SEMI AUTOMATIC BEER BOTTLING MACHINE APPLICATION

This semi automatic beer bottling machine is typically used for small to medium-scale beer production and can be applied to these products:

Traditional Beer

The semi-automatic beer filling machine is suitable for conventional beer types such as lagers, stouts, ales, and more. It can fill beer into bottles and perform sealing operations.

Craft Beer

For craft beer brewers, a semi auto beer bottling machine is a practical tool. It provides flexibility and efficiency for small to medium-scale craft beer production, facilitating packaging and sales.

Customized Beer

The semi automatic beer filling machine can be used for customizing beer products. Bars, restaurants, or small-scale breweries can use it to fill specialty recipes or flavored beers, offering personalized choices to customers.

Small-Batch Production and Experimental Brewing

The semi-automatic beer filling machine is suitable for small-scale beer production and experimental brewing. It helps brewers control the filling process, ensuring product quality and consistency.

So for small to medium-sized breweries or limited production demands, a semi auto beer bottle filling machine is an economical and practical choice.

HOW SEMI AUTOMATIC BEER BOTTLING MACHINE WORKS

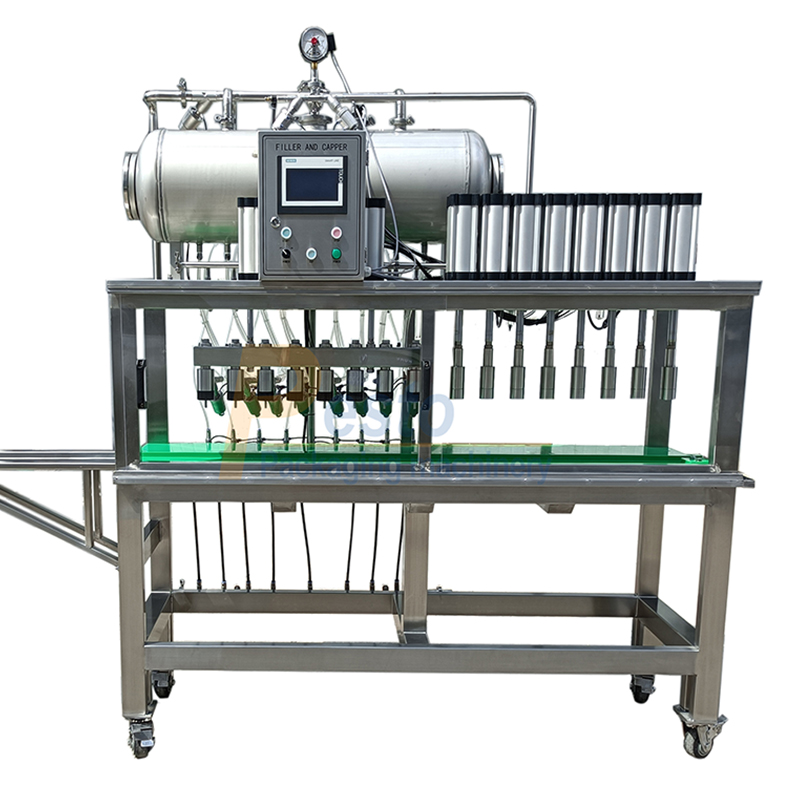

Pestopack's semi automatic beer bottling machine, operates through the following steps:

1. Beer bottle preparation

The empty bottles are cleaned, sanitized, and prepared for filling. This involves rinsing with a sanitizing machine and draining.

2. Beer bottle feeding

The cleaned bottles are placed onto the semi auto beer bottling machine's bottle rack, ready for the filling process.

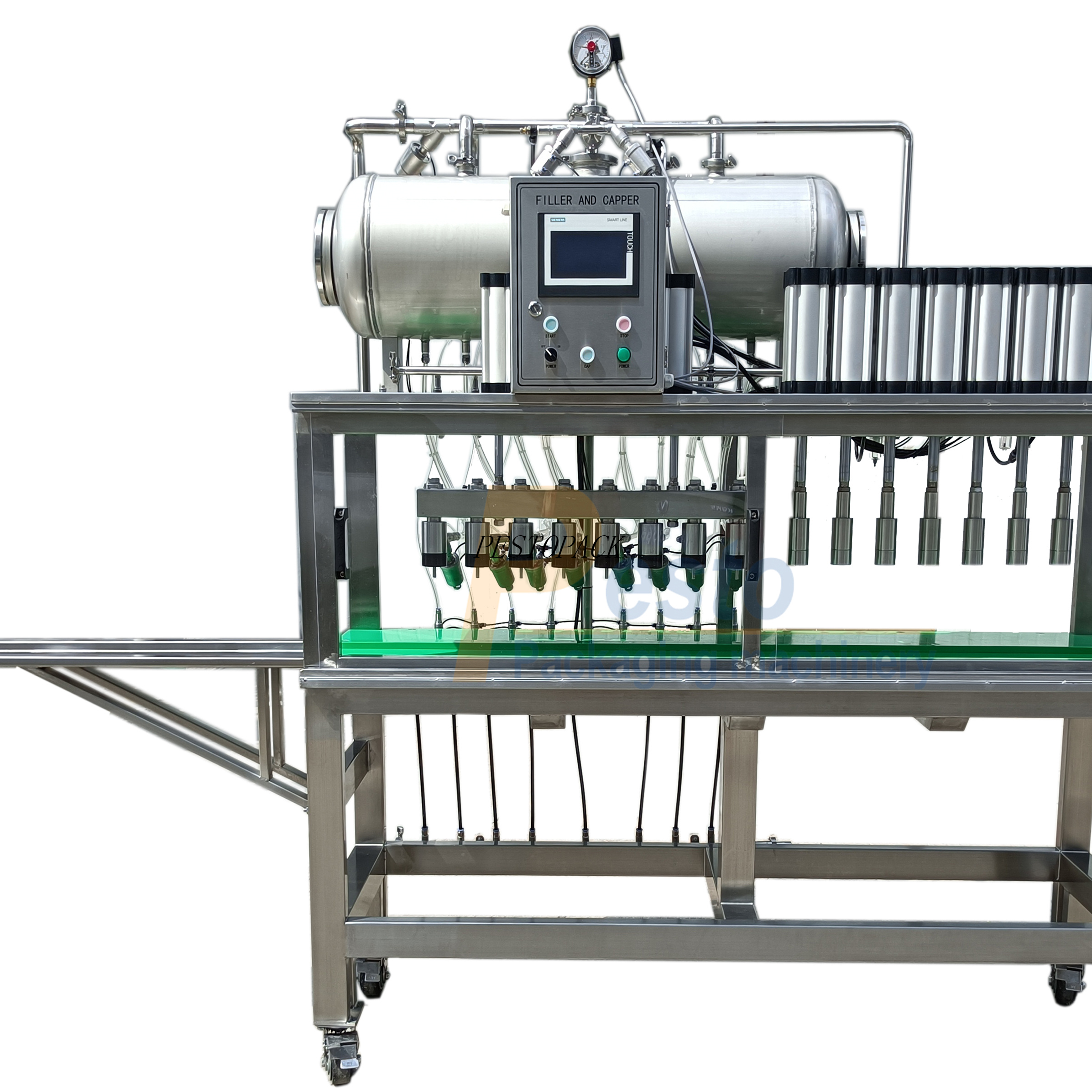

3. Pressurization

Before filling, the bottles are pressurized with carbon dioxide (CO2) gas. This step helps create a controlled environment inside the bottle, preventing excessive foaming and loss of carbonation during filling.

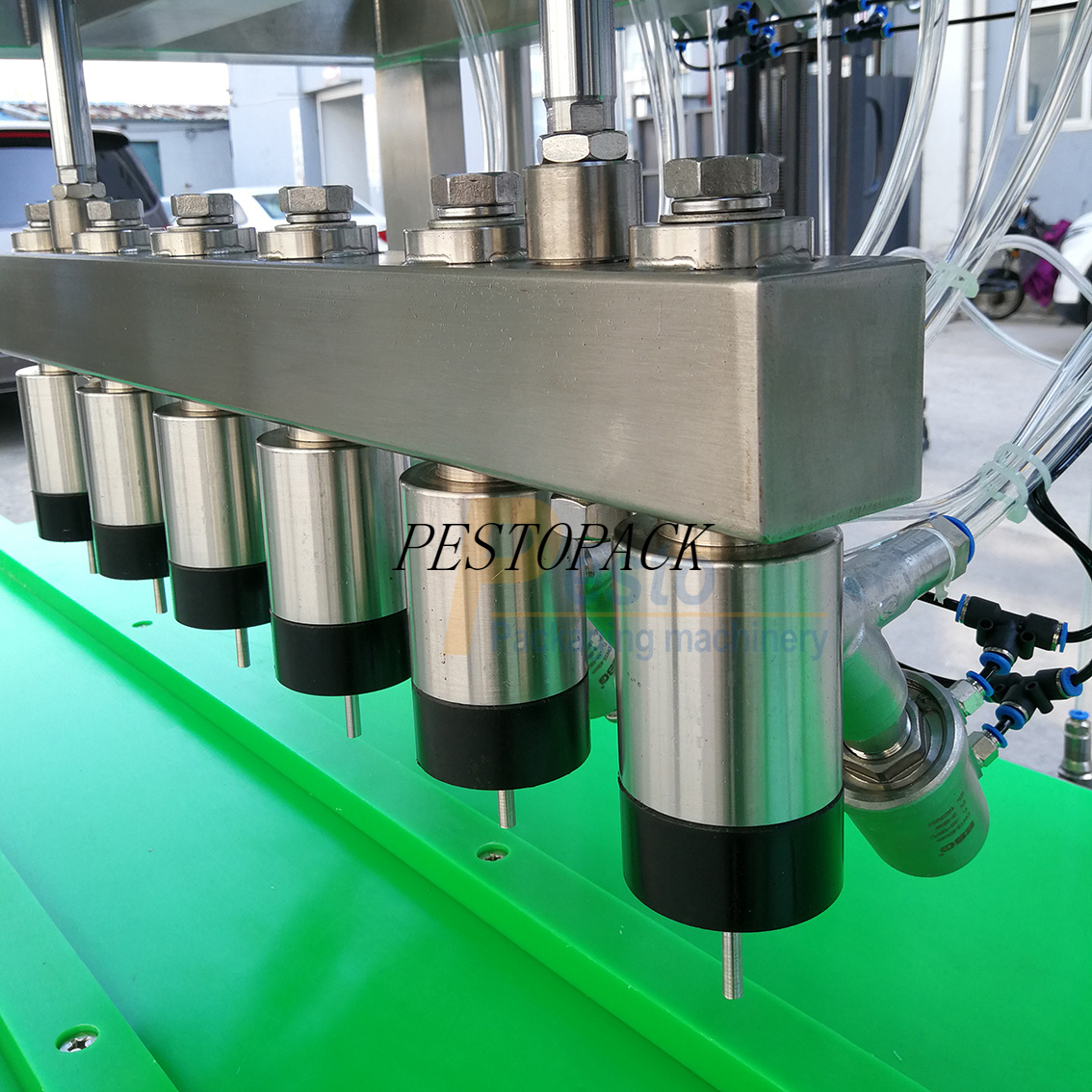

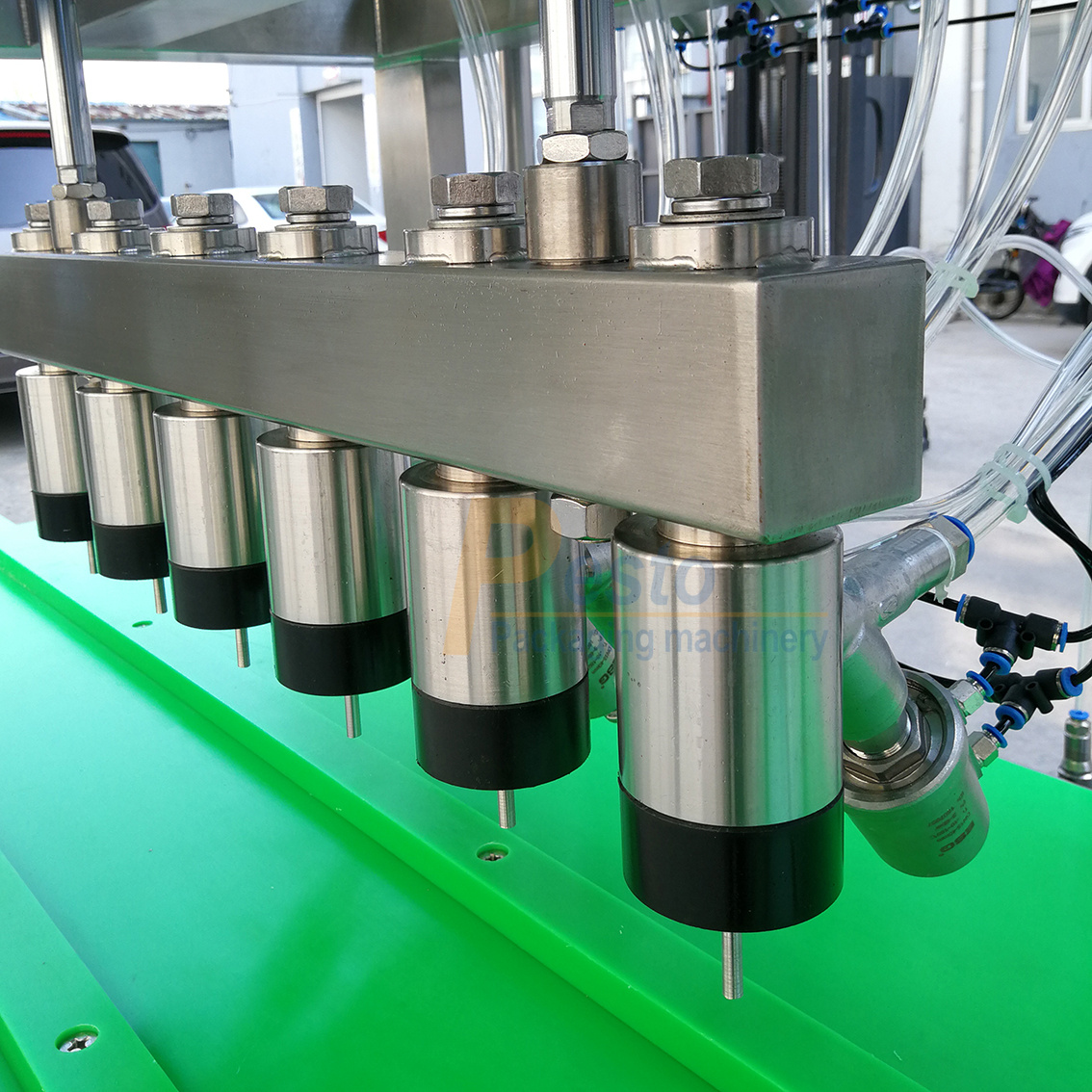

4. Beer bottle filling

The isobaric filling process begins. The manual beer bottling machine includes a filling station equipped with 4-10 filling heads.The filling heads have two main functions: they release the pressurized CO2 gas from the bottle, creating a vacuum, and simultaneously fill the bottle with beer. This dual-action prevents excessive foaming and maintains a consistent fill level.

5. Pressure Equalization

After filling, the semi automatic beer bottling machine restores the internal pressure inside the bottle to match the external pressure. This equalization step helps ensure proper carbonation levels in the beer and prevents excess pressure build-up inside the bottle.

6. Beer bottle capping

Once the pressure equalization is complete, the bottles move to the capping station. The manual beer bottling machine has a capping mechanism capable of handling different types of bottle caps, such as crown caps or twist-off caps. The capping mechanism seals the bottles with caps, ensuring proper sealing to maintain carbonation and freshness.

7. Beer bottle removal

Once the bottles are filled and capped, they are manually removed from the semi auto beer bottling machine.

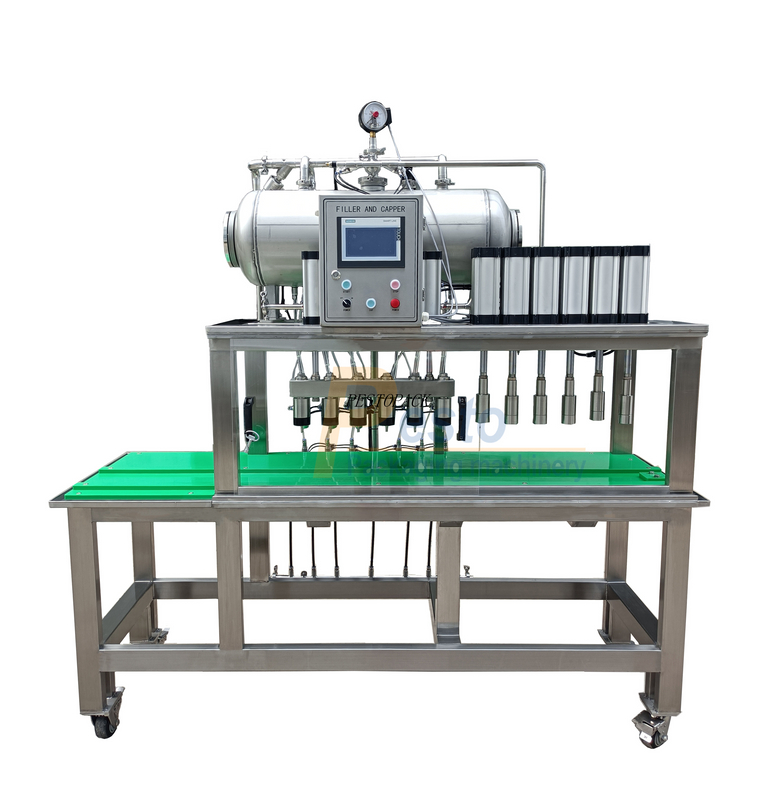

SEMI AUTOMATIC BEER BOTTLING MACHINE FOR SALE

Production Capacity | 300-600 bottles/hr |

Applicable Bottles | 330ml-2L |

Working Stations | 4, 6, 8, 10 |

Power Supply Voltage | AC 220V 50HZ (customized) |

Dimensions | 1800*800*2200mm(Different types dimension will be different) |

Net Weight | 300kg(Different types weight will be different) |

4 heads semi-auto beer bottling machine

6 heads semi-auto beer bottling machine

8 heads semi-auto beer bottling machine

10 heads semi-auto beer bottling machine

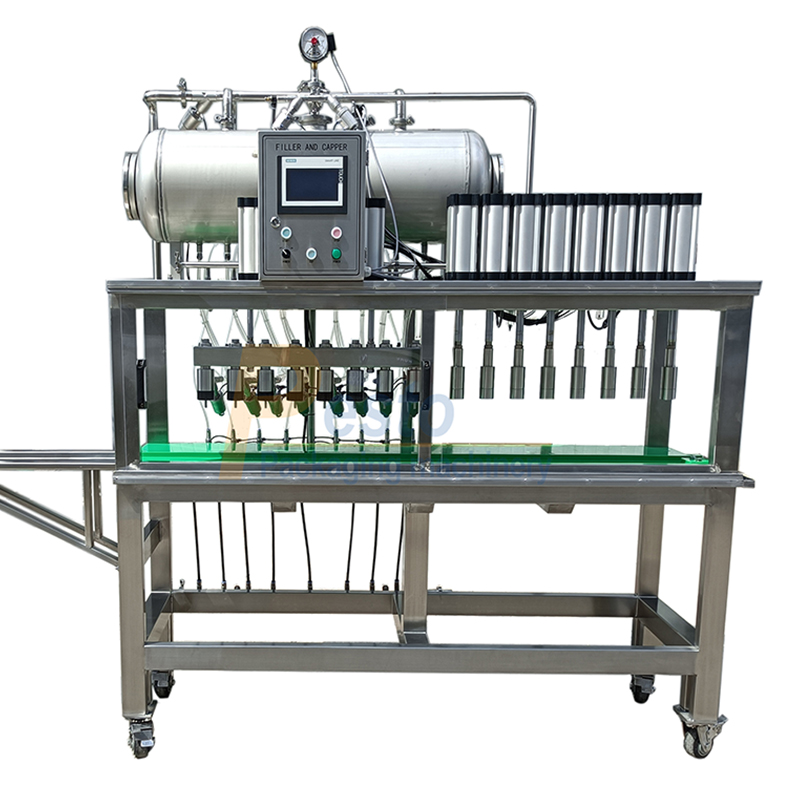

FEATURES OF SEMI AUTOMATIC BEER BOTTLING MACHINE

Semi-automatic operation:

Our mini beer bottling machine combines the advantages of automation with the flexibility of manual control. It automates the filling process while providing the brewer with control over critical parameters, ensuring consistent and precise packaging.

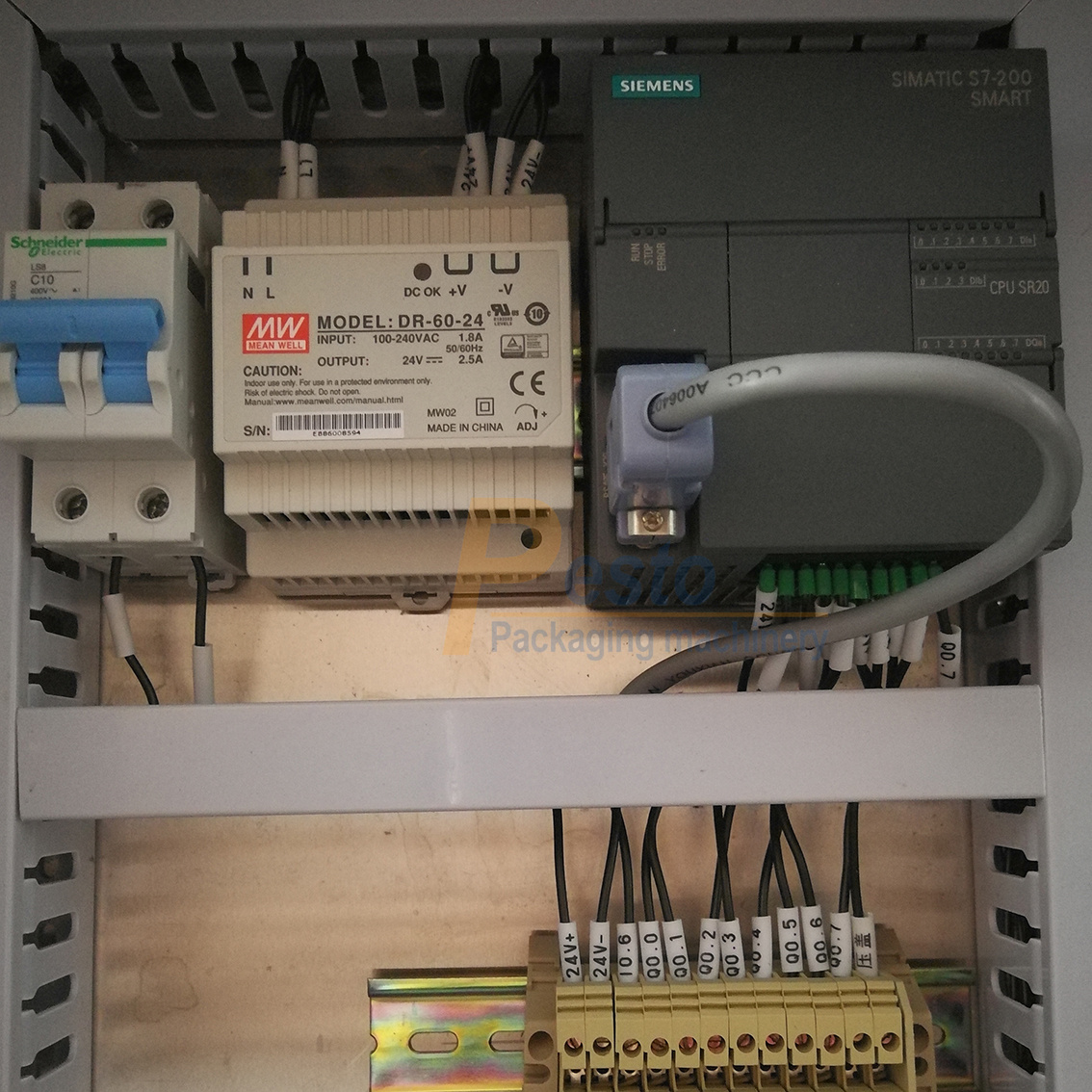

Easy Setup and Operation:

With its user-friendly interface, our semi-automatic beer bottle filling machine can be set up and operated effortlessly in touch screen.Minimal training is required, allowing your staff to quickly adapt to the system and reduce the learning curve.

Enhanced Efficiency:

By automating the repetitive tasks involved in beer bottling, our manual beer bottling machine significantly increases your brewery's productivity. It reduces the time required for packaging, allowing you to meet growing demand without compromising on quality. Filling and capping process can be finished in this machine.

Consistent Fill Levels:

Maintaining consistent fill levels is crucial for customer satisfaction. Our semi automatic beer filling machine employs precise measurement systems to ensure accurate fill levels in every bottle, eliminating product inconsistencies and minimizing wastage.

Customizable for Your Brewery:

Every brewery has its unique requirements. Our manual beer bottling machine offers customization options to accommodate different bottle sizes, shapes, and beer styles. It adapts to your specific needs, enabling you to diversify your product range and meet market demands effectively.

WHY CHOOSE OUR BEER BOTTLING MACHINE

1. Time and Resource Savings:

Automating your beer bottling process with our beer filling machine saves you valuable time and resources. Reduce labor costs, minimize product wastage, and optimize your brewery's operational efficiency.

2. Precision and Quality Control:

With precise fill level control and consistency, our beer bottling machine ensures that every bottle meets the highest quality standards. Delivering a consistently excellent product helps build customer loyalty and enhances your brand reputation.

3. Scalability and Growth:

As your brewery expands, our semi-automatic beer bottling machine scales with you. It allows you to meet increasing production demands while maintaining the desired level of control and consistency.

4. Improved Brewery Operations:

By simplifying and streamlining your beer packaging process, our manual beer bottling machine frees up your staff's time, enabling them to focus on other critical tasks, such as recipe development, quality assurance, and customer engagement.

FAQ About Semi Automatic Beer Bottling Machine

Q1: What is the capacity?

300–600 bottles/hr, ideal for small breweries.

Q2: What bottle sizes are supported?

From 330ml to 2L, covering most beer bottles.

Q3: How much does it cost?

Price depends on model (4–10 heads). Request a beer bottling machine price.

Q4: Manual vs Semi Automatic?

Manual machines need more labor; semi automatic beer filling machines ensure consistency.

Q5: Is it suitable for craft beer?

Yes, widely used in craft breweries for flexible, small-batch production.

Q6: Does it keep beer fresh?

Yes, the isobaric filling system with CO₂ maintains carbonation and freshness.

CONTACT US TODAY FOR GETTING BEER BOTTLING MACHINE PRICE

Ready to take your brewery's beer packaging process to the next level? Contact us today for our semi automatic beer botting machine. Experience the benefits of streamlined operations, improved effieciency and consistent quality. Let our machine revolutionize your brewery's packaging capabilities. Request a quote now! Besides water and beverage machinery, we also have oil filling machine, sauce filling machine, detergent filling machine for choosing. Please contact us for more details.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu