Introduction: How to Choose the Right Bottling Equipment in Russia

Why Russia’s Bottled Water Market Remains Strong

Understanding the Factors Behind Water Bottling Machine Price

Water Bottling Machine Price Range in 2025

Automation Options and Their Impact on Cost

Machine Types Popular in Russia

Material Selection and Hygiene Standards

Control Systems and Electrical Configuration

Bottle Formats, Caps, and Mold Design

Utilities and Facility Requirements (Adapted for Russia)

Total Cost of Ownership (TCO) and Return on Investment

Why Choose Pestopack — Factory-Direct from China

What’s Included in Pestopack’s Service

Budgeting for Different Business Scales

Logistics, Delivery, and Compliance for Russia

Line Layout and Process Flow

Frequently Asked Questions (FAQs)

How to Request a Personalized Quote

Conclusion — Build Your Future Water Line with Pestopack

Introduction: How to Choose the Right Bottling Equipment in Russia

Are you planning to start or upgrade a bottled water production plant in Russia?

Then understanding the real water bottling machine price and what factors influence it is the first step to building a profitable operation.

The Russian bottled water market is large, diverse, and growing. From small regional brands to national distributors, entrepreneurs are looking for filling solutions that balance cost, performance, and reliability.

This guide will give you a complete, transparent overview of water filling machine prices, configuration options, and how Pestopack Machinery, a professional China-based factory, helps Russian investors access global-standard equipment at factory-direct prices.

Explore our complete product range here: Water Filling Machines

Why Russia’s Bottled Water Market Remains Strong

Despite fluctuations in global logistics and raw material costs, Russia’s bottled water sector continues expanding steadily. Consumers increasingly prefer bottled water for convenience, taste, and safety — particularly in areas where tap water quality varies.

Some key insights:

Per capita bottled water consumption has surpassed 60 liters annually, and keeps rising.

Still water accounts for about 80% of the market, but demand for sparkling and mineral water is growing fast.

The most popular sizes are 0.33L–0.6L for travel, 1–1.5L for family use, and 19L bottles for offices and homes.

This growth fuels strong investment in local production. Many regional producers are upgrading from manual or semi-automatic setups to fully automatic 3-in-1 water filling machines for higher efficiency and hygiene.

Understanding the Factors Behind Water Bottling Machine Price

The cost of a water filling machine depends on more than just capacity. Every part of the design — from automation to materials — contributes to overall performance and value.

1. Capacity (BPH – Bottles Per Hour)

The higher the speed, the more complex the structure.

A line running 2,000 bottles/hour uses simpler valves and mechanics than one producing 18,000 bottles/hour, which requires servo drives, heavier frames, and advanced synchronization.

Each jump in capacity adds not only speed but also precision and reliability requirements.

2. Automation Level

A semi-automatic line is ideal for startups with limited labor costs but offers lower output.

A fully automatic 3-in-1 monoblock — combining rinsing, filling, and capping — reduces labor, improves consistency, and ensures long-term return on investment.

The difference can be 25–40% in initial price, but automation usually pays back within one to two years.

3. Material and Hygiene Design

All parts in contact with water should be made of SUS316 stainless steel, ensuring corrosion resistance and purity.

Outer frames typically use SUS304, strong enough for structure and easy to clean.

CIP (Clean-in-Place) systems, positive pressure filling chambers, and laminar flow protection all add value and compliance with hygienic standards.

4. Components and Control System

The brain of the machine matters.

Pestopack uses high-end components like Siemens PLC, Schneider contactors, Omron sensors, and Inovance servos.

This not only improves stability but also guarantees parts availability worldwide — crucial for Russian users seeking long-term maintenance support.

Water Bottling Machine Price Range in 2025

Here’s an overview of factory-direct pricing (Ex-Works China) for reference:

Production Capacity (BPH) | Typical Machine Type | Estimated Price (USD) |

2,000–4,000 BPH | 3-in-1 Monoblock | 25,000–60,000 |

6,000–12,000 BPH | 3-in-1 or Tribloc | 60,000–150,000 |

15,000–24,000 BPH+ | High-Speed Tribloc | 160,000–350,000+ |

Complete turnkey lines — including blow molding, labeling, packaging, and palletizing — can range from USD 120,000 to 600,000+ depending on automation and configuration.

Automation Options and Their Impact on Cost

Automation Type | Features | Price Impact |

Semi-Automatic | Manual bottle loading/capping | Lowest price, higher labor |

Full-Automatic | Integrated rinse–fill–cap, automatic cap sorter | Mid-high price, best OEE |

Servo Smart Changeover | Recipe memory, automatic height adjustment | Slightly higher cost, fastest format change |

Semi-auto lines are flexible for startups, but if you plan to scale, investing in automation early saves both time and money later.

Machine Types Popular in Russia

3-in-1 PET Monoblock (Rinse–Fill–Cap): Compact, reliable, and ideal for 0.33–1.5L still or lightly carbonated water.

5-Gallon (19L) Line: For returnable bottles — includes automatic decapper, brush washer, high-temperature rinse, and pressure filling.

Glass Bottle Filling Machine: Premium option for high-end mineral water or sparkling brands.

Blow–Fill–Cap Tribloc: Integrates blowing, filling, and capping in one block — eliminates conveyors and ensures perfect hygiene.

Material Selection and Hygiene Standards

High-quality materials define product safety and machine lifespan:

Contact parts: SUS316 (anti-corrosive, food-grade)

Structure: SUS304 (rigid and cleanable)

Seals: Viton or PTFE, resistant to chemical and temperature changes

CIP design: Fully automated internal cleaning with hot water or disinfectant

HEPA protection: For ultra-clean filling environments

Pestopack’s water filling machines comply with ISO 9001 and CE certifications — a standard required by many Russian importers.

Control Systems and Electrical Configuration

Automation ensures precision and repeatability.

Our systems integrate:

PLC + HMI: Easy operation with Russian-language support

Servo-driven lifting: Smooth nozzle movement and accurate filling levels

Automatic fault display: Quick troubleshooting

Recipe memory: Fast switching between bottle sizes

Bottle/no-bottle sensors: Prevents dripping or spillage

The result? Stable performance, lower maintenance, and faster changeovers.

Bottle Formats, Caps, and Mold Design

Most PET water bottles in Russia use 1810 or 1881 necks.

If you need custom shapes, our engineers can design preforms and molds tailored to your brand.

We also consider lightweighting trends — reducing resin cost while maintaining bottle strength.

Always plan molds early, as they determine star wheel sizes, label position, and capping torque.

Utilities and Facility Requirements (Adapted for Russia)

Your plant’s infrastructure plays a big role in machine selection:

Electricity: 380V / 50Hz (standard industrial Russian supply)

Compressed Air: Stable and dry, 0.8 MPa for capping or blowing

Water Supply: Treated via RO + UV or gentle filtration for mineral content

Room Layout: Plan for linear product flow and leave clear space for maintenance, CIP, and QC labs

Cold climates require insulated piping and stable indoor temperature for consistent filling accuracy.

Total Cost of Ownership (TCO) and Return on Investment

Many buyers focus only on the purchase price — but smart investors evaluate lifetime cost.

Factors influencing your ROI:

OEE (Overall Equipment Efficiency) – downtime and micro-stops directly affect output.

Labor – full-automatic systems reduce the need for operators.

Energy & Water Use – optimized rinsers and gravity fillers lower utility bills.

Spare Parts – standard global components reduce future costs.

A well-configured Pestopack line typically achieves payback in 12–24 months, depending on production scale.

Why Choose Pestopack — Factory-Direct from China

As a direct manufacturer, Pestopack eliminates middlemen and ensures full control over quality, delivery, and service.

Our 20,000 m² factory designs, builds, and tests every water filling machine before shipment.

We’ve delivered to over 30 countries, including clients in Eastern Europe, the Middle East, and Africa.

Our Key Advantages

Factory-direct pricing with transparent cost structure

Global after-sales support including online guidance and local technician assistance

Experienced engineers with deep water line integration knowledge

Shorter lead times thanks to complete in-house manufacturing

Flexible customization for bottle types, caps, or layouts

We don’t just sell machines — we deliver long-term production solutions built for reliability.

What’s Included in Pestopack’s Service

✅ Pre-sale engineering: Layout drawings, bottle design, and budget planning

✅ Production: Full machine assembly and 72-hour test run before shipping

✅ FAT/SAT: Factory Acceptance Test in China + Site Acceptance Test in Russia

✅ Training: Operator instruction and maintenance guide

✅ After-sales: Remote video support, spare parts package, and on-site installation

You’re not just buying a machine — you’re gaining a technical partner.

Budgeting for Different Business Scales

Startup Investors (2,000–4,000 BPH)

A compact 3-in-1 water filling machine with basic automation can produce 0.5–1.5L PET bottles efficiently.

Estimated budget: USD 25,000–60,000.

Medium-Scale Enterprises (6,000–12,000 BPH)

Choose a full-automatic monoblock with auto cap sorter, servo nozzle lift, and neck-handling.

Budget: USD 60,000–150,000.

Large Industrial Producers (15,000–24,000 BPH+)

Fully integrated tribloc systems with synchronized blow molding, filling, and capping, plus sleeve labeler and packer.

Budget: USD 160,000–350,000+.

Pro Tip: Design your factory utilities and layout with future expansion in mind — Pestopack can scale your line easily when demand grows.

Logistics, Delivery, and Compliance for Russia

All equipment is securely wood-crated, film-wrapped, and rust-protected before shipping.

We provide:

Full packing list, HS codes, and manuals

CE certificate and technical passport in English/Russian

Assistance with customs clearance and documentation

Remote guidance for installation and testing

Our technicians can assist during commissioning, ensuring smooth handover and operator confidence.

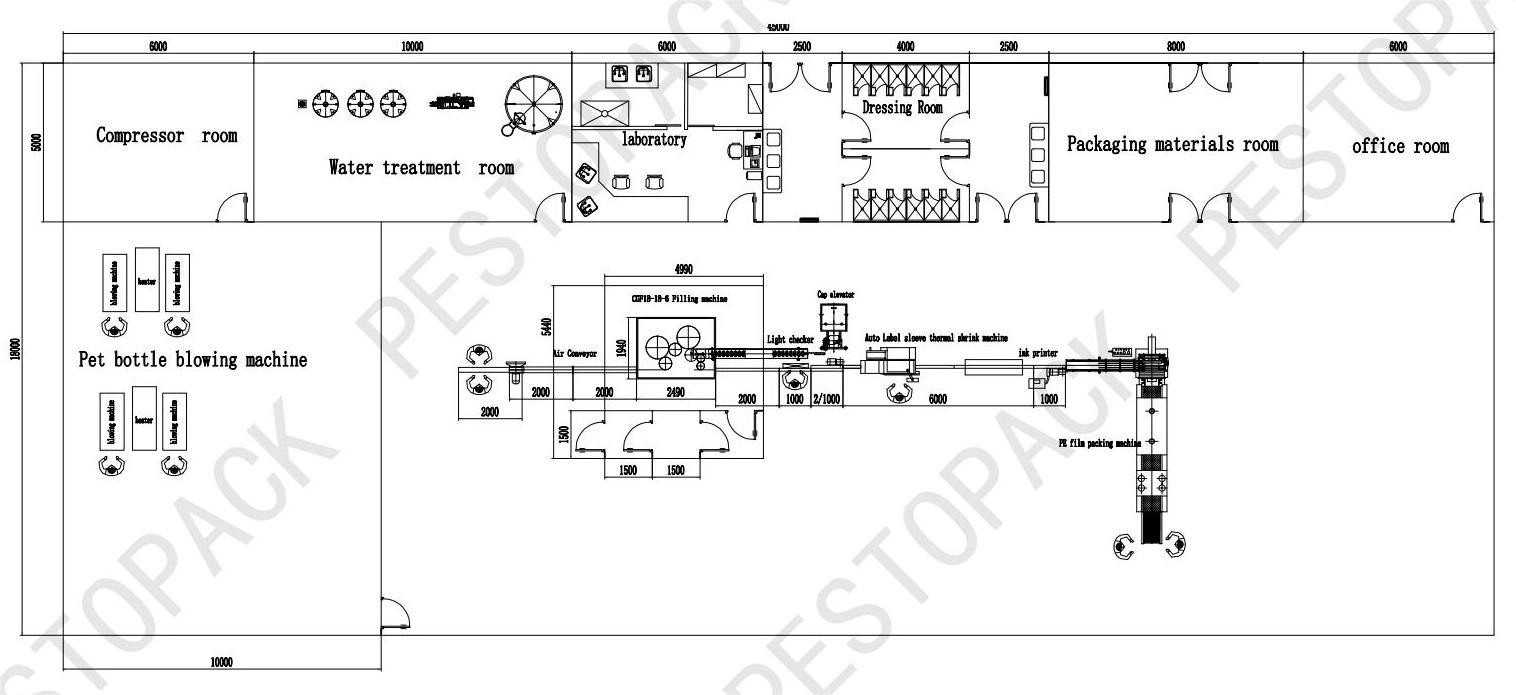

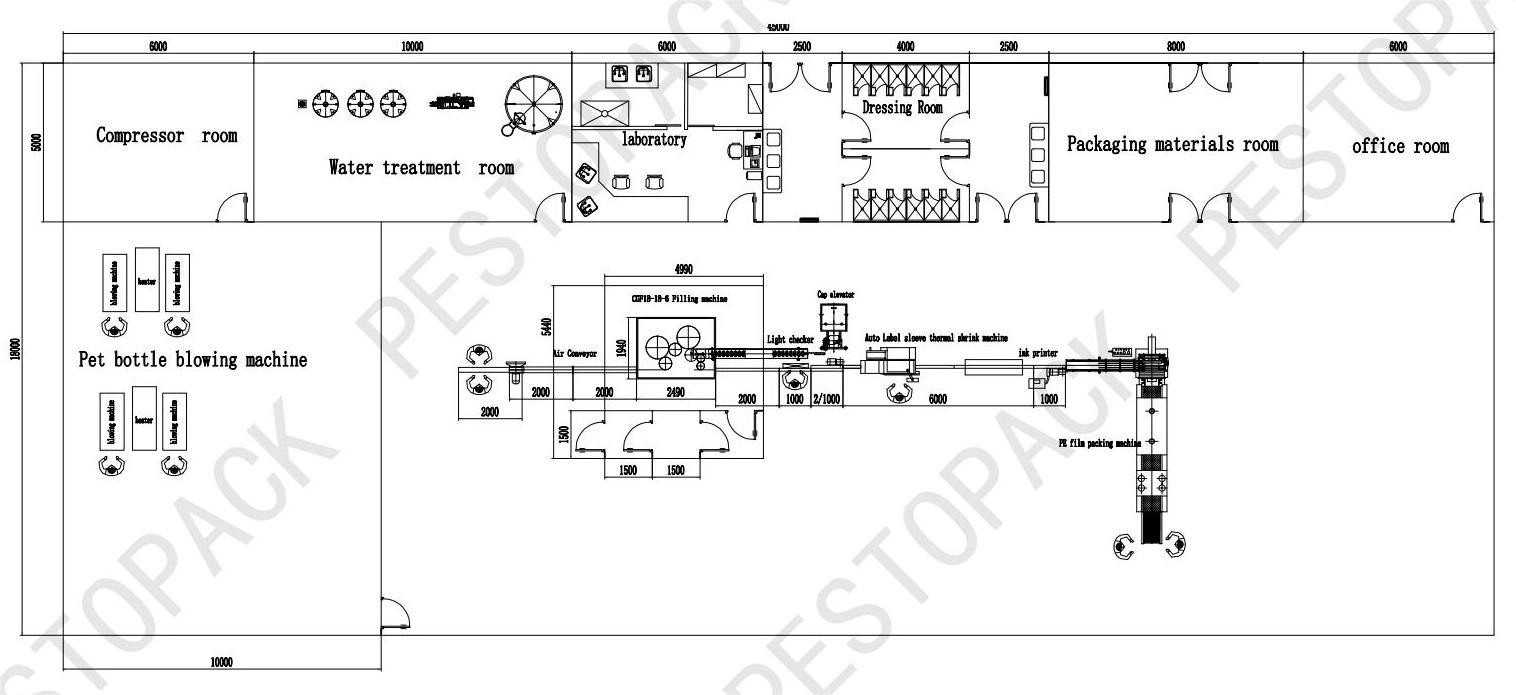

Line Layout and Process Flow

A standard layout for a still-water plant:

Blow Molding → Rinsing/Filling/Capping → Blow Dryer → Labeling → Coding → Film Wrapping → Palletizing

Balance speeds between modules to prevent accumulation or downtime.

We also integrate CIP skids, conveyors, and inspection units for seamless automation.

Learn more about complete system integration here:

Water Bottling Line Overview

Frequently Asked Questions (FAQs)

Q1. What is the standard lead time?

8–12 weeks after deposit and layout confirmation.

Q2. What warranty do you provide?

12 months for mechanical and electrical parts; lifetime technical support.

Q3. Can one line handle different bottle sizes?

Yes, through quick-change starwheels and recipe memory.

Q4. What about water types — purified vs. mineral?

Both are possible; just configure the filling valve type and CIP system accordingly.

Q5. Do you supply full lines including labeler and packer?

Yes, Pestopack offers complete turnkey bottling solutions.

Q6. Can you handle 5-gallon bottles?

Absolutely. We supply automatic 5-gallon washing, filling, and capping systems.

How to Request a Personalized Quote

To prepare an accurate proposal, please share:

Target production capacity (BPH)

Bottle sizes and neck type (1810/1881)

Product type (still, mineral, sparkling)

Label and packaging method (OPP, sleeve, shrink, carton)

Power and utility availability (electricity, water, air)

Plant layout or available space

Delivery timeline and installation preference

With this information, our engineers will tailor the most cost-effective and efficient solution for your project.

Conclusion — Build Your Future Water Line with Pestopack

Investing in a water filling machine is a long-term decision — one that shapes your product quality, production efficiency, and profit margin.

With Pestopack Machinery, you get more than just equipment. You gain a reliable partner offering:

Factory-direct pricing from China

Customized engineering for the Russian market

Comprehensive after-sales service

Global installation and spare parts support

Let’s make your water bottling project in Russia efficient, hygienic, and profitable.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu