Introduction

Why Pakistan is a promising market for bottled water

Understanding the key prerequisites before setup

Selecting the right configuration for a small- to medium-scale plant

Core equipment selection: water treatment through bottling line

Operation and running of the plant: common pain-points & how to address them

Cost estimation and ROI for a small/medium factory in Pakistan

Summary and next steps for entrepreneurs

Conclusion

Introduction

If you’re reading this, you’re likely considering launching or upgrading a bottled water plant in Pakistan and want practical advice on configuration, equipment choice, and how to run it smoothly. Building a small or medium-scale plant is absolutely doable — but you must pick the right size, the right machines (especially the critical water treatment and water filling machine), and plan for the real-world operational headaches. In this article we’ll walk you through start to finish: from regulatory steps to equipment choice (including picking a supplier like Pestopack Machinery in China that offers factory-direct pricing and global service), through to running the plant and avoiding common pitfalls.

Why Pakistan is a promising market for bottled water

In Pakistan the demand for clean drinking water is strong and growing. The bottled/mineral water segment has seen expansion because city water supply frequently has quality or reliability issues. Regulatory reports show the requirement to meet standards set by Pakistan Standards and Quality Control Authority (PSQCA).

For an SME, this means opportunity. Local production with cost-efficient line configuration can give competitive edge.

However — don’t mistake promise for a guaranteed win! You’ll need the right setup, solid water treatment, efficient filling, and an operation plan that keeps costs under control.

Understanding the key prerequisites before setup

Before you order machines or lay floor tiles, you must get the groundwork sorted.

Regulatory compliance and licensing

You must obtain the required license from PSQCA, ensure your product meets bottled drinking-water specifications (e.g., TDS, microbiological limits) as per PS:4639-2004.

Failure to comply may mean penalties or shutdowns. Make sure your plant layout, water treatment, storage, labeling all conform.

Securing a reliable water source

Your line’s output is only as good as the water going in. Choose a source (ground-water, bore-well, municipal feed) that is reliable in quality and supply. Pre-treat it properly to remove sediment, bacteria, hardness etc.

Poor source choice means higher treatment costs downstream.

Market study and site selection

Pick a location that balances cost (land, utilities) with supply chain (bottles, caps, distribution). Understand demand in your region and the competitive landscape.

As part of your study, you might build internal links for further reading, for example our resource on water filling machine and also the one on water bottling line for deeper dive.

This sets you up to choose a plant size that matches the market you intend to serve.

Selecting the right configuration for a small- to medium-scale plant

This is where you pick “how big” and “how automated” your line will be.

Production capacity considerations

For SME plants in Pakistan you may target capacities ranging from a few thousand bottles per hour to tens of thousands. Choose a capacity that aligns with your market and budget.

Too large, and you tie up capital and risk under-utilisation; too small, and you might not hit cost-economies.

Choosing bottle types, volumes & formats

Decide the bottle volumes you will fill (e.g., 500 ml, 1.5 l) and whether you want PET, glass or jerry-can formats. Format impacts machine choice, changeover times and running costs.

If you plan multiple formats, choose flexibility in your line.

Equipment supplier: Why choose Pestopack Machinery

Pestopack Machinery is a China-based manufacturer providing direct-factory pricing and global service. For a small/medium plant you’ll benefit from their experience in liquid-filling lines, including water. With their support you can get an integrated solution (water purification + filling line) tailored to SME scale.

Selecting a supplier with experience in your type of product and market (Pakistan) helps mitigate risk.

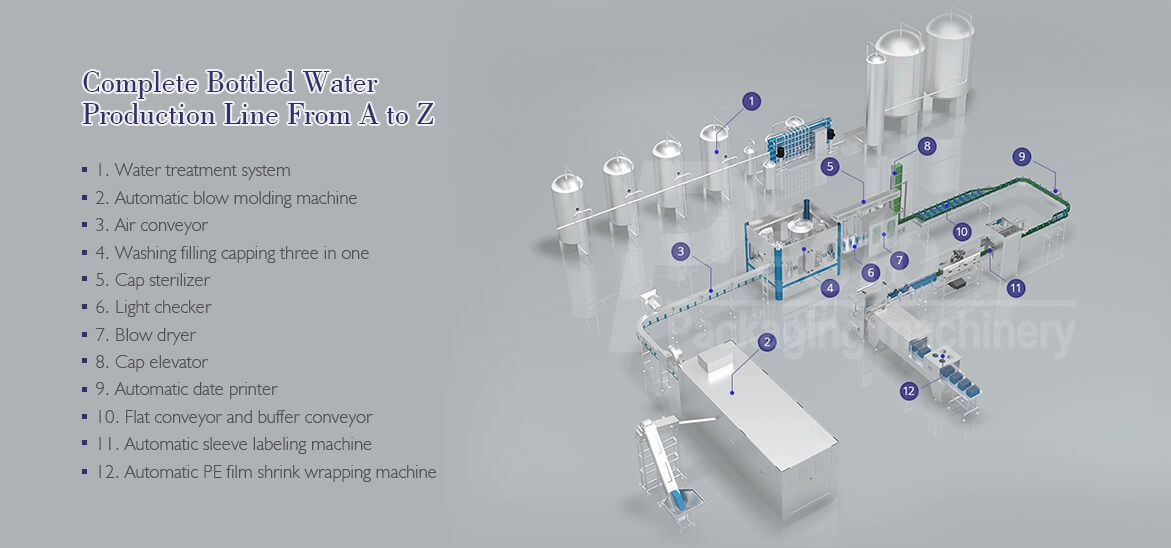

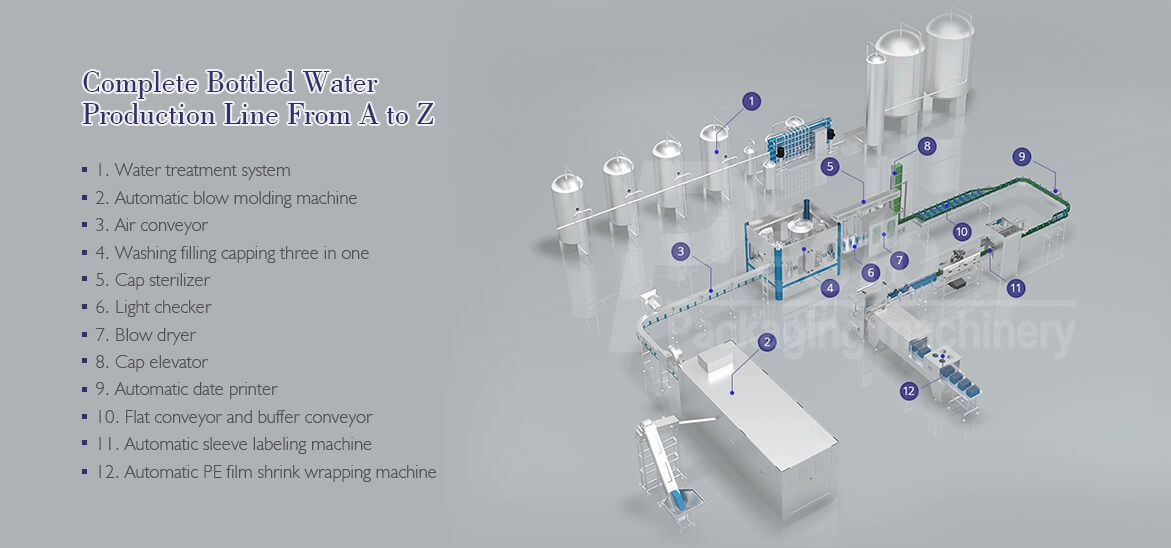

Core equipment selection: water treatment through bottling line

Let’s break down the major equipment blocks.

Water purification system: RO, UV, filters

Start with a pretreatment (sand filter, activated carbon) → RO (reverse osmosis) → UV disinfection. Many Pakistani plants use RO systems as core. Scribd+1

Ensure you size the system based on your line capacity + makeup for waste and maintenance.

Also select materials (stainless steel, food-grade plastics) suited to local water conditions (hardness, TDS, seasonal variation).

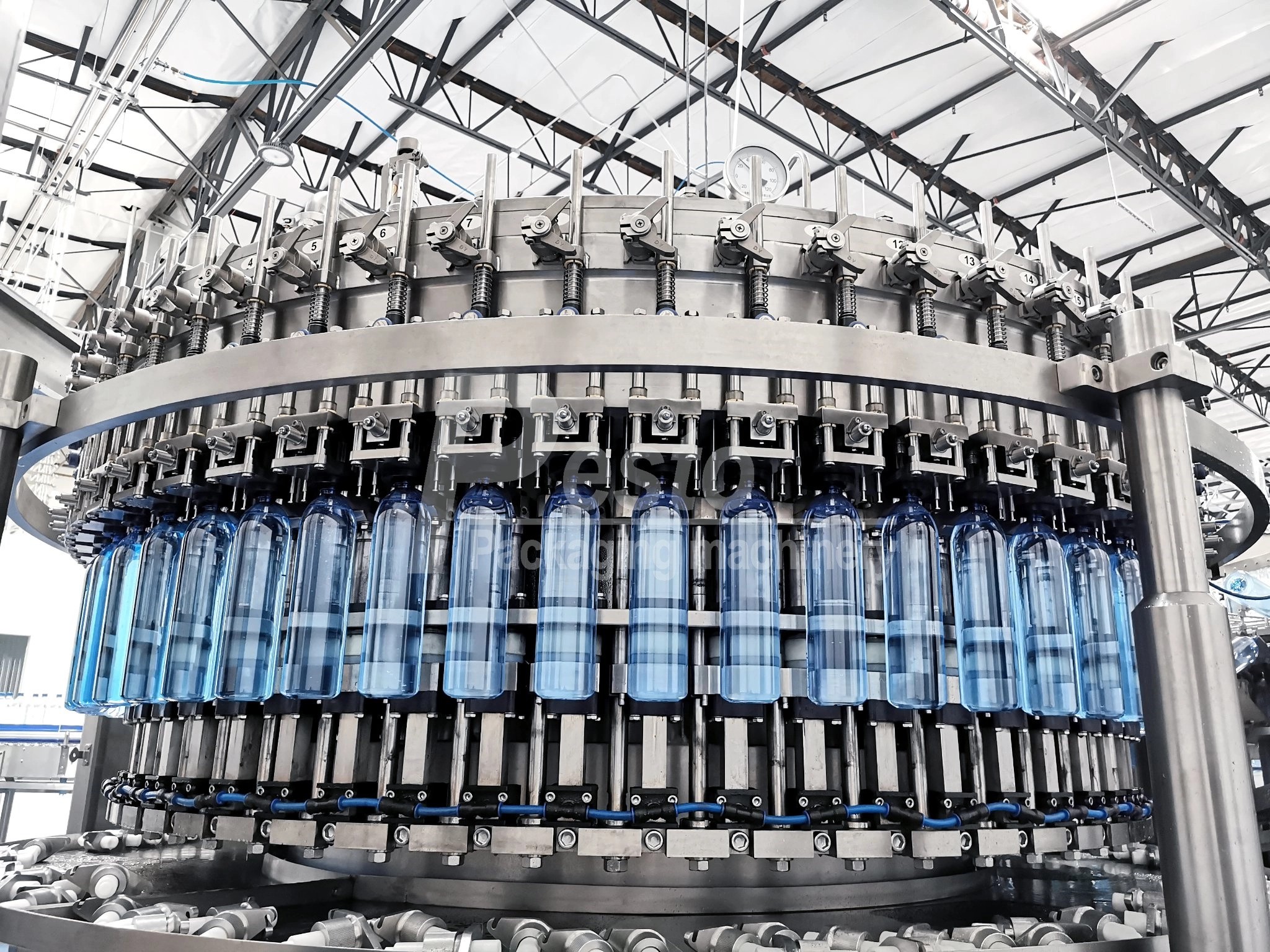

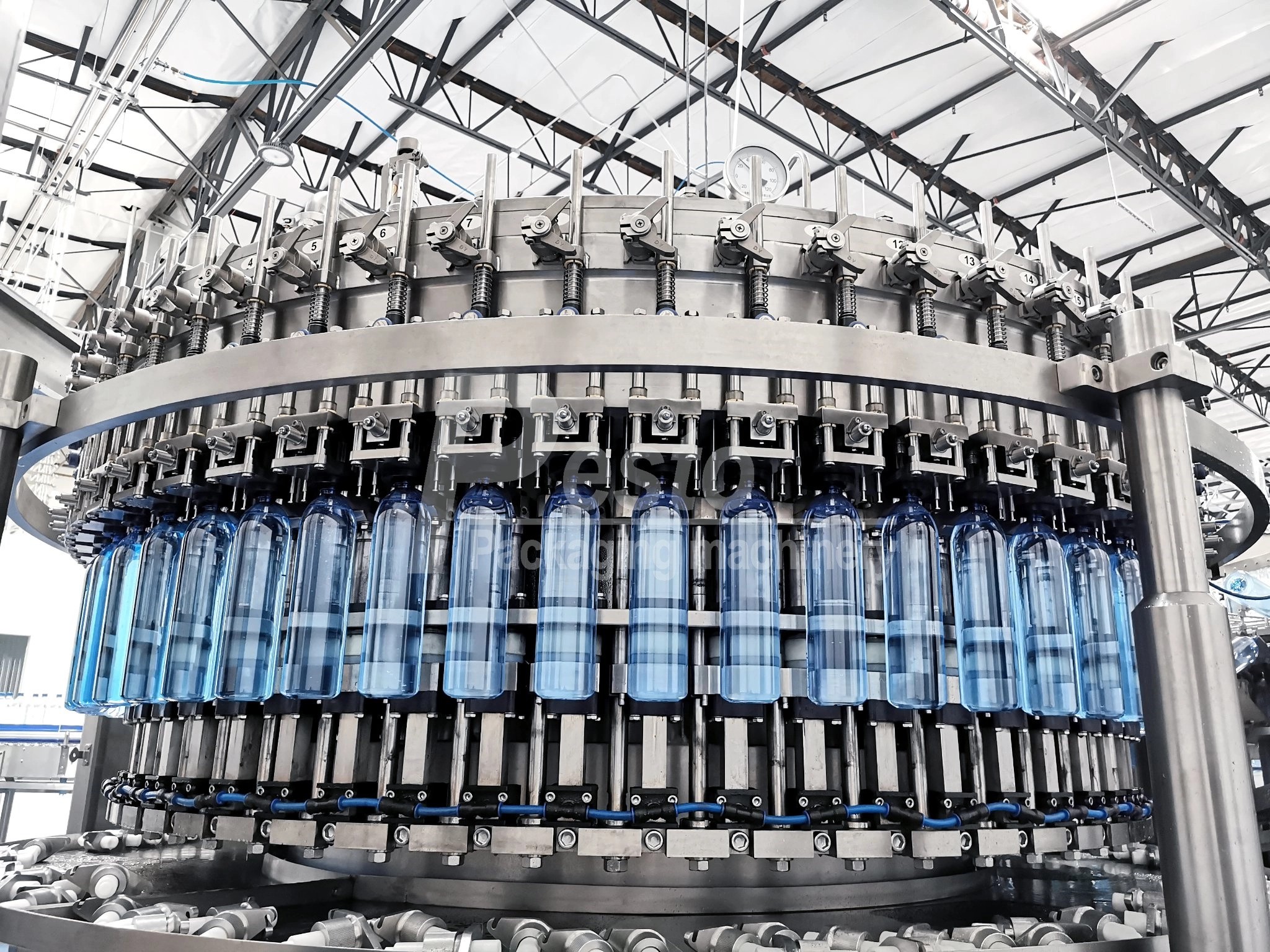

The filling machine – the heart of the line (keyword: water filling machine)

Here’s the central piece of equipment. For water bottling you’ll want a filling machine that offers:

Accurate fill volumes to reduce waste

Hygienic design to prevent contamination

Easy change-over if using multiple bottle sizes

Whether you go for semi-automatic or fully automatic depends on budget, labour cost, and expected scale.

Semi-automatic vs fully automatic filling machines

Semi-automatic: Lower cost, more hands-on, better for smaller capacity or flexible formats.

Fully automatic: Higher cost, lower labour, higher speed, best if you have stable format and larger volume.

Make sure the supplier (such as Pestopack) offers spare parts, service, and teaches your staff the set-up and maintenance.

Capping, labeling & packaging equipment

After filling you’ll need:

Capping machine (screw caps, sport-tops, tamper-evident)

Labeling machine (single panel, wraparound, or shrink label)

Packaging/palletising (shrink-wrapper, carton packer)

Each must match your production speed and bottle format. Mismatch here leads to bottlenecks.

Conveyors, palletising and auxiliary equipment

Don’t forget the supporting systems: conveyors between tanks to filling to capping; storage tanks; rinse/sanitisation systems; quality-control stations.

These “minor” pieces often cause big delays if overlooked.

Operation and running of the plant: common pain-points & how to address them

Building the line is only half the battle — running it profitably is the other.

Quality control and hygiene challenges

In Pakistan the challenge of microbial contamination is real. As per the pre-feasibility study, many smaller plants failed because hygiene/control was deficient.

Address this by:

Installing hygiene loops (CIP systems)

Monitoring regularly (TDS, bacteria, coliforms)

Ensuring staff training and cleaning schedules

Maintenance, downtime and spare parts in Pakistan context

Downtime kills profit. Use preventive maintenance: filter changes, gasket replacements, belt inspections.

Choose a supplier like Pestopack who offers global support and spare-parts availability. Map out spare parts that localize and stock them.

Plan for service visits and train a staff member on basic troubleshooting.

Energy, utilities, and cost control strategies

Utility bills (water, power) can be significant in Pakistan. A few tips:

Use energy-efficient RO membranes and pumps

Recover waste water if feasible

Monitor compressed air and steam usage (if any)

Every saving helps in the SME environment.

Cost estimation and ROI for a small/medium factory in Pakistan

Let’s put numbers around the idea to make it concrete.

Investment breakdown (machinery, installation, utilities)

Based on local data: a small RO + filling plant in Pakistan might cost in local currency as per earlier study (machinery + installation) ~ Rs 6,240,000 for smaller scale.

You’ll add bottles, caps, buildings, utility connections, labour.

Choose a configuration from Pestopack that matches your budget but leaves room for growth.

Revenue, break-even, and scaling up advice

Estimate your per-bottle cost (water treatment + bottle + cap + label + energy + labour). Then set your sale price accordingly.

If you run e.g., 2,000 bottles/hour with 8-hour shift → ~16,000 bottles/day → maybe ~400,000/month. Then subtract costs and aim for break-even within 1-2 years.

Plan for scaling: once market ok, add another filling line or bigger bottle format.

Summary and next steps for entrepreneurs

Here’s your takeaway: building a water bottling line in Pakistan is feasible for SMEs if you carefully pick capacity, source reliable equipment (especially the water filling machine), address regulatory and operational issues, and partner with an experienced supplier like Pestopack Machinery for factory-direct pricing and global service.

Internal links to further resources

For deeper dives:

Final checklist before commissioning

Before you hit “Go”, tick off:

✅ Licensed and permits in place

✅ Water source tested and treatment system sized

✅ Bottle format & market demand defined

✅ Supplier selected (Pestopack) and ordering placed

✅ Equipment layout and utility plan done

✅ Quality-control plan written and staff trained

✅ Spare parts and maintenance schedule set

✅ Cost & ROI reviewed and financing ready

Conclusion

If you follow each of these steps, you’ll be well-positioned to build a successful bottled-water venture in Pakistan. Choose the right machine (especially the filling machine), partner with a strong supplier, and keep your operations tight. Good luck with your project — may your plant flow smoothly and profitably!

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu