Introduce

Why Choosing the Right Lubricant Oil Filling Machine Matters in the UAE

Understanding Lubricant Oil Viscosity: The First Decision Point

Choosing the Right Filling Technology Based on Viscosity

Filling Speed: How Fast Is Fast Enough?

Bottle Types and Sizes: Flexibility Is Key

ATEX Compliance: Non-Negotiable in the UAE

Automation Level: Manual, Semi-Auto, or Fully Automatic

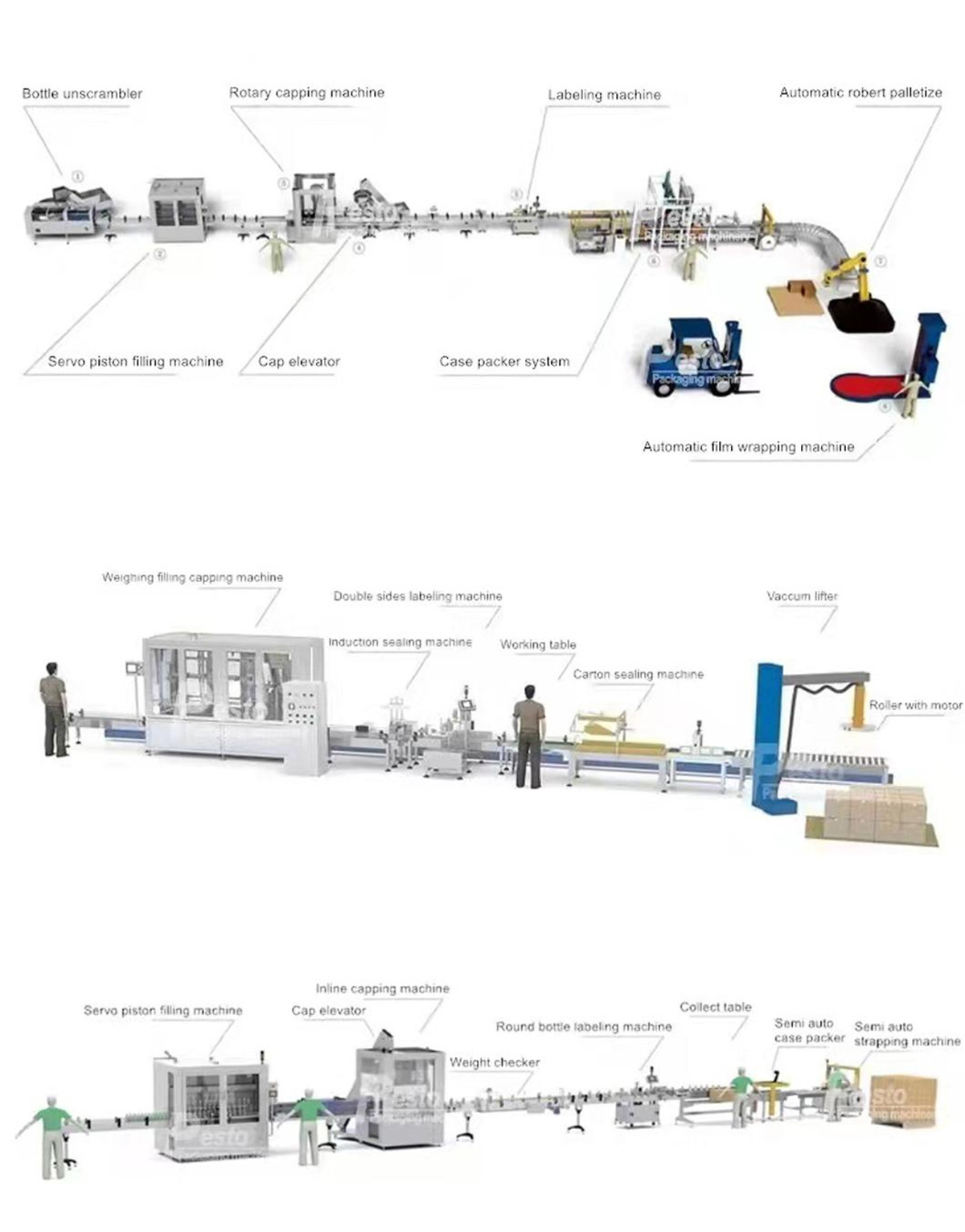

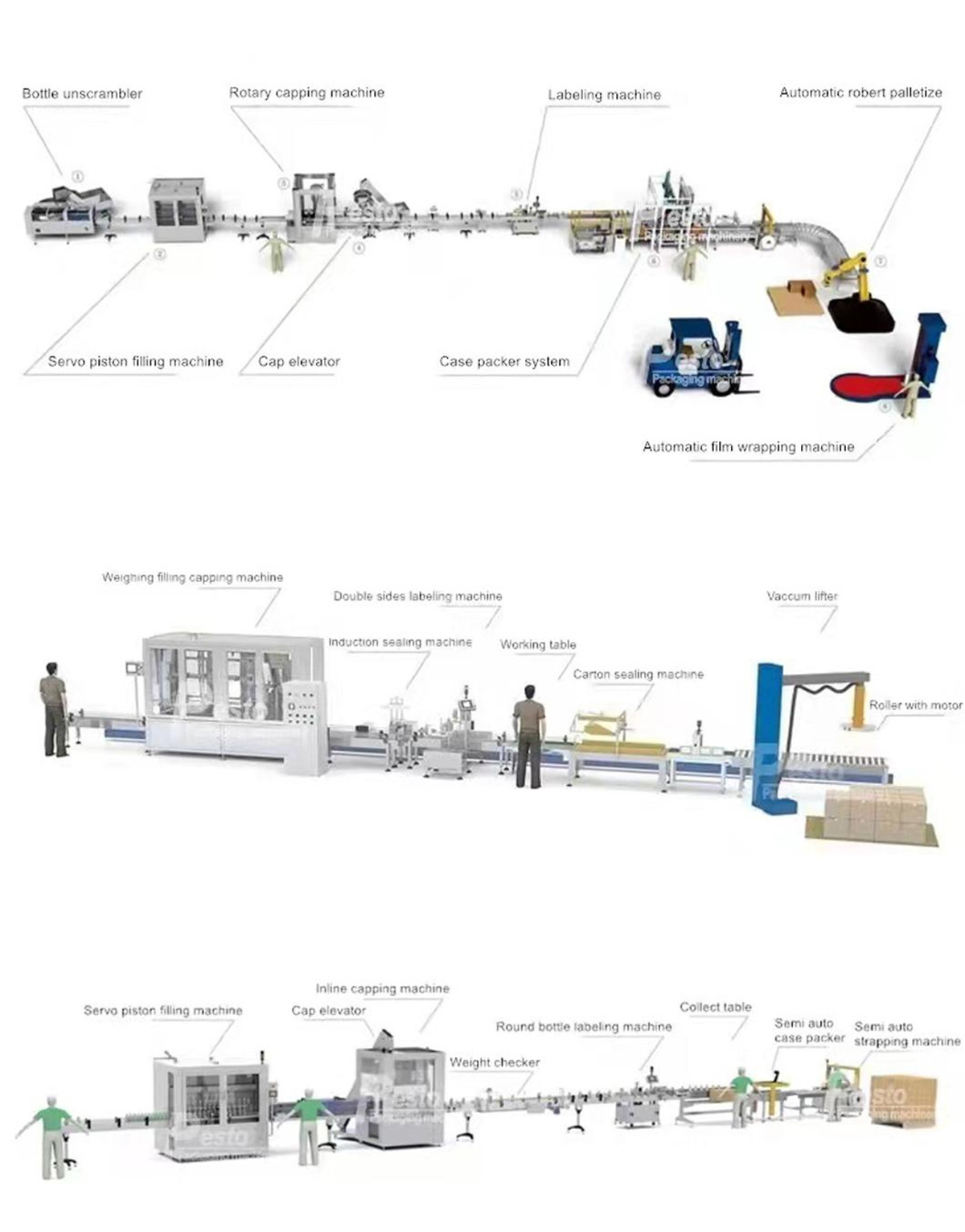

Integration with Capping, Labeling, and Packing

Why Pestopack Machinery Is a Trusted Choice in the UAE

Cost Considerations: What Affects the Price

Comparing Suppliers: How to Avoid Costly Mistakes

Common Buyer Mistakes (And How to Avoid Them)

Final Thoughts: How to Choose with Confidence

Introduce

If you’re planning to package engine oil, gear oil, hydraulic oil, or industrial lubricants in the UAE, one question always comes up sooner or later:

“Which lubricant oil filling machine is right for my product and market?”

Sounds simple, right?

But once you start digging deeper—viscosity differences, filling accuracy, explosion-proof requirements, speed expectations, bottle sizes—it quickly becomes overwhelming.

This guide is written to simplify that decision.

No marketing fluff.

No generic explanations.

Just a clear, practical, step-by-step guide tailored specifically for lubricant oil producers in the UAE and wider Middle East.

Why Choosing the Right Lubricant Oil Filling Machine Matters in the UAE

The UAE is not just a local market—it’s a regional lubricant hub.

From Dubai and Sharjah to Abu Dhabi, lubricant products are:

That means your filling machine must handle:

Wide viscosity ranges

High ambient temperatures

Strict safety and ATEX considerations

Different bottle formats for different markets

A wrong choice doesn’t just slow production—it can cause:

Leaking bottles

Inaccurate filling

Safety risks

Costly downtime

Let’s break it down the right way.

Understanding Lubricant Oil Viscosity: The First Decision Point

What Is Viscosity and Why Does It Matter?

Think of viscosity like how fast honey pours compared to water.

Low viscosity oil → flows easily

High viscosity oil → thick, slow, resistant

In lubricant filling, viscosity directly affects:

Typical Lubricant Oil Viscosity Ranges

Product Type | Typical Viscosity |

Hydraulic oil | Low to medium |

Engine oil | Medium |

Gear oil | High |

Industrial grease-like oils | Very high |

If your machine is not designed for your actual viscosity, you’ll face endless adjustments—or worse, permanent performance issues.

Choosing the Right Filling Technology Based on Viscosity

Magnetic Pump Filling Machines (Best for Medium Oils)

Magnetic pump systems are widely used in UAE for:

Why they work well:

Limitations:

Often recommended for small to medium production lines.

Gear Pump Filling Machines (For Higher Viscosity Oils)

Gear pumps are a popular upgrade when oil thickness increases.

Advantages:

Common UAE applications:

Gear oil

Heavy-duty lubricants

Industrial oils

Piston Filling Machines (For Extreme Viscosity & Accuracy)

When accuracy matters more than speed, piston fillers shine.

Why choose piston filling:

Trade-off:

Filling Speed: How Fast Is Fast Enough?

Don’t Overpay for Speed You Don’t Need

A common mistake is chasing maximum speed numbers without understanding real demand.

Ask yourself:

Daily output target?

Bottle size range?

Shift hours?

Labor availability?

Typical Speed Ranges in UAE Lubricant Plants

Machine Type | Typical Speed |

Semi-automatic | 300–600 BPH |

Linear automatic | 1,000–4,000 BPH |

Rotary filling line | 6,000–12,000+ BPH |

More speed = more:

Motors

Servo systems

Controls

Investment

The key is matching speed to real production needs, not marketing numbers.

Bottle Types and Sizes: Flexibility Is Key

In the UAE market, lubricant packaging is rarely uniform.

You may need to fill:

250 ml bottles

500 ml bottles

1L, 4L, 5L jerry cans

10L–20L containers

A good lubricant oil filling machine should offer:

Quick changeover

Adjustable guides

Recipe memory in PLC

This is where customized solutions outperform standard machines.

ATEX Compliance: Non-Negotiable in the UAE

What Is ATEX and Why Is It Important?

ATEX standards regulate equipment used in potentially explosive environments.

Lubricant oils may not always be highly volatile—but:

Additives

Vapors

Cleaning solvents

High temperatures

…can create risks.

In the UAE, ATEX-ready design is often required, especially for:

Export-oriented plants

Industrial zones

Multinational clients

Key ATEX Features to Look For

Skipping ATEX now often means costly retrofits later.

Automation Level: Manual, Semi-Auto, or Fully Automatic?

Manual & Semi-Automatic Machines

Best for:

Startups

Small batch production

Limited budgets

Pros:

Low investment

Simple operation

Cons:

Labor dependent

Lower consistency

Fully Automatic Lubricant Oil Filling Lines

Ideal for:

Includes:

Automatic filling

Automatic capping

Labeling

Packing integration

Integration with Capping, Labeling, and Packing

A filling machine alone is rarely enough.

In real UAE factories, the line usually includes:

Bottle unscrambler

Filling machine

Cap elevator + capper

Labeling machine

Shrink or carton packing

Choosing a supplier who understands line-level integration saves huge time and cost later.

Why Pestopack Machinery Is a Trusted Choice in the UAE

Who Is Pestopack Machinery?

Pestopack Machinery is an experienced manufacturer specializing in:

Lubricant oil filling machines

Complete liquid filling lines

Customized solutions for viscous products

With years of global project experience, Pestopack supports:

What Makes Pestopack Different?

Deep understanding of oil viscosity behavior

Customized filling solutions (not one-size-fits-all)

ATEX-aware designs for Middle East markets

Strong after-sales and technical support

Whether you’re filling engine oil or industrial lubricants, Pestopack focuses on reliability first, speed second, cost control always.

Cost Considerations: What Affects the Price?

If you want a detailed breakdown, this guide is worth reading:

Lubricant Oil Filling Machine for Sale in UAE – Price & Solution Guide (2026)

Key price factors include:

Filling technology

Automation level

Speed

ATEX requirements

Line integration

There is no “cheap and perfect” solution—only right-fit solutions.

Comparing Suppliers: How to Avoid Costly Mistakes

Before finalizing any supplier, ask:

Do they have real lubricant oil projects?

Can they handle your viscosity range?

Do they understand UAE compliance?

Is after-sales support clear?

For a broader supplier overview, you can also check:

Top 10 Lube Oil Filling Machine Manufacturers in UAE (2026 Guide)

This helps benchmark capabilities—not just prices.

Common Buyer Mistakes (And How to Avoid Them)

❌ Choosing speed over stability

❌ Ignoring viscosity testing

❌ Overlooking ATEX from day one

❌ Buying a standalone machine without line planning

The best investment is not the cheapest—it’s the one that keeps running smoothly for years.

Final Thoughts: How to Choose with Confidence

Choosing a lubricant oil filling machine in the UAE is not about chasing specs.

It’s about:

When viscosity, speed, and ATEX are correctly matched, your filling line becomes a competitive advantage, not a daily headache.

If you’re unsure, start small, test thoroughly, and work with a supplier who thinks long-term, not just about selling a machine.

Need Help Selecting the Right Lubricant Oil Filling Machine?

Explore practical solutions and configurations here:

lubricant-oil-filling-machine

Or talk to a team that understands both machines and markets.

Top 10 Lube Oil Filling Machine Manufacturers in UAE (2026 Guide)

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu