CORROSIVE LIQUID FILLING MACHINE

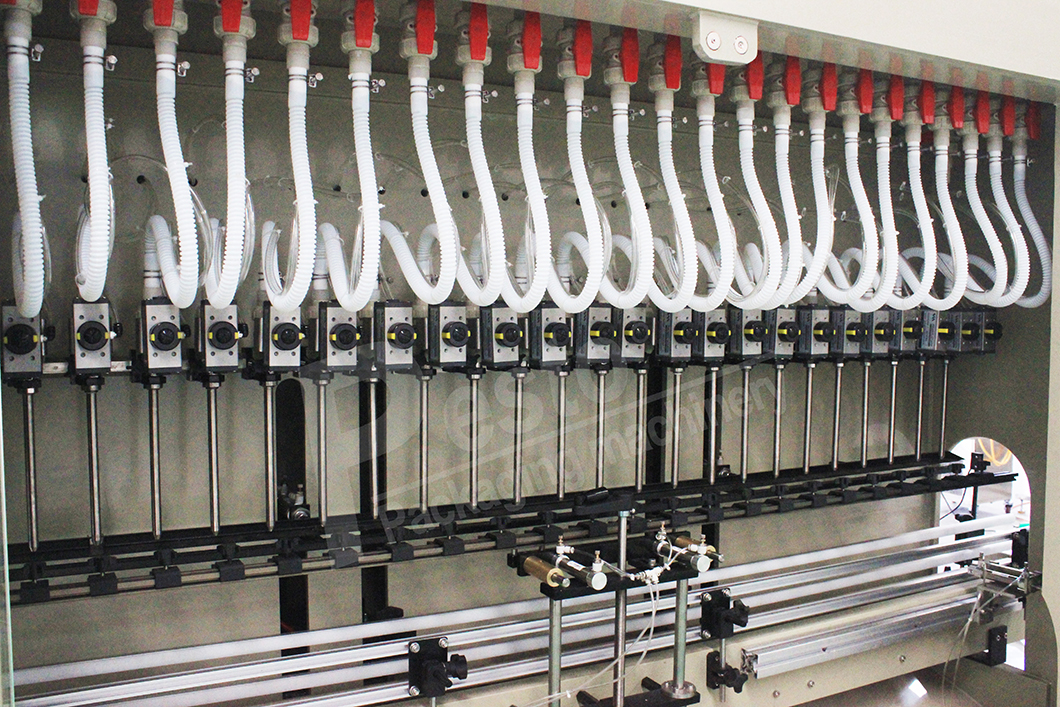

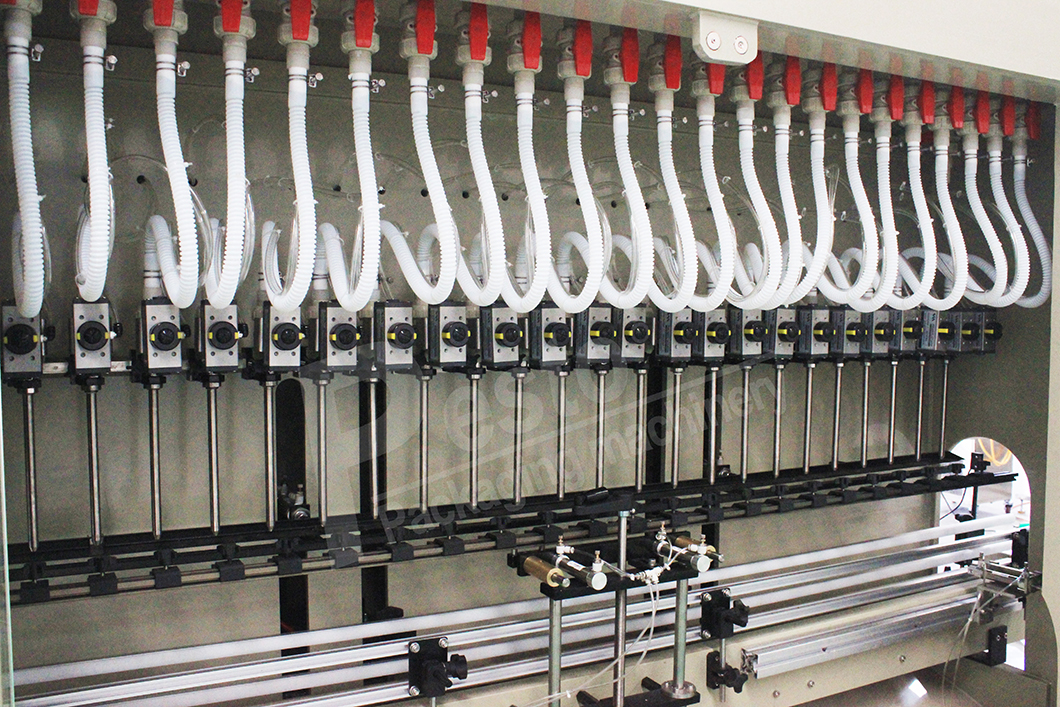

Our corrosive liquid filling machines are designed to meet the needs of corrosive products. Automatic corrosive liquid filler provides a time based volumetric fill. This corrosive liquid filler is manufactured to be a part of a complete, automated, inline packaging system and can be integrated into almost any existing packaging line. Bleach liquid filling machine is specially developed for the low viscosity but corrosive liquid filling. The whole machine is controlled by PLC, which can realize the precise filling, stable performance and easy parameter setting. It is application for filling acid, alkali materials, highly corrosive pesticides, 84 disinfectant, toilet cleaner, iodine, etc.

CORROSIVE LIQUID FILLING MACHINE FEATURES

Corrosive liquid filling machine are constructed by PP to anti corrosive including the conveyor, control cabinet.

The feeding pipe is made of titanium alloy with high strength and corrosion resistance.

PLC control, and touch screen operation. It is easy for changing size or modifying parameters.

Aviation pipeline plug, waterproof, electricity-proof and dust-proof.Independent anti-corrosive appliance control cabinet, safe and reliable.

Designed for easy changeover and cleaning.

No bottle no filling. Filling nozzle can adjustment individually.

Three-step-filling, it fill slowly at the beginning and then accelerate to faster speed, finally slow down once again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

ANTI-CORROSION FILLER PARAMETERS

Filling heads | 4 | 6 | 8 | 12 |

Production speed

(bottles/hour) | 1L:1000,5L:800 | 1L:1800,5L:1200 | 1L:2200,5L:1600 | 1L:3500,5L:2800 |

Filling accuracy | 1-5L:±5ml |

Filling range | 500-5000ml |

Suitable bottles | Round barrel:height:100-320mm;diameter:Φ100-180mm

Drum: length:100-200mm;width:40-80mm;height:150-300mm

Neck diameter:≤Φ30mm |

Power | 3KW | 3KW | 4KW | 5KW |

Power source | 220/380V 50/60Hz |

Air source | 0.6Mpa |

Dimension(mm) | 1600×1100×2200 | 2000×1100×2200 | 2400×1100×2200 | 2600×1500×2200 |

CORROSIVE LIQUID FILLING MACHINE DETAILS

1. Aviation pipeline plug, waterproof, electricity-proof and dust-proof, safe and reliable. Independent anti-corrosive appliance control cabinet, safe and reliable.

2. The whole corrosive liquid filling machine adopts anticorrosive PP material. The feeding pipe is made of titanium alloy with high strength and corrosion resistance.

3. The conveyor belt is made of anti-corrosion materials, further prevents corrosion of the machine.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu