- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

DGF14-12-5

PESTOPACK

One Year and Life-Long Technical Support

Engineers Available to Service Overseas

Water, Juice and other soft drinks

Liquid

Full Automatic

2000-18000 bottles per hour

Soda, carbonated drinks, beverages, soft drinks in pet as well as glass bottles.

PLC+Touch screen

SUS304

Water purify-Beverage Processing-Bottle blowing-Washing Filling Sealing-Labeling-Packing

Siemens/Schneider/Mitsubishi/AirTac/Delta/Can customized

| Availability: | |

|---|---|

| Quantity: | |

Product Description

The carbonated water filling machine is an overpressure filling machine, which is a machine working according to the fully automatic principle. The filling of the bottles is usually done in a carbon dioxide controlled atmosphere. This is to ensure that the quality of the beverage is maintained. The principle of using overpressure allows the filling of carbonated drinks without releasing carbon dioxide (CO2) from the drink. The general working principle of a carbonated drink filling machine is that the bottle is pressurized and the liquid is released through a tube into a measuring cylinder. The beverage is then discharged into the bottle at an exact predetermined volume along the bottle wall. Air is extracted from the bottle through an air tube located outside the tank space. The volume of the filling liquid is determined by adjusting the height of the filling valve piston. Carbonated drinks filling machines have a wide range of applications in the beverage industry.

They are specifically designed to fill carbonated beverages, such as soda, sparkling water, energy drinks, and carbonated juices, Sprite, Coca-Cola, into bottles. PESTOPACK offers a series of carbonated drink filling machines for sale for carbonated beverage production plant.

It is a specialized equipment designed to automatically fill soda into PET bottles.

It is specifically designed to fill carbonated water or sparkling water into bottle

It is a specialized equipment used for filling non-alcoholic beverages, such as Coca-cola, Sprite, energy drinks into bottles.

The machine is mainly used for filling carbonated drink. We have a wide range of carbonated drink filling machines from 2000BPH to 24000BPH.

Washing, filling and capping can be achieved in one machine. With advanced sensors and control systems, our carbonated drink filling machine guarantees precise filling levels, eliminating product waste and ensuring consistent product quality.

Suspension type card bottle conveying structure, more convenient and fast to change the bottle type. Easily adjust the machine to accommodate different bottle sizes and shapes, providing flexibility for diverse product lines.

The carbonated water filling machine adopts advanced PLC programmable automatic control technology.The key electrical components are used in Germany Siemens, Japan Mitsubishi, France Schneider, Omron and other well-known products..

Equipped with advanced safety features, our carbonated beverage filling machine ensures operator protection and prevents accidents. Automatic control of the cap feeding system, automatic detection of the filling temperature, high-temperature alarm of the material, low-temperature shutdown and automatic reflux, no bottle no filling and capping.

| Model | DGF14-12-5 | DGF18-18-6 | DGF24-24-8 | DGF32-32-10 | DGF40-40-10 | DGF50-50-12 | DGF60-60-15 |

| Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

| Filing heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

| Capping heads | 5 | 6 | 8 | 10 | 10 | 12 | 15 |

| Capacity (b/h) | 2000 | 5000 | 7000 | 9000 | 14000 | 18000 | 24000 |

| Power (KW) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

| Dimension(mm) | 2300*1650*2500 | 2600*1920*2550 | 3100*2200*2800 | 3850*3000*2850 | 4850*2800*2750 | 5750*3550*2750 | 6500*5500*2750 |

| Weight (kg) | 2500 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 |

The soft drink filling machine includes washing filling and capping parts. All parts in carbonated drinks filling machine that have direct contact with the liquid are made of high quality stainless steel.

The suspending bottleneck damping design in carbonated drink filling machine make the botte stable during the high-speed moving conditions.

All 304 stainless steel rinser heads in carbonated drink filling machine, water spray style inject design, save water consumption and cleaner.

High precision filling nozzle, PLC variable signal control, ensure high filling precision.All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean.No bottle no filling.

Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping. No bottle no capping and Automatic stop when lack of bottle.

Advanced technologies,such.as human-machine interface touch-screen and SIEMENS PLC computer proqram control are adopted in this soda water filling machine.

All parts that have direct contact with the beverages are made of high quality stainless steel. And many critical components such as the decelerator, motor are from famous international companies.

Carbonated drink production line need purified water.

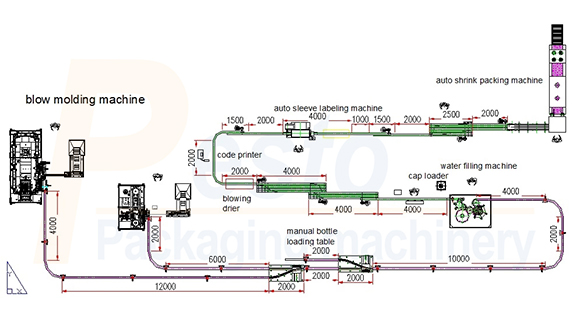

Flow chart:

Raw water--Pump--Silica sand filter--Carbon filter--Water softner--Reverse Osmosis -UV sterilizer--Finished water tank

We provide various of carbonated drinks processing equipments according to production capacity and beverage technological requirements.

Syrup Melting pot; Syrup Pump&Syrup filter; Mixing tank; Double filter; Chiller; Drink mixer; CO2 filter; CIP system

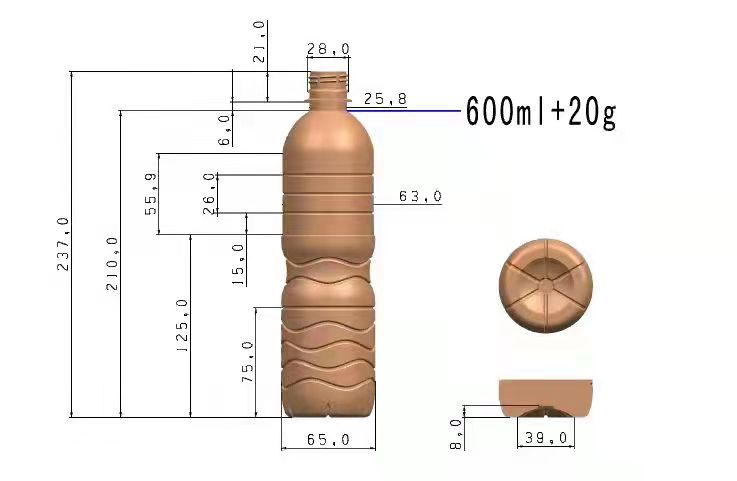

Produce PET Bottles such as: water, beverage, carbonated drinks, wine, soybean, vinegar bottles and so on.

High quality compact machine most popular pet bottle blowing machine With touch screen, Use Festo ( German brand) , SMC (Japan brand ) & Parker ( U.S.A Brand) pneumatic components. PLC use Mitsubishi (Japan brand).

Adopt the new type double bend arm and the four rod-clamping structure: Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

The machine is applied to PET glass bottle tea or juice hot filling production line and PET bottle carbonated drink filling production line.

After hot filling, It can put down the temperature of hot filling drink to 36℃-40℃, to make the sterilization and cooling the bottle temperature for later good packing.

Shrink wrapping machine is mainly used for the industry packages for beverage, carbonated drinks, foods ,no foods glass, plastic bottles and cans, etc.

The machine can automatic finish bottle in-feeding, bottle formation, convey bottle, feed film to wrap and hot shrink to finish package.

Feeding film is tracked by photoelectrical sensor to ensure the accuracy film length.

PLC control, English and Man-machine interface, operating easy and simple maintain.

Film packaging machine collate products and pack them in film.

Function: The conveying belt will feed bottles into the position required, and then when the quantity arrive whole package, for example 12 bottles, 15 bottles, the machine will push the bottles to film wrapping , and then with conveying belt the package will be send to the shrink tunnel , finish the shrink process.

We offer advanced carbonated drink production line to meet our customers' needs in the field of carbonated beverage manufacturing. Our carbonated drink filling line incorporate the latest technology and innovative design to enhance production efficiency, ensure product quality and consistency, and provide reliable operation and ease of maintenance.

Company Profile

PESTOPACK is one of carbonated drink filling machine suppliers in China. We are specialized in liquid filling machinery and packing machinery field over 12 years.

In order to meet the demand for carbonated beverage filling equipment that fit seamlessly into existing operations, we have developed a range of carbonated drinks filling machine that is unmatched in reliability, efficiency and cost effectiveness. And, because we understand that every glass bottle filling machine line has its own unique requirements, each of our carbonated drinks bottling equipment is customized to the individual needs of our customers. Besides water and beverage machinery, we also product oil filling machine, sauce filling machine and detergent filling machine in various industry.

At Pestopack, we stand out with our commitment to excellence and customer satisfaction:

With 12 years of experience, we have in-depth knowledge of the beverage industry and understand its evolving needs.

We invest in research and development, constantly improving our carbonated beverage filling machines to incorporate the latest technologies and stay ahead of the competition.

We work closely with our clients to provide tailored solutions that meet their specific requirements, ensuring our machines seamlessly integrate into their production lines.

From installation and training to ongoing technical support, we offer comprehensive services to ensure a smooth and successful implementation of our carbonated drink filling machines.

Turnkey Solution

PESTOPACK has invested its best resources in technical research, to design and realize innovative in bottle blowing, carbonated beverage filling machine, labeling and packing systems which enable to respond and reach different demands and achieve new goals everyday, seizing the market's expectations in the pass years . At the same time , we also provides turnkey solution for customers, from plant layout design, bottle and label design, soft drink filling machine manufacturing, carbonated beverage filling line setup, raw material supply, to operators training. We are always trying our best to meet the demands of our customers continuously and seeking for mutual development.

We can supply bottle preform, caps, label rolls with very reasonable price.

Layout design

Layout designWe will design and confirm the machine layout according to your factory sketch.

Our designers can design bottle styles according to your requirement.

We can provide the label design according to the bottle size and style you want.

After Sales Service