Automatic Mango Juice Filling Machine: Complete Guide for Juice Bottling Lines

The demand for packaged fruit juices, especially mango juice, has grown rapidly worldwide. Consumers are looking for safe, hygienic, and convenient packaging, while manufacturers need reliable, high-speed filling solutions. This is where the automatic mango juice filling machine becomes essential.

In this guide, we’ll cover everything you need to know about the machine — from its working principle and technical parameters to the auxiliary equipment required for a complete juice bottling line.

What Is a Mango Juice Filling Machine?

A mango juice filling machine is a fully automated bottling system designed to:

It is built for high-speed beverage production, ensuring minimal oxygen content, product freshness, and extended shelf life.

The system integrates multiple stages into one monoblock structure, making it compact, efficient, and easy to maintain.

How Does the Mango Juice Filling Machine Work?

The process includes three primary stages:

1. Bottle Rinsing

Empty PET bottles are loaded into the system.

They are rinsed with sterile water to remove dust and contaminants.

A neck-handling technology ensures stable bottle transfer without deformation.

2. Juice Hot-Filling

Fresh mango juice (UHT-sterilized) enters the filling tank.

A temperature-controlled hot-fill system ensures consistent filling.

Umbrella-type filling nozzles reduce foaming and enhance accuracy.

3. Bottle Capping

Capping heads seal bottles with precision torque.

Cap sterilization is included to prevent contamination.

Servo-driven capping reduces downtime and improves sealing efficiency.

With automatic temperature control, CIP cleaning, and a return tank system, the process ensures food safety and efficiency.

Key Features of Mango Juice Filling Machine

1. Full Filling Technology

Prevents bottles from sinking after cooling and minimizes oxygen content.

2. Constant Material Flow

Hopper and distributor ensure stable liquid flow without frothing.

3. Sealed Hopper with Gas Discharge

Maintains product hygiene and accurate temperature monitoring.

4. Umbrella-Type Filling Heads

Designed for fast, sanitary filling.

5. Perfect Temperature Control

Keeps hot-fill juice at the required filling temperature.

6. Return Tank System

Automatically circulates juice to prevent waste.

7. Automatic CIP System

Ensures full hygiene with minimal operator intervention.

Technical Specifications

Parameter | Details |

Model | RCGF32-32-8 |

Rinsing Heads | 32 |

Filling Heads | 32 |

Capping Heads | 8 |

Capacity | 12,000 bph |

Power | 6 kW |

Dimensions | 3500 × 3000 × 2850 mm |

Weight | 6800 kg |

Larger models are available with capacity up to 28,000 bph.

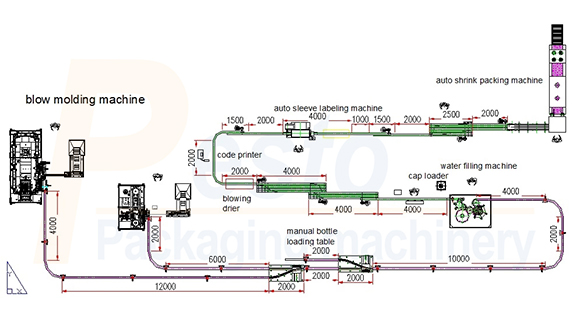

Auxiliary Equipment

-

-

Sand filter, carbon filter, sodium ion exchanger

-

-

-

Finished water tank & pump

Ensures clean, safe water for juice preparation.

High-shear emulsifying tank + Plate heat exchanger

Mixing tank

UHT sterilizer + homogenizer machine + Buffer tank

Hot water system + Hot water tank

CIP cleaning system

Blower : Industry-leading blower performance with self-regulation systems for repeatable and consistently high bottle quality.

Production flexibility: Up to 200 different equipment size configurations from one platform.

Top quality: Electrical stretching for bottle integrity, full material distribution control and performance.

Fast output: Boosted uptime and speed.

Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

Optimum uptime: 30 % reduction in changeover and maintenance downtime

Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

Hygiene improvement through volume control and contactless filling

Automatic dummy bottles: Safer, easier cleaning procedures

Automatic bottle changeover improves uptime

Mainly for cooling and sterilization

The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

Conveyor belt adopts Rexnor technology, flat surface with small wear

Smooth and reliable operation with low energy consumption

Greater performance and ergonomics

Boasted production uptime

Sustainable and quality production

Packing Machine

Pack consistency and quality

Gentle and precise infeed configuration

Flexible handling of multiple SKUs

Automatic pack and raw material changeovers

Heat, glue, carton and film optimisation

Advantages of Our Mango Juice Filling Machine

High-speed capacity (up to 28,000 bph)

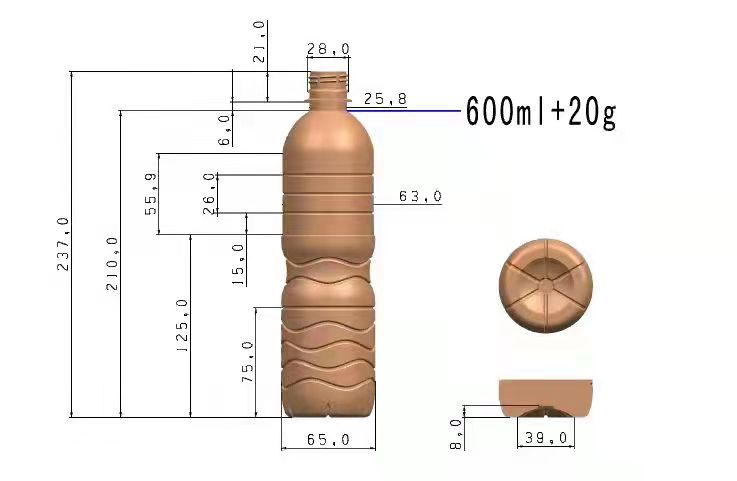

Supports round & square PET bottles (200–2000 ml)

Food-grade stainless steel contact parts

Hygienic hot-fill process with UHT sterilization

Reduced downtime thanks to automatic bottle changeovers

Energy-efficient design for lower operating costs

Market Applications

The mango juice filling machine is widely used in:

This makes it a versatile investment for beverage manufacturers in Africa, Asia, Europe, and the Middle East.

FAQs: Mango Juice Filling Machine

Q1: What is the capacity range of mango juice filling machines?

Models range from 3,000 bph up to 28,000 bph, depending on bottle size and line configuration.

Q2: Can the machine fill other juices besides mango juice?

Yes, it is suitable for orange juice, apple juice, mixed fruit drinks, tea, and other hot-fill beverages.

Q3: What bottle types are compatible?

Both round and square PET bottles from 200–2000 ml, diameter 50–115 mm, and height 150–350 mm.

Q4: Is UHT sterilization included?

Yes, the line integrates a UHT sterilizer + homogenizer for product stability and shelf life.

Q5: How does the machine ensure hygiene?

Conclusion

Investing in a mango juice filling machine ensures your juice production line achieves high efficiency, hygiene, and scalability. With capacities up to 28,000 bph and compatibility with multiple bottle types, it is the ideal solution for modern juice manufacturers.

Whether you’re starting a new juice plant or expanding production, our mango juice bottling line provides a turnkey solution for success.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu