VIDEO OF 5 GALLON WATER BOTTLING PLANT

DESCRIPTION OF 5 GALLON WATER BOTTLING PLANT

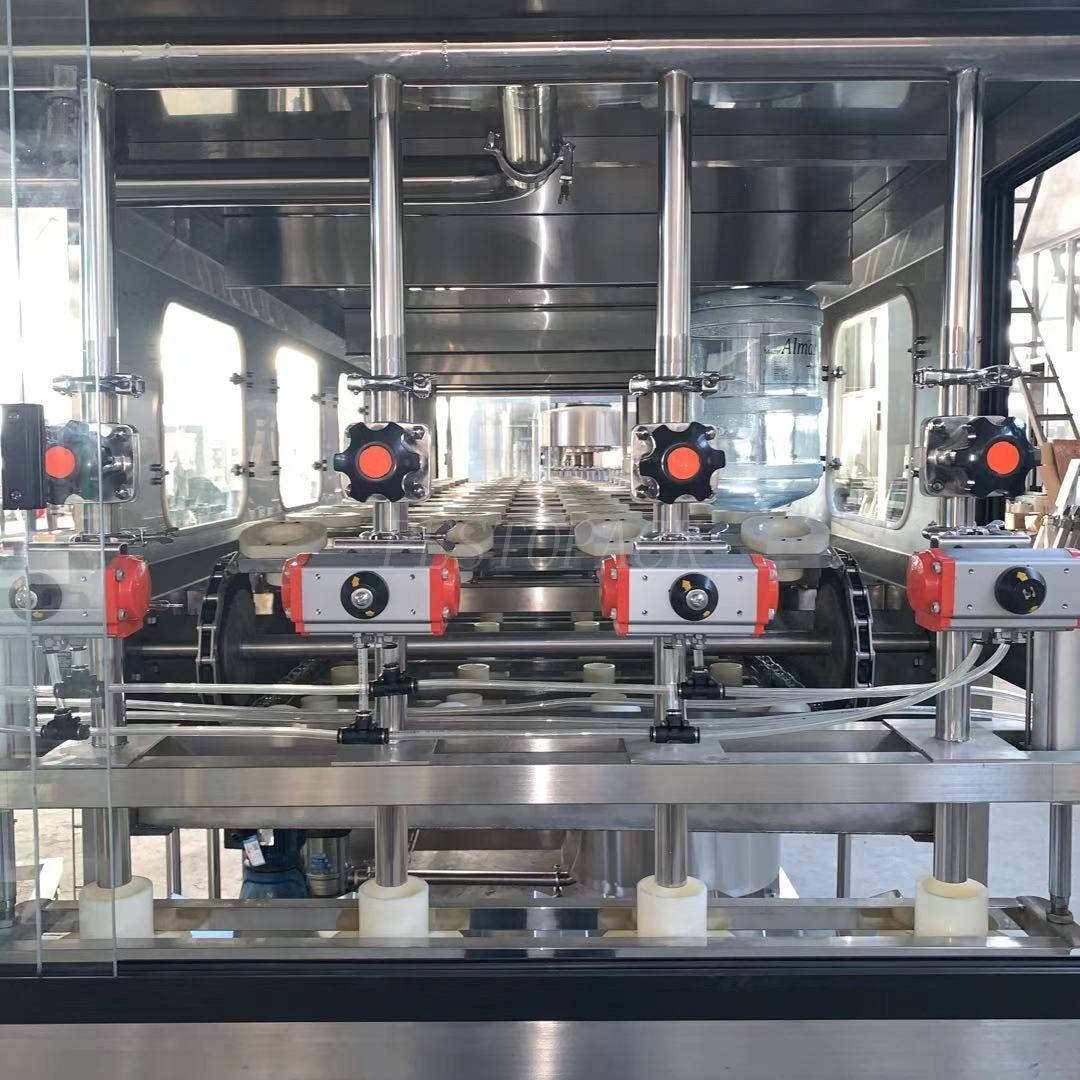

This 5 gallon water filling machine is specially designed for producing 3–5 gallon barreled drinking water. It integrates bottle washing, filling, and capping into one compact unit, offering a modern and fully automatic production solution.

To ensure hygiene and quality:

The washing machine applies multi-stage liquid sprays and thimerosal sterilization, which can be recycled for efficiency.

The capping section automatically sterilizes and seals caps with a built-in water spraying system.

This plant carries out the entire process automatically: barrel loading, washing, sterilizing, filling, capping, counting, and product discharge. With advanced integration of mechanical, electrical, and pneumatic technologies, it is a reliable and highly automated solution for large-scale water bottling operations.

FEATURES OF 5 GALLON WATER BOTTLING PLANT

Flexible Capacity – Designed for 1 to 5 gallon bottled water.

Bottle Compatibility – Handles PET, PVC, and PE bottles in multiple shapes.

Premium Quality Line – Equipped with stainless steel rinse nozzles, pressure filling valves, screw cappers, and a hot steam shrink film machine.

PLC Controlled – Filling time is precisely managed by a PLC control system.

Durable Build – High-grade stainless steel frame for longevity.

-

User-Friendly Design – Attractive appearance, easy operation, stable performance, and low maintenance.

5 GALLON WATER BOTTLING PLANT SPECIFICATION

Bottle Material: PET Bottle

Cap Material: Plastic

Bottle Volume: 3L–20L

Production Speed: 100–1200 BPH

Suitable Bottle Size: 3 to 5 gallons

TECHNICAL PARAMETERS

| Type | QGF-1200 |

| Filling nozzle | 8

|

| Filling capacity | 18.9L |

| Barrel size | 270*490mm

|

| Production capacity | 1200BPH |

| Air source | 0.6Mpa

|

| Air consumption | 1.8m3/min

|

| Motor power | 13.5KW

|

| Rated voltage | 380V/50HZ |

| Weight | 4500kg

|

COMPLETE 5 GALLON WATER BOTTLING PLANT SOLUTION

A fully automatic production line typically includes:

Bottle Blowing System – Semi-automatic or fully automatic PET bottle blowing machines.

Water Treatment System – Sand filter, carbon filter, RO/UF system, ozone sterilizer, UV sterilizer, and more.

Air Conveyor – Efficient empty bottle loading.

5 Gallon Decapping, Washing, Filling & Capping Line – Core section of the bottling plant.

Cap Loader – Automatic cap loading system.

Code Printer – Inkjet or laser printer for batch coding and traceability.

Shrink Labeling Machine – For bottle labeling and branding.

-

Palletizer Machine – For efficient packaging and stacking.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu