JUICE BOTTLE FILLING MACHINE

HOW SMALL JUICE BOTTLE FILLING MACHINE WORKS

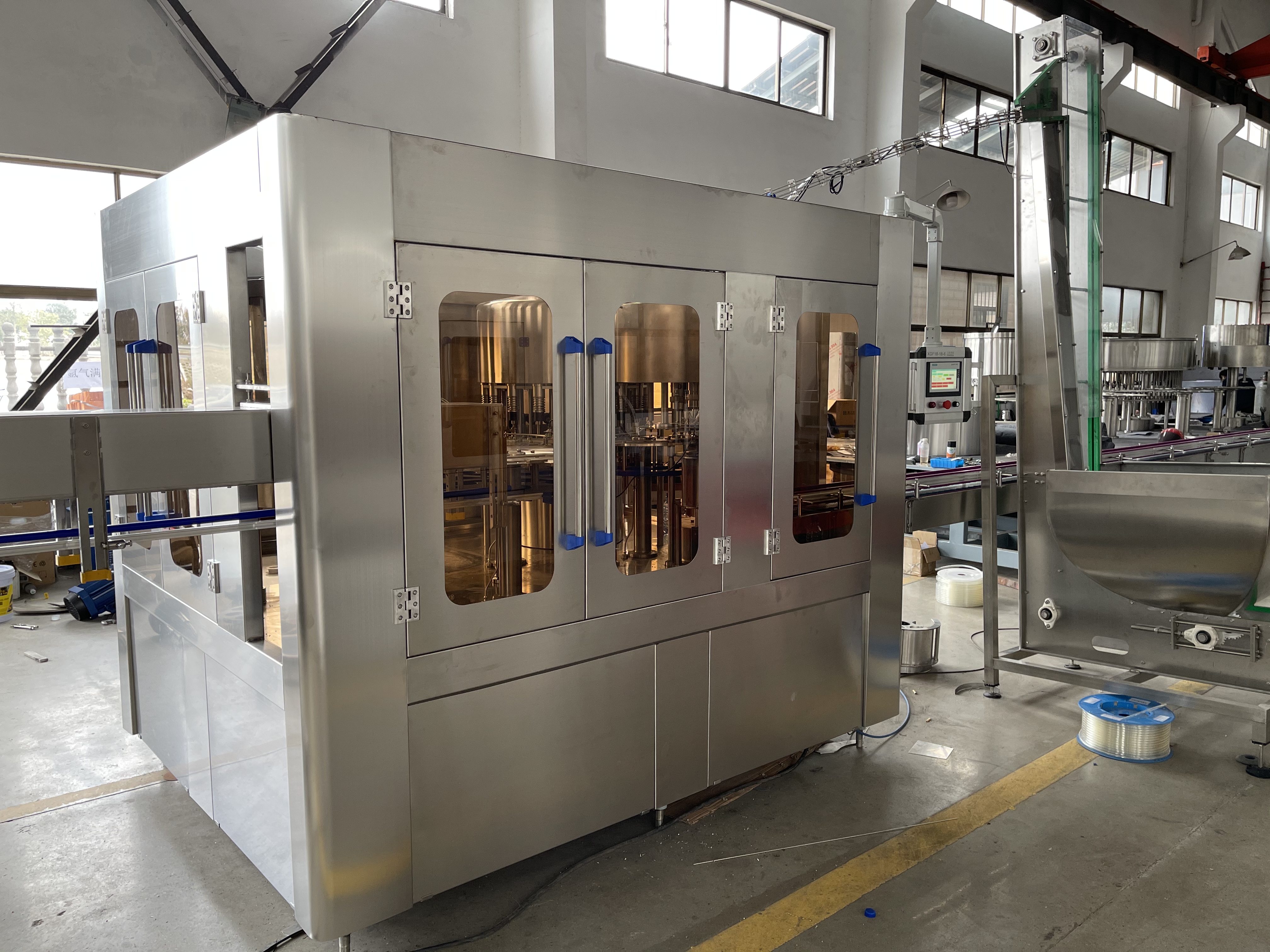

Hot Juice Bottle Filling Machine can be used for PET bottle and glass bottle. In this juice filling machine , the function of fluent and fast filling action, high filling precision, hot filling process, reliable capping and low material loss makes it effectively prevent secondary pollution of the neck with high automation in the whole process. The juice bottle filling machine can achieve the replacement of different bottles only by exchanging equivalent parts.This system can also form complete set of juice production line with other related systems, providing proposals for full-set of hot filling Process.Cap Overturn sterilizer, bottle cooling tunnel, air dryer, shrink sleeve labeling machine and PE packing machine, which connect with the small juice bottle filling machine, it constitute a complete juice production line.

FETURES OF SMALL JUICE BOTTLE FILLING MACHINE

✅Monoblock structure, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier.

✅Small juice bottle filling machine is specially designed stainless steel bottle clamp dose not contact the thread parts of the bottle neck, avoiding the second contamination.

✅High speed and large flow filling valve assures the high filling speed and exact fluid level.

✅Parts contact of small juice bottle filling machine with the liquid are all of excellent stainless steel or food level plastic.The electric system is of international brand and achieves the national food sanitary standard.

✅The bottle-out starwheel is of screwdown shape.When bottle size is changed, there is no need to adjust the transferring chain's height.

✅Full filling is to avoid the bottle from sinking after the bottle cooling off, and to decrease the dissolved oxygen to the utmost extent.

✅The storage hopper has the characteristic of gas discharge, full sealing and temperature detecting. In moderate and high speed production line, the material distributor replaces the big liquid tank to realize the complete CIP.

✅Sanitary filling head system is of umbrella structure, high filling speed. Perfect filling temperature control system.

✅Return tank system has the function of supplying the material automatically. Perfect CIP system is used in small juice bottle filling machine.

TECHNICAL PARAMETERS

| Model | RCGF14-12-5 |

| Rinsing heads | 14 |

| Filing heads | 12 |

| Capping heads | 5 |

Capacity

(b/h) | 3000 |

Power

(KW) | 2.2 |

| Dimension(mm) | 2300*1650*2500 |

Weight

(kg) | 2600 |

DETAILS OF SMALL JUICE BOTTLE FILLING MACHINE

Air conveyor

Bottles are transferred via suspending bottleneck damping design, ensuring stable movement at high speeds. Simple part changes allow quick adaptation for different bottle types.

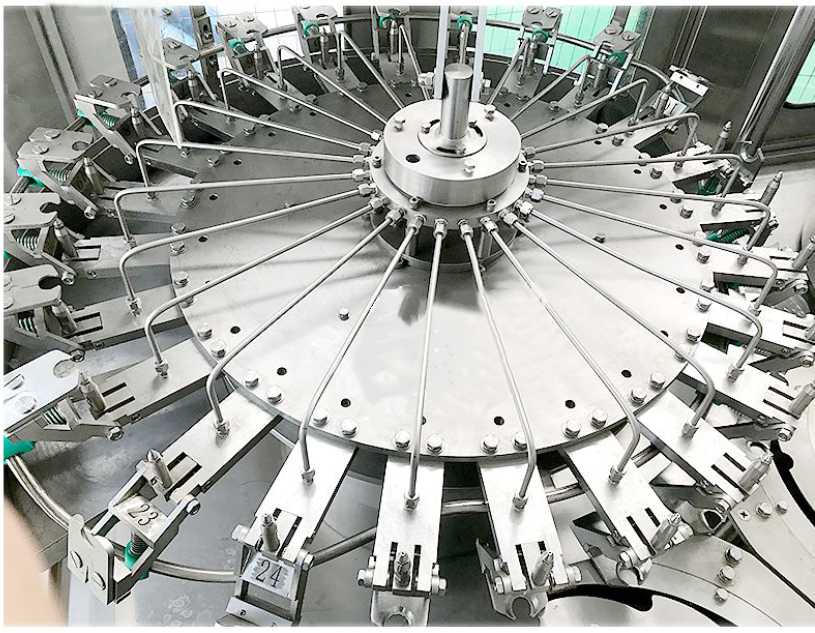

Washing part

A new-generation stainless steel grab ensures bottles are washed without contacting screw thread areas. Precision nozzles clean the interior thoroughly

Filling part

The advanced micro negative pressure hot filling technology used in this juice filling machine makes the filing quick, steady and accurate.

Capping part

Utilizes magnetic torque capping, with adjustable power for secure sealing without damaging caps.

Touch screen

Adopts SIEMENS PLC and human-machine interface for easy operation and monitoring.

Components parts

All beverage-contact parts are made from high-quality stainless steel. Motors and decelerators are sourced from reliable international brands.

FAQ

Q1: Can the small juice bottle filling machine handle both PET and glass bottles?

Yes, it is compatible with both PET and glass bottles, with easy part adjustments for different formats.

Q2: What is the capacity of the RCGF14-12-5 model?

This model reaches up to 3000 bottles per hour, making it suitable for medium-scale juice plants.

Q3: How does it ensure hygiene?

The machine uses sanitary stainless steel clamps, food-grade plastics, a CIP system, and prevents neck contamination.

Q4: Is it possible to integrate this machine into a full juice line?

Absolutely. It can be paired with sterilizers, cooling tunnels, dryers, and packing systems for a turnkey juice production solution.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu