1. IS BUILDING A WATER BOTTLING PLANT PROFITABLE IN NIGERIA

2. PROCESS FOR BUILDING A WATER BOTTLING PLANT IN NIGERIA

Establish the water bottling plant in Nigeria

Register with the Corporate Affairs Commission

Register with NAFDAC

Equipment Required for Building a Water Bottling Plant in Nigeria

Hiring workers

Have distributors

3. HOW TO FIND A RELIABLE WATER BOTTLING MACHINE SUPPLIER

4. COST FOR BUYING A COMPLETE WATER BOTTLING PLANT MACHINE

Are you looking to start a water bottling plant in Nigeria?This post contains the basic details on how to go about it.Water plays a very critical role in the existence of human life. An investment in this water bottling plant in Nigeria is therefore a smart investment option where you should expect to have a very high returns on your investment in a very short time.

IS BUILDING A WATER BOTTLING PLANT PROFITABLE IN NIGERIA

With the increasing demand for clean and safe drinking water in Nigeria, entrepreneurs are contemplating the viability of building water bottling plants. Building a water bottling plant in Nigeria holds significant profit potential, given the rising demand for clean water. However, success in this venture requires a comprehensive understanding of the market, compliance with regulatory requirements, strategic investment, and effective marketing. Entrepreneurs willing to navigate the challenges and capitalize on the opportunities can find a lucrative business opportunity in the Nigerian bottled water industry. Thorough research and careful planning are the keys to unlocking the profitability of building a water bottling plant in Nigeria.

Market Dynamics

The bottled water industry in Nigeria has experienced substantial grouth in recent years. A rising population, coupled with a grouwing awareness of health and hygiene, contributes to the increased demand for purified water. Entrepreneurs looking to tap into this market should conduct thorough market research to understand consumer preferences, identify potential niches, and assess the competitive landscape.

Consumer Preferences

Understanding the preferences of the Nigerian consumer is crucial for success in the bottled water industry. Nigerians often prefer purified and mineral water, and regional variations may exist. Analyzing consumer behavior through surveys, focus groups, and online analytics tools can provide valuable insights into product preferences and packaging choices.

Regulatory Environment

Navigating the regulatory landscape is a critical aspect of building a water bottling plant in Nigeria. Entrepreneurs need to obtain various government approvals and certifications, including business registration, environmental impact assessments, and quality certifications. Staying compliant with regulatory requirements ensures a smooth operation and enhances the credibility of the business.

Infrastructure and Logistics

Infrastructure challenges, such as power supply and transportation, can impact the operational efficiency of a water bottling plant. Entrepreneurs should carefully assess the availability of reliable infrastructure in potential locations. Proximity to transportation hubs and reliable power sources can significantly contribute to the success of the venture.

Investment and Operational Costs

The initial investment required to build a water bottling plant in Nigeria includes costs associated with facility construction, water treatment equipment, bottling and packaging machinery, quality control measures, and branding. Additionally, ongoing operational costs, such as utilities, labor, and marketing, need to be factored into the financial plan. A well-structured budget and financial forecast are essential for accurate cost estimation.

Marketing and Branding Strategies

Effectively marketing bottled water products is crucial for success. Entrepreneurs should develop robust branding strategies to differentiate their products in a competitive market. Utilizing digital marketing tools, such as online advertising and social media, can enhance brand visibility and reach a wider audience.

PROCESS FOR BUILDING A WATER BOTTLING PLANT IN NIGERIA

Having a clear and detailed water bottling plant plan in place will serve to give you an edge for grant applications, in writing business proposals, to apply for business loans and so on. Your business plan should include all the details for your startup, this includes: description of your water bottling plant in Nigieria, your product description.Your operational goals, both long and short term, risks in the business and specific strategies to tackle these risks. A financial analysis of the intended costs of running the business, acquiring equipment and projected profits.

Establish the water bottling plant in Nigeria

You will have to acquire a land to construct and establish a pure water factory in Nigeria. You don't need any elaborate building, a small bungalow with few rooms should do. The water bottling plant in Nigeria should be structured thus:

l A storage room to store raw materials

l A water production line room

l A second storage room for finished products

| Testing room

l Changing room

l Administrative room

l Bathroom and toilet

PESTOPACK is a manufacturer of water bottling plant for sale, we can design layout for all water bottling machines into workshop according to customer's workshop size.

Register with the Corporate Affairs Commission

It is very important that as a water bottling plant business in Nigeria,you are registered with the Corporate Affairs Commission of Nigeria(CAC).As you start up your water bottling plant business in Nigeria, you will need a business name and a business logo, so it is a good idea to take out time in picking a suitable name for the business. Once this is done, go ahead and register your business name with the CAC. This is not hard to do and usually takes two to three weeks max to Complete.

Register with NAFDAC

Once done, you have to register your pure water bottling plant business in Nigeria with NAFDAC so as to access their approval before you can start production. This process takes upwards of three months before it can be completed for receiving your certificate.Your processing fee shouldn't cost more than N50,000. Note that all requirements must be met for your water bottling plant business in Nigeria to be approved by NAFDAC.Without the approval and certification from NAFDAC you cannot produce or sell pure water in Nigeria.

Equipment Required for Building a Water Bottling Plant in Nigeria

Here are all equipment you will need to establish your water bottling factory in Nigeria.

l A pure water distillation system

| Bottle blowing machine

l Water bottling machine

| Labeling machine

| Laser printer

| Packing machine

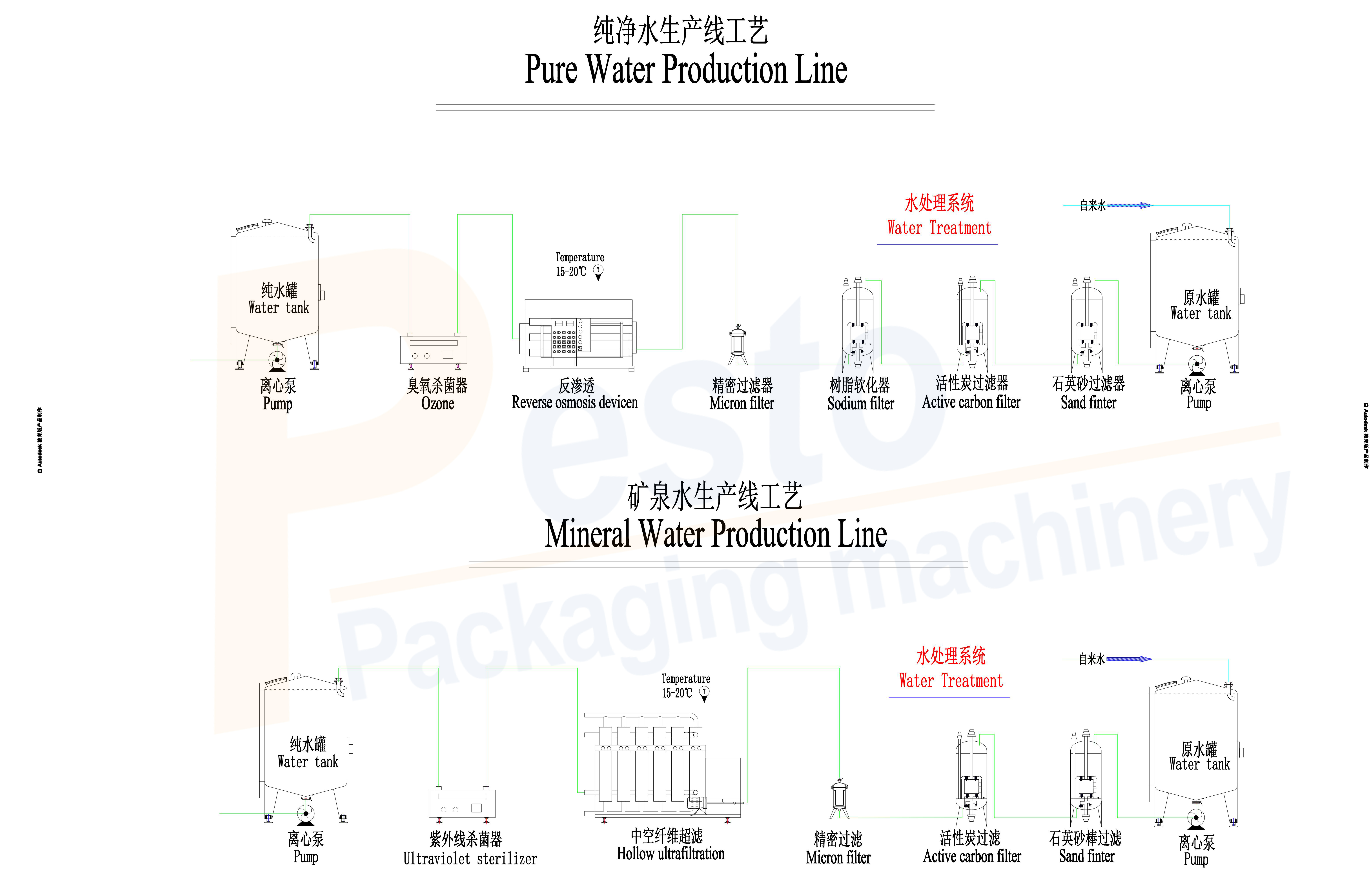

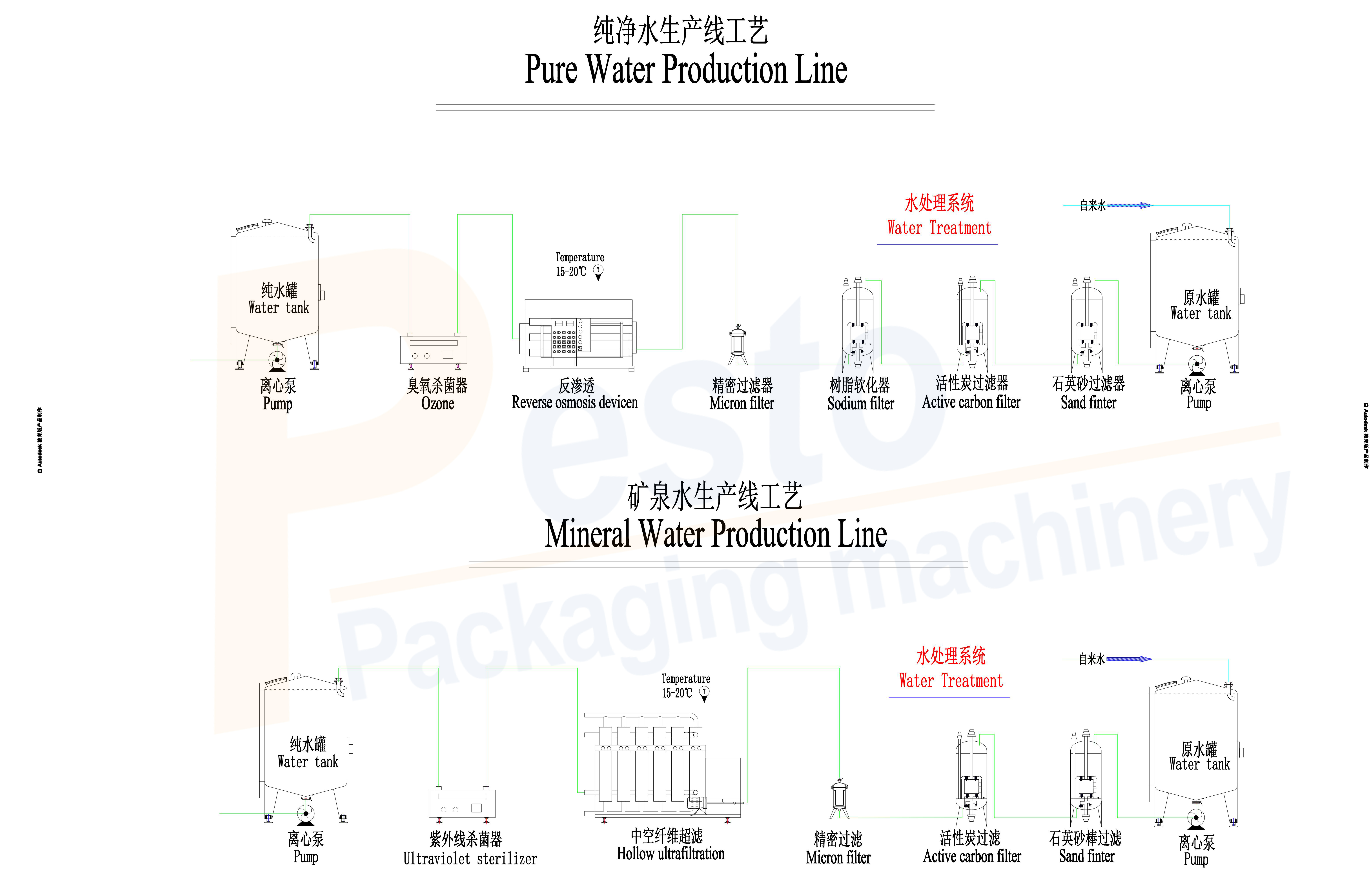

Water Distillation System

There are various kinds of water purification systems including, distillation, reverse osmosis, carbon filtration, ultra violet light filtration system amongst others. Your water bottling plant should have a highly effective water purification system in place. You will have to study each method carefully and select the one that suits you most. Distillation, ultra violet light filtration and reverse osmosis are however the most commonly used water purification systems in Nigeria.

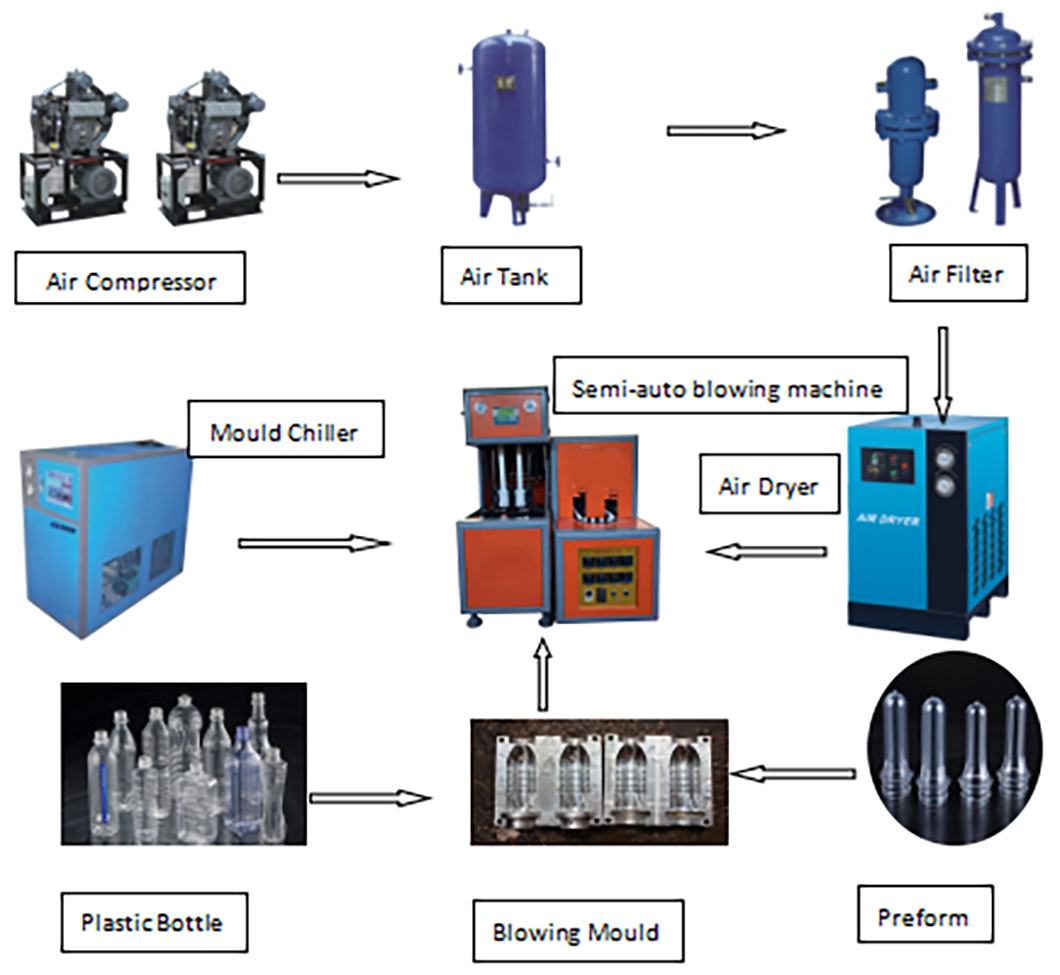

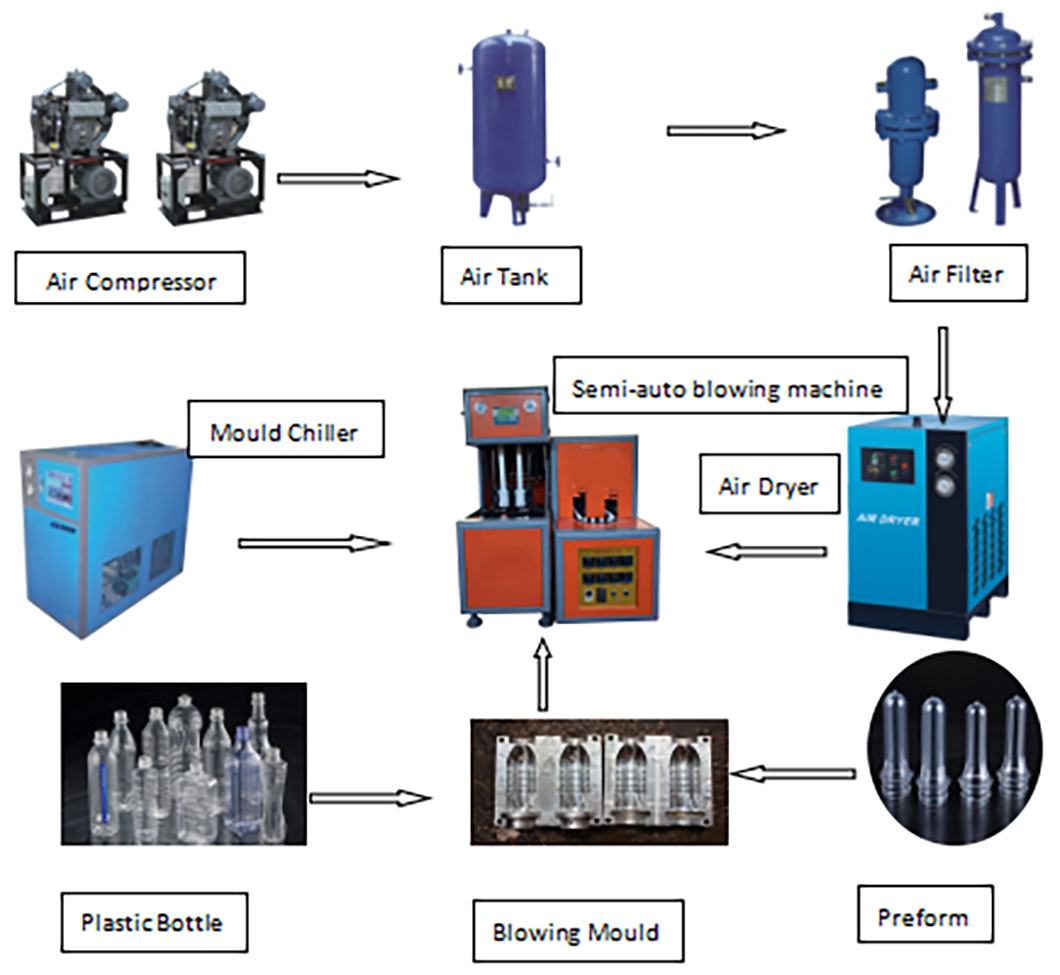

Bottle Blowing Machine

Most customers will choose semi automaitc bottle blowing machine for starting the water bottling plant business. If you have enough budget, you also can choose full automatic bottle blowing machine instead of, which have high efficiency and high capacity.

Water Filling Machine

Water filling machine for sale can automatically complete washing,filling and sealing. There are actually different types of water filling machines, from the very small ones to the huge automatic ones mentioned above. It is however highly recommended that if you can afford it, you get the specialized automatic machines that can serve multiple functions.

Labeling Machine

It is suitable for labeling before and after filling when the bottle type label is required for pasting. Mainly used in beverage, daily chemical, condiment and other industries.

Packing Machine

It is widely used in the combination packaging of beverage, food, pharmaceutical and chemical products. No matter whether it is square, round, or flat, it can be packaged and has excellent visual effects. It is the preferred matching equipment for water filling production line.

Hiring workers

When planning for your new startup of water bottling plant in Nigeria, be prepared to factor in costs for hiring factory workers. This is unavoidable given the many processes involved in pure water production line even when an automatic system is being implemented. You will need to hire workers to perform tasks like loading, offloading, accounting, driving, counting, supervision, etc.

Have distributors

Although most small pure water factories do not have registered distributors, it would help to have distributors registered under you. This way, you can enjoy a larger market share with increased revenue. A good way of doing this is to take your proposal public. Publish ads on newspapers, magazines etc. Next, you want to fully take your water bottling plan business online in Nigeria to give it the kind of exposure you desire.

HOW TO FIND A RELIABLE WATER BOTTLING MACHINE SUPPLIER

Conduct In-Depth Research

Begin your search by conducting thorough research on potential suppliers. Utilize online resources, industry publications, and business directories to compile a list of candidates. Pay attention to customer reviews, testimonials, and industry forums to gauge the reputation of the suppliers.

Assess Industry Reputation

Investigate the reputation of potential suppliers within the water bottling industry. A supplier with a solid reputation is more likely to offer reliable and high-quality equipment. Seek recommendations from industry peers and forums, and consider suppliers who have successfully served businesses similar to yours.

Verify Certifications and Compliance

Ensure that the supplier adheres to industry standards and holds relevant certifications. Certifications like ISO and CE are indicators of a commitment to quality and compliance. Verify that their equipment meets the regulatory standards of the regions where you plan to operate.

Evaluate Manufacturing Facilities

Request detailed information about the supplier's manufacturing facilities. A transparent supplier should be willing to share insights into their production processes, technology, and quality control measures. If possible, consider visiting their facilities to assess the manufacturing capabilities firsthand.

Assess Technical Support and Training

Evaluate the level of technical support and training provided by the supplier. A reliable supplier will offer comprehensive training on machine operation, maintenance, and troubleshooting. Inquire about their responsiveness to technical queries and their commitment to assisting clients post-purchase.

Review Warranty and After-Sales Service

Carefully review the warranty terms offered by potential suppliers. A reputable supplier typically provides a solid warranty and robust after-sales service. Understand the terms and conditions of the warranty, and inquire about their after-sales support to ensure ongoing assistance if issues arise.

PESTOPACK is a prominent player in the water bottling machinery industry, known for our commitment to quality, innovative solutions, and excellent customer service, PESTOPACK has successfully served numerous clients globally. Our state-of-the-art manufacturing facilities, adherence to industry standards, and comprehensive after-sales support make us a reliable choice for businesses seeking top-tier water bottling machines. By following the outlined guide and considering PESTOPACK as your preferred supplier, you can ensure that your investment is backed by quality, reliability, and ongoing support.

COST FOR BUYING A COMPLETE WATER BOTTLING PLANT MACHINE

Navigating the investment landscape for acquiring a water bottling machine for sale involves careful consideration of various factors, including production capacity, automation options, and associated costs.

Selecting Production Capacity

Consider the scale of your operation and choose the most suitable production capacity for your water bottling plant machine. Options range from 2000 BPH to 36000BPH, catering to diverse business sizes and production needs.

Semi-Automatic Option

For smaller-scale operations or those seeking a cost-effective entry point, the semi-automatic water bottling plant machine is an attractive option.

Investment Estimate: With a minimum cost starting at approximately $50,000, the semi-automatic production line provides a budget-friendly solution without compromising on efficiency.

Fully Automatic Option

Opting for a fully automatic water filling machine offers enhanced efficiency and productivity.

Investment Estimate: Costs for a fully automatic production line vary based on production capacity and technological features. Please contact our team for asking proposal, detailed quotations can be obtained based on specific requirements.

Operational Cost

Estimate ongoing operational costs, including electricity, labor, and routine maintenance, to ensure the sustained and efficient operation of the water bottling plant machine.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu