Table of Contents

Introduction: What Is a Water Bottling Plant?

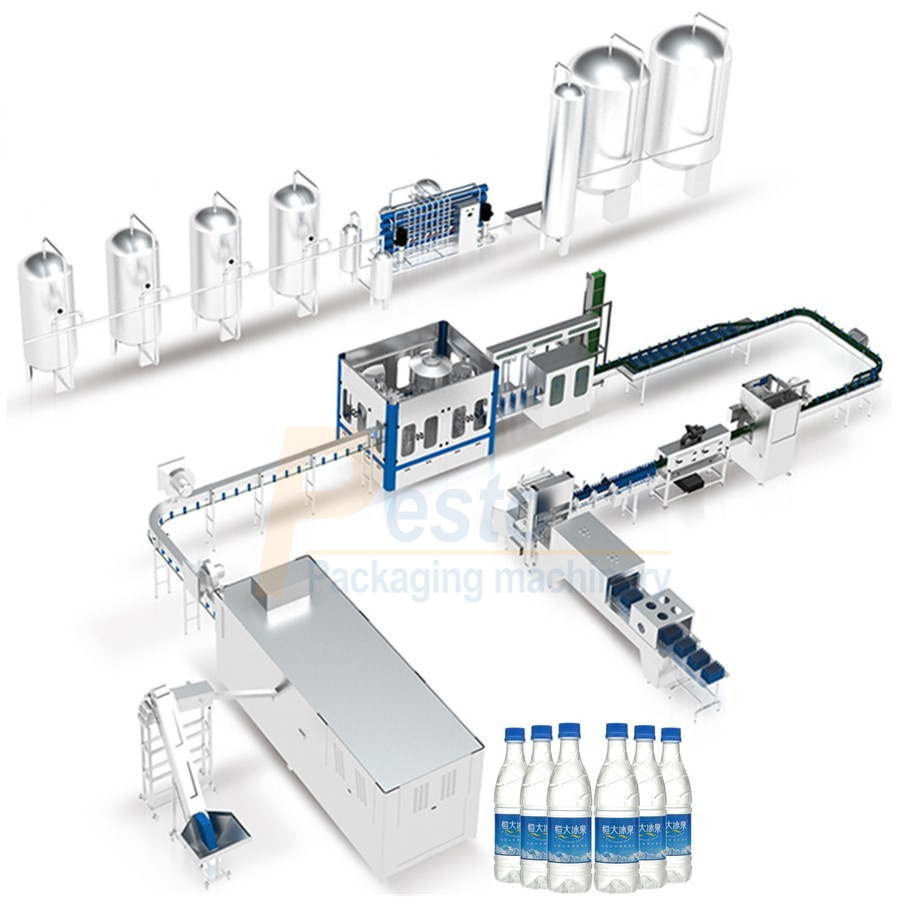

A water bottling plant is a factory in which bottled water like spring water, purified water, mineral water, sparkling water is produced. A complete water bottling plant needs various automation equipment to realize the production of bottled water, including water treatment system, bottle blowing machine, filling machine, labeling machine, packaging machine, palletizing equipment, etc. It looks complicated, but with a professional water bottling machine supplier to assist you, everything becomes very simple.

How to start a water bottling plant can be quite a difficult question for who just starting out. The article below will show you details for creating the most successful bottled water factory.

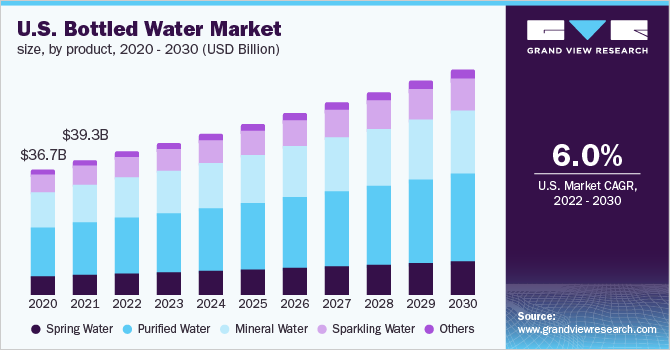

1. Research Water Bottling Plant Business Market

The first and very important step in learning how to start a water bottling plant is market research. According to Grand View Research,the global bottled water market size was valued at USD 283.01 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 6.7% from 2022 to 2030. Growing concerns about various health issues such as gastrointestinal ailments caused by drinking contaminated water has led to increased demand for clean and hygienic packaging options. The shortage of potable water in several regions has further increased the demand for safe drinking water, thereby boosting product sales, thereby boosting the market growth. As consumers become more health conscious, products with labels such as alkaline, electrolyte-rich, fortified, caffeinated water, and fortified with additional hydrogen or oxygen are gaining popularity, because it is healthier than high-calorie, carbonated and sugary beverages such as sports drinks and juices. However, the above report is only a preliminary statistics of the global data, you need to conduct a subdivision survey for the target market.

2. Plan Your Water Bottling Plant Business

Raw water source

Raw water is the natural water (from ground water, surface water, well water, lakes and rivers) that has not been treated. Like spring water normally get from underground water. Purified water usually comes from ground water or tap water. It's treated in a water processing system to remove impurities and contaminants. Before confirming raw water source place for water bottling plant, first obtain testing report from the third-party agency, which can understand the water quality and decide what type of water treatment equipment to use.

Location

Location is one of the key factors that determine the profitability of a water bottling plant business. Proximity to water sources and convenient transportation are crucial to gaining a larger market share.

Machinery

When making equipment planning, in addition to considering the budget, future capacity expansion should also be considered. Whether it is a small scale water bottling plant or large scale water production plant, you can consult the water bottling line manufacturer, and they can give professional advice.

Space

The water bottling plant has the following sections to be considered: water treatment, bottling line, raw material storage, finished product storage, laboratories, changing rooms, offices. Generally speaking, a 6000BPH (3000LPH) water bottling workshop needs 600 square meters.

Raw material source

Packaging materials like bottles, labels, packing films are mainly used in bottled water. PET bottles are popular packaging for water, some premium brands use glass bottles.

Running expenses

In addition to equipment costs, other factors like employee salaries, electricity costs, consumable materials, equipment maintenance should be considered when planning water bottling plant. Water treatment equipment and shrink labeling machine need electricity, filling machines and packing machines use air compressor.

3. Licencing Water Bottling Business

Business License

When you're ready to start your water bottling business, complete the business license registration process in your local place. This is to legitimize your company in the market and at the same time only with a business license you can apply for a financial loan.

Necessary permits

Failure to obtain the necessary permits and licenses can result in hefty fines and even the closure of your water bottling business. Like in the United States, the Food and Drug Administration (FDA) regulates bottled water. FDA regulations for bottled water include good manufacturing practice (GMP), identity standards, and labeling requirements. You can consult the local government department for more detailed policy requirements.

4. Preparing Water Bottling Factory

After getting the company qualification, you can turn the plan into reality. If you want to start a small water bottling plant, renting a space is the best choice. For building a water bottling factory, all factors need to be considered like convenient transportation, close to water sources, sufficient space, stable electricity, standard factory buildings, safety and sanitation, etc.

5. Branding and Design

Packaging has been playing a crucial role in the growing penetration of the water product. But the competition in the bottled water market is also very fierce. Creative bottle designs, label designs, slogans may gain a bigger market share.

6. Buy Water Bottling Plant Machines

After comparing several equipment manufacturers, find one that suits you and buy their equipment. In addition to the price, you should pay more attention to the quality of the equipment and after-sales service, so that your bottled water production will have no worries.

At PESTOPACK, we understand that purchasing a complete water bottling system is a long-term investment, not just a one-time transaction. That's why we offer:

Over 15 years of experience specializing in water and beveage industry

CE-certified machinery for global standards

Full support from project design, equipment selection, layout planning, to on-site installation

Rapid-response after-sales service with dedicated engineers

Customized production lines tailored to your water source, bottle shape, and market needs

We have a wide range of selection from 2000BPH to 36000BPH. If you want to start your business on a small scale, you can find a reliable solution within our 2000–6000BPH water bottling plant configurations. If your project requires high capacity and automation, we offer complete 2000–24000BPH water bottling plant for sale, including water treatment, blowing, filling, labeling, and packaging systems—all integrated into one efficient line.

7. Sale Your Bottled Water

After all things are ready, you need to establish an official website, establish a telephone system, find distributors, online and offline sales channels, to provide as many sales opportunities as possible.

8. Water Bottling Plant Cost & Setup Explained

The cost of a water bottling plant varies depending on the capacity, bottle type, automation level, label material, packaing type and your location. Here's a general reference:

Small-scale plant (2000-6000 BPH): $52,000 – $160,000

Medium-scale (6000–12000 BPH): $1600,000 – $350,000

Large-scale (24000-36000 BPH): $770,000+

Additional costs include:

Land/factory setup

Utility connections (electricity, water, compressed air)

Labor and training

Import duties and shipping

9. Looking for a Water Bottling Plant for Sale?

PESTOPACK offers complete, customizable solutions tailored to your business scale. From bottle blowing to palletizing, we help you build a fully integrated water bottling plant with high productivity and low operational cost.

Check our water filling machine for sale to explore technical specifications, floor layout, and equipment videos.

10. FAQ

Q1: What types of water can I bottle with your plant?

A: You can bottle purified water, mineral water, spring water, or even sparkling water depending on your equipment configuration.

Q2: What is included in a complete water bottling plant?

A: Water treatment unit, bottle blowing machine, rinsing-filling-capping machine, labeling, laser printer, shrink wrapping/carton packing, and palletizing system.

Q3: How long does installation take?

A: For a small capacity, installation and testing take around 30 days depending on on-site conditions. For middle and large capacity, it takes 60-90 days for installation and training.

Q4: Do you offer installation support and factory layout?

A: Absolutely. Our engineers can help you with water filling machine layout and do installation support at your site.