Introduction to Chili Sauce Filling Machines

Chili sauce is one of the most widely consumed condiments in the world. From small household brands to international food manufacturers, the demand for safe, hygienic, and consistent packaging has never been higher. Traditional manual filling methods are time-consuming, labor-intensive, and often lead to inconsistencies.

This is where automatic sauce filling machine come in. These machines streamline the entire filling process, ensuring accuracy, efficiency, and compliance with food safety standards. For manufacturers aiming to scale production or maintain consistent quality, investing in an automatic solution is essential.

PestoPack, a global leader in food and beverage packaging solutions, has developed state-of-the-art chili sauce filling machines designed specifically for viscous sauces with particles. Our machines integrate advanced technology to deliver speed, precision, and long-term reliability.

How the Automatic Chili Sauce Filling Machine Works

At the heart of the chili sauce filling machine lies the piston-type quantitative filling principle. This method ensures precise volume control, even with chunky or oily sauces.

Here’s how it works:

Integration of Light, Machine, Electricity, and Gas

The system combines mechanical design, electrical automation, pneumatic controls, and optical detection for a smooth and efficient filling process.

Piston-Cylinder Drive

The piston creates suction to pull the sauce into the chamber and then pushes it into the bottles with high accuracy. This ensures uniform filling across every bottle.

Pressure-Type Filling

Unlike gravity-based systems, the chili sauce filling machine doesn’t require a high-level tank. This simplifies installation, reduces space requirements, and increases efficiency.

Acrylic Transparent Protection

During filling, an acrylic transparent cover ensures hygienic operation by isolating the sauce from external contaminants.

This combination of features guarantees consistency, prevents leakage, and meets international food safety standards.

Applications of Chili Sauce Filling Machine

One of the main advantages of this machine is its ability to handle viscous products with particles. It is not limited to chili sauce alone.

It can be used for:

Chili sauce with seeds and oil content

Douban sauce (fermented bean paste)

Mushroom sauce with pieces of mushroom

Garlic or ginger paste

Hot sauces that require hot-fill or particle handling

Tomato paste and ketchup

Mixed sauces containing oil and solid particles

This versatility makes the machine ideal for companies producing multiple sauce products.

Key Features of the Chili Sauce Filling Machine

The PestoPack chili sauce filling machine comes with several advanced features:

Closed Structure Rack – Ensures safe and hygienic operation.

Servo-Driven Piston Metering – Provides exceptional filling precision with ≤0.1% error.

Food-Grade Stainless Steel (SUS304 / SUS316 optional) – Guarantees compliance with food safety regulations.

Anti-Drip System – Prevents product leakage and keeps the working area clean.

Independent Storage Tank – Allows for easy cleaning and CIP (Clean-In-Place) system integration.

Adjustable Speed Conveyor – Controlled via Delta variable frequency drive.

Photoelectric Bottle Detection – Intelligent system that prevents filling when bottles are missing or misaligned.

Customizable Mixing Speed – Keeps oil and solids evenly distributed.

These features ensure long-term reliability, low maintenance, and superior product quality.

Technical Parameters of Chili Sauce Filling Machine

Here’s a quick comparison of available models:

Model | Filling Heads | Speed (500ml bottles) | Precision | Machine Size (mm) | Power | Air Supply |

PT-Z-20S | 20 | ≤5000 BPH | ≤0.1% | 2800×1300×2350 | 3.5KW | 0.6–0.8Mpa |

PT-Z-16S | 16 | ≤4000 BPH | ≤0.1% | 2800×1300×2350 | 3.5KW | 0.6–0.8Mpa |

PT-Z-12S | 12 | ≤3000 BPH | ≤0.1% | 2400×1300×2350 | 3KW | 0.6–0.8Mpa |

PT-Z-8S | 8 | ≤2500 BPH | ≤0.1% | 2000×1300×2350 | 3KW | 0.6–0.8Mpa |

PT-Z-6S | 6 | ≤1600 BPH | ≤0.1% | 2000×1300×2350 | 3KW | 0.6–0.8Mpa |

Manufacturers can select the machine type based on production speed, bottle size, and sauce viscosity.

Sanitization Filling Head

1. Food-grade 304SUS hose

2. Shut off filling heads

3. With a drop collection tray

4. High filling accuracy

5. High quality and food grad O rings and seals inside of the nozzles

Three-way valve

1. Easy disassembly of three-way connectors, No dead corner

2. Long-life valve and high performance

3. This valve guarantees the shut-off accuracy and more stability, and no dead corner

4. Suitable for thin to viscous liquid and Sauce

No Dead Corner Top Tank

1. The top tank is with a round or semi-round design with no dead corners, more easy Cleaning

2. Double jacket hopper optional

3. Mixing system optional

4. 304SS construction material, 316SS for option

5. Mixing and heating function for potion

Advantages of PestoPack Chili Sauce Filling Machines

Accuracy: Servo-controlled piston filling guarantees precise dosing.

Efficiency: High production speeds up to 5000 bottles/hour.

Hygiene: Stainless steel construction and acrylic isolation ensure food safety.

Flexibility: Handles sauces of different viscosities and with particles.

Low Maintenance: Easy disassembly and CIP options reduce downtime.

By investing in PestoPack equipment, manufacturers enjoy a balance of performance, durability, and cost-efficiency.

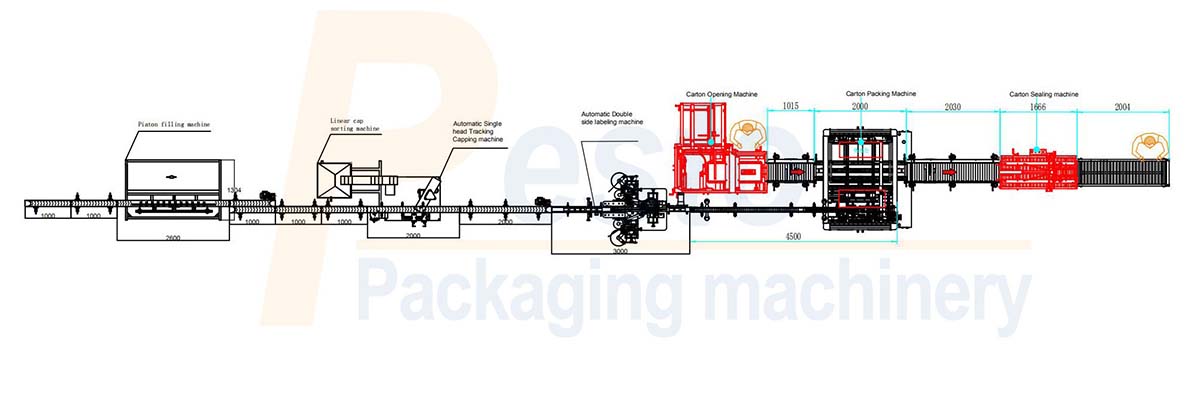

Chili Sauce Production Line Layout

A complete chili sauce filling line includes:

Sauce preparation and mixing tank

Chili sauce filling machine

Capping machine (screw cap or lug cap)

Labeling machine (self-adhesive, sleeve, or OPP labeler)

Shrink wrapping or carton packing machine

By integrating these machines, food manufacturers can achieve fully automated production.

See also: Ketchup Filling Machine, Jam Filling Machine, and Carton Packing Machine.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu