BLEACH FILLING MACHINE APPLICATION

The main ingredient in bleach is typically a chloride compound, with sodium hypochlorite (NaClO) being the most common. Other possible ingredients may include alkaline or oxidizing agents, such as sodium hydroxide (NaOH) or hydrogen peroxide (H2O2). Bleach generally has a low viscosity, indicating high fluidity. This makes it easy to pour, mix, and spread. Bleach is typically alkaline, with a high pH value. Generally, the pH value of bleach falls within the alkaline or neutral range, usually between 11 and 13. A higher pH value indicates stronger alkalinity, which gives bleach its powerful oxidizing properties.Bleach is a chemical substance with strong corrosive properties. It can react with various substances, including organic materials and metals. The corrosiveness of bleach can cause discoloration, corrosion, or damage when it comes into contact with other chemicals or surfaces.

Matching the ingredient, viscosity, PH and corrosion of bleach with the appropriate bleach filling machine is essential for efficient and accurate production. It ensures that the bleach is dispensed smoothly into the bottles, minimizing wastage and maintaining product quality.

HOW BLEACH FILLING MACHINE WORKS

HOW OUR BLEACH FILLING MACHINE FIT YOUR PRODUCTS

Our bleach filling machine is specially designed to accommodate a wide range of bleach agent products

Safe And Reliable

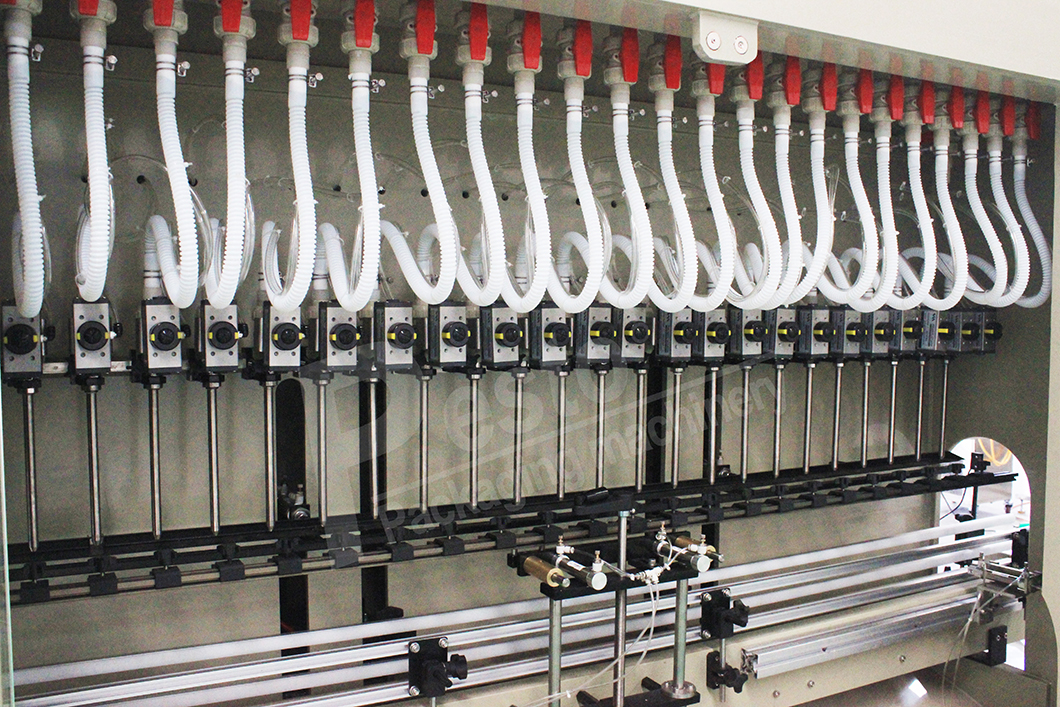

Our bleach filling machine equips with aviation pipeline plug with waterproof, electric-proof and dust-proof. Equips with independent anti-corrosion electrical control cabinet.

Anti-foam

To prevent excessive foam during filling process, we use botton-up filling method, and change design of the filling nozzle to optimize the flow of the liquid, minimizing the formation of bubbles.

Anti-corrosion Material

Not like liquid soap filling machine, the whole bleach filling machine and conveyor belt is made of anti-corrosion PP material, and the feeding pipe is made of titanium alloy, providing high strength and corrosion resistance.

Adjustable Filling Parameters

Our bleach filler allows for the adjustment of filling parameters such as fill volume, fill speed, and accuracy. This flexibility enables the machine to handle different sizes and viscosities of bleach products.

Customizable Filling Process

We understand that different bleach products may have unique characteristics and requirements. Our detergent filling machine can be customized to meet your specific needs.

Advanced Controls and Automation

Our bleach filling equipment features advanced controls and automation, allowing for precise control over the filling process. This ensures consistent and accurate filling, minimizing product wastage and maximizing productivity.

TECHNICAL PARAMETERS

| Filling heads | 4 | 6 | 8 | 12 |

Production speed

(bottles/hour) | 1L:1000,5L:800 | 1L:1800,5L:1200 | 1L:2200,5L:1600 | 1L:3500,5L:2800 |

| Filling accuracy | 1-5L:±5ml |

| Filling range | 500-5000ml |

| Suitable bottles | Round barrel:height:100-320mm;diameter:Φ100-180mm

Drum: length:100-200mm;width:40-80mm;height:150-300mm

Neck diameter:≤Φ30mm |

| Power | 3KW | 3KW | 4KW | 5KW |

| Power source | 220/380V 50/60Hz |

| Air source | 0.6Mpa |

| Dimension(mm) | 1600×1100×2200 | 2000×1100×2200 | 2400×1100×2200 | 2600×1500×2200 |

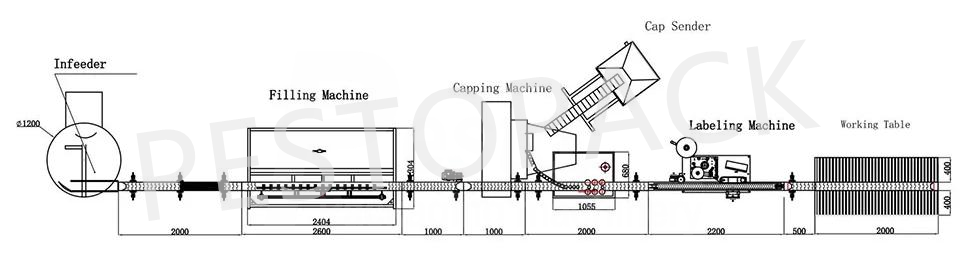

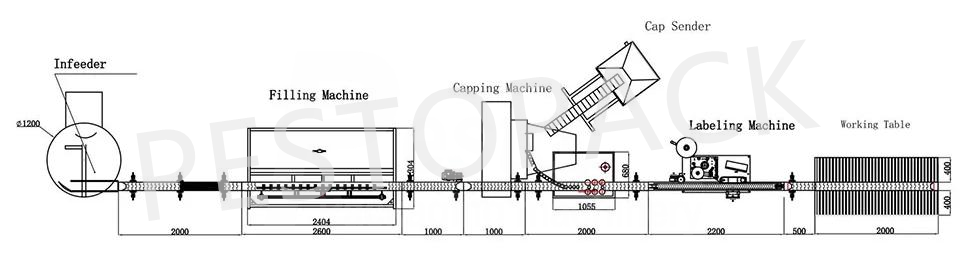

INTEGRATE A COMPLETE BLEACH FILLING LINE

Pestopack has a wealth of expertise and experience in integrating a complete filling line for bleach production. Our team consists of skilled professionals who understand the intricacies of bleach filling processes and have a deep knowledge of the industry requirements. We offer tailored solutions to meet your unique needs. This includes designing the layout, selecting appropriate equipment, and integrating the necessary components for a complete bleach filling line. We take into consideration factors such as production capacity, bottle sizes, packaging requirements, and quality control measures. We have access to a wide range of high-quality liquid detergent filling machine and packaging equipment specifically designed for bleach applications. Our expertise lies in seamlessly integrating these machines into a cohesive and efficient production line.

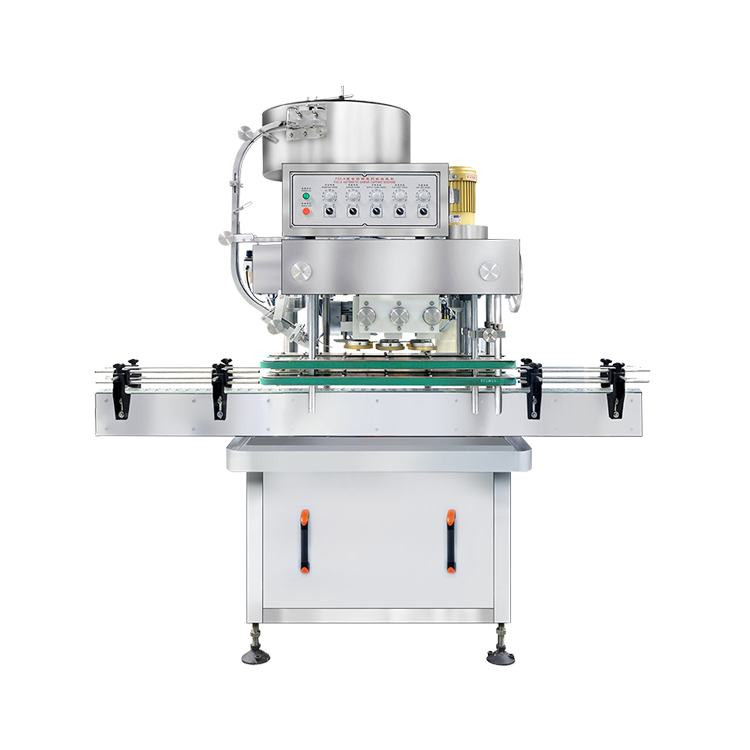

Bleach Capping machine Selection

Bleach Labeling Machine Selection

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu