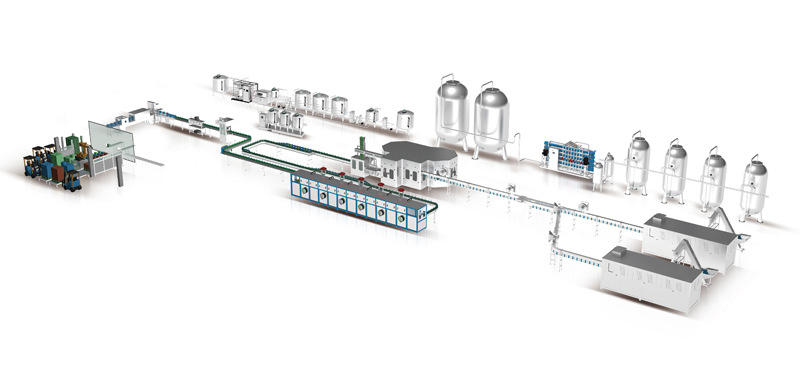

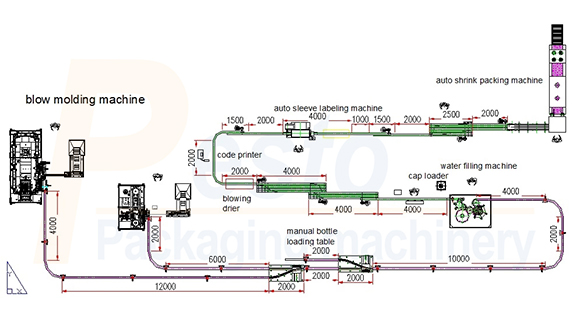

AIR CONVEYOR

The air conveying system of the juice filling machine is a kind of pneumatic conveying. It is a conveying technology integrated system that uses the clean air flow as the conveying power and sets the guide rails outside the pipeline. It includes conveying duct and air blower with the filter device and control system etc. The air conveyor speed of fruit juice filling machine is fast. The main structure is made of stainless steel. Speed and air volume adjustment device to adjust the conveying speed of the airflow to ensure the softness of the PET bottle during operation

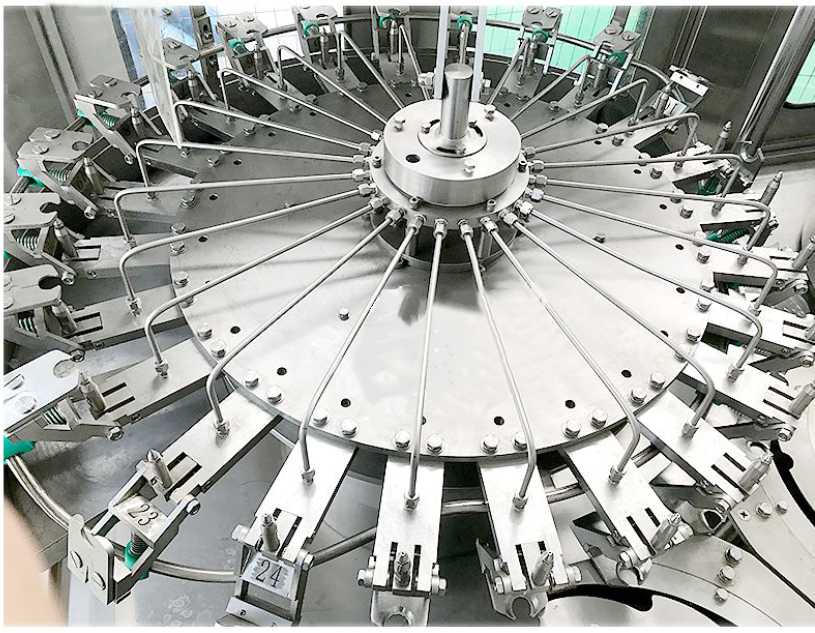

WASHING PART

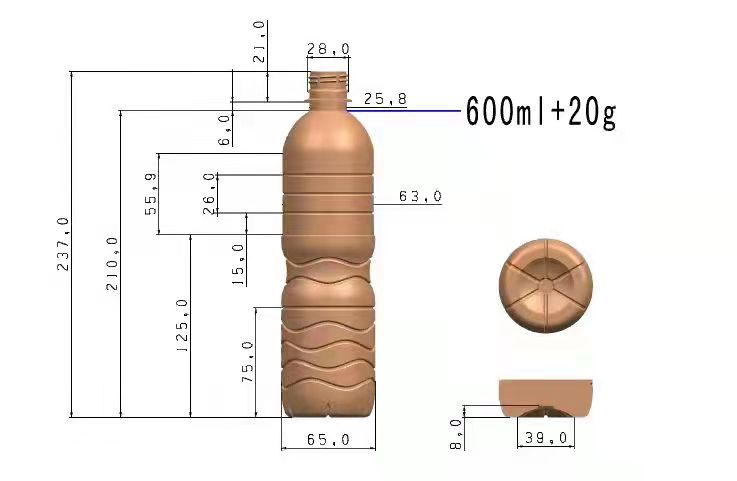

This part of fruit juice filling machine is mainly used for rinsing new bottles of beverages, water and other products. The PET bottles enter the equipment from the bottle-separating star wheel and are clamped by turning mechanism. Hold the bottle mouth and turn the bottle mouth down, rinse with sterile water and drain automatically. Turn it over until the bottle mouth is facing up, and transport it to the filling part through the bottle-out star wheel. The main structure of this part in fruit juice filling machine is made of stainless steel, it is simple structure and easy adjustment.

FILLING PART

The filling valve of fruit juice filling machine adopts the method of pressure filling and negative pressure backflow, which is fast and sensitive in filling and has high filling precision. There is no spring in the valve, it is convenient for cleaning. The whole fruit juice filling machine has a CIP cleaning interface. The double guide rod bottle lifting structure is adopted to stabilize the bottle lifting and centering.The beverage filling machine adopts stepless frequency conversion speed regulation.

CAPPING PART

The capping part of juice bottling machine uses magnetic rotating head for capping, the capping torque can be adjusted by magnetic adjustment, the capping pass rate is high, and noise is low. Use magnetic torque capping head, the capping effect is stable and reliable. There is a mechanism for preventing the passage of the reverse cover and the removal of the reverse cover, and a set of photoelectric switches are installed on the falling cover guide rail, which will automatically stop the machine when there is no cover on the falling cover guide rail.

CAP ELEVATOR

This cap elevator machine of fruit juice filling machine uses gravity of caps to make the reverse cap in the under the action of its own gravity, it freely falls back to the hopper on the lifting conveyor belt to complete the cap arrangement.The noise is small, the bottle cap is not easy to be damaged when the cap is arranged, and multiple caps can be arranged at the same time, which can double the efficiency of the cap arrangement.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu