Q: What types of water can be produced with this water production machine — pure water, mineral water or spring water?

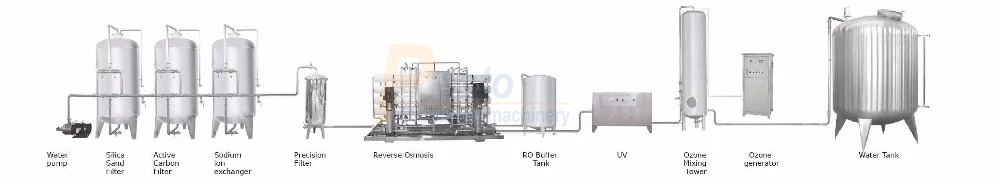

A: Our machine supports multiple water types. By selecting the appropriate water treatment module — RO or ultrafiltration — you can produce pure water, mineral water, spring water or even alkaline drinking water. This flexibility makes it ideal for bottled water plants and mineral or spring water businesses worldwide.

Q: What bottle formats and capacities does the machine support?

A: The system supports PET bottles of various sizes (200 ml, 500 ml, 1 L etc.), and production capacities from small-scale operations (~3,000 BPH) to high-speed lines (up to 24,000 BPH). It suits both small-medium businesses targeting local retail and larger industrial bottled water production.

Q: How automated is the water production line? Can it operate with minimal labor?

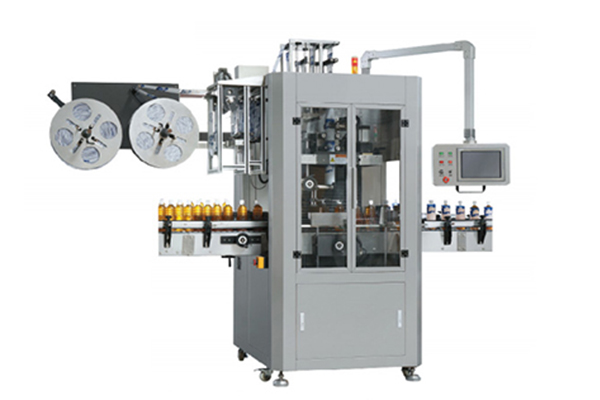

A: Yes. The line integrates all major stages — water treatment, bottle blowing (optional), rinsing, filling, capping, labeling and packaging — into a turnkey automated solution. The 3-in-1 filling machine (rinser + filler + capper) significantly reduces manual handling, lowering labor needs while ensuring hygienic, uniform filling.

Q: Can I adjust the configuration according to local raw water quality or local market demand (e.g. in Africa, Middle East, Asia)?

A: Absolutely. We customize the water treatment system based on your raw water source — tap water, well water, borehole, brackish or seawater. For clients targeting mineral or spring water markets, we offer ultrafiltration; for less pure sources, we provide complete RO + filtration + sterilization. This ensures the line adapts to diverse global water sources.

Q: What is the expected lead time and after-sales support for the water production machine?

A: Typical delivery time is 30–60 days, depending on capacity and customization. After shipment, we provide full support: installation, operator training, spare-parts supply, and 24/7 technical service — ensuring smooth operation for your bottled water line.

Q: How to choose the right water production machine capacity for my market/business scale?

A: Capacity choice depends on your target market (local consumption or export), expected sales volume, bottle size, and budget. For small towns or local retail, a 3,000–6,000 BPH line may suffice. For commercial-scale distribution or export markets (e.g. to neighboring countries), consider a larger line: 12,000–24,000 BPH. Also factor in packaging format and logistic capacity when selecting equipment.

Q: Is the machine suitable for export markets — e.g. setting up a bottled water plant in West Africa, Middle East or Eastern Europe?

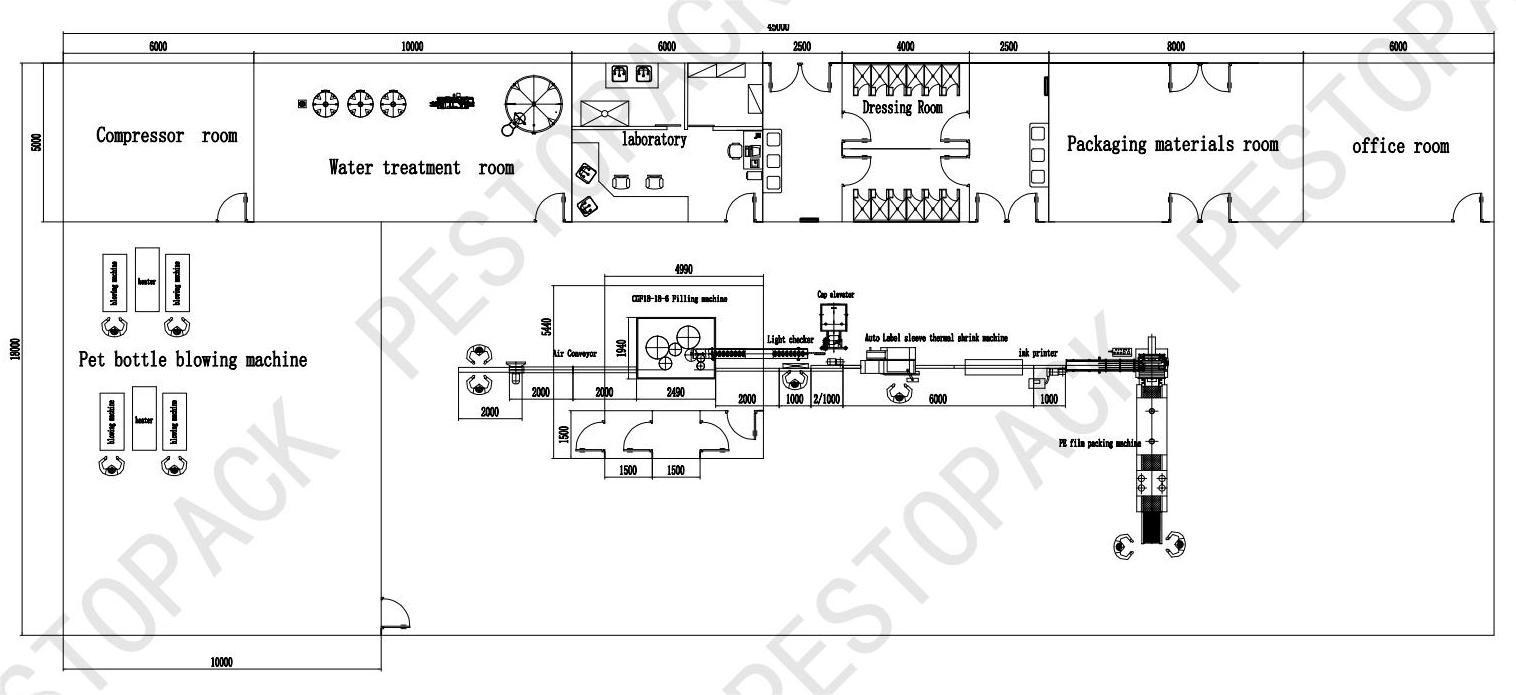

A: Yes. Our water production machine is designed with global export in mind. We use food-grade stainless steel and internationally-standard components. We have experience supplying complete bottled water lines worldwide and can provide layout design optimized for different workshop sizes and local infrastructure conditions.

Q: What are the main benefits of buying a complete water production machine from us rather than assembling separate filling, capping and labeling machines?

A: A turnkey water production machine delivers a fully integrated bottled water line — streamlined workflow, simplified installation, consistent hygiene, optimized layout — reducing total cost and setup complexity compared to sourcing individual machines separately. This is especially valuable for new water bottling businesses or ventures in developing markets aiming for efficient scale-up.

Why Choose PESTOPACK – Trusted Water Production Machine Manufacturer with 20+ Years Experience

We integrate research, development, design, and production of complete water and beverage machinery.

Our workshops use advanced machining equipment (CNC, laser cutting, plasma cutting, water jet cutting) to ensure precision and reliability of parts.

Every machine undergoes testing before leaving the factory — ensuring smooth operation for your bottled water line.

We maintain sufficient spare-parts inventory to ensure timely delivery and support for global clients.

Experienced, English-speaking installation teams — capable of producing customized layouts and helping you benefit as quickly as possible.

If you are looking to launch a mineral water, spring water or purified drinking water business — whether for local retail, regional distribution or export markets — our water production machine is a robust, efficient, and scalable solution.

Full Service & Support – Pre-Sales, Installation & After-Sales for Water Production Machines

Before Sales: We provide working videos, explain machine principles, supply full production process flows, propose factory layout, offer guidance on raw materials such as PET preforms and labels, and maintain 24/7 online consultation support.

Installation / Commissioning / Training: We dispatch experienced technicians to your factory, carry out equipment installation and test production, and train your operators. We guarantee that all equipment is brand new (never used) and deliver high-quality turnkey installation.

After-Sale Service: We offer a 12-month quality guarantee, supply wearing parts (and spare parts) at lowest price, and provide ongoing technical support. If problems arise, we can dispatch engineers to your site, ensuring your line runs smoothly.

Contact Us

If you have any questions or need a quotation, feel free to contact us. We will respond promptly and help you configure the most suitable bottled water production line for your business needs.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu