MINERAL WATER FILLING MACHINE FACTORY

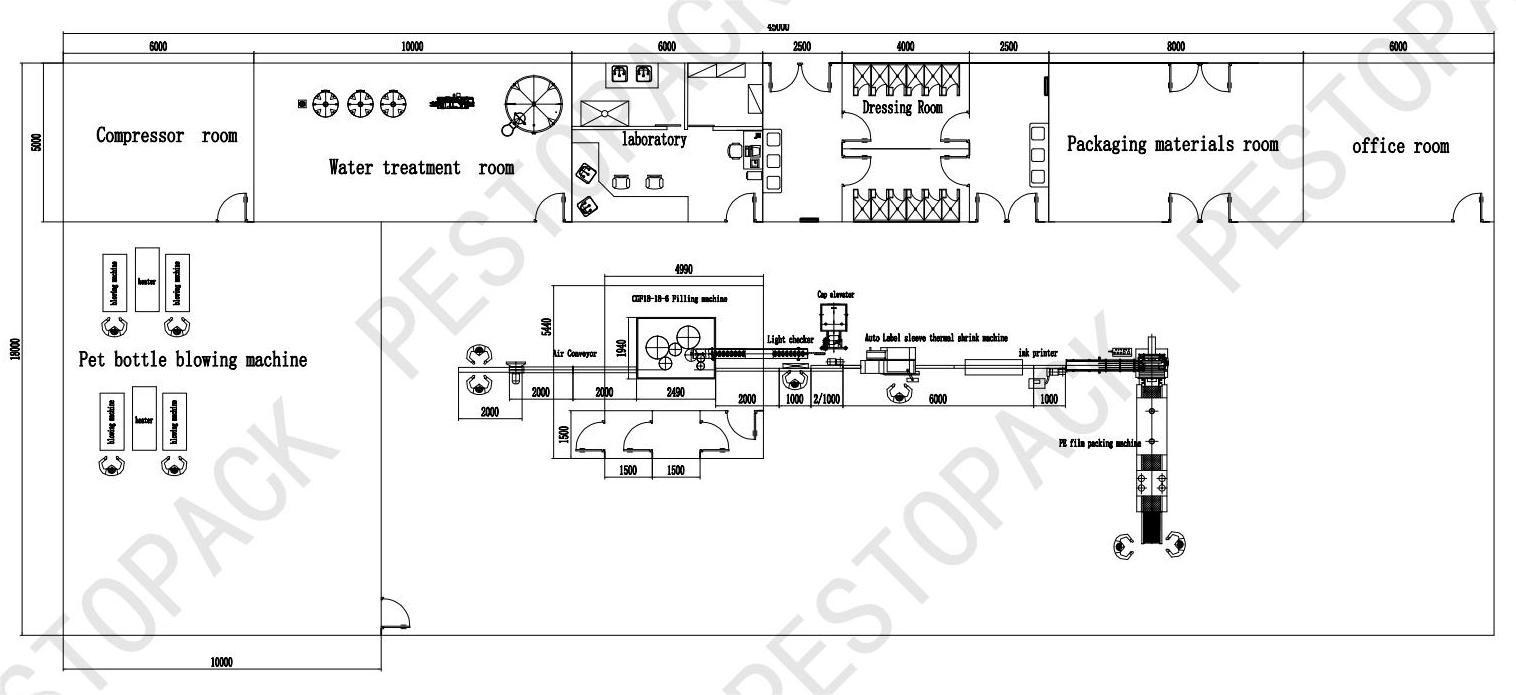

PESTOPACK is one of the professional minaral water filling machine manufacturers with more than 12 years of experience in this field. PESTOPACK offers complete filling solutions for water and beverages. We warmly welcome people from all walks of life to visit our company for inspection and guidance. Achieve win-win cooperation!

Our business scope are:

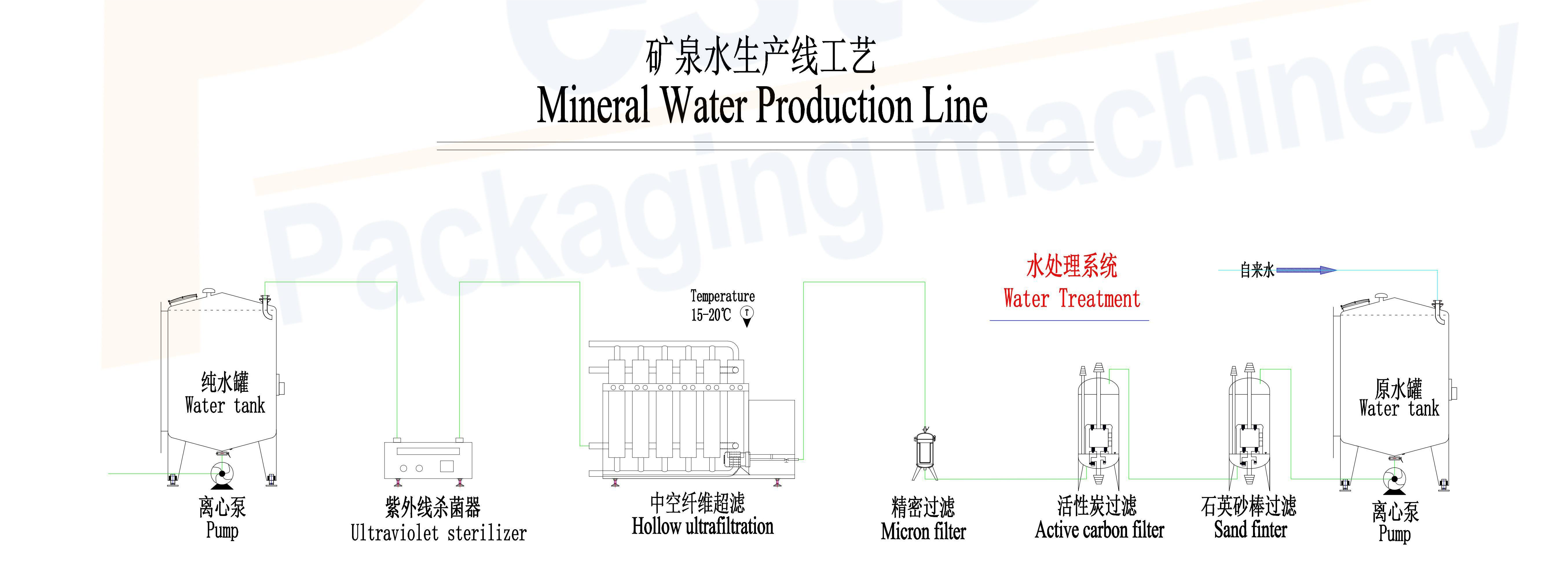

1.1-30 tons of pure water/mineral water treatment

2. 5 Gallon Water Filling Machine

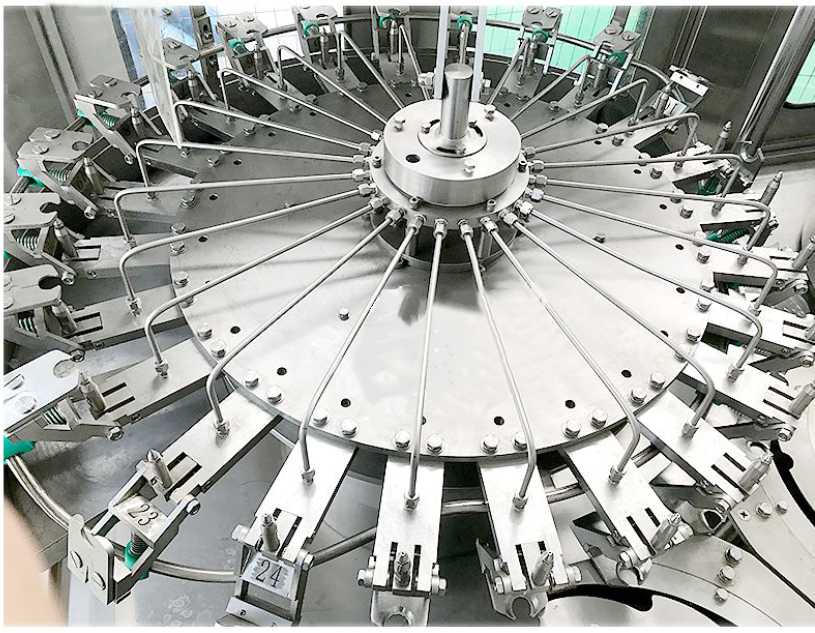

3. Water bottle filling machine (PET bottle from 200 to 2000 ml)

Capacity from 2000-24000 BPH (based on 500 ml PET bottle) production line and turnkey project.

4. Juice three-in-one filling machine (PET bottle from 200 to 2000 ml)

Capacity from 2000-24000 BPH (based on 500 ml PET bottle) production line and turnkey project.

5. 3 in 1 filling machine for carbonated drinks (PET bottle from 200 to 2500 ml)

Capacity from 2000-24000 BPH (based on 500 ml PET bottle) production line and turnkey project.

6. Can filling and capping machine

7. Edible oil filling machine (PET or glass bottle filling machine)

8. Bottle washer (glass or pet)

9. Bottle filling machine (glass or pet)

10. Bottle capping machine (glass or pet)

11. Labeling machine (PVC, glue or opp labels)

12. Shrink wrapping machine

13. Pallet packing machine

14. PET bottle blowing machine semi-automatic or fully automatic

15. PET bottle preform injection molding machine

16. PP, PVC, EVA extrusion blow molding machine

17. Cooling tunnel & bottle reversal sterilizer

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu