Advantages of Using Automatic Juice Filling Machines

Hygiene & Safety – Hot filling kills microorganisms.

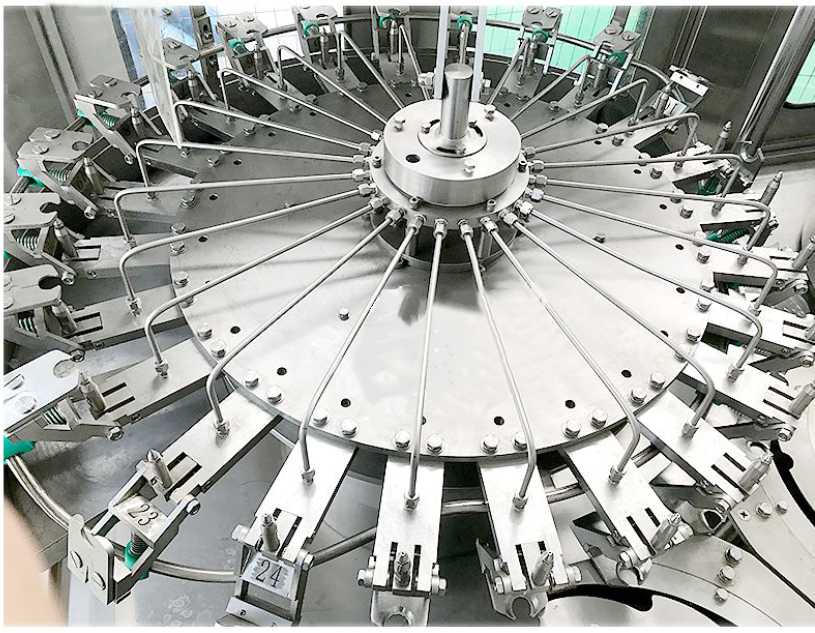

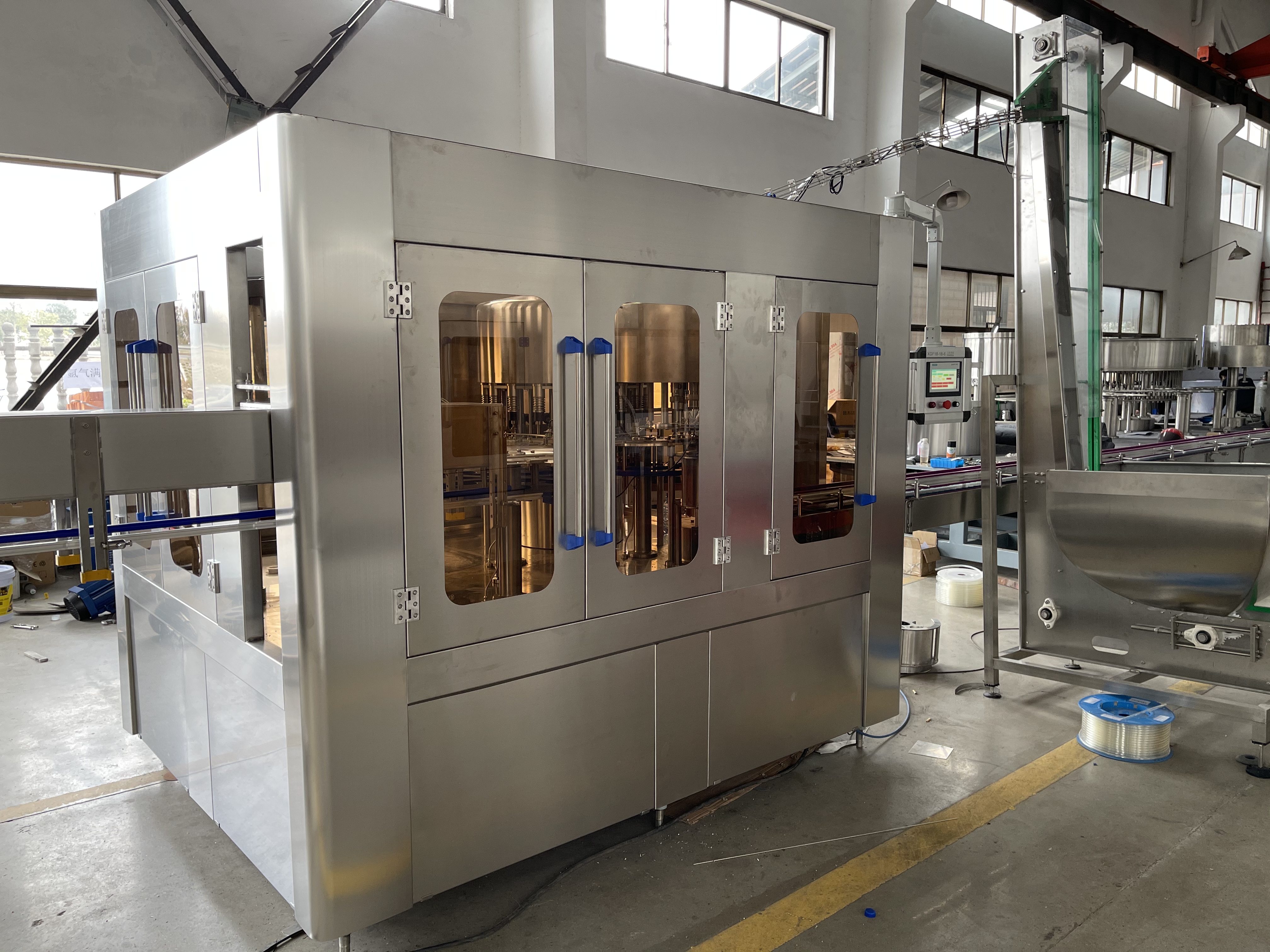

Efficiency – 3-in-1 design reduces production time.

Scalability – Suitable for small to mid-size juice factories.

Cost-Effectiveness – Lower labor costs due to full automation.

Durability – Stainless steel construction ensures long service life.

Why Choose PESTO Automatic Juice Filling Machines?

14+ years of global experience in beverage machinery.

Installed in over 30 countries across Africa, Middle East, Asia, and Europe.

ISO 9001 & CE certified for international quality standards.

Factory-direct pricing ensures competitive cost.

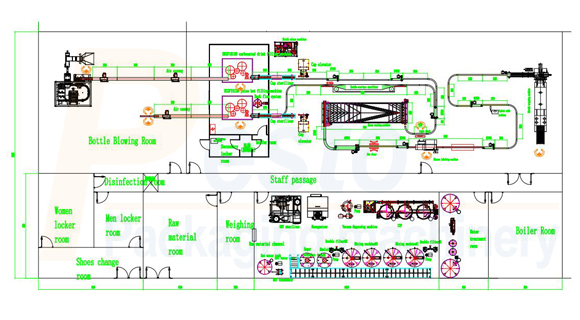

Comprehensive service – from layout design to installation and after-sales support.

FAQs About Automatic Juice Filling Machines

1. Can this machine handle both PET and glass bottles?

It is primarily designed for PET and plastic bottles, but glass bottle compatibility is available with modifications.

2. What bottle sizes can be used?

It supports bottles from 200ml to 2000ml without extensive changeover.

3. How does the machine ensure hygiene?

The hot filling process, stainless steel construction, and advanced rinsing system ensure strict hygiene compliance.

4. Can the line include labeling and packing?

Yes, we provide complete turnkey juice production lines, including labeling and packing machines.

5. What certifications do you provide?

Our machines are ISO 9001 & CE certified, ensuring compliance with international beverage standards.

Conclusion

Investing in an automatic juice filling machine is a strategic step for beverage manufacturers looking to expand their capacity while ensuring consistent product quality. With advanced automation, hygienic design, and seamless integration into a complete bottling line, PESTO’s solutions provide everything needed for juice and tea production at industrial scale.

If you are planning to establish or upgrade a juice bottling plant, our team can design a tailor-made production line to meet your requirements.

Explore our related solutions:

Contact us today at sales@pestopack.com to request a quote or discuss your projec

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu