Introduce

Why Start a Water Bottling Plant in Kenya?

Understanding the Key Terminology

The Role of Machinery & Supplier Selection

Step 1 Conducting Market Research and Feasibility Study

Step 2 Designing Your Water Bottling Line Layout

Step 3 Water Source & Treatment System

Step 4 Equipment Selection for the Bottling Line

Step 5 Installation and Commissioning

Step 6 Regulatory Approvals & Quality Standards

Step 7 Staffing, Training and SOPs

Step 8 Marketing, Distribution & Sales Channels

Financing Your Project

Common Challenges and How to Overcome Them

Why Choose Pestopack Machinery

Conclusion & Next Steps

Introduce

If you’re thinking about starting a bottled-water business in Kenya, you’re entering a rapidly expanding market. Consumers are increasingly seeking safe, pure, and convenient drinking water options, and local production gives you an edge over importers.

In this guide, you’ll learn every essential step—from market research to line design, equipment selection, installation, and sales. Whether you’re searching for a water bottling plant for sale or planning to build one from scratch, this article will walk you through it in plain language, backed by real industrial insight from Pestopack Machinery, a global leader in turnkey bottling equipment made in China.

Why Start a Water Bottling Plant in Kenya?

Kenya’s bottled-water industry is booming. Urbanization, tourism, and rising health awareness are driving steady demand. Government reports and private data indicate double-digit growth for bottled water over the last few years.

Starting a local bottling plant means:

Eliminating import dependency.

Reducing logistics and customs costs.

Adapting bottle design and branding to Kenyan tastes.

Creating jobs locally.

In short, Kenya’s growing economy and youthful population make it an ideal environment for water production investment.

Understanding the Key Terminology

Before jumping into the technical part, let’s get clear on key terms.

A water bottling line is the complete system of machines that wash, fill, cap, label, and package bottled water.

A water bottling plant for sale refers to a turnkey factory setup or an integrated production solution available for purchase or installation.

If you want to explore actual turnkey offers, check this internal link: Water Bottling Plant for Sale.

The Role of Machinery & Supplier Selection

Machinery quality determines the long-term success of your business. A reliable supplier ensures stable output, hygiene compliance, and ease of maintenance.

Pestopack Machinery, based in China, is one of the world’s trusted manufacturers specializing in water, beverage, and oil filling lines. They export to Africa, the Middle East, and Europe—offering factory-direct pricing, customized design, and global after-sales service.

With Pestopack, you don’t just buy equipment—you get engineering guidance, line layout design, and technical support tailored to your production goals.

Step 1 – Conducting Market Research and Feasibility Study

Success starts with understanding the local market.

Demand Analysis: Identify consumption volumes by region (Nairobi, Mombasa, Kisumu, Nakuru).

Competitor Review: Visit local brands on shelves—check bottle shapes, cap colors, label styles, and price points.

Feasibility: Determine production capacity (e.g., 2,000 BPH or 8,000 BPH) based on your financial capacity and projected demand.

Location: Choose a site with a clean water source, stable electricity, and good road access.

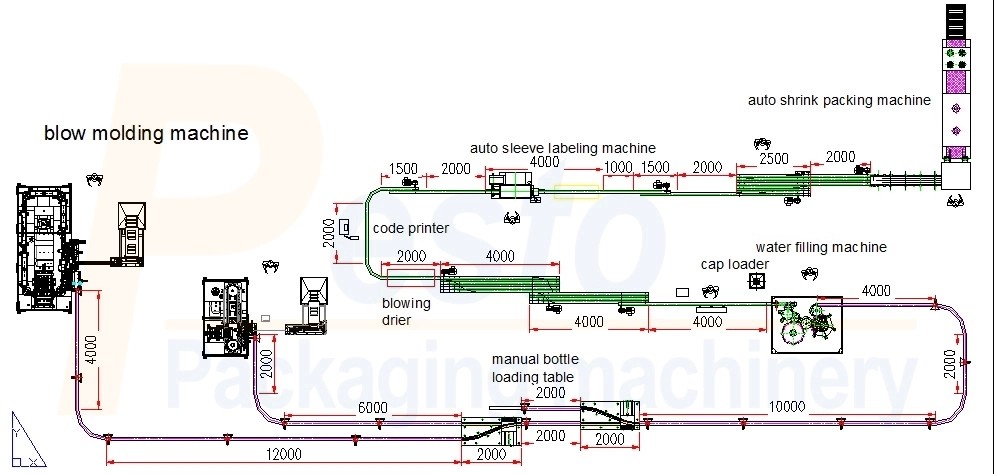

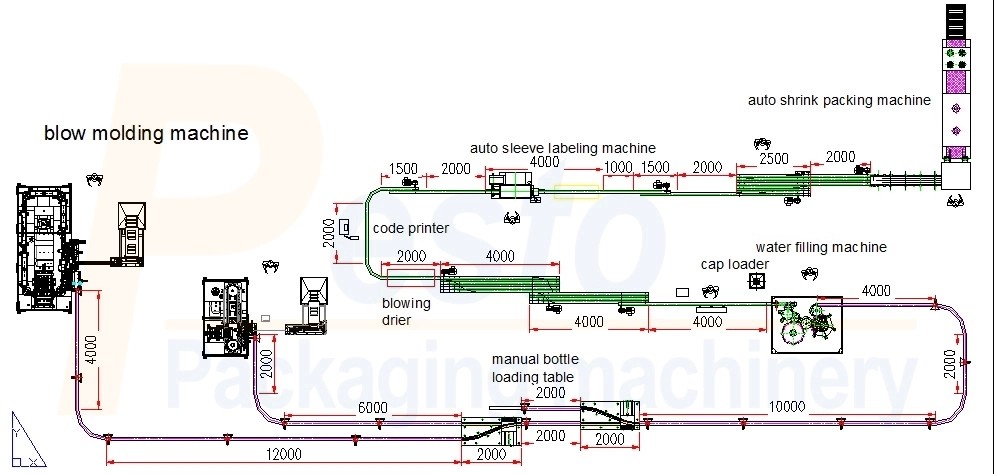

Step 2 – Designing Your Water Bottling Line Layout

A logical workflow saves time and ensures hygiene:

Water Source ➜ Water Treatment ➜ Bottle Blowing ➜ Rinsing ➜ Filling ➜ Capping ➜ Labeling ➜ Packing ➜ Palletizing ➜ Storage.

During design:

Plan future expansion space.

Keep wet and dry areas separate.

Ensure adequate drainage, ventilation, and easy maintenance access.

Step 3 – Water Source & Treatment System

Water purity defines your brand. Kenya’s Bureau of Standards (KEBS) enforces strict bottled-water quality guidelines.

Typical stages in a water treatment system include:

Raw water pump & sand filter – removes sediments.

Activated carbon filter – eliminates chlorine and odor.

Softener or dosing system – adjusts mineral levels.

RO (Reverse Osmosis) unit – purifies to drinking standard.

UV sterilizer or ozone system – ensures microbiological safety.

Pestopack integrates all these into a single skid for simplified installation.

Step 4 – Equipment Selection for the Bottling Line

Selecting the right equipment is the most crucial stage in setting up a water bottling plant for sale or a new installation. It determines product consistency, energy use, and long-term maintenance cost.

Let’s explore each category in detail.

Bottle Blow-Moulding or Bottle Supply

Two main approaches exist:

1. Onsite Bottle Production (Blow-Moulding)

Uses PET preforms and a blow-moulding machine to form bottles.

Pros: Control over quality, lower unit cost, flexible designs.

Cons: Higher capital cost, needs compressor and chiller.

Example:Pestopack PET-2000 — automatic two-cavity blow-moulding machine, 2,000–2,500 BPH, Siemens controller, automatic preform feeder.

2. Outsourced Bottle Supply

Buy bottles from local suppliers in Nairobi or Mombasa.

Pros: Quick startup, no need for blowers or moulds.

Cons: Higher ongoing cost, storage space required.

Best for: Small or pilot plants (<2,000 BPH).

Bottle Rinsing, Filling & Capping Machines

This 3-in-1 monoblock is the heart of every bottling line. It includes:

1. Rinsing Unit

Rinses bottles using purified or ozone water.

Constructed with SS304 or SS316L.

Neck-handling rotary design for stable high-speed operation.

Ensures no foreign particles before filling.

2. Filling Unit

Gravity filling for still water.

Key specs: filling accuracy ± 0.2–0.5%, high-speed valves, no-bottle-no-fill system.

Fully enclosed stainless filling chamber to avoid contamination.

CIP cleaning ports for sanitation.

3. Capping Unit

Magnetic torque system to prevent over-tightening.

Automatic cap sorter and elevator for continuous feeding.

Compatible with 28 mm and 30 mm PET caps (1810 / 1881 / 3025 necks).

Examples from Pestopack:

Model | Capacity | Features |

RFC 12-12-6 | 3,000 BPH | Compact rotary filler, SS304 structure |

RFC 24-24-8 | 8,000 BPH | Siemens PLC, automatic lubrication, safety doors |

RFC 36-36-10 | 15,000 BPH | High-speed servo drive, full SS316L contact parts |

Labeling, Packing & Palletizing

Once filled and capped, your bottles move to the packaging stage.

1. Labeling

Choose between:

OPP Hot-Melt Labeler – efficient for mass production.

Shrink Sleeve Labeler – eye-catching 360° graphics.

Sticker Labeler – versatile for small or diverse SKUs.

Example:Pestopack OPP-9 Rotary Labeler – 9,000 BPH, servo drive, auto label correction.

2. Date Coding & Inspection

3. Packaging

Shrink Wrapper: wraps 6, 12 or 24 bottles in PE film.

Tray + Film Packer: ideal for 1.5 L water packaging.

Carton Packer: for premium export packaging.

4. Palletizing

Manual, semi-automatic, or robotic.

Pestopack’s ABB robotic palletizer handles up to 12 cycles/minute with programmable stacking patterns.

Automation and Control Systems

Automation ensures precision and efficiency.

PLC Control: Siemens / Omron / Delta systems.

HMI Touch Screen: Easy operation and fault diagnosis.

Sensors: Detect missing bottles or caps.

Remote Support: Some Pestopack lines allow online monitoring and parameter tuning.

Material and Construction Quality

Only food-grade materials should contact water:

SS304: Standard for still water.

SS316L: For higher purity or mineral water.

FRP: For chemical-resistant water treatment tanks.

Pestopack uses international brands like Schneider, SMC, FESTO, and NSK for long-term reliability.

Customization for the Kenyan Market

Kenya’s warm climate and power fluctuations require tailored designs:

Tropicalized electrical cabinets with cooling fans.

Voltage stabilizers and inverters.

Modular conveyor belts resistant to humidity.

Optional solar-compatible power integration.

Pestopack custom-designs each line—from 2,000 BPH starter systems to 18,000 BPH industrial plants—making them ideal for Kenya’s diverse business scales.

Example Equipment Configuration

Process | Machine Type | Model | Capacity | Key Features |

Bottle Blowing | Automatic PET Blower | PET-2000 | 2,000 BPH | IR heating, Siemens PLC |

Rinsing–Filling–Capping | 3-in-1 Monoblock | RFC 24-24-8 | 8,000 BPH | SS304, magnetic capper |

Labeling | Rotary OPP Hot-Melt | OPP-9 | 9,000 BPH | Servo drive, hot-melt system |

Packaging | Shrink Wrapper | PE-450 | 10 packs/min | Energy-efficient tunnel |

Palletizing | Robotic Palletizer | ABB-R10 | 12 cycles/min | Programmable stacking |

You can also watch a complete line video demonstration here:

Pestopack Video Gallery

Step 5 – Installation and Commissioning

Shipping equipment to Kenya typically takes 30–40 days by sea.

After customs clearance, coordinate with your supplier’s technicians for on-site setup and trial runs.

A typical installation includes:

Line alignment and wiring.

Water and air connection.

Test production for leak, flow, and torque accuracy.

Pestopack’s engineers can guide local teams online or visit for training.

Step 6 – Regulatory Approvals & Quality Standards

Comply with the Kenya Bureau of Standards (KEBS) requirements:

KEBS product certification (standard mark).

Microbiological tests, pH 6.5 – 8.5, and total dissolved solids below 500 mg/L.

Hygienic building design and labeling compliance.

Maintaining documentation is essential for inspections and brand credibility.

Step 7 – Staffing, Training and SOPs

Your plant needs:

Operators: manage bottling and labeling.

Technicians: handle preventive maintenance.

QC Staff: monitor water and packaging quality.

Sales Team: handle distribution contracts.

Pestopack provides operation manuals, training videos, and standard maintenance schedules.

Step 8 – Marketing, Distribution & Sales Channels

Success doesn’t stop at production—it’s about getting your bottles onto shelves.

Tips:

Design attractive, Kenyan-style labels with bright colors.

Target supermarkets, hotels, schools, and corporate offices.

Offer wholesale discounts for distributors.

Highlight safety and purity in marketing materials.

Show your production video or factory capability in meetings—watch sample videos here: Pestopack Video.

Financing Your Project

Typical Investment Breakdown

Item | Estimated Cost (USD) |

Land & Building | 20,000 – 50,000 |

Water Treatment | 8,000 – 15,000 |

Bottling Line Equipment | 25,000 – 120,000 |

Packaging & Labeling | 5,000 – 15,000 |

Installation & Training | 3,000 – 10,000 |

ROI often comes within 2–3 years depending on sales volume and distribution reach.

Common Challenges and How to Overcome Them

Challenge | Solution |

Power Instability | Install backup generator or solar inverter. |

Import Delays | Choose experienced exporter like Pestopack for fast customs documentation. |

Water Source Fluctuation | Add raw water storage tanks and automatic level control. |

Machine Downtime | Implement preventive maintenance and stock key spares. |

Market Competition | Build a strong local brand with consistent quality and eco-friendly packaging. |

Why Choose Pestopack Machinery

Pestopack isn’t just another supplier—it’s your engineering partner.

Key Advantages:

Over 20 years of experience in water and beverage machinery.

Turnkey service: design → manufacture → installation → training.

Factory-direct pricing with no intermediaries.

Global after-sales network.

Proven projects across Africa, including Nigeria, Tanzania, Ethiopia, and Kenya.

Visit their official site to learn more: Pestopack Machinery

Conclusion & Next Steps

Starting a water bottling plant in Kenya is a smart investment if done strategically.

By choosing the right location, following regulations, and partnering with an experienced equipment supplier like Pestopack Machinery, you can build a reliable and profitable production line.

Now’s the time to take action:

With a well-planned setup, you’ll be bottling success—literally.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu