1. Determine your production needs and capacity

2. Consider the water source and quality

3. Look for efficiency and sustainability features

4. Research water production line manufacturers

5. Different types of water production line

6. Consider your budget

7. Why buy water production line from PESTOPACK

Water is an essential resource that is required for various purposes, including drinking, cooking, and cleaning. In order to meet the demand for clean and safe drinking water, many companies and organizations invest in water production lines. However, with so many different types and models of water production lines available on the market, choosing the right one can be a daunting task. In this article, we will provide some tips and guidelines on how to choose the right water production line.

1. Determine your production needs and capacity

The first step in choosing the right water production line is to determine your specific production needs and capacity. This includes considering the amount of water you need to produce, the types of bottles or packaging you will be using, and the level of automation you require. Make sure to choose a water production line that is capable of meeting your current and future production needs.

Here are some key steps you should take:

Identify your market demand:

First, you need to determine the demand for your product in the market. This will help you understand how much water you need to produce to meet the demand. If you are new of water business, you should learn more about how to start a water bottling plant.

Analyze your production processes: Next, you should analyze your current production processes to identify any bottlenecks or inefficiencies that might be limiting your production capacity.

Determine your available resources: You also need to consider the resources you have available, such as equipment, labor, and materials, to determine your production capacity.

Assess your production costs: Another important factor to consider is the cost of producing water. This will help you determine how much you can afford to produce, while still making a profit.

Plan for growth: Finally, you should plan for future growth and expansion by considering factors such as increasing demand, new products, and new markets.

2. Consider the water source and quality

The quality of the water source is another important factor to consider when choosing a water production line. The water source may contain impurities, minerals, or contaminants that can affect the taste, odor, and appearance of the water. Make sure to choose a water production line that is equipped with the necessary filtration and purification technologies to ensure that the water is clean, safe, and meets the required standards.

Here are some key points to keep in mind:

Identify the water source: You need to identify the source of the water you will be using for your production line. This could be municipal water, well water, or surface water from a nearby river or lake.

Test the water quality: Once you have identified your water source, you need to test the water quality. This will help you determine if the water is safe to drink and meets any regulatory standards. You should test for contaminants such as bacteria, viruses, minerals, and chemicals.

Consider water treatment system: If the water quality does not meet the necessary standards, you may need to install water treatment system such as filtration systems, reverse osmosis units, hollow untrafiltration or UV disinfection systems.

Consider ongoing water quality monitoring: Even if the water quality initially meets regulatory standards, you should consider ongoing monitoring to ensure that it remains safe and meets any new or updated standards.

3. Look for efficiency and sustainability features

Efficiency and sustainability are important considerations when choosing a water bottling machine. Look for models that are energy-efficient, water-efficient, and minimize waste generation. This will not only help you save on operational costs but also contribute to environmental sustainability.

Here are some key points to keep in mind:

Choose energy-efficient equipment: Energy-efficient equipment can help you reduce your energy consumption and save money on your energy bills.

Optimize water usage: Water is a valuable resource, and optimizing its usage can help you reduce your operating costs and minimize your environmental impact.

Minimize waste: Minimizing waste can help you reduce your operating costs and reduce your environmental impact.

Use renewable energy sources: Using renewable energy sources such as solar or wind power can help you reduce your carbon footprint and increase your energy independence. Consider installing solar panels or wind turbines to power your water production line.

Choose sustainable materials: Choosing sustainable materials such as recycled plastic or biodegradable packaging can help you reduce your environmental impact and appeal to environmentally conscious consumers.

4. Research water production line manufacturers

When selecting a water production line, it's important to research the manufacturers and suppliers to ensure that they have a good reputation for quality, reliability, and customer service. Look for manufacturers and suppliers that have been in the business for a long time, and offer warranties and technical support.

Finding a good water filling machine manufacturer for a water production line can be a crucial factor in the success of your business. Here are some key steps to help you find a reliable and trustworthy manufacturer:

Research: Start by doing some online research to identify potential machine manufacturers for your water production line. To save your time, you'd better find a turnkey water production line supplier which they can intergrate all machines into a complete line.

Visit the manufacturing facility: If possible, visit the manufacturing facility in person to see their production process, quality control procedures, and the condition of their machinery. This will give you a better idea of their capabilities and the quality of their work.

Consider cost and warranties: Compare the prices and warranties of the machines offered by different manufacturers. Look for manufacturers that offer competitive prices, good warranties, and after-sales support.

Communication and support: Communication and support are critical factors when dealing with a manufacturer. Look for manufacturers who are responsive to your inquiries, willing to answer your questions, and offer good customer support.

By following these steps, you can find a good machine manufacturer for your water production line who can provide you with high-quality equipment and reliable support.

5. Different types of water production line

There are several types of water bottling plant for sale, each designed to produce a specific type of water. Here are some examples:

Spring Water Production Line: This type of water production line is used to produce natural spring water, which is sourced from underground springs. The water is collected and transported to the production facility, where it is bottled and packaged for distribution.

Purified Water Production Line: This type of water production line is used to produce purified water, which is free from impurities and contaminants. The water is treated using various methods, such as reverse osmosis, distillation, and carbon filtration, before it is bottled and packaged.

Mineral Water Production Line: This type of water production line is used to produce mineral water, which contains naturally occurring minerals and trace elements. The water is sourced from underground mineral springs and is treated to remove impurities before bottling and packaging.

Alkaline Water Production Line: This type of water production line is used to produce alkaline water, which has a higher pH level than regular drinking water. The water is treated with ionization or electrolysis technology to raise its pH level and create alkaline water.

Carbonated Water Production Line: This type of water production line is used to produce carbonated water, which is water that has been infused with carbon dioxide gas to create bubbles. The water is pressurized and carbonated before it is bottled and packaged.

Flavored Water Production Line: This type of water production line is used to produce flavored water, which is water that has been infused with natural or artificial flavors. The water is mixed with flavorings and sweeteners before it is bottled and packaged.

6. Consider your budget

Budget is an important consideration when choosing a water production line. Determine how much you are willing to spend on the initial investment, operational expenses, and maintenance costs. Keep in mind that the cheapest option may not always be the best in terms of quality and performance.

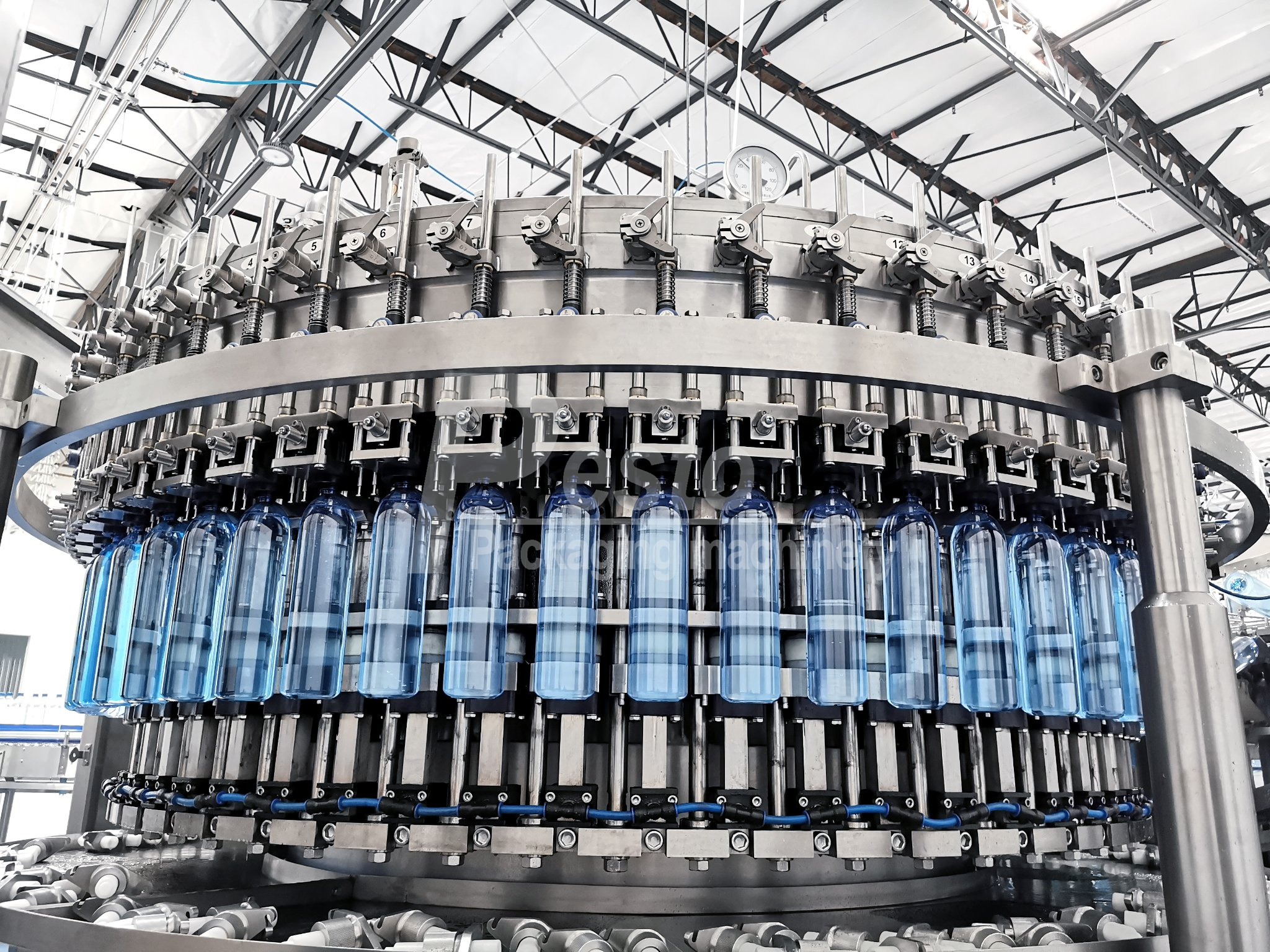

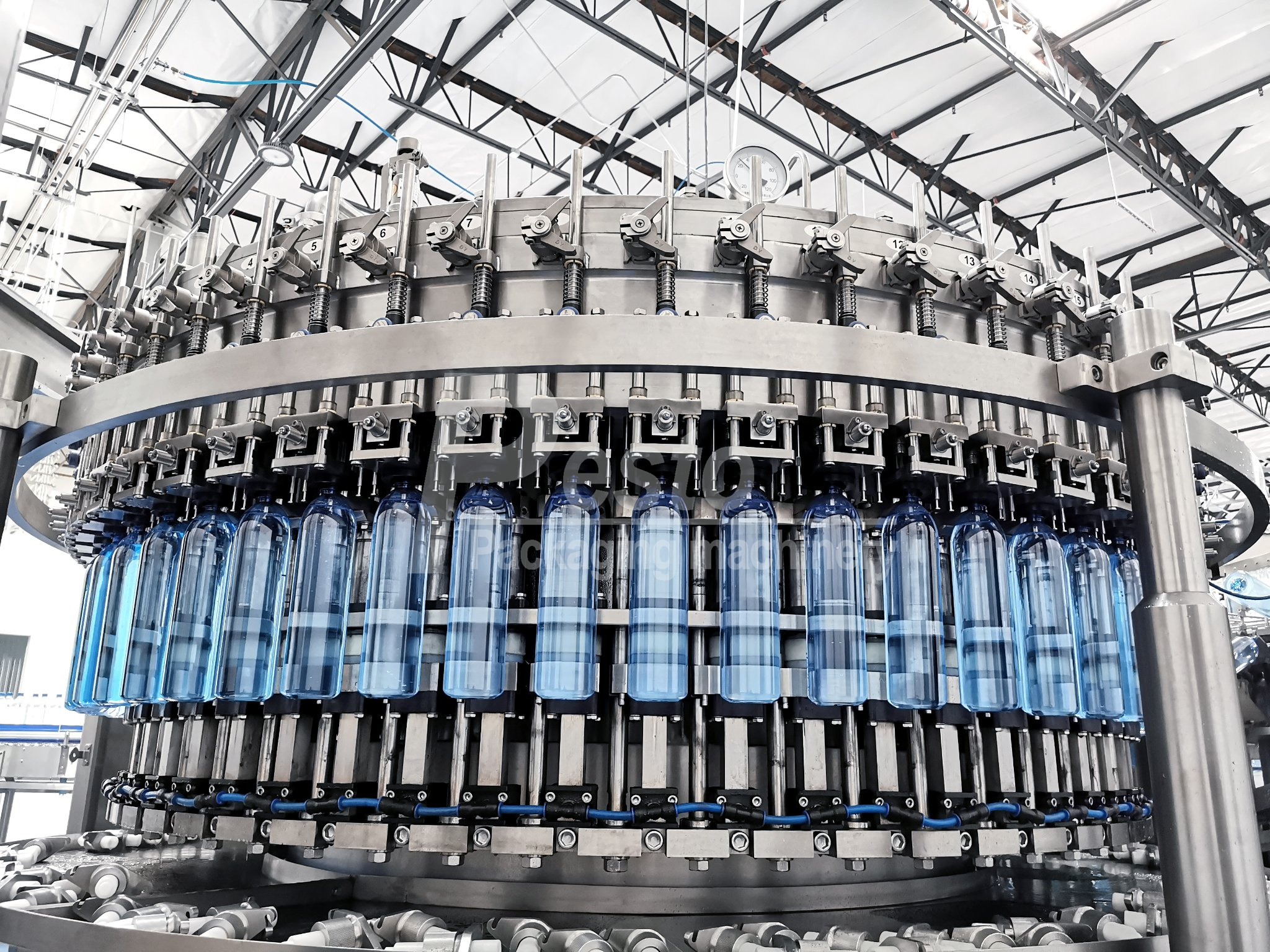

7. Why buy water production line from PESTOPACK

PESTOPACK is an innovation manufacturer of water and beverage production lines in China, and there are several compelling reasons why you should consider purchasing your equipment from us.

PESTOPACK water production lines are designed to be of the highest quality and built to last. PESTOPACK uses only the finest materials and components in the manufacture of its equipment, ensuring that each machine is rugged, durable, and able to withstand the rigors of continuous use in a busy production environment.

PESTOPACK water production lines are equipped with the latest technology to ensure maximum efficiency, precision, and reliability. PESTOPACK is committed to staying at the forefront of technological innovation, and its equipment incorporates the most advanced features and capabilities available.

PESTOPACK recognizes that every customer has unique needs and requirements when it comes to water production. That's why the company offers a wide range of customization options for its equipment, including the ability to tailor machines to specific production volumes, bottle sizes, and water types.

PESTOPACK is committed to providing exceptional customer service, and its team of experts is available to assist you at every step of the process, from initial consultation to installation and ongoing support. The company prides itself on its responsiveness, attention to detail, and dedication to ensuring that each customer's needs are fully met.

Despite the exceptional quality and performance of its equipment, PESTOPACK water production lines are competitively priced, making them an excellent value for businesses of all sizes. PESTOPACK is committed to offering fair and transparent pricing, with no hidden fees or charges.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu