PESTOPACK is a leading provider of advanced oil bottling machines designed for edible and cooking oils. Combining high-speed performance, precise filling, and fully automatic capping, our machines cater to small, medium, and large-scale production lines. From PET bottle handling to precise weight-based filling, PESTOPACK’s solutions are engineered to meet the highest international standards.

Whether you are starting a new edible oil production line or upgrading your existing facility, our oil bottling machine ensures maximum efficiency, hygiene, and reliability.

Application

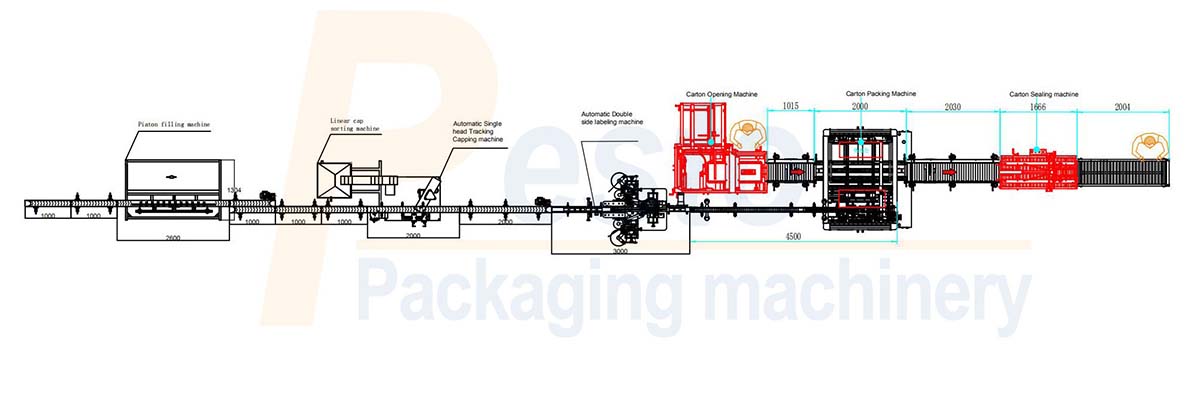

1. Bottle Feeding and Transfer

Empty bottles are automatically fed to the filling station via a variable pitch screw and star-wheel conveyor system. The bottle supports are equipped with weight sensors and slanting detection to ensure correct placement. Any misaligned or missing bottles are detected immediately, preventing faulty filling and reducing material waste.

2. Precision Filling Process

The filling process is fully automated and weight-controlled:

Slow Filling Start: The filling valve begins at a slow rate to avoid spillage.

Normal Filling: The machine automatically switches to normal speed for efficiency.

Slow Filling End: As the liquid approaches the predetermined level, the machine slows down again for precise weight measurement.

Automatic Stop: Weight sensors signal the filler to stop when the desired quantity is reached.

This weight-based filling technology ensures consistent volume across every bottle, minimizing product loss and maintaining quality standards.

3. Capping Process

After filling, bottles move to the capping station:

Caps are supplied automatically via cap elevator, unscrambler, and chute systems.

Electromagnetic capping heads securely place and tighten caps, minimizing the risk of bottle damage.

Bottles without caps or missing bottles trigger an automatic stop, ensuring production integrity.

4. Conveying for Further Processing

Once capped, bottles are transported to labeling and packing stations using a conveying chain, allowing seamless integration with additional bottling line equipment.

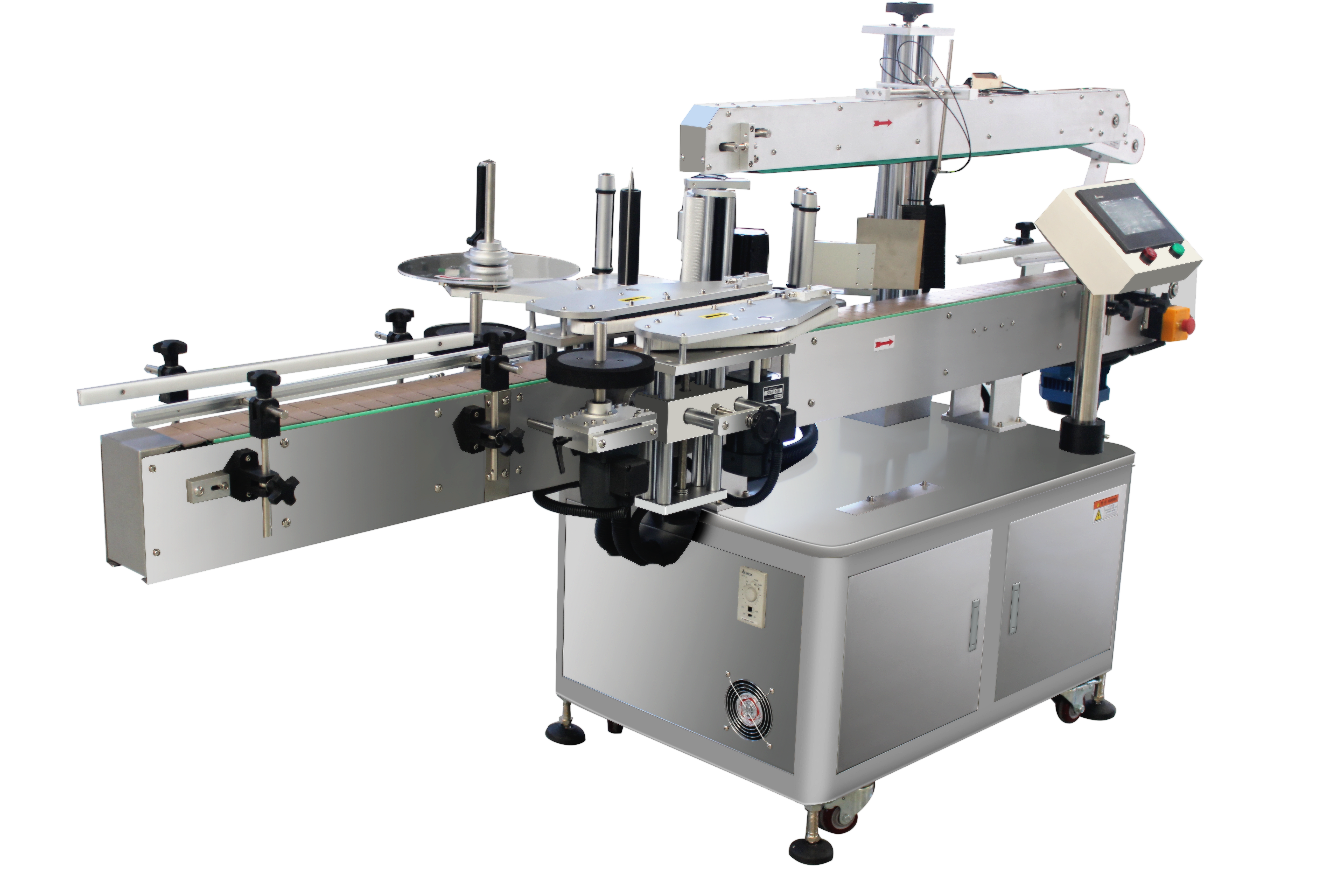

Fully Automated Operation: Intelligent detection systems handle missing, crooked, or jammed bottles automatically. Filling valves only operate when bottles are in place.

Sanitary Construction: The machine frame includes oil traps for clean operations. All product-contact parts are made of 304 stainless steel, eliminating dead corners and preventing contamination.

Flexible Bottle Size Handling: Changeovers between bottle sizes are fast and simple, requiring minimal adjustments.

Adjustable Filler and Capper: Height adjustment allows operators to handle bottles of different shapes and sizes with ease.

Corrosion Resistance & Low Maintenance: Stainless steel construction and lubrication-free design reduce operating costs.

High Accuracy Weight Filling: Weight sensors provide precise measurement for each bottle.

Two-Pass Cylinder Filling: The slow-fast-slow filling ensures consistent liquid levels and maximum precision. Manual sanitary butterfly valves facilitate inspection and maintenance.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu