Accutek Packaging Equipment

PestoPack

Krones AG

Tetra Pak

Bosch Packaging Technology (Syntegon)

Ronchi Mario

GEA Group

ProMach

Filamatic

Inline Filling Systems

Liquid filling machines are essential for many industries, including food, beverages, pharmaceuticals, cosmetics, and chemicals. Choosing the right liquid bottle filling machine manufacturer is crucial to ensuring your production line runs efficiently and meets your quality standards. Below is a list of some of the top liquid filling machine manufacturers known for their innovation, quality, and reliable solutions, along with their key features and leading products.

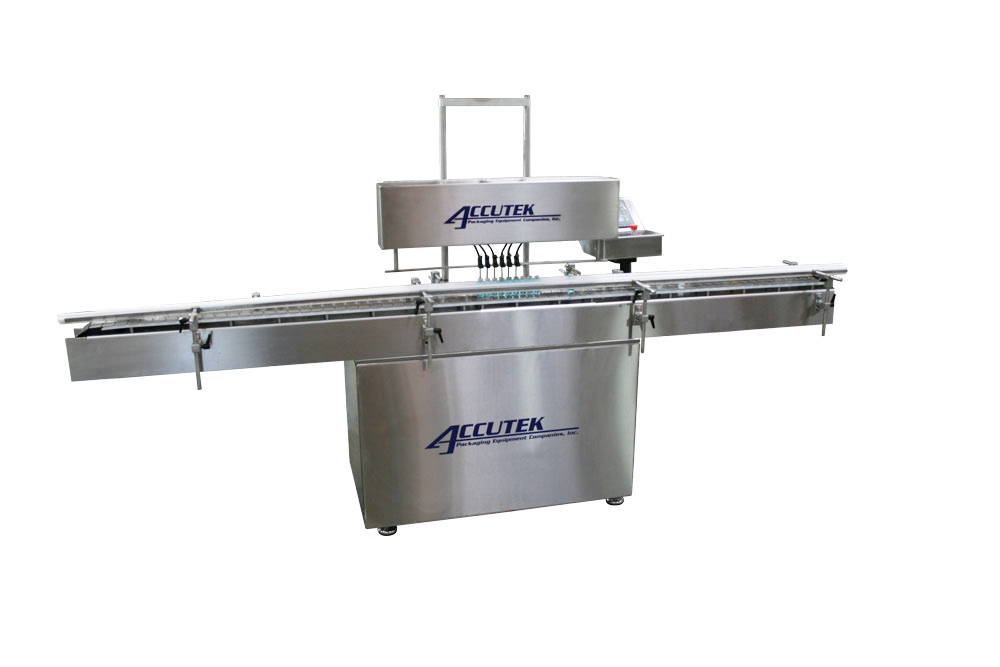

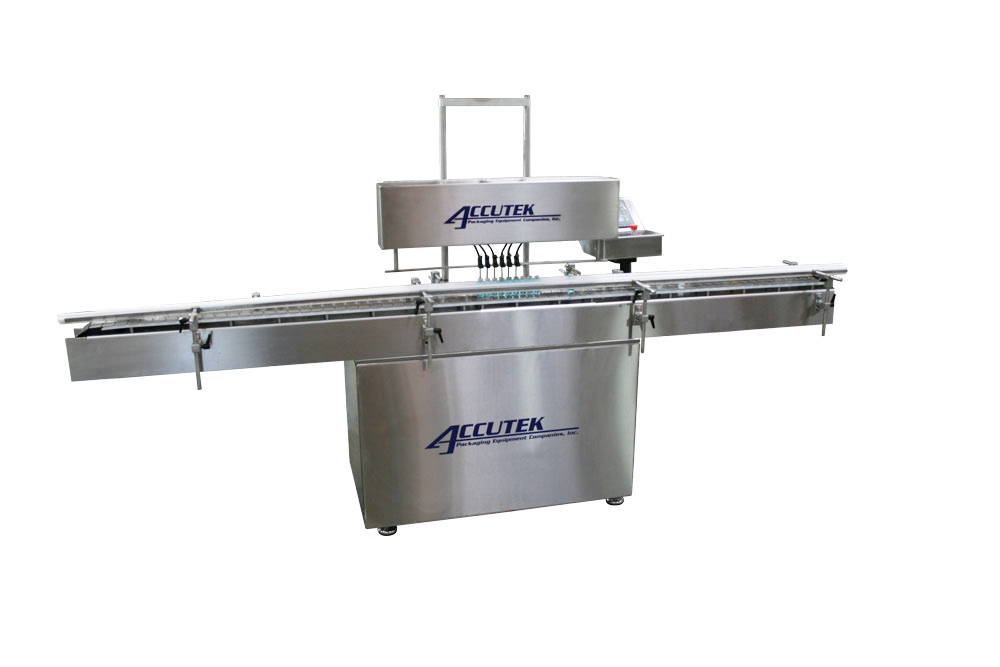

Accutek Packaging Equipment

Accutek Packaging Equipment is widely recognized as one of the most reliable and versatile manufacturers of liquid filling machines. Their extensive product line serves a variety of industries, including food and beverages, pharmaceuticals, cosmetics, chemicals, and more. What sets Accutek apart is their commitment to designing durable, flexible, and cost-effective solutions, making them especially suitable for small to mid-sized businesses that need efficient machinery without breaking the budget.

Accutek’s machines are designed to handle liquids with a broad range of viscosities, from water-like substances to thicker materials like creams or gels. This adaptability ensures that businesses, regardless of their industry, can find a machine that fits their specific needs, whether they’re handling beverages, oils, lotions, or other products. The company also places a strong emphasis on providing scalable solutions, allowing businesses to start small and easily upgrade their production capabilities as demand increases.

Accutek is also known for its excellent customer service, ensuring that clients receive support throughout the purchase, installation, and maintenance of their equipment. This commitment to service, combined with their high-quality machinery, makes Accutek a top choice for many industries.

Key Features

Full Range of Machines: Accutek offers a wide variety of filling machines, ranging from semi-automatic systems for smaller production lines to fully automatic machines designed for high-output operations.

Adaptability to Different Containers: The equipment is capable of filling various container shapes and sizes, making it a versatile choice for businesses that produce a variety of products.

Cost-Effective Solutions: Accutek provides affordable machines without compromising quality, making it an ideal choice for small and mid-sized businesses looking to optimize production.

Customizable Options: Their machines can be tailored to specific industry needs, ensuring precision and efficiency for each unique application.

Key Product

Auto Mini Pinch

The Auto Mini Pinch is one of Accutek’s most popular semi-automatic filling machines, known for its simplicity, affordability, and reliability. It is specifically designed for small production lines and can handle low-viscosity liquids like water, juices, alcohol, and other similar products. The machine is easy to operate and requires minimal training, making it ideal for businesses that are just starting out or for those that need an efficient, low-cost solution for filling operations.

This machine stands out due to its:

User-Friendly Design: The Auto Mini Pinch is easy to set up and maintain, allowing operators to quickly get the machine up and running without extensive technical expertise.

Compact Size: Its small footprint makes it a perfect fit for businesses with limited space.

Precision Filling: Despite its compact and cost-effective nature, the Auto Mini Pinch ensures accuracy in filling, reducing waste and ensuring consistent product quality.

Versatility: It can be used with a variety of containers, making it suitable for industries ranging from beverages to cosmetics and pharmaceuticals.

The Auto Mini Pinch is particularly suited for businesses looking for a reliable, entry-level filling machine to enhance production efficiency without a significant upfront investment. Its ability to deliver consistent results with minimal operational complexity makes it a top choice for small-scale manufacturers.

PestoPack

PestoPack is quickly becoming a recognized name in the liquid filling machinery industry, offering a broad range of solutions that cater to diverse business needs. Whether you're a small business or a large-scale manufacturer, PestoPack provides machines that are designed to meet the demands of industries as varied as cosmetics, food, beverages, pharmaceuticals, and chemicals. With an emphasis on customization, PestoPack’s filling systems are suitable for handling everything from low-viscosity liquids like water and oils to high-viscosity products like gels, creams, and pastes.

PestoPack’s flexibility extends beyond the types of liquids it can fill, offering solutions that scale according to production needs. From manual and semi-automatic machines that are perfect for small production runs to fully automated systems that can handle high-output manufacturing, PestoPack designs its equipment to grow alongside your business. Their machines are known for their durability, reliability, and precision, ensuring consistent, high-quality results with every production run.

The company’s commitment to affordability without compromising on performance makes them an attractive choice for businesses seeking cost-effective solutions. PestoPack machines are designed with ease of use and maintenance in mind, which reduces downtime and increases overall productivity. With customizable features that allow the machines to adapt to a variety of container types and sizes, PestoPack offers versatile options that can fit seamlessly into different production lines.

Key Features

Customizable Solutions for Diverse Industries: PestoPack specializes in creating flexible machines that can be customized to fit the unique needs of various industries. Whether you're working with food products, cosmetics, or chemicals, their machines can be tailored to handle your specific production requirements.

Handling Various Liquid Viscosities and Container Sizes: From thin liquids like water to thicker substances like creams and gels, PestoPack machines are built to handle a wide range of viscosities. Their equipment is also adaptable to various container sizes, making it suitable for businesses with diverse product lines.

Competitive Pricing with Reliable Performance: PestoPack offers machines that deliver reliable, consistent results at competitive prices. Their equipment is engineered to provide long-term durability, reducing the need for frequent maintenance and ensuring minimal downtime.

Scalable for Growing Production: Whether you need a manual filler for small batch production or a fully automated system for large-scale manufacturing, PestoPack provides solutions that can scale with your business as your production demands grow.

Key Product

PestoPack Automatic Liquid Filler

The PestoPack Automatic Liquid Filler is one of the company’s most versatile and high-performing machines, designed to handle a wide variety of liquid products. This fully automated system is engineered to meet the needs of industries ranging from cosmetics to food and beverages, where precision, consistency, and efficiency are crucial. The machine can handle both low-viscosity liquids, such as water and oils, and high-viscosity products like creams, lotions, and gels, making it an ideal solution for businesses with diverse product lines.

What makes the PestoPack Automatic Liquid Filler stand out:

Versatile Liquid Handling: This machine can easily handle liquids of varying viscosities, from thin, water-like liquids to thicker, more challenging substances like creams and gels. This versatility makes it ideal for industries like cosmetics, food, beverages, and pharmaceuticals, where the nature of the products can vary greatly.

Customizable for Different Container Types: The PestoPack Automatic Liquid Filler is built with customization in mind. It can be configured to fill a variety of container shapes and sizes, offering flexibility to manufacturers that produce multiple products or require frequent container size changes.

Precision and Efficiency: With automated controls and advanced filling technology, the machine ensures that each container is filled with accuracy and consistency. This reduces product waste and ensures uniformity across all filled containers, a key requirement in industries like food and pharmaceuticals.

Wide Application: The PestoPack Automatic Liquid Filler is used across multiple industries for different types of products, such as:

Oil Filling Machine: Ideal for filling edible oils, essential oils, and industrial oils, ensuring precise fills and high efficiency for large production runs.

Lotion Filling Machine: Suited for cosmetics and personal care products like lotions and moisturizers, where product texture and consistency are important.

Cream Filling Machine: Designed to handle thick creams for industries such as cosmetics and pharmaceuticals, maintaining product integrity and ensuring smooth operation.

Adaptable for Different Production Scales: Whether you’re a small business looking to automate your production line or a large manufacturer seeking high-speed filling solutions, the PestoPack Automatic Liquid Filler is scalable to meet your production needs. Its flexible design allows it to integrate easily into existing production lines or serve as the foundation for new production setups.

Ease of Use and Maintenance: Designed with the operator in mind, the machine is easy to set up, operate, and maintain. This reduces downtime and ensures that production runs smoothly, even in high-demand environments.

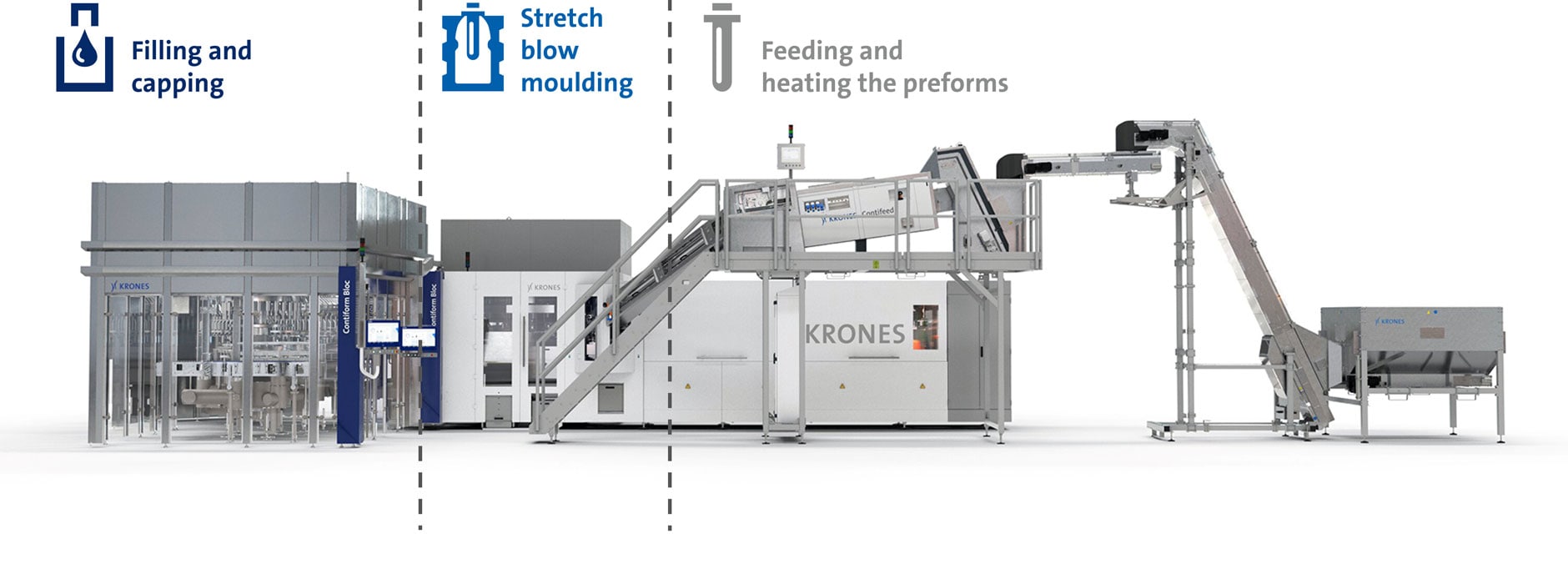

Krones AG

Krones AG is a renowned global leader in the packaging and bottling technology industry, with a well-established reputation for delivering advanced, high-speed liquid filling solutions. Their machines are primarily recognized in the beverage industry, where they serve some of the world’s largest and most successful brands. Krones' comprehensive approach to manufacturing and engineering enables them to produce machines that not only meet the demanding requirements of large-scale operations but also set industry standards in terms of precision, efficiency, and sustainability.

Krones' filling machines are engineered for high-volume production, ensuring that even at peak speeds, accuracy and quality are not compromised. The company’s commitment to innovation is evident in its integrated systems that combine multiple production stages—such as blow molding, filling, and capping—into a single seamless process. This approach reduces bottlenecks, improves overall production efficiency, and optimizes space utilization in the manufacturing environment.

With a strong emphasis on sustainability, Krones has made energy efficiency a cornerstone of its equipment design. Their machines are built to minimize energy consumption and reduce waste, aligning with global trends toward more eco-friendly manufacturing practices. This makes Krones AG a go-to solution provider for companies looking to scale their operations while maintaining environmental responsibility.

Key Features

Advanced High-Speed Filling Technology: Krones machines are designed for high-speed operations, making them ideal for large-scale beverage production. They can fill thousands of bottles per hour, ensuring maximum throughput without sacrificing precision.

Integrated Systems for Greater Efficiency: By combining multiple functions like blow molding, filling, and capping into one machine, Krones minimizes the need for multiple production lines and reduces downtime between processes.

Sustainability and Energy Efficiency: Krones is committed to creating eco-friendly machines that use less energy, reduce emissions, and produce less waste. Their systems are designed with sustainability in mind, helping manufacturers meet stringent environmental regulations.

Ideal for Large-Scale Beverage Production: Whether it’s water, soft drinks, beer, or carbonated beverages, Krones' machines are equipped to handle large production volumes, making them an excellent choice for global beverage brands with high demands.

Key Product

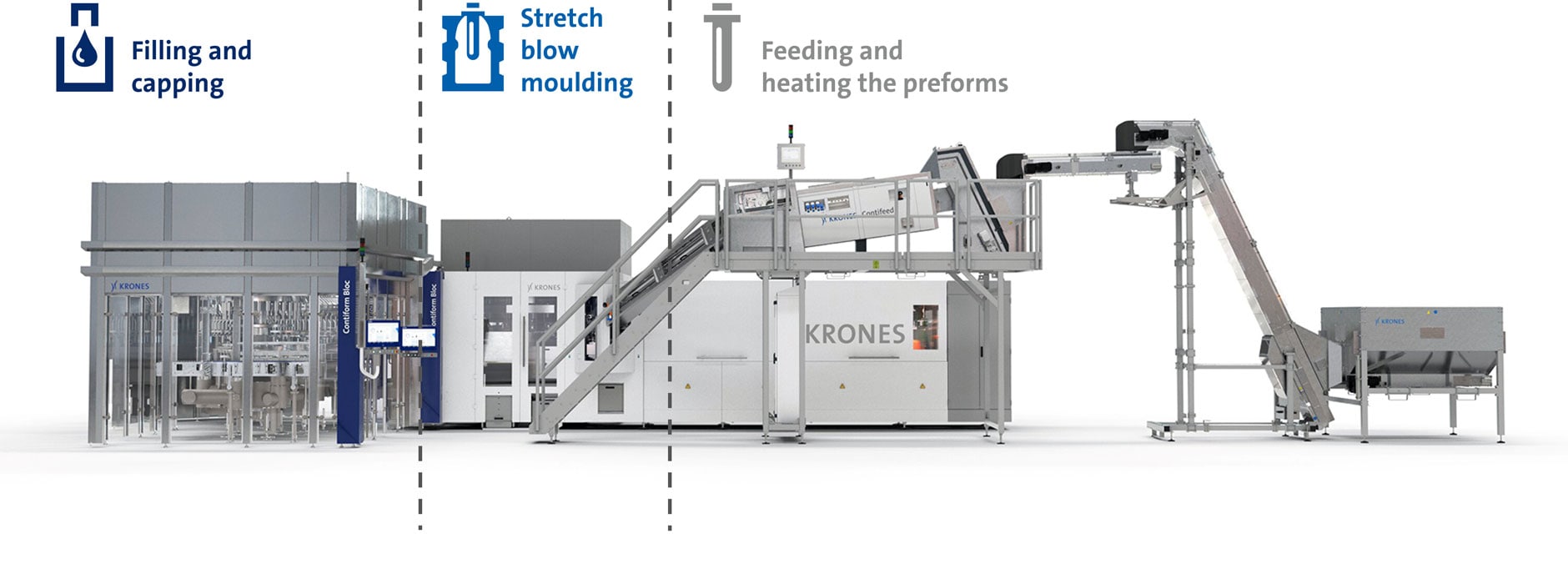

Krones Contiform Bloc

The Krones Contiform Bloc is one of the flagship machines in Krones' portfolio, designed to offer a streamlined solution for large beverage manufacturers. It integrates three crucial processes—blow molding, filling, and capping—into one cohesive system, drastically improving production line efficiency. The Contiform Bloc is particularly suitable for bottling water, juices, carbonated soft drinks, and other liquid beverages, providing businesses with a versatile and reliable solution for their high-volume needs.

What sets the Krones Contiform Bloc apart:

Blow Molding Integration: The Contiform Bloc includes an advanced blow molding unit, which allows manufacturers to create PET bottles on-site. This eliminates the need for pre-made bottles, saving on transportation and storage costs, while giving manufacturers more control over bottle design.

Precise and High-Speed Filling: The machine is designed for accurate, high-speed filling, ensuring that every bottle is filled to the exact specifications, even at high output speeds. This precision reduces product waste and ensures consistent quality across all products.

Seamless Capping: The built-in capping system ensures that bottles are securely sealed immediately after filling, maintaining product freshness and safety. The seamless integration of this process within the same machine eliminates the need for separate capping equipment, which simplifies the production line.

Energy-Efficient Operation: In line with Krones' sustainability goals, the Contiform Bloc is designed to be energy-efficient, consuming less power while maintaining high levels of performance. This results in reduced operational costs and a lower environmental impact.

By combining these three production processes into one compact machine, the Krones Contiform Bloc helps manufacturers save valuable space, reduce operational complexity, and significantly boost production efficiency. The machine’s versatility makes it a top choice for beverage companies looking to streamline their production lines while maintaining high standards of product quality and sustainability.

Tetra Pak

Tetra Pak is a world leader in liquid food processing and packaging, renowned for its pioneering solutions that have revolutionized the way liquids are packaged and distributed globally. With a strong focus on aseptic filling technology, Tetra Pak enables manufacturers to package liquid products in sterile conditions, extending the shelf life of products without the need for preservatives. This breakthrough technology has made Tetra Pak a trusted partner for companies in the dairy, juice, and liquid food sectors, providing sustainable and efficient packaging solutions that meet the high standards of food safety and quality.

Tetra Pak is committed to innovation, continually evolving its packaging technology to meet the changing demands of consumers and manufacturers. Their solutions are designed to reduce product waste, enhance operational efficiency, and improve product preservation. By offering flexible systems that cater to both small and large-scale operations, Tetra Pak ensures that businesses of all sizes can benefit from their advanced packaging technology.

In addition to their technical expertise, Tetra Pak is also dedicated to sustainability. Their machines and packaging materials are designed to minimize environmental impact by reducing energy consumption, using renewable resources, and creating recyclable packaging. This focus on sustainability, combined with their cutting-edge technology, makes Tetra Pak a leader in both innovation and environmental responsibility.

Key Features

Aseptic Filling Technology: Tetra Pak's aseptic filling machines ensure that liquid products, such as milk, juices, and liquid food items, are packaged in sterile environments. This process significantly extends the shelf life of products without the need for refrigeration or preservatives, which is particularly valuable in markets where cold chain logistics are challenging.

Tailored Solutions for Dairy and Beverage Industries: Tetra Pak’s machines are specifically designed to meet the unique needs of the dairy and beverage sectors, offering precise filling solutions that maintain the quality and safety of sensitive liquid products.

Efficient Packaging Systems: Tetra Pak's equipment is designed for high efficiency, ensuring minimal product waste during the filling process. The company’s systems are built to optimize the use of raw materials and reduce operational costs, helping manufacturers maximize profitability.

Flexibility for Small and Large-Scale Operations: Whether you're a small startup or a large enterprise, Tetra Pak provides solutions that scale to your needs. Their machines are adaptable, allowing manufacturers to switch between different carton sizes and product types with ease, ensuring operational flexibility.

Key Product

Tetra Pak A3/Flex

The Tetra Pak A3/Flex is one of the company’s flagship filling machines, designed for manufacturers seeking flexible, high-performance packaging solutions for their liquid food products. This machine specializes in aseptic filling, allowing liquid food and beverages to be safely packaged in sterile cartons, extending their shelf life without the need for preservatives or refrigeration. The A3/Flex is particularly popular in the dairy and juice industries, where product quality and freshness are paramount.

What makes the Tetra Pak A3/Flex stand out:

Flexible Carton Sizes: The A3/Flex is designed with flexibility in mind, allowing manufacturers to switch between different carton sizes and shapes without the need for extensive equipment modifications. This versatility ensures that manufacturers can adapt quickly to changing market demands or introduce new product lines with minimal disruption to production.

Extended Shelf Life: Thanks to its advanced aseptic filling technology, the A3/Flex helps manufacturers preserve the freshness and nutritional value of their products for longer periods, without preservatives. This not only enhances product quality but also reduces the need for cold storage, making distribution more cost-effective.

Efficient and Reliable Operation: The A3/Flex is built for high-speed production, ensuring that manufacturers can meet large-scale demands while maintaining efficiency and minimizing waste. The machine’s precision filling technology ensures consistent fill levels, reducing product loss and improving profitability.

Sustainable Packaging: The A3/Flex supports Tetra Pak’s broader sustainability goals by using renewable materials and creating recyclable packaging solutions. This helps manufacturers reduce their environmental footprint while meeting the growing consumer demand for eco-friendly products.

Bosch Packaging Technology (Syntegon)

Syntegon, formerly known as Bosch Packaging Technology, is a global leader in manufacturing advanced filling and packaging solutions, particularly for the pharmaceutical and cosmetic industries. With decades of experience, Syntegon is synonymous with precision, reliability, and innovation, offering high-performance machines that meet the strict regulatory standards of these sensitive sectors. Their solutions are engineered to ensure the safety, quality, and efficiency of production processes, from filling to sealing, while maintaining flexibility to adapt to changing industry needs.

Syntegon is renowned for delivering high-precision liquid filling machines that ensure accuracy, minimize product waste, and offer exceptional reliability. These features are crucial in the pharmaceutical industry, where even minor discrepancies in filling can impact product quality and safety. Similarly, in the cosmetics industry, where consistent product quality is paramount, Syntegon’s machines ensure the perfect fill every time, even with varying viscosities.

The company’s modular approach allows their equipment to be easily integrated into existing production lines, providing businesses with scalable solutions that grow alongside their operations. Whether for small-batch production or large-scale manufacturing, Syntegon’s machines offer the flexibility to meet a wide range of needs.

Key Features

High-Precision Filling Solutions: Syntegon's machines are engineered for precise and consistent filling, ensuring that every ampoule, vial, or cosmetic container is filled to exact specifications, reducing waste and enhancing product quality.

Ideal for Pharmaceuticals and Cosmetics: Syntegon specializes in solutions that meet the stringent regulatory requirements of the pharmaceutical industry, such as cGMP compliance, while also catering to the cosmetic sector’s need for versatility and high-quality aesthetics.

Customizable for Complex Production Requirements: Syntegon’s equipment can be customized to fit the specific needs of various production lines, offering flexibility in terms of capacity, automation level, and product type. This makes it easy for businesses to scale their operations or adjust to new product lines without needing extensive reconfigurations.

Small and Large-Scale Operation Capabilities: Whether you’re producing small batches or running a large-scale manufacturing operation, Syntegon offers tailored solutions that ensure efficiency and precision at any production level.

Key Product

Syntegon ALF 5000

The Syntegon ALF 5000 is a cutting-edge liquid filling and closing machine designed for the high-speed, high-precision filling of ampoules and vials, making it an essential asset for pharmaceutical companies. This machine ensures that sterile liquid products are filled with exacting precision while maintaining the highest safety standards, minimizing the risk of contamination. The ALF 5000’s reliability, speed, and accuracy make it a preferred choice for large-scale pharmaceutical production, where efficiency and precision are critical.

What sets the Syntegon ALF 5000 apart:

High-Speed Operation: The ALF 5000 is capable of filling up to 600 containers per minute, making it ideal for high-output production lines. Its speed doesn’t compromise on accuracy, ensuring that each container is filled to the exact required volume, reducing waste and increasing throughput.

Precise Filling for Sensitive Products: Designed specifically for sterile pharmaceutical products, the ALF 5000 ensures that each vial or ampoule is filled with precision, which is essential in the pharmaceutical industry, where even slight deviations can affect product efficacy and safety.

Integrated Closing System: The ALF 5000 doesn’t just fill containers; it also provides a fully integrated closing system, ensuring that ampoules and vials are securely sealed immediately after filling. This prevents contamination and guarantees product sterility, which is vital in pharmaceutical production.

Minimal Product Loss: With its highly accurate dosing system, the ALF 5000 minimizes product loss during the filling process. This feature is crucial in industries like pharmaceuticals, where product cost can be extremely high.

Scalable and Customizable: The ALF 5000 can be tailored to specific production needs, allowing manufacturers to configure the machine according to their operational requirements, such as handling different container sizes or integrating additional sterilization steps.

Ronchi Mario

Ronchi Mario is an industry leader specializing in the design and production of high-performance liquid filling machines, particularly for the cosmetic and personal care sectors. Known for their precision engineering and innovative technology, Ronchi Mario offers solutions that meet the diverse needs of manufacturers handling a wide range of liquid viscosities—from light perfumes to dense creams. With a focus on efficiency, accuracy, and flexibility, Ronchi Mario’s equipment is built to deliver consistent results across varying product types, making it a top choice for premium brands in the cosmetics, personal care, and even pharmaceutical industries.

Ronchi Mario has earned its reputation by providing filling systems that are not only highly accurate but also adaptable to different production scales. Their machines are equipped with cutting-edge servo-driven technology, which ensures precision while maintaining high-speed operations. This combination of speed and accuracy is especially crucial for manufacturers aiming to meet high-volume demands without compromising product quality.

The company’s commitment to customer-centric innovation is evident in the flexibility of their machinery. Ronchi’s machines are designed to handle a variety of container sizes and liquid viscosities, giving manufacturers the freedom to expand their product lines without investing in new equipment. This adaptability, paired with Ronchi’s dedication to sustainability and energy efficiency, makes their machines a valuable asset for companies looking to optimize production while maintaining environmental responsibility.

Key Features

Flexibility Across Liquid Viscosities: Ronchi’s machines can seamlessly switch between different liquid viscosities, from water-thin perfumes and oils to thicker lotions and creams, making them ideal for manufacturers with diverse product ranges.

Cosmetic and Personal Care Expertise: With decades of experience, Ronchi Mario has tailored their machines to meet the unique requirements of the cosmetic and personal care industries, ensuring that products like creams, lotions, shampoos, and perfumes are filled with the utmost precision and care.

High-Speed, High-Accuracy Filling Technology: The incorporation of servo-driven technology in their machines allows for precise control over filling volumes, ensuring accuracy even at high production speeds. This results in minimized product waste and maximized production efficiency.

Adaptable for Small and Large-Scale Production: Whether you’re running a small batch or a large-scale production line, Ronchi Mario’s machines are designed to scale with your business, providing flexibility and reliability as your operation grows.

Key Product

Ronchi Exacta

The Ronchi Exacta is a servo-driven rotary filling machine that exemplifies Ronchi Mario’s commitment to precision and speed. Widely used in the cosmetic and personal care industries, the Exacta is engineered to handle a broad range of liquid products, offering high-performance filling for everything from fragrances to viscous creams. The Exacta’s ability to deliver precise fills at high speeds makes it an essential tool for manufacturers looking to maintain product quality while optimizing production output.

What distinguishes the Ronchi Exacta:

Servo-Driven Precision: The Ronchi Exacta uses advanced servo technology to ensure exact control over the filling process. This means that regardless of the liquid’s viscosity, the machine can deliver accurate fills, reducing product waste and ensuring consistency across all containers.

Rotary System for High-Speed Filling: The rotary design of the Exacta allows for continuous filling, significantly increasing production speed without sacrificing accuracy. This is particularly beneficial for manufacturers dealing with high-demand products like shampoos, lotions, or perfumes.

Versatile Container Handling: The Exacta is designed to accommodate various container shapes and sizes, making it a versatile solution for companies that produce a wide range of cosmetic or personal care products. This flexibility reduces the need for frequent machine reconfiguration, saving time and improving overall efficiency.

Ease of Use and Maintenance: The Exacta is engineered for user-friendly operation, with intuitive controls that simplify the setup and changeover process. The machine is also designed for easy maintenance, ensuring minimal downtime and maximizing productivity.

Sustainability: Ronchi Mario is committed to producing energy-efficient machines that reduce waste and power consumption, aligning with the growing emphasis on sustainability in manufacturing.

GEA Group

GEA Group is a global leader in processing technology, offering cutting-edge liquid filling systems that are particularly valued in the food and beverage industries. With a strong focus on hygiene, efficiency, and scalability, GEA has earned a reputation for delivering innovative solutions that meet the rigorous demands of modern food and beverage production. Their filling machines are widely used for processing dairy products, beverages, and other liquid foods, ensuring that the highest hygiene standards are maintained throughout the production process.

GEA’s commitment to hygiene is especially vital in sectors like dairy, where contamination can compromise product quality. Their filling machines are designed to create sterile environments, which help extend the shelf life of products without the need for preservatives. The company’s solutions also cater to scalability, allowing businesses to start with smaller setups and expand as demand grows. Whether it’s for artisanal dairy producers or large-scale beverage companies, GEA’s equipment can adapt to varying production needs.

In addition to their technical expertise, GEA focuses on sustainability and energy efficiency, developing machines that reduce waste, energy consumption, and environmental impact. Their modular systems are easy to upgrade, providing long-term value and flexibility as production lines evolve. GEA’s dedication to these principles has made them a trusted partner for companies that prioritize both efficiency and sustainability in their production processes.

Key Features

High-Hygiene Standards: GEA’s filling systems are designed to meet stringent hygiene requirements, particularly for dairy and beverage products. The equipment ensures that liquids are processed in sterile environments, preventing contamination and maintaining product quality.

Modular Systems for Flexibility: GEA’s machines are highly modular, which means that businesses can easily upgrade or expand their production lines as needed. This flexibility is particularly useful for companies looking to scale up production without having to invest in entirely new systems.

Suitable for Small and Large-Scale Production: Whether you're a small dairy farm or a global beverage company, GEA’s machines can be tailored to fit your production requirements, offering reliable performance at both small and large scales.

Energy-Efficient and Sustainable: GEA is committed to producing energy-efficient machines that minimize waste and power consumption. This focus on sustainability helps businesses reduce their environmental footprint while keeping operating costs low.

Key Product

GEA Fillstar CX

The GEA Fillstar CX is one of GEA’s flagship aseptic filling machines, specifically designed for the high-capacity filling of dairy products and beverages. This machine is engineered to handle a wide variety of packaging materials, making it a versatile choice for manufacturers producing everything from milk and yogurt to juices and other liquid beverages. The Fillstar CX’s aseptic technology ensures that products are filled in a sterile environment, significantly extending their shelf life without the need for refrigeration or preservatives.

What sets the GEA Fillstar CX apart:

Aseptic Filling for Long Shelf Life: The Fillstar CX is equipped with advanced aseptic filling technology, which allows liquid products to be filled in sterile conditions. This extends the shelf life of dairy products and beverages, reducing the need for preservatives and ensuring the highest product quality.

High-Capacity Filling: The machine is designed for high-volume production, making it an excellent choice for manufacturers who need to meet large-scale demand. The Fillstar CX can handle large output while maintaining precision, reducing product waste, and ensuring consistency in every fill.

Flexible Packaging Options: The Fillstar CX is compatible with a wide range of packaging materials, including PET bottles, cartons, and other packaging formats. This versatility allows manufacturers to meet diverse consumer demands and explore new packaging designs without the need for extensive modifications to their production lines.

Energy-Efficient Operation: GEA’s Fillstar CX is designed with energy efficiency in mind. The machine’s optimized processes reduce energy consumption, helping manufacturers lower operational costs while contributing to sustainability efforts.

Sterile and Hygienic Design: As hygiene is a top priority for GEA, the Fillstar CX incorporates a fully sterile environment during the filling process. This not only ensures product safety but also meets the strict regulatory standards for food and beverage production.

ProMach

ProMach is a global leader in packaging machinery, offering comprehensive solutions that cater to a variety of industries, including food, beverages, chemicals, pharmaceuticals, and personal care. With a robust portfolio of liquid filling machines, ProMach has built a reputation for delivering highly efficient, durable, and reliable systems that ensure long-term performance with minimal maintenance requirements. Their machines are engineered to maximize productivity while maintaining the flexibility to adapt to evolving production needs, making ProMach a go-to choice for companies of all sizes.

One of ProMach’s key strengths is their ability to offer scalable solutions. Whether you’re a small business looking for entry-level equipment or a multinational corporation seeking high-speed, large-scale production systems, ProMach provides machines that can grow with your business. Their liquid filling machines are designed for efficiency and precision, ensuring that every drop is accurately dispensed, no matter the size or shape of the container. This attention to detail has made ProMach a trusted partner for manufacturers looking to enhance productivity while maintaining product quality.

In addition to their cutting-edge technology, ProMach places a strong emphasis on customer support and service. From initial consultation to installation and ongoing maintenance, ProMach offers comprehensive assistance to ensure that their equipment integrates seamlessly into production lines. This commitment to customer satisfaction, combined with their innovative and customizable machinery, makes ProMach a top-tier packaging machinery manufacturer.

Key Features

High-Efficiency Filling Machines for Diverse Industries: ProMach’s liquid filling machines are built to serve a wide range of industries, from food and beverages to chemicals and pharmaceuticals. Their machines are designed for high efficiency, reducing downtime and maximizing throughput.

Durable, Low-Maintenance Equipment: ProMach machines are engineered for longevity, with durable components that minimize the need for frequent maintenance. This ensures continuous operation and reduces costs associated with downtime.

Scalable and Customizable Solutions: ProMach offers scalable equipment that can grow with your business. Their machines are highly customizable, allowing manufacturers to tailor their systems to fit specific production needs, whether for small-scale operations or large industrial setups.

Advanced Technology for Precision Filling: ProMach’s advanced filling technology ensures that each container is filled with exact precision, maintaining consistency across all product lines while minimizing waste.

Key Product

Pacific Rotary Filler

The Pacific Rotary Filler is one of ProMach’s most advanced and popular filling machines, specifically designed for high-speed, high-volume beverage production. As a rotary filler, it offers continuous motion filling, which is crucial for meeting the demands of large-scale beverage manufacturers. The Pacific Rotary Filler is known for its precision and consistency, making it ideal for filling various container shapes and sizes, from small bottles to larger containers.

What sets the Pacific Rotary Filler apart:

High-Speed Filling: The Pacific Rotary Filler is designed for high-output production lines, capable of filling thousands of containers per hour. Its rotary design allows for continuous, non-stop filling, which significantly increases production speed without sacrificing accuracy.

Precision and Consistency: One of the standout features of the Pacific Rotary Filler is its ability to deliver consistent fills with pinpoint accuracy, ensuring that every container is filled to the exact specifications. This reduces product waste and ensures uniformity across all products, which is critical for maintaining brand integrity.

Versatile Container Compatibility: The Pacific Rotary Filler is highly adaptable and can handle a wide variety of container shapes and sizes, making it a versatile solution for beverage manufacturers that produce multiple product lines. Whether you’re filling glass bottles, plastic containers, or cans, the machine can be easily configured to meet specific packaging requirements.

Durability and Reliability: Built to handle the rigorous demands of high-speed production environments, the Pacific Rotary Filler is known for its durability and low-maintenance design. The machine’s robust construction ensures long-term reliability, minimizing downtime and maintenance costs.

Ideal for Large-Scale Beverage Production: With its ability to handle high production volumes efficiently, the Pacific Rotary Filler is an excellent choice for large-scale beverage manufacturers who need to fill various types of containers with precision and speed.

Filamatic

Filamatic is a leading manufacturer specializing in liquid filling systems specifically tailored for the pharmaceutical, biotech, and health product industries. With over 60 years of experience, Filamatic has become synonymous with precision, reliability, and regulatory compliance, offering highly sophisticated equipment that caters to the unique needs of these sectors. Their machines are designed to handle a wide range of liquid viscosities, from thin, water-like solutions to thick, viscous liquids such as gels and syrups. This versatility makes Filamatic a trusted choice for manufacturers dealing with complex liquid formulations, such as medicines, supplements, and health products.

One of Filamatic's standout qualities is its commitment to regulatory compliance. Their equipment is built to meet stringent FDA and cGMP standards, ensuring that all processes are conducted with the highest level of quality and safety. This makes Filamatic an ideal partner for pharmaceutical companies that must adhere to rigorous industry regulations. Their filling systems are known for their accuracy, which is essential in the pharmaceutical sector, where precise dosages are critical to both product effectiveness and safety.

Filamatic’s solutions are also highly flexible, offering scalable systems that can accommodate small batch production as well as large-scale manufacturing. Their machines are modular and customizable, allowing manufacturers to adapt to changing product lines or increasing production demands without investing in entirely new equipment.

Key Features

Precision Filling Systems for Pharmaceuticals and Biotech Products: Filamatic's machines are designed for accuracy, ensuring that even the most complex liquid products are filled to exact specifications, which is critical for pharmaceutical products that require precise dosages.

Compliance with FDA and cGMP Standards: Regulatory compliance is at the core of Filamatic's offerings. Their machines meet the rigorous standards required by the pharmaceutical and biotech industries, ensuring quality, safety, and consistency in every product.

Flexible Systems for Small and Large Production Runs: Filamatic’s equipment is adaptable to both small-scale and large-scale production needs. Their systems are highly modular, making it easy to scale up operations or switch between different product lines without significant downtime or reconfiguration.

Handling of Low and High-Viscosity Liquids: Whether dealing with water-thin liquids or thick gels, Filamatic's machines are equipped to handle a broad range of viscosities, ensuring smooth and consistent filling for various products.

Key Product

Filamatic Monobloc System

The Filamatic Monobloc System is a versatile, all-in-one machine designed for pharmaceutical companies that require a compact, efficient solution for liquid filling, capping, and labeling. This system offers a streamlined approach to production, allowing manufacturers to automate multiple stages of the packaging process in a single, integrated machine. The Monobloc System is ideal for companies seeking to optimize space, reduce operational complexity, and maintain high levels of precision and reliability.

What sets the Filamatic Monobloc System apart:

All-in-One Solution: The Monobloc System integrates filling, capping, and labeling into one machine, significantly reducing the need for separate equipment and manual intervention. This not only saves space but also increases production efficiency by automating multiple processes in a single, seamless operation.

Precision Filling for Pharmaceuticals: With precise dosing capabilities, the Monobloc System ensures that every container is filled to exact specifications, which is especially important in the pharmaceutical industry where accuracy is critical for both safety and efficacy.

Versatile Capping and Labeling: The Monobloc System’s built-in capping and labeling features provide flexibility for different container types and sizes. Whether using vials, bottles, or other pharmaceutical packaging formats, the machine can easily adapt to ensure a perfect fit and label application.

Compact and Efficient Design: Designed with efficiency in mind, the Monobloc System takes up minimal floor space while maximizing output. This makes it an excellent choice for companies with limited production space but high production demands.

Regulatory Compliance: Like all Filamatic machines, the Monobloc System meets FDA and cGMP standards, ensuring that pharmaceutical products are filled and packaged in compliance with industry regulations.

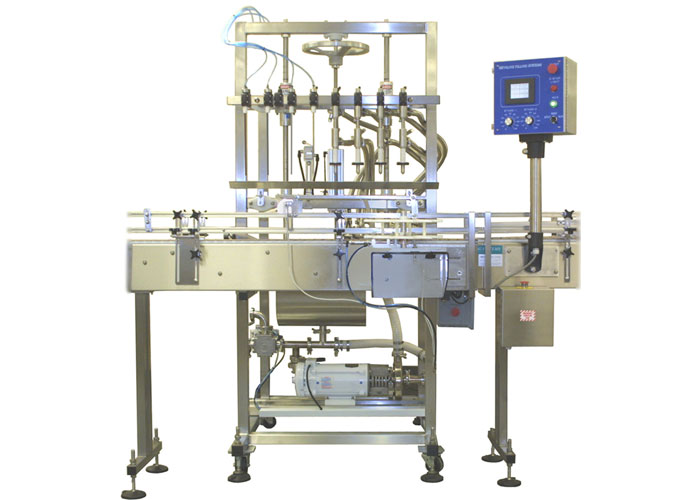

Inline Filling Systems

Inline Filling Systems is a trusted name in the packaging industry, recognized for producing durable and efficient liquid filling machines that cater to various industries, including chemicals, food, beverages, cosmetics, and pharmaceuticals. Known for their rugged designs and reliable performance, Inline Filling Systems’ machines are built to withstand the rigors of industrial production environments. Their solutions are tailored to meet the needs of both small-scale operations and large-scale manufacturing, making them a versatile option for companies looking to improve efficiency and precision across different production volumes.

One of the standout features of Inline Filling Systems is their ability to handle a wide range of liquid viscosities, from thin, water-like liquids to thick, viscous products such as sauces, creams, and gels. This versatility makes their equipment highly adaptable, allowing manufacturers to use the same machine for various products without requiring significant reconfiguration or downtime. Their machines are also customizable, meaning they can be tailored to fit specific production line requirements, whether it’s adjusting for container sizes, fill volumes, or product types.

Inline Filling Systems places a strong emphasis on efficiency and accuracy, ensuring that each machine is designed to minimize product waste and maximize output. Their commitment to quality and flexibility has made them a top choice for industries with demanding production requirements, such as chemicals and food processing, where consistency and reliability are paramount.

Key Features

Rugged and Reliable Industrial Equipment: Inline Filling Systems’ machines are built to withstand the tough conditions of industrial production environments. Their robust construction ensures long-term durability and minimal downtime, even in high-output settings.

Handles a Wide Range of Liquid Viscosities: From thin liquids like water and beverages to thicker substances like sauces, gels, and creams, Inline Filling Systems’ machines are engineered to handle liquids of varying viscosities with precision and efficiency.

Customizable for Specific Production Needs: Inline Filling Systems offers highly customizable machines that can be adapted to meet the unique requirements of each production line. Whether manufacturers need to handle different container shapes and sizes or adjust for varying fill volumes, the machines can be configured for optimal performance.

Ideal for Small and High-Volume Production: Inline Filling Systems caters to both small and large-scale operations, making their equipment suitable for growing businesses as well as established manufacturers with high production demands.

Key Product

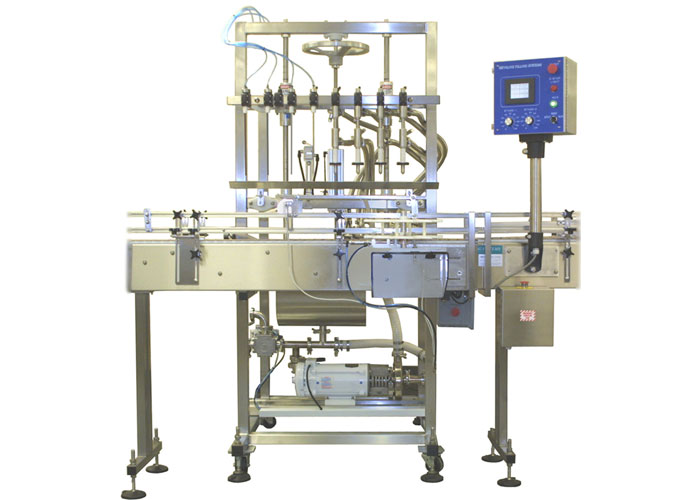

Servo Pump Filler

The Servo Pump Filler is one of Inline Filling Systems’ most versatile and advanced filling machines. Designed to handle both thin and thick liquids, this machine ensures accurate, consistent fills while maintaining efficiency across a variety of products. It is especially well-suited for industries like food and beverage, chemicals, and cosmetics, where liquid consistency can vary greatly between products.

What sets the Servo Pump Filler apart:

Versatile Filling Capabilities: The Servo Pump Filler is engineered to handle a wide range of viscosities, from water-like liquids to thick, dense products like sauces and creams. This versatility makes it ideal for manufacturers with diverse product lines.

Precision and Accuracy: The servo-driven technology allows for precise control over the filling process, ensuring that each container is filled to exact specifications. This level of accuracy reduces product waste and enhances production efficiency, especially in high-volume operations.

Efficient for Various Container Types: The Servo Pump Filler can be easily configured to fill different container shapes and sizes, making it a flexible solution for manufacturers with varying packaging needs. Whether filling bottles, jars, or larger containers, the machine can be adapted to meet production requirements.

Quick Changeovers: Inline Filling Systems has designed the Servo Pump Filler for easy changeovers between product runs, minimizing downtime and allowing manufacturers to switch between different products or packaging formats quickly and efficiently.

Durability for High-Output Production: The Servo Pump Filler is built with industrial-grade components that ensure reliable performance over time. Its durable construction makes it suitable for continuous operation in demanding production environments, reducing the need for frequent maintenance.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu