Introduce

Understanding the Saudi Lubricant Oil Filling Market

Key Types of Lubricant Oil Filling Machines Used in Saudi Arabia

Top 10 Lubricant Oil Filling Machine Manufacturers in Saudi Arabia (2026)

How to Choose the Right Lubricant Oil Filling Machine Manufacturer

Lubricant Oil Filling Machine Price Expectations in Saudi Arabia

Future Trends in Saudi Lubricant Oil Packaging (2026 and Beyond)

Final Thoughts

Introduce

Saudi Arabia’s lubricant oil market is growing fast. With expanding automotive, industrial, mining, and energy sectors, demand for engine oil, gear oil, hydraulic oil, and specialty lubricants keeps rising year after year.

If you’re planning to set up a new lubricant oil filling line or upgrade an existing packaging facility, one key question always comes first:

Which lubricant oil filling machine manufacturer should I trust in Saudi Arabia?

This guide is written exactly for that moment.

Instead of marketing hype or vague claims, this article walks you through the top lubricant oil filling machine manufacturers active in the Saudi market in 2026, what types of solutions they typically offer, how to evaluate them, and how to avoid costly mistakes during procurement.

Whether you are a factory owner, project investor, operations manager, or technical buyer, this guide is designed to help you make confident, long-term decisions.

Understanding the Saudi Lubricant Oil Filling Market

Why lubricant oil filling machines matter in Saudi Arabia

Lubricant oil is not like bottled water or soft drinks. It has very different characteristics:

High viscosity (especially gear oil and heavy-duty lubricants)

Sensitivity to temperature

High value per liter

Strict requirements for filling accuracy and cleanliness

In Saudi Arabia, lubricant oil packaging lines must also cope with:

That’s why choosing the right lubricant oil filling machine manufacturer is not just about price — it’s about reliability, engineering experience, and after-sales support.

Key Types of Lubricant Oil Filling Machines Used in Saudi Arabia

Before we look at manufacturers, let’s quickly align on machine types commonly used in the Saudi market.

Volumetric piston filling machines

Widely used for:

Engine oil

Hydraulic oil

Gear oil

Advantages:

Net weight filling machines

Preferred for:

Premium lubricant brands

High-value oils

Advantages:

Servo-driven filling systems

Increasingly popular in Saudi Arabia due to:

Top 10 Lubricant Oil Filling Machine Manufacturers in Saudi Arabia (2026)

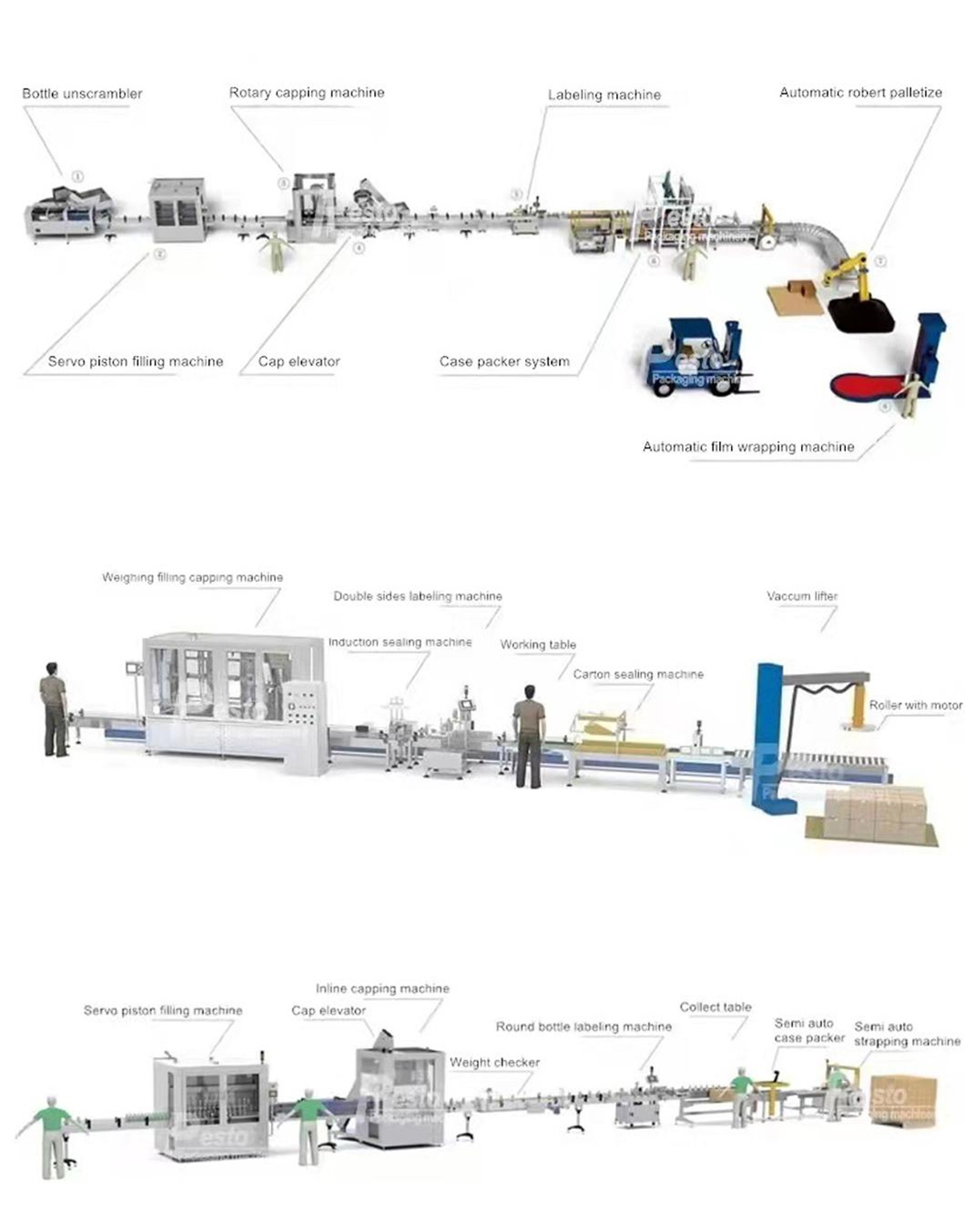

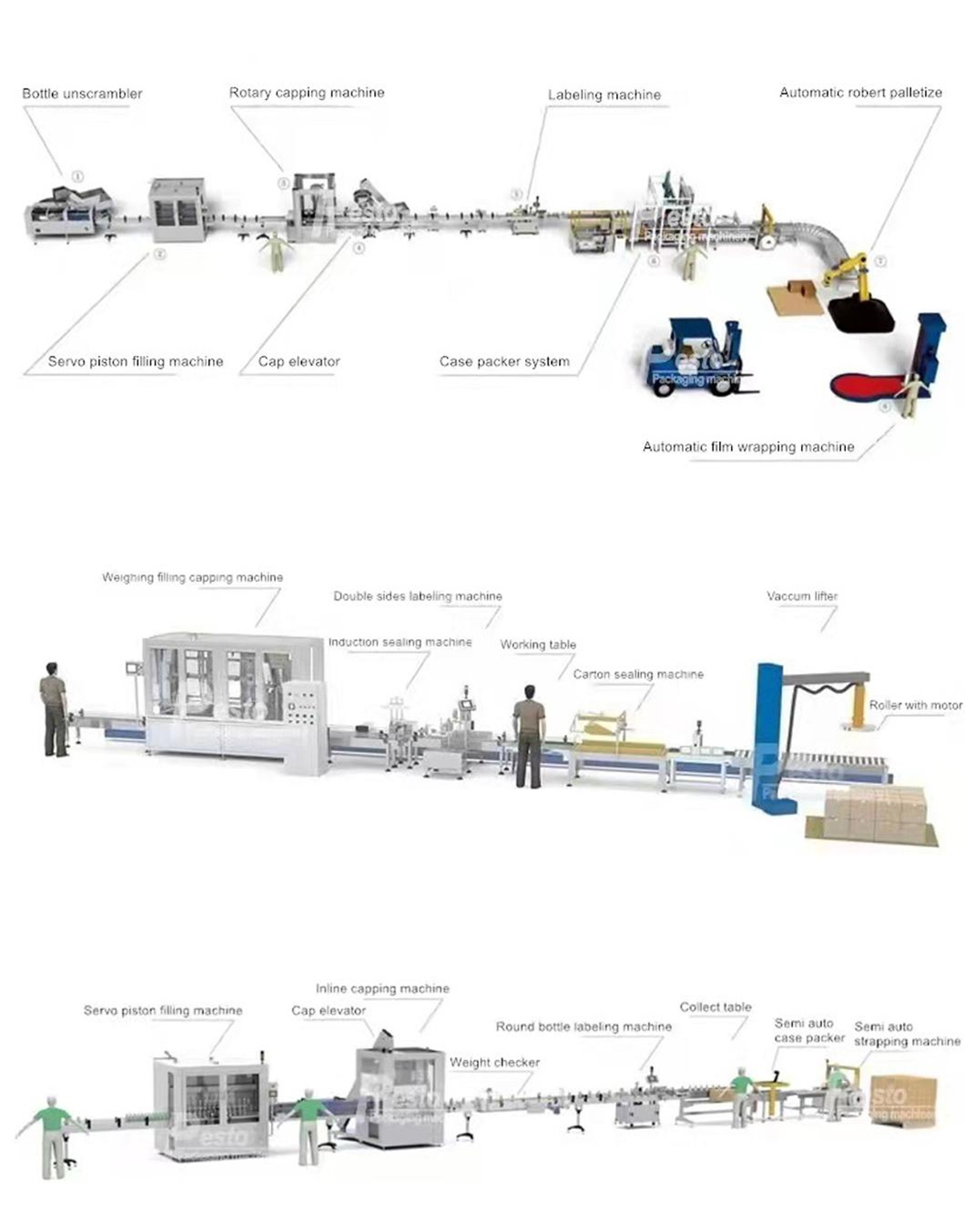

Below are 10 manufacturers commonly selected by lubricant oil producers operating in Saudi Arabia. These companies supply filling, capping, labeling, and end-of-line packaging solutions suitable for lubricant oil applications.

1. Pestopack Machinery (Featured Manufacturer)

Pestopack Machinery has become a go-to supplier for lubricant oil filling machines across the Middle East, including Saudi Arabia, thanks to its strong engineering focus and project-oriented solutions.

Why Pestopack stands out in the Saudi market

Pestopack is not just a machine supplier. It acts as a solution partner, offering:

Customized lubricant oil filling lines

Servo piston and net weight filling technology

Compatibility with engine oil, gear oil, hydraulic oil, and synthetic lubricants

Bottles from 0.5L to 25L

Fully automatic integration (filling, capping, labeling, carton packing, palletizing)

Their equipment is designed to handle high-viscosity oils while maintaining filling accuracy and production stability, even under high-temperature conditions common in Saudi factories.

If you want to explore technical details, you can check this dedicated page:

https://www.pestopack.com/lubricant-oil-filling-machine.html

Pricing transparency and project planning

One challenge many Saudi buyers face is unclear pricing. Pestopack addresses this by providing structured quotations and configuration-based budgeting.

You can review pricing references here:

https://www.pestopack.com/lube-oil-filling-machine-price.html

Support for first-time investors

Not sure how to choose the right machine configuration?

Pestopack provides practical guidance covering:

Filling technology selection

Container type compatibility

Capacity planning

Future expansion considerations

A useful starting point is:

https://www.pestopack.com/how-to-choose-lubricant-oil-filling-machine.html

2. MEMCO (Middle East Factory for Machines Co. Ltd.)

Suitable for

MEMCO is typically suitable for:

Saudi-based factories requiring local manufacturing presence

Projects emphasizing local service response

Government or semi-government industrial projects

Typical configuration

MEMCO often supplies:

Locally fabricated filling and packaging systems

Integrated conveyors and handling systems

Automation tailored to factory layout

Procurement advice

MEMCO works best when:

Watch out for

Ask for proven lubricant oil references, not just general liquid filling

Clarify filling accuracy and anti-drip solution in writing

Confirm spare parts availability for critical components

3. Saudi Equipment & Supplies Co. (SESC)

Suitable for

SESC is commonly selected by:

Typical configuration

SESC projects often include:

Filling and capping systems

Line integration and automation

Coordination with external equipment suppliers

Procurement advice

SESC is best evaluated as:

Watch out for

Clearly define which equipment is manufactured vs sourced

Lock down brands and specifications in the contract

Avoid unclear responsibility during commissioning

4. Ideas Packaging Machinery

Suitable for

Ideas Packaging Machinery is suitable for:

Small to mid-capacity lubricant oil plants

Step-by-step factory upgrades

Companies entering the lubricant market with limited SKUs

Typical configuration

Typical solutions include:

Procurement advice

Choose this supplier if:

Watch out for

Ensure the filling system can handle high-viscosity oils

Confirm anti-stringing nozzle design

Verify long-term spare parts support

5. Sidel

Suitable for

Sidel is generally suitable for:

Large corporate lubricant brands

Multinational groups with strict engineering standards

Projects with long-term lifecycle planning

Typical configuration

Sidel solutions emphasize:

Procurement advice

Sidel is best considered when:

Watch out for

Confirm specific lubricant oil filling references

Review lead times carefully

Ensure system flexibility for SKU changes

6. Krones

Suitable for

Krones is often chosen by:

Large-scale industrial producers

High-capacity lubricant oil plants

Corporations seeking long-term engineering partners

Typical configuration

Krones projects may include:

Procurement advice

Krones is suitable if:

Watch out for

Evaluate cost vs actual utilization

Confirm lubricant-specific filling valve suitability

Clarify local service response in Saudi Arabia

7. Serac

Suitable for

Serac is suitable for:

Premium lubricant oil brands

Producers sensitive to filling accuracy and giveaway

Plants running fewer but higher-value SKUs

Typical configuration

Serac commonly offers:

High-precision filling systems

Advanced capping solutions

Clean and controlled filling environments

Procurement advice

Serac is ideal if:

Watch out for

8. Shemesh Automation

Suitable for

Shemesh Automation fits:

Multi-SKU lubricant oil producers

Factories requiring full automation integration

Chemical and oil producers with complex packaging needs

Typical configuration

Typical lines include:

Filling, capping, labeling

End-of-line packaging

Centralized control systems

Procurement advice

Choose Shemesh if:

Watch out for

Clarify customization scope

Confirm changeover time between SKUs

Review service coverage in the region

9. Accutek Packaging Equipment

Suitable for

Accutek is suitable for:

Small to mid-size lubricant oil plants

Flexible, modular production setups

Companies planning gradual expansion

Typical configuration

Accutek solutions may include:

Procurement advice

Accutek is a good choice if:

Watch out for

Confirm suitability for high-viscosity oils

Evaluate long-term durability

Ensure availability of technical support

10. PACK’R

Suitable for

PACK’R is well suited for:

Lubricant producers focused on weight accuracy

Plants producing premium or regulated oil products

Operations where product giveaway must be minimized

Typical configuration

Typical PACK’R systems include:

Net weight filling machines

Multi-container capability

Integration with palletizing systems

Procurement advice

Choose PACK’R if:

Watch out for

How to Choose the Right Lubricant Oil Filling Machine Manufacturer

Ask the right questions before buying

Before signing any contract, ask yourself:

What oil viscosity range will I fill?

What container sizes will I run today — and tomorrow?

Do I need net weight or volumetric filling?

How many shifts per day will the line operate?

Is local technical support available?

Choosing a manufacturer without answering these questions often leads to overpaying or underperforming equipment.

Capacity planning: avoid common mistakes

Many buyers focus only on “bottles per hour”.

Instead, consider:

Changeover time

Cleaning time

Downtime risk

Operator skill level

A well-designed 3000 BPH line can outperform a poorly configured 6000 BPH line in real-world production.

Lubricant Oil Filling Machine Price Expectations in Saudi Arabia

Prices vary depending on:

Filling technology

Automation level

Container range

Integration scope

As a rough reference:

Semi-automatic systems: entry-level investment

Fully automatic servo piston lines: mid-range

Net weight filling + robotic palletizing: premium segment

For realistic budgeting, always request configuration-based quotations, not generic price lists.

Future Trends in Saudi Lubricant Oil Packaging (2026 and Beyond)

Saudi lubricant producers are increasingly focusing on:

Manufacturers who can support scalable growth will dominate the market.

Final Thoughts

Choosing a lubricant oil filling machine manufacturer in Saudi Arabia is not a short-term decision. It directly impacts:

Product quality

Operating costs

Brand reputation

Expansion capability

By understanding machine types, supplier strengths, and real operational needs, you can avoid costly mistakes and build a packaging line that grows with your business.

If you are looking for a reliable, flexible, and project-experienced partner, Pestopack Machinery remains one of the strongest choices for lubricant oil filling solutions in the Saudi market.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu