Introduction

Overview of Poland’s Bottled Water Industry

Understanding Water Bottling Machines

Factors Affecting Water Bottling Machine Price in Poland

Average Water Bottling Machine Price Range in Poland (2025)

Why Many Polish Investors Choose to Import from China

About Pestopack Machinery: A Trusted Partner for Polish Investors

How to Choose the Right Bottling Machine for Your Project

Water Bottling Line Configuration Example

Hidden Costs and Budgeting Tips

The Future of Bottled Water Production in Poland

Final Thoughts: Invest Wisely in 2025

Introduction

In 2025, Poland’s bottled water industry continues to boom. With rising health consciousness and strong demand for clean drinking water, investors are actively setting up new bottling plants across the country. But the most common question remains: What is the water bottling machine price in Poland in 2025?

Understanding pricing is crucial for entrepreneurs and established beverage companies alike. Whether you’re planning a small startup or expanding your production line, knowing how much to budget helps you make smarter decisions.

Overview of Poland’s Bottled Water Industry

Market Growth and Consumer Trends

Poland ranks among the top bottled water consumers in Europe. The average person now drinks over 120 liters of bottled water annually. Consumers are shifting toward healthier, non-sweetened beverages, creating massive opportunities for both domestic and export-oriented bottlers.

Increasing Demand for Automated Bottling Systems

As demand grows, so does the need for efficiency. Many Polish bottlers are replacing manual or semi-automatic machines with fully automatic water bottling lines that minimize labor and ensure hygienic filling. Automation also helps maintain consistent production speeds, a key factor in profitability.

Understanding Water Bottling Machines

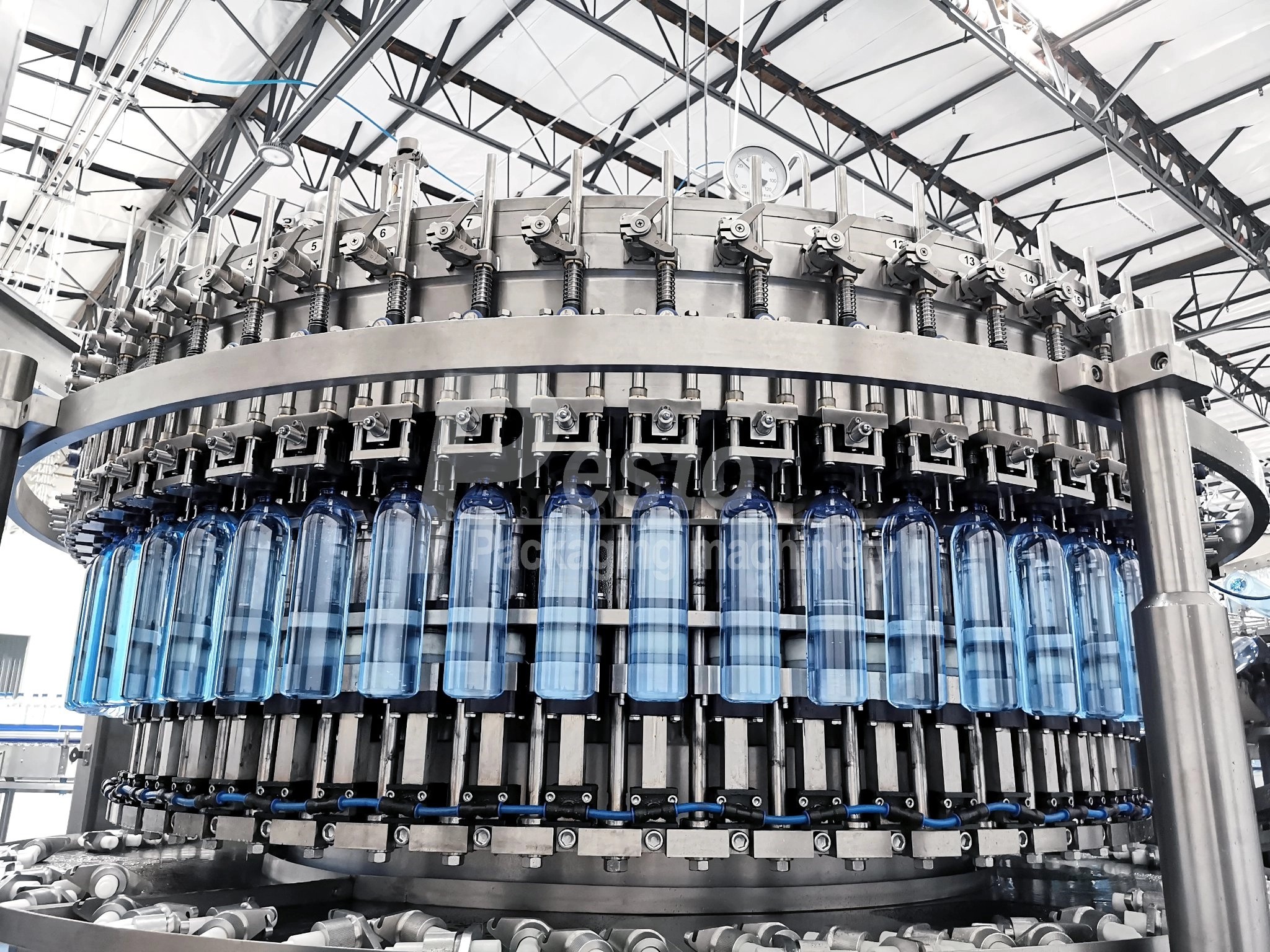

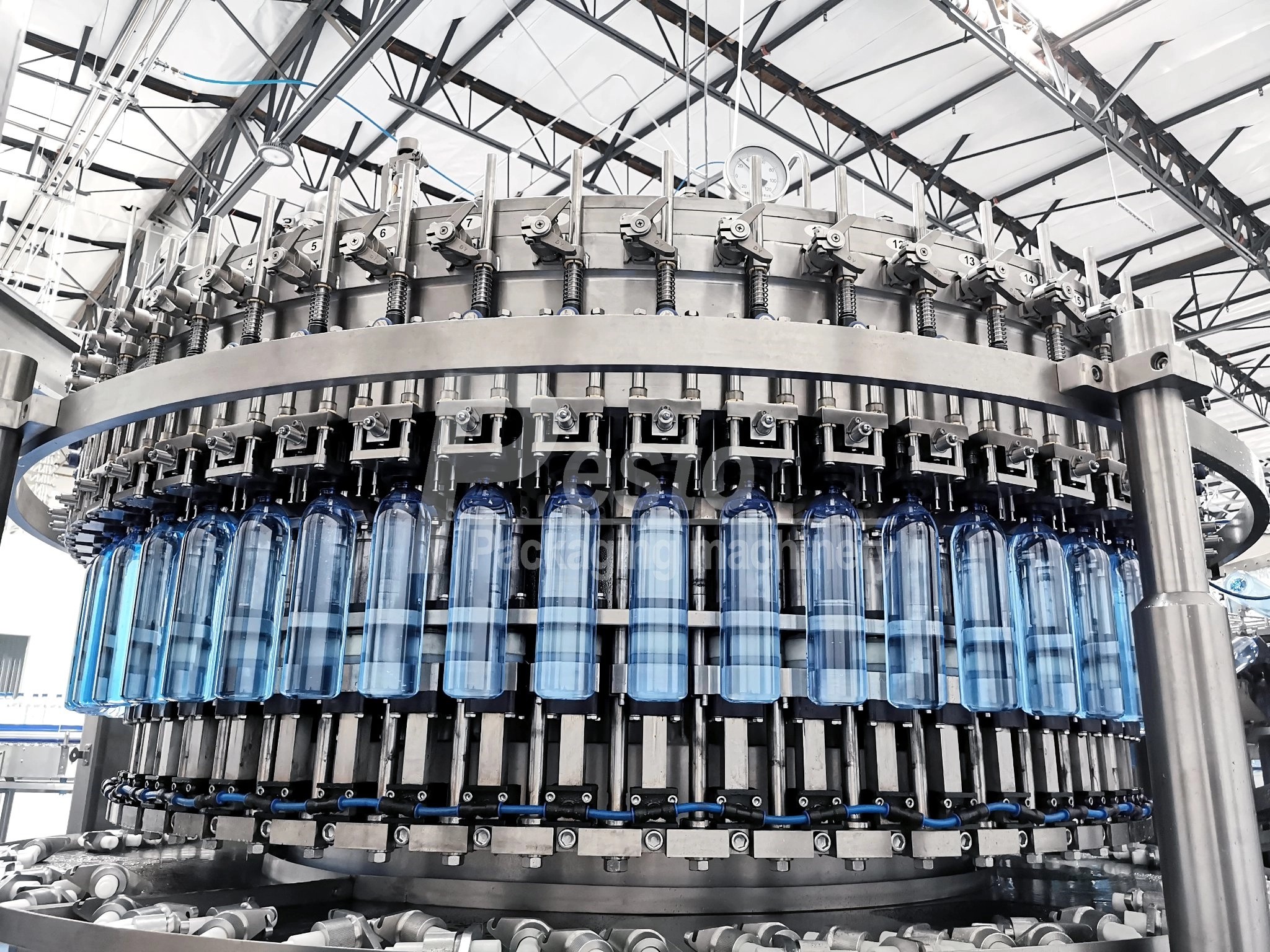

A water bottling machine is more than a single piece of equipment—it’s a coordinated system that includes rinsing, filling, and capping units, often integrated with labeling and packaging systems.

Key Components of a Modern Bottling Line

Bottle rinsing system – ensures hygiene by washing each bottle before filling.

Filling machine – precisely controls water volume using gravity, pressure, or servo-piston mechanisms.

Capping machine – seals the bottles to prevent contamination.

Labeling and packaging units – add branding and prepare bottles for market.

Types of Water Bottling Machines Available in 2025

Manual and semi-automatic – suitable for startups with small output.

Fully automatic rotary systems – ideal for large-scale factories (6,000–36,000 BPH).

Complete turnkey lines – include water treatment, filling, labeling, and shrink wrapping.

For more information on equipment models, visit Water Filling Machines.

Factors Affecting Water Bottling Machine Price in Poland

Prices can vary significantly, depending on several technical and operational parameters.

Machine Capacity and Output Speed

A 2,000 BPH (bottles per hour) system can cost far less than a 12,000 BPH or 24,000 BPH high-speed line. The higher the capacity, the greater the investment—but also the lower the per-bottle cost.

Level of Automation: Semi vs. Fully Automatic

Semi-automatic machines are affordable and ideal for small entrepreneurs. However, fully automatic rotary systems deliver better hygiene, accuracy, and long-term stability, making them more cost-effective over time.

Material and Component Quality

The use of 304 or 316 stainless steel, Siemens PLCs, and Schneider electronics directly affects price. Machines with premium components generally cost more but last longer and reduce maintenance downtime.

Bottle Types and Packaging Configurations

Whether you use PET bottles, glass bottles, or 5-gallon containers will influence cost. Similarly, the packaging type—shrink film, carton, or wrap-around—affects the total investment.

Brand, Warranty, and After-Sales Support

Local Polish suppliers may offer fast service but limited options. Meanwhile, international manufacturers like Pestopack Machinery combine factory-direct pricing with global after-sales support.

Average Water Bottling Machine Price Range in Poland (2025)

Entry-Level Systems for Startups

Capacity: 1,000–3,000 BPH

Price Range: €18,000–€35,000

These compact systems are perfect for new investors entering the bottled water market.

Medium-Scale Production Lines

Capacity: 4,000–8,000 BPH

Price Range: €45,000–€90,000

Ideal for regional brands looking to increase output while maintaining flexibility.

Large-Scale Industrial Bottling Lines

Capacity: 10,000–36,000 BPH

Price Range: €120,000–€350,000

Such systems include fully automated rinsing, filling, capping, labeling, and packaging.

Why Many Polish Investors Choose to Import from China

Cost Advantages and Global Service

Buying from China has become a smart strategy for Polish investors. Chinese factories have lower production costs and advanced technology, making it possible to purchase high-quality lines at 20–40% less than European prices.

Factory Direct Sales from Pestopack Machinery

Pestopack Machinery, based in Zhangjiagang, China, offers factory-direct pricing with global delivery and installation service. The company has successfully delivered lines to over 30 countries, including Poland, Romania, Turkey, and Kenya.

Their water bottling machines are CE-certified, built from food-grade stainless steel, and designed for stable long-term operation.

About Pestopack Machinery: A Trusted Partner for Polish Investors

Decades of Manufacturing Experience

With over 20 years of experience, Pestopack Machinery specializes in complete water bottling solutions, from water purification to labeling and packaging. Their lines are known for precise filling accuracy and energy efficiency.

Tailored Solutions for the Polish Market

Pestopack understands European market standards, including hygienic design and electrical compliance. Each system can be customized for 0.5L, 1.5L, or 5L PET bottles, and labeling options like OPP hot melt, shrink sleeve, or adhesive sticker.

Case Examples and After-Sales Support

Pestopack has successfully installed multiple water bottling lines in Eastern Europe. They provide on-site installation, online support, spare parts, and lifetime technical service—a key reason investors trust them.

How to Choose the Right Bottling Machine for Your Project

Step 1: Define Capacity and Bottle Size

Start by estimating your daily production goal. For example, a 6,000 BPH line can produce nearly 150,000 bottles per day on an 8-hour shift.

Step 2: Decide on Packaging Type

Will you pack bottles in film wrap or cartons? Your choice will affect downstream equipment such as shrink wrappers or case packers.

Step 3: Compare Suppliers and Technical Support

Beyond price, evaluate spare part availability, maintenance training, and warranty terms. A slightly higher upfront investment can save thousands later.

Water Bottling Line Configuration Example

Typical 3000–6000 BPH Line Setup

A standard mid-capacity system includes:

Water treatment (RO + UV sterilizer)

Blow molding machine

3-in-1 rinsing-filling-capping machine

OPP labeling machine

Shrink wrapping or carton packaging unit

Air compressor and conveyors

For a visual overview, visit Water Bottling Line Details.

Integration with Water Treatment and Labeling Systems

Modern lines integrate smart PLC controls that synchronize all processes—ensuring that filling, capping, and labeling flow seamlessly.

Hidden Costs and Budgeting Tips

Installation, Shipping, and Training

Don’t overlook logistics. Freight, customs duties, and on-site installation may add 10–15% to the total cost. Pestopack’s engineering team supports Polish customers with detailed layout plans and remote commissioning assistance.

Spare Parts and Maintenance Considerations

Choose suppliers that guarantee quick spare-part delivery. Pestopack keeps essential parts in stock to minimize downtime.

The Future of Bottled Water Production in Poland

Sustainable Packaging and Automation Trends

Eco-friendly packaging is becoming mainstream. Many Polish brands now use lightweight PET bottles or recyclable materials. In parallel, automation and smart monitoring systems are driving efficiency and traceability.

Final Thoughts: Invest Wisely in 2025

As Poland’s water market continues to grow, investing in reliable bottling equipment is more important than ever. Water bottling machine price varies depending on your goals—but choosing a manufacturer that offers both quality and support ensures long-term profitability.

Contact Pestopack Machinery for a Quotation

Whether you’re launching a new water brand or upgrading your plant, Pestopack Machinery provides cost-effective solutions backed by technical excellence and global service.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu