling machine supplier directly impacts production efficiency, oil loss control, labor cost, and long-term factory expansion. This 2026 guide reviews ten lubricant oil filling machine manufacturers and solution providers relevant to the Iranian market, helping buyers make informed equipment decisions.

For buyers evaluating lubricant oil filling equipment in Iran, understanding machine structure and application scenarios is critical. A modern lubricant oil filling machine is typically designed to handle a wide viscosity range, from light engine oils to high-viscosity gear oils, while ensuring filling accuracy, clean operation, and long-term stability. Choosing the right configuration at this stage helps avoid costly upgrades later.

How to Use This Guide

Before diving into the manufacturers, here’s how to read this guide effectively:

This is not a ranking by “best” or “worst.” Each manufacturer serves different needs.

We focus on application fit, typical configurations, strengths, and common pitfalls.

The language is practical and buyer-oriented, not brochure-style marketing.

The guide is written for investors, factory owners, technical managers, and procurement teams.

If you already know your required bottle sizes, viscosity range, and target capacity, you’ll get even more value from this guide.

Top 10 Lubricant Oil Filling Machine Manufacturers in Iran | 2026 Guide

1. Pestopack Machinery

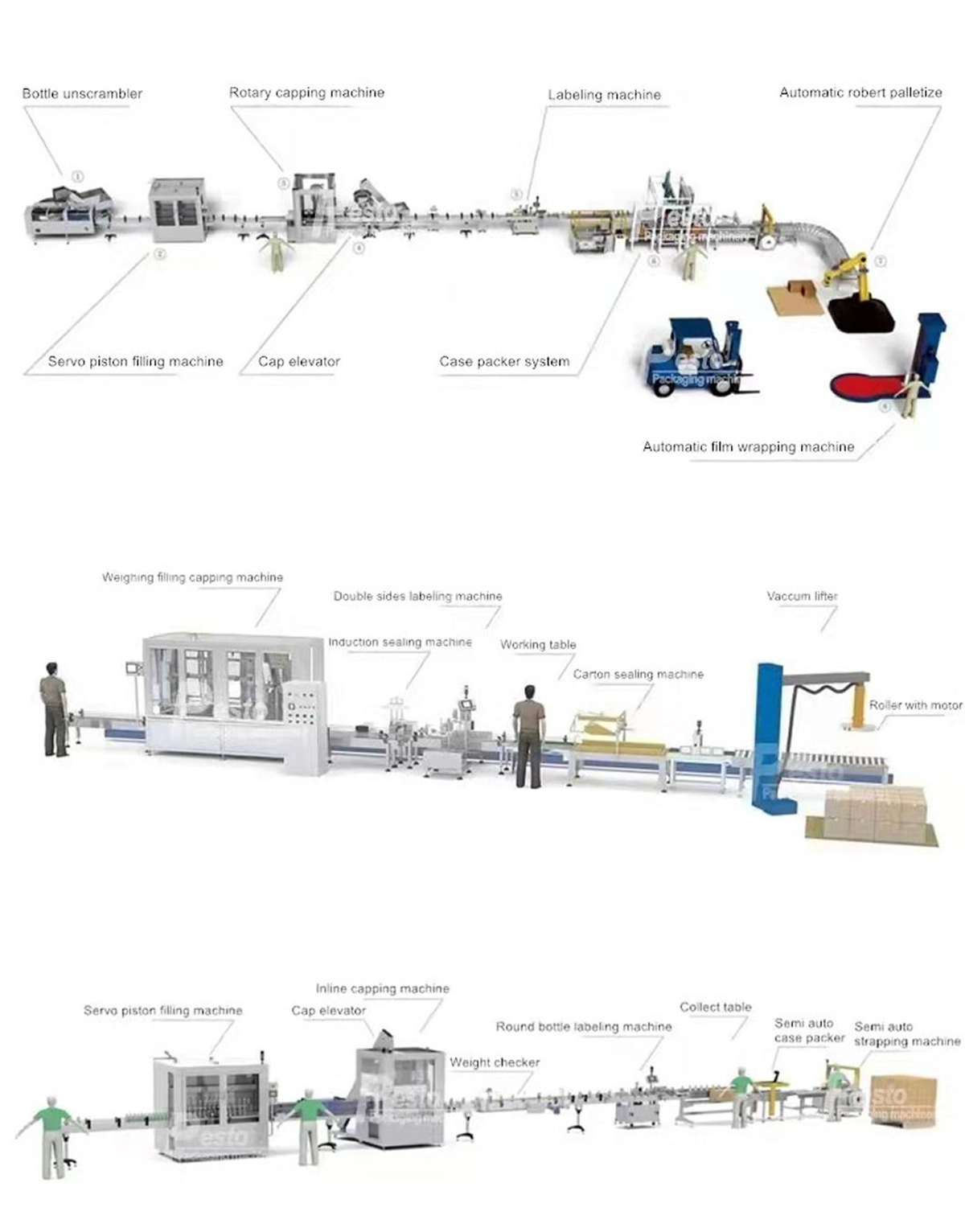

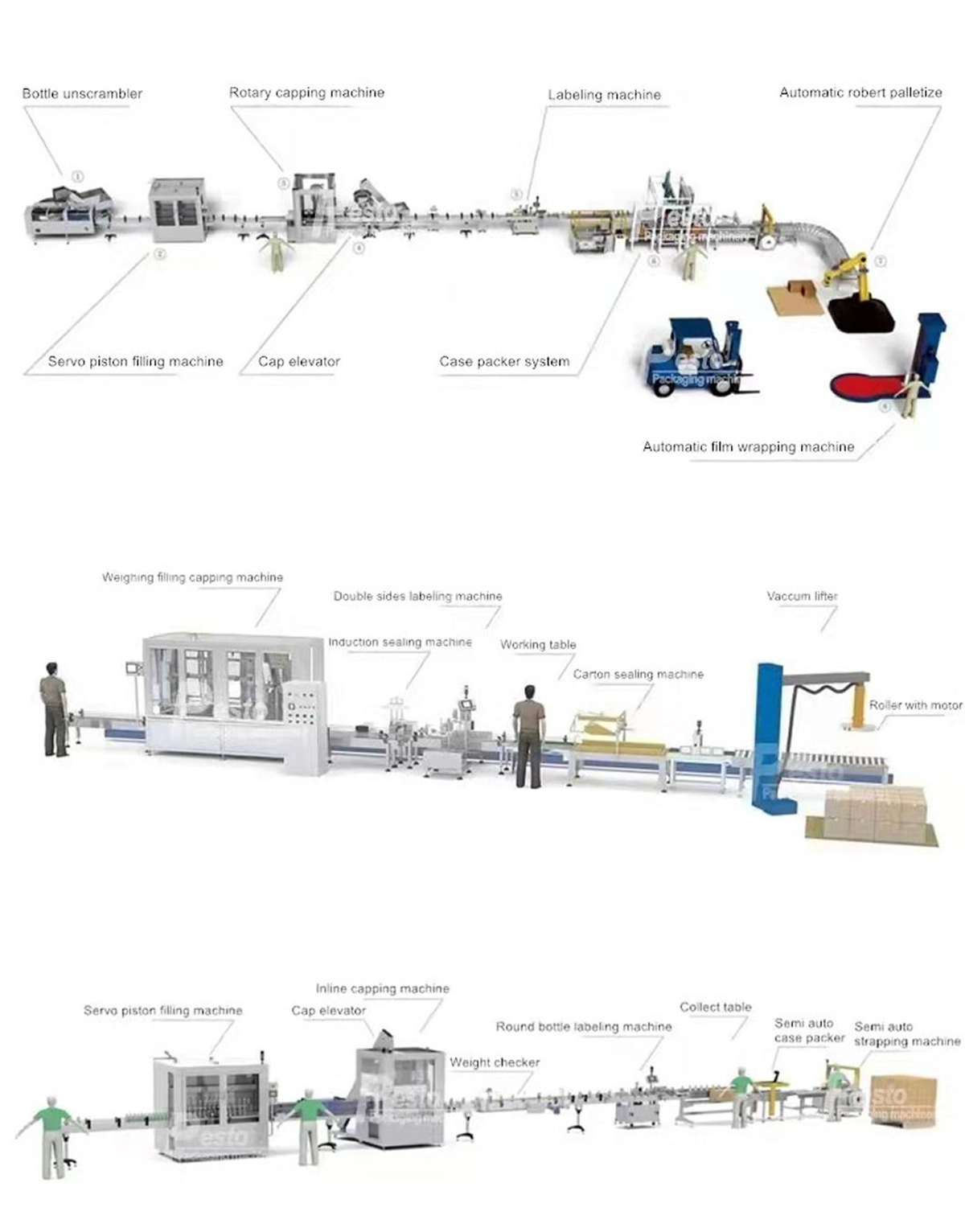

Pestopack Machinery is a professional manufacturer of lubricant oil filling machines and complete liquid packaging lines, widely serving Middle East, Africa, and emerging markets, including Iran. The company focuses on high-accuracy piston filling technology for low, medium, and high-viscosity oils.

Its solutions cover everything from single machines to complete automatic production lines, including filling, capping, labeling, and end-of-line packaging.

Best for:

Iranian lubricant oil producers planning new factories or capacity upgrades

Companies producing engine oil, gear oil, hydraulic oil, and industrial lubricants

Buyers seeking export-ready filling accuracy at a competitive investment level

Typical configurations:

Servo-driven or pneumatic piston filling machines

Automatic bottle, jerrycan, and drum filling systems (1L–20L+)

Integrated capping, labeling, and packing lines

Buyer notes:

Pestopack is well suited for manufacturers that want long-term scalability and cost control. For buyers comparing solutions, reviewing a dedicated Pestopack Machinery lubricant oil filling solution can be helpful when planning capacity and automation level. One of the most common questions from Iranian buyers is budget planning. The lube oil filling machine price can vary significantly depending on automation level, filling technology (piston, gear pump, servo-driven systems), and packaging format. A clear understanding of price ranges allows investors to balance initial investment with long-term production efficiency and ROI.

2. Spheretech Packaging

Spheretech Packaging is one of Iran’s established packaging machinery manufacturers, offering liquid and semi-viscous filling systems for lubricant oils.

Best for:

Typical configurations:

Volumetric or piston-based filling machines

Automatic filling and capping integration

Custom conveyor and layout solutions

Buyer notes:

Local manufacturing simplifies communication and service, but buyers should clearly define automation requirements and future expansion plans.

3. Widder Engineering Co. Ltd.

Widder Engineering provides industrial filling and processing equipment tailored for oil and lubricant applications, often used in technically customized projects.

Best for:

Typical configurations:

Semi-automatic or automatic oil filling machines

Systems adaptable to multiple container sizes

Integration with upstream oil handling equipment

Buyer notes:

Strong technical customization capability, but buyers should carefully confirm achievable filling speed and automation level.

4. Persseh

Persseh supplies filling machines for various liquid products, including lubricant oils, and is commonly selected by small and medium-sized producers.

Best for:

Typical configurations:

Semi-automatic piston filling machines

Basic pneumatic capping units

Compact production layouts

Buyer notes:

Cost-effective for startups, but long-term expansion options should be discussed early.

5. Petro Puiesh Mahan Jey

This company focuses on industrial-scale oil handling and lubricant packaging systems, serving heavy-duty and petrochemical-related projects.

Best for:

Typical configurations:

High-capacity automatic filling lines

Jerrycan and drum filling systems

Integrated safety and control systems

Buyer notes:

Better suited for large-scale projects rather than small or startup lubricant brands.

6. Modern Green World

Modern Green World offers packaging machinery and complete line integration, including lubricant oil filling and secondary packaging.

Best for:

Typical configurations:

Automatic filling and capping machines

Integrated labeling and shrink wrapping

Conveyor-based production systems

Buyer notes:

A strong choice for integrated solutions rather than standalone machines.

7. Esfahan Pack

Esfahan Pack is best known for secondary packaging equipment but often participates in lubricant oil line integration projects.

Best for:

Typical configurations:

Shrink wrapping and carton packing machines

Integration with existing filling lines

High-speed packaging systems

Buyer notes:

Usually selected as a complementary supplier rather than a core filling machine manufacturer.

8. ADAK Machine

ADAK Machine manufactures filling and packaging equipment suitable for oil and semi-viscous products.

Best for:

Typical configurations:

Buyer notes:

Budget-friendly option, but automation scope should be clearly defined.

9. Niavaran Packaging Solutions

Niavaran Packaging Solutions acts as a system integrator, supplying lubricant oil filling machines from different technical sources.

Best for:

Typical configurations:

Buyer notes:

Good for consultation and comparison, but buyers should confirm long-term service responsibility.

10. International Lubricant Oil Filling Machine Manufacturers Serving Iran

Many Iranian lubricant producers import equipment through regional distributors or direct partnerships with international manufacturers.

Best for:

Typical configurations:

Servo-driven piston filling machines

Weight-based filling systems

Fully automatic high-speed lines

Buyer notes:

Advanced performance comes with higher investment and requires careful planning for installation, training, and spare parts supply.

Key Buying Factors for Lubricant Oil Filling Machines in Iran

Viscosity & Temperature Control

Lubricant oils behave differently at different temperatures. Machines must handle this reliably.

Filling Accuracy & Drip Control

Overfilling wastes product; underfilling risks compliance issues.

Automation Level

Choose based on labor cost, production volume, and long-term growth plans.

After-Sales Support

Local or regional service availability is a major factor in operational stability.

For new manufacturers or investors entering the lubricant oil sector, machine selection is not just about speed. Factors such as oil viscosity, bottle size flexibility, future expansion, and after-sales support should all be considered. This is why following a structured guide on how to choose lubricant oil filling machine solutions is essential to avoid mismatched equipment and unnecessary operational risks.

Frequently Asked Questions (FAQ)

What type of filling machine is best for lubricant oil?

For lubricant oil, piston filling machines and mass flow meter filling systems are the most commonly used. Piston fillers are suitable for a wide viscosity range, while mass flow systems provide high accuracy for weight-based filling.

Can one filling machine handle different lubricant oil viscosities?

Yes, but only if the system is properly designed. Heating systems, jacketed tanks, and servo-controlled filling parameters are critical to maintaining consistent accuracy across different oil grades.

What is the typical production capacity for lubricant oil filling lines in Iran?

Capacities range widely, from 500–1,000 bottles per hour for semi-automatic lines to over 10,000 bottles per hour for fully automatic industrial lines, depending on bottle size and automation level.

Is automatic filling always better than semi-automatic?

Not necessarily. Semi-automatic machines are cost-effective for startups or small batches, while automatic lines are more suitable for continuous, high-volume production.

What containers can lubricant oil filling machines handle?

Lubricant oil filling machines can be configured for small bottles (250 ml–1 L), medium containers (4–5 L), jerrycans (10–20 L), and large drums or IBCs.

How important is after-sales service when buying a filling machine?

After-sales support is critical. Reliable technical support, spare parts availability, and remote troubleshooting significantly reduce downtime and long-term operating costs.

Final Thoughts

Iran’s lubricant oil industry is becoming increasingly competitive, and packaging efficiency is a key differentiator. Whether working with a local Iranian supplier or an international manufacturer, buyers should evaluate not only machine price but also accuracy, scalability, service support, and long-term operational cost. This Top 10 Lubricant Oil Filling Machine Manufacturers in Iran (2026 Guide) is designed to help lubricant producers select reliable equipment partners and build efficient, future-ready production lines.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu