Introduction

The bottled water industry continues to grow worldwide, driven by rising health awareness, increasing demand for safe drinking water, and the popularity of premium and flavored products. To meet this demand, businesses rely on the expertise of water bottling machine manufacturers. Choosing the right partner ensures production efficiency, cost savings, and reliable after-sales service.

This guide introduces the Top 25 Water Bottling Machine Manufacturers in 2025, covering their strengths, specialties, and global market presence.

Why Choosing the Right Water Bottling Machine Manufacturer Matters

Production Efficiency

A well-designed bottling line can process anywhere from 2,000 to 80,000 bottles per hour, directly impacting factory output and profitability.

Cost and ROI

Low-cost equipment may save upfront investment, but downtime and high maintenance can offset the benefits. The best manufacturers balance competitive pricing with long-term durability.

After-Sales Service

Reliable global service, technical support, and spare parts availability are critical for minimizing downtime and keeping production stable.

How We Selected the Top 25 Water Bottling Machine Manufacturers

Experience and Certifications: Proven track record in bottled water and ISO/CE certifications.

Global Reach: Service networks and installations across multiple continents.

Technology and Innovation: Automation, sustainability, and flexibility in bottling solutions.

Comparison Table of Water Bottling Machine Manufacturers

| Manufacturer | Country | Strengths | Capacity Range | Notable Feature |

| Pestopack | China | Factory-direct, global service | 2,000–36,000 BPH | Competitive pricing |

| Krones | Germany | Global leader, turnkey lines | 12,000–80,000 BPH | Advanced automation |

| KHS | Germany | Sustainable technology | 10,000–72,000 BPH | Eco-friendly solutions |

| Sidel | France | PET bottling expertise | 8,000–65,000 BPH | Lightweight design |

| GEA Group | Germany | Aseptic systems | 5,000–50,000 BPH | Hygienic production |

| SACMI | Italy | Modular solutions | 5,000–40,000 BPH | Flexibility |

| Norland International | USA | Startup-focused | 1,000–12,000 BPH | Compact systems |

| Accutek Packaging | USA | Affordable & flexible | 1,000–24,000 BPH | Entry-level lines |

(Full details are in each manufacturer’s profile below)

Top 25 Water Bottling Machine Manufacturers in 2025

1. Pestopack Machinery (China)

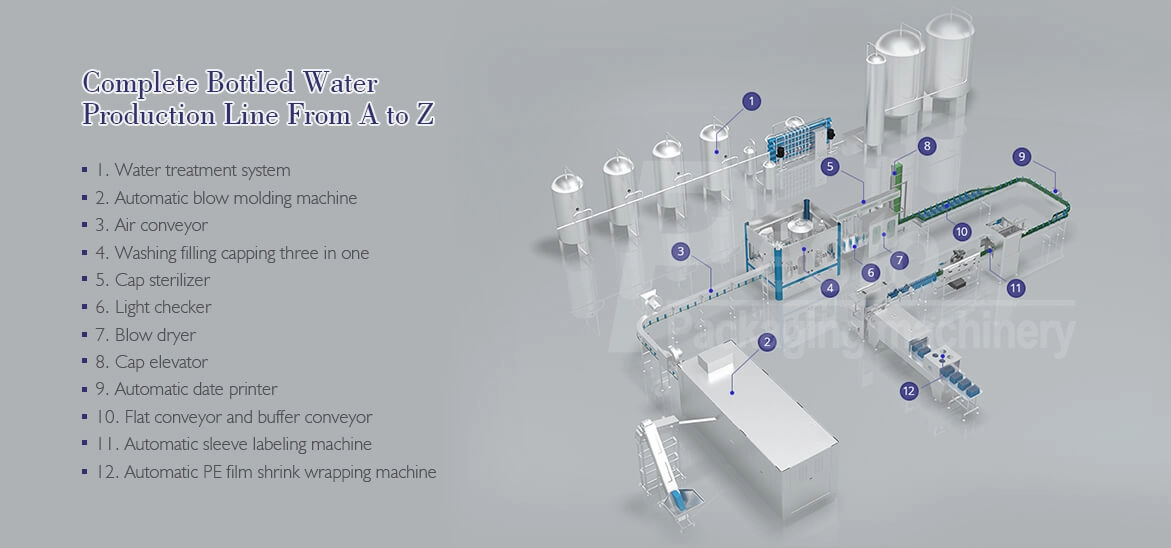

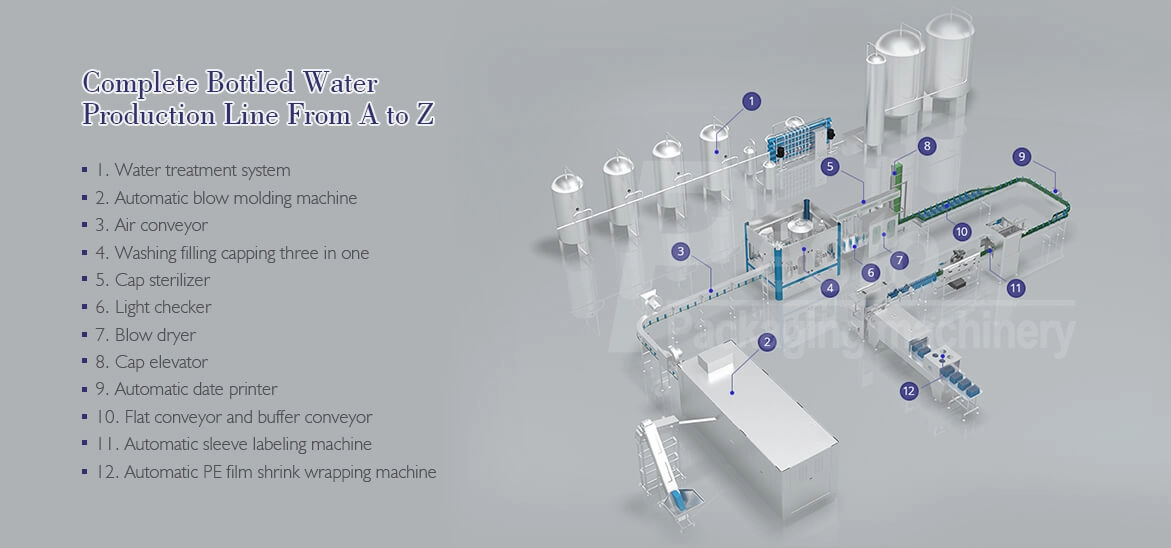

Pestopack Machiner offers factory-direct pricing and complete turnkey solutions for bottled water plants. With over 20 years of industry experience, Pestopack serves clients worldwide across diverse markets.

The product portfolio covers 2,000–36,000 BPH bottling lines, delivering customized designs, reliable quality, and comprehensive global after-sales service. Please explore our water bottling line.

2. Krones (Germany)

Krones is one of the largest and most advanced water bottling machine manufacturers, delivering complete turnkey systems for PET, glass, and cans. Their lines are capable of up to 80,000 BPH, making them the preferred choice for multinational beverage companies.

With a focus on automation and sustainability, Krones invests in lightweight PET designs, energy-efficient heating, and water-saving rinsers. Though their systems require significant investment, they provide unmatched durability and long-term ROI.

3. KHS (Germany)

KHS specializes in efficient and eco-friendly bottling solutions. Their InnoPET Blomax blow molders and Innofill systems are widely used by water brands looking for precision and reliability.

They are best known for their Nature MultiPack™ innovation, which drastically reduces plastic packaging. With modular lines handling 10,000–72,000 BPH, KHS is ideal for producers prioritizing sustainability and scalability.

4. Sidel (France)

Sidel is a PET packaging pioneer, offering complete lines from bottle design to filling and labeling. Their lines range from 8,000 to 65,000 BPH, serving both small brands and global leaders.

They focus on lightweight PET bottles and aseptic PET filling, ensuring reduced costs and extended shelf life for flavored or functional water.

5. GEA Group (Germany)

GEA is known for its aseptic and hygienic filling technologies, serving dairy and water industries worldwide. Their systems handle 5,000–50,000 BPH, focusing on safety and precision.

Automation, energy efficiency, and hygienic design make GEA attractive for water brands requiring reliable and clean production.

6. SACMI (Italy)

SACMI designs modular bottling systems suitable for both medium and large-scale producers. Their flexible approach allows upgrades as businesses grow.

They emphasize innovation and versatility, with production speeds from 5,000–40,000 BPH, widely applied in Europe and Latin America.

7. AVE Technologies (Italy)

AVE Technologies specializes in water, wine, and juice bottling systems. Their solutions are popular among mid-sized producers for affordability and reliability.

They are recognized for user-friendly operation and European build quality, serving brands across multiple continents.

8. IC Filling Systems (UK)

IC Filling Systems provides compact bottling solutions for breweries, wineries, and small water plants. Their portable and mobile systems make them unique.

They are ideal for small and medium enterprises, offering customized solutions at accessible price points.

9. Norland International (USA)

Norland International focuses on complete water bottling solutions for startups, including purification, filling, and packaging.

Their systems typically range from 1,000–12,000 BPH, making them perfect for small and growing bottled water businesses.

10. Filamatic (USA)

Filamatic provides flexible liquid filling machines used in beverages, pharmaceuticals, and cosmetics.

For water bottling, they are best known for semi-automatic to fully automatic solutions, catering to diverse production needs.

11. Accutek Packaging (USA)

Accutek offers one of the broadest portfolios in the U.S., covering piston, gravity, and servo fillers.

They serve small to medium-scale producers, with lines ranging from 1,000–24,000 BPH, and are known for affordable entry-level lines.

12. Federal / ProMach (USA)

Federal, part of ProMach, specializes in sanitary filling systems, particularly for milk, juice, and water.

Their strength lies in hygienic rotary fillers and strong integration with complete packaging solutions.

13. Inline Filling Systems (USA)

Inline Filling Systems builds overflow, gravity, piston, and pump fillers for water and beverages.

They target SMEs and offer flexible, U.S.-built equipment designed for scalability and customization.

14. E-PAK Machinery (USA)

E-PAK Machinery provides cost-effective bottling systems for water, sauces, and other liquids.

With a wide selection of fillers, they are popular among mid-sized bottled water producers.

15. Shemesh Automation (UK)

Shemesh Automation is a global supplier specializing in turnkey packaging lines for beverages and chemicals.

Their systems are recognized for automation and reliability, serving clients in over 30 countries.

16. Ronchi Mario (Italy)

Ronchi Mario is famous for precision filling and capping machines. Though widely used in cosmetics, they also serve the water and beverage sector.

They stand out for servo-driven technology and Italian engineering quality.

17. Serac (France)

Serac is a leader in weight-based filling systems, widely used for water, dairy, and edible oils.

Their precision technology ensures minimal waste and consistent quality across batches.

18. OPTIMA Packaging Group (Germany)

OPTIMA designs high-tech filling and packaging equipment for beverages and pharmaceuticals.

Their bottling systems are known for automation, hygiene, and flexibility, serving premium water producers.

19. IMA Group (Italy)

IMA Group is a global engineering firm with advanced bottling and packaging technologies.

Their aseptic and high-speed filling systems are ideal for large-scale bottled water brands.

20. Bosch/Syntegon (Germany)

Formerly Bosch Packaging, Syntegon is a global leader in automated filling and packaging lines.

They deliver high-precision bottling systems with a strong reputation in the pharmaceutical and beverage industries.

21. APACKS (USA)

APACKS manufactures bottling lines that balance affordability and performance.

They are popular among small and medium water bottlers for reliable entry-level systems.

22. Liquid Packaging Solutions (USA)

Liquid Packaging Solutions provides flexible systems for both small startups and established plants.

Their lines are customizable, allowing businesses to expand capacity as demand grows.

23. NJM Packaging (USA)

NJM Packaging, part of ProMach, supplies bottling equipment to both pharmaceutical and beverage industries.

They are trusted in the U.S. market for durable machines and strong after-sales support.

24. Tech-Long (China)

Tech-Long is one of China’s most established bottling equipment manufacturers, with installations in more than 60 countries. They provide blow molding, filling, and packaging systems at competitive prices.

With capacities ranging from 6,000–60,000 BPH, Tech-Long combines affordability with advanced engineering, making them a strong alternative to European giants.

25. NewamStar (China)

NewamStar specializes in high-speed beverage bottling lines, particularly in water and carbonated drinks. Their rotary fillers can reach 72,000 BPH.

They are known for engineering innovation and complete turnkey plants, making them a preferred supplier in Asia and emerging markets.

Regional Insights

North America

The U.S. is home to Accutek, Filamatic, Federal/ProMach, and Norland International, serving both startups and large-scale plants. Many focus on flexibility and modular designs to meet diverse customer needs.

Europe

Germany, France, and Italy dominate with giants like Krones, KHS, GEA, Sidel, and SACMI. Europe emphasizes automation, energy efficiency, and sustainability, setting the global benchmark.

Asia-Pacific

China’s Tech-Long, NewamStar, and Pestopack Machinery are rapidly expanding their global footprint. They offer competitive factory-direct pricing, strong customization, and full turnkey solutions, making them attractive to emerging markets.

Middle East & Africa

Growing bottled water consumption fuels demand for cost-effective bottling lines. Chinese and European manufacturers are both expanding here, with Pestopack having multiple successful projects in the region.

Latin America

Brands seek affordable yet robust bottling machinery, often importing from the U.S. and Europe. The trend toward mid-range capacity (6,000–18,000 BPH) is strong in this region.

Industry Trends & Market Outlook

Market Growth: The global bottled water market is projected to surpass USD 400 billion by 2030, driven by rising health consciousness and demand for safe drinking water.

Smart Bottling Lines: IoT-enabled monitoring and predictive maintenance are becoming standard, reducing downtime.

Sustainability Push: Lightweight PET bottles, recyclable materials, and water-saving filling valves are major focus areas.

Shift Toward Flexibility: Manufacturers increasingly design multi-format machines that can handle PET, glass, and aluminum cans in one line.

Emerging Markets: Africa, South Asia, and the Middle East will see the fastest growth, with high demand for 2000–12,000 BPH lines that balance cost and performance.

Conclusion

The Top 25 Water Bottling Machine Manufacturers in 2025 represent the best partners for water producers worldwide. Whether you are a startup or a multinational brand, these manufacturers offer the technology, service, and reliability to build a successful bottled water business.

Internal Resources

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu