Acid Filling Machine – Complete Guide to Corrosive Liquid Filling Solutions

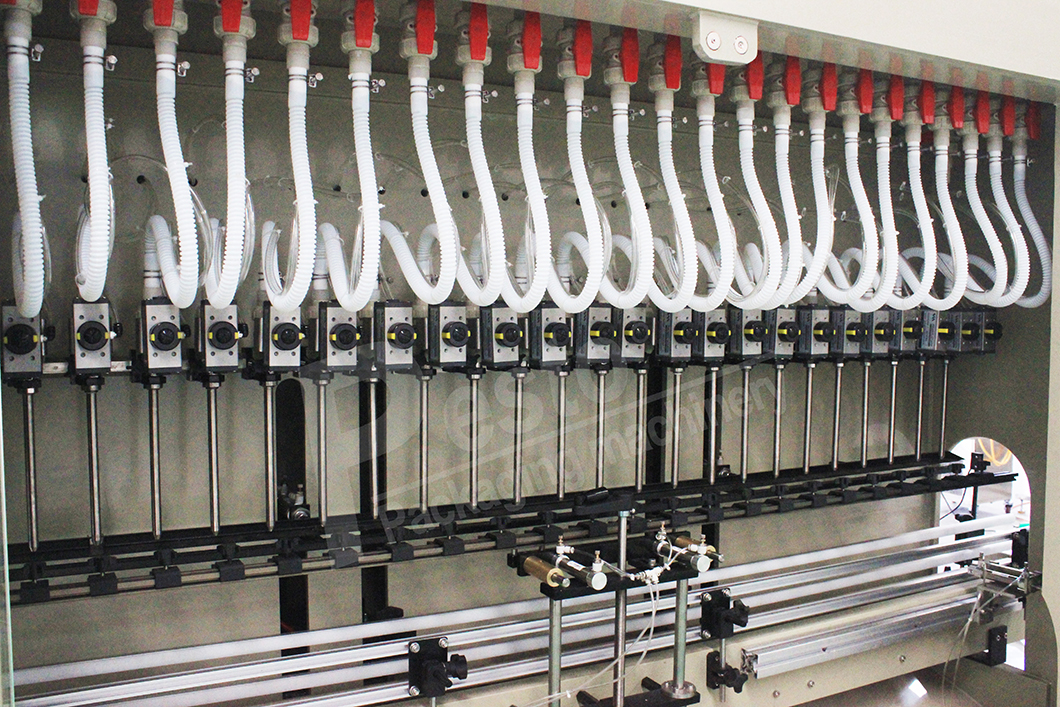

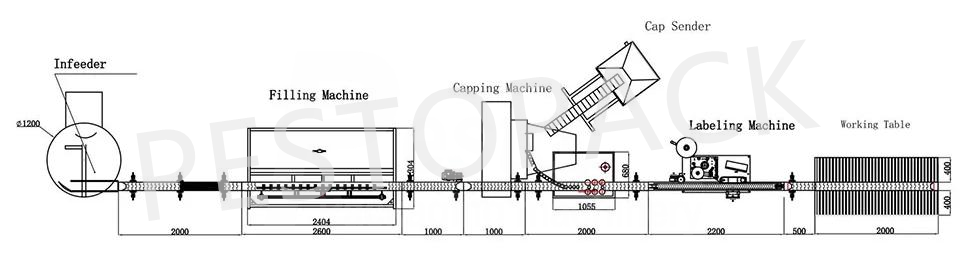

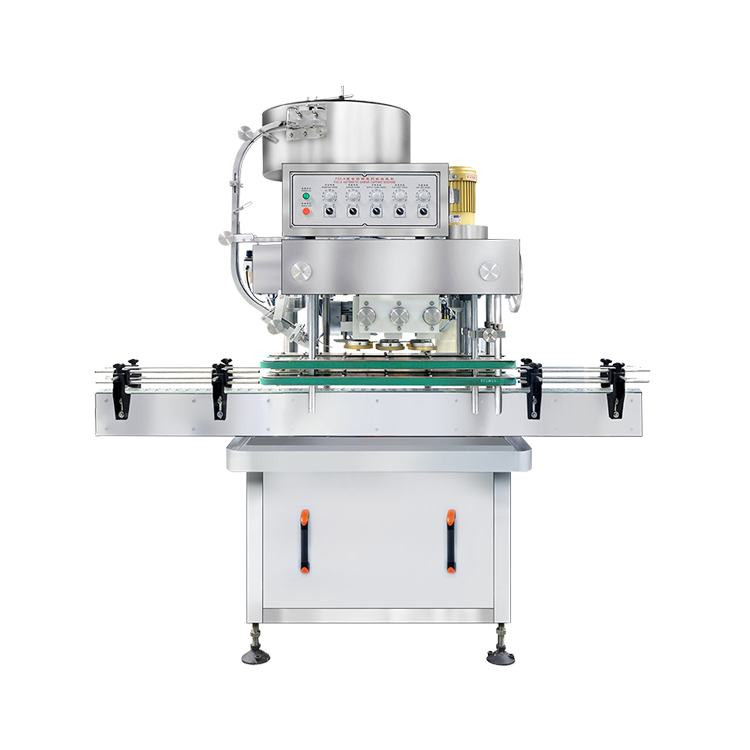

Handling acidic cleaning products and corrosive liquids in production requires specialized filling equipment that ensures safety, accuracy, and long-term durability. Pestopack’s acid filling machine is engineered with acid-resistant materials, smart automation, and protective safety features, making it the perfect choice for manufacturers of acid-based household cleaners, industrial chemicals, and detergents.

In this in-depth guide, we’ll cover:

The properties of acid-based cleaning liquids

How an acid filling machine works

Technical features and parameters

Integration of complete filling lines (capping, labeling, packaging)

Advantages of Pestopack’s acid filling machine

FAQs for buyers

Understanding Acidic Cleaning Products

What Are Acidic Cleaning Liquids?

Acidic cleaning products are low pH solutions designed to remove stubborn dirt, mineral deposits, rust, limescale, and oxides. They are commonly used in:

Household cleaning (bathroom cleaners, toilet descalers, limescale removers)

Industrial cleaning (metal surface treatment, scale removal)

Commercial kitchens (removing grease combined with mineral buildup)

Characteristics of Acid-Based Products

1. Powerful Stain Removal

– Breaks down limescale, mineral salts, and rust deposits effectively.

2. Antibacterial Properties

– Many formulas include acidic components with natural antibacterial performance.

3. Low Viscosity

– Acidic liquids are generally thin, water-like solutions that flow easily.

4. Low Foaming Behavior

– Unlike alkaline detergents, acids generate minimal foam but retain high cleaning efficacy.

These unique properties require specialized filling equipment detergent filling machine, since standard liquid filling machines may corrode or fail when exposed to strong acids.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu